- DL manuals

- SMC Networks

- Chiller

- HRZ001-H

- Operation Manual

SMC Networks HRZ001-H Operation Manual - 7.3.1

HRX-OM-I051

Chapter 7 System Maintenance

7.3 Storage

HRZ Series

7-4

7.3.1

Draining of circulating fluid out of tank

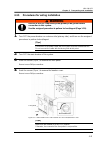

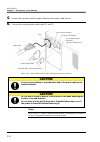

1.

Prepare the container for circulating fluid recovery at the back of this system.

2.

Connect the drain hoses to the main and

sub tank drain ports each. Insert the tip

of the hose into the container.

Prepare a drain hose (Rc3/8-diameter) on your

responsibility.

3.

Remove the cap of the circulating fluid fill port.

4.

Open the valves of the main and sub tank drain ports to drain the circulating fluid.

5.

Apply air purge from the the circulating fluid return to push the circulating fluid remaining in

the heat exchange back in the tank and drain it.

Max. 10cm

Drain port

Container for circulating

fluid recovery

Drain port

Circulating fluid fill port cap

Circulating fluid return

Figure 7-1 Container for Circulating Fluid Recovery

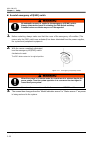

Use the clean container for circulating fluid recovery. Reuse of the

recovered circulating fluid with contaminated will cause insufficient

cooling and system failure

Be sure to wait until the circulating fluid obtains room temperature for its

draining. Potential burns and dew intrusion may occur if disregarded.

If the recovered circulating fluid is contaminated by foreign

substances, completely remove them. Do not reuse comtaminated

fluid.

Potential insufficient cooling, system failure and froth in the

circulating fluid may occur if disregarded.

Recovered circulating fluid must be sealed in a container to prevent

contamination from moisture or foreign substances.

Stored in a cool, dark place.

Keep it from flame.

Summary of HRZ001-H

Page 1

Hrx-om-i051-p 1 st edition:january.2005 17 th edition:sep.2016 operation manual original instructions thermo-chiller hrz001-l hrz002-l hrz004-l hrz008-l hrz001-l1 hrz002-l1 hrz004-l1 hrz008-l1 hrz001-l2 hrz002-l2 hrz004-l2 hrz008-l2 hrz001-h hrz002-h hrz004-h hrz008-h hrz001-h1 hrz002-h1 hrz004-h1 h...

Page 2: To The Customers

To the customers thank you for purchasing our thermo chiller hrz series (hereinafter called “this system”). For the long-term, safe use of this system, be sure to read and understand this manual thoroughly before performing operation of this system. warnings and precautions defined in this manual ...

Page 3: Table Of Contents

Hrx-om-i051 table of contents hrz series toc-1 table of contents chapter 1 safety.................................................................................... 1-1 1.1 before using this system ....................................................................................... 1-1 1.2 dange...

Page 4: Chapter 4

Hrx-om-i051 table of contents hrz series toc-2 3.3.4 wiring installation ................................................................................................................. 3-8 3.3.5 procedures for wiring installation .......................................................................

Page 5: Chapter 6

Hrx-om-i051 table of contents hrz series toc-3 5.4.2 example 2: communication mode is switched from “dio remote” to “local”. ........... 5-13 5.4.3 example 3: alarm signal of contact s ignal is changed from “n/a” to “alarm1”. ............. 5-14 chapter 6 error message and troubleshooting ..............

Page 6

Hrx-om-i051 table of contents hrz series toc-4.

Page 7: Chapter 1 Safety

Hrx-om-i051 chapter 1 safety hrz series 1.1 before using this system 1-1 chapter 1 safety 1.1 before using this system this "safety" chapter describes the safety-related items that users should be aware of upon handling this system. This system, which is operated under high voltage, is outfitted wit...

Page 8: Manual

Hrx-om-i051 chapter 1 safety 1.2 danger, warning, and caution used in this manual hrz series 1-2 1.2 danger, warning, and caution used in this manual 1.2.1 hazard levels this system is designed with its first priority being the safety of workers and the prevention of system damage. This manual class...

Page 9: 1.2.3

Hrx-om-i051 chapter 1 safety hrz series 1.2 danger, warning, and caution used in this manual 1-3 1.2.3 symbols this manual provides the following symbols in addition to “danger”, “warning”, and “caution” to present the warning details in easy-to-understand manner. symbol of electrical hazard sym...

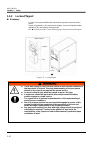

Page 10: 1.3 Hazard Warning Label

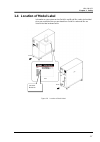

Hrx-om-i051 chapter 1 safety 1.3 hazard warning label hrz series 1-4 1.3 hazard warning label the hazard warning labels are applied to the sections of this system where potential hazards are present during system operation and maintenance. The hazard warning labels are in appropriate sizes and color...

Page 11: 1.3.2

Hrx-om-i051 chapter 1 safety hrz series 1.3 hazard warning label 1-5 1.3.2 location of hazard warning label high voltage hazard figure 1-7 high voltage hazard confirm the locations of the hazard warning labels. read the contents of the hazard warning labels carefully and keep them in mind. Do ...

Page 12

Hrx-om-i051 chapter 1 safety 1.3 hazard warning label hrz series 1-6 hot/cold surface hazard figure 1-8 hot/cold surface hazard front rear hazard warning label no.5 hazard warning label no.6.

Page 13

Hrx-om-i051 chapter 1 safety hrz series 1.4 location of model label 1-7 1.4 location of model label information on your system such as serial no. And model no. Need to be furnished when you contact the store you purchased from. Serial no. And model no. Are listed on the label as shown below. Figure ...

Page 14: 1.5 Safety Measures

Hrx-om-i051 chapter 1 safety 1.5 safety measures hrz series 1-8 1.5 safety measures 1.5.1 safety precautions while this system is protected by various safety measures including the safety interlocks, the following basic safety precautions should be observed to assure further safe operations. Read an...

Page 15: 1.5.2

Hrx-om-i051 chapter 1 safety hrz series 1.5 safety measures 1-9 1.5.2 safety interlock system safety interlock system the function of the safety interlock system is not only protect personnel by restricting operation that may cause damage to this system or the facility around it but also eliminate...

Page 16: 1.5.3

Hrx-om-i051 chapter 1 safety 1.5 safety measures hrz series 1-10 1.5.3 lockout/tagout summary lockout in this system disables the main breaker operation to prevent electric shocks. Tagout, to be placed on a locked out main breaker, to prevent improper breaker operation (on) conducted by other pers...

Page 17

Hrx-om-i051 chapter 1 safety hrz series 1.5 safety measures 1-11 lockout procedure 1. Turn the breaker handle to ‘off ’. 2. Turn the breaker handle to ‘reset’. Hold the breaker handle with hand. The handle turns back to ‘off ’ if released. 3. Push the lock pushing part of the breaker handle, and...

Page 18: 1.5.4

Hrx-om-i051 chapter 1 safety 1.5 safety measures hrz series 1-12 1.5.4 protective equipment this manual defines protective equipment according to work type. Wear proper protective equipment as shown below, according to work type. for system transportation, installation and removal protective foo...

Page 19: 1.6 Emergency Measures

Hrx-om-i051 chapter 1 safety hrz series 1.6 emergency measures 1-13 1.6 emergency measures 1.6.1 emergency off [emo] switch press the red emergency off [emo] switch on the front of the system only if the need to shut off the power arises due to emergency such as natural disaster, fire, earthquake or...

Page 20

Hrx-om-i051 chapter 1 safety 1.6 emergency measures hrz series 1-14 reset of emergency off [emo] switch 1. Before restarting, always make sure that the cause of the emergency off condition (the reason why the emo switch was activated) has been eliminated from the power supplies, the system and per...

Page 21: 1.7 Waste Disposal

Hrx-om-i051 chapter 1 safety hrz series 1.7 waste disposal 1-15 1.7 waste disposal 1.7.1 disposal of refrigerant and compressor oil hfc- refrigerant and compressor oil are present in this system. When recovering the refrigerant or compressor oil, the precautions provided below should thoroughly be r...

Page 22: 1.7.2

Hrx-om-i051 chapter 1 safety 1.8 material safety data sheet (msds) hrz series 1-16 1.7.2 circulating fluid disposal as to the disposal of a circulating fluid (ethylene glycol solution, fluorinated fluid), consign the specialized industrial waste disposal agency with the contents detailed. 1.7.3 syst...

Page 23

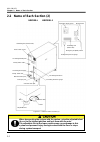

Hrx-om-i051 chapter 2 name of each section hrz series 2.1 name of each section (1) 2-1 chapter 2 name of each section 2.1 name of each section (1) hrz001-l hrz002-l hrz004-l hrz001-l1 hrz002-l1 hrz004-l1 hrz001-l2 hrz002-l2 hrz004-l2 hrz008-l2 hrz001-h hrz002-h hrz004-h hrz008-h hrz001-h1 hrz002-h1 ...

Page 24

Hrx-om-i051 chapter 2 name of each section 2.2 name of each section (2) hrz series 2-2 2.2 name of each section (2) hrz008-l hrz008-l1 figure 2-2 name of each section (2) when transporting the system with the casters, raise the adjustable feet (4 pcs.) to the highest position and lock them with the ...

Page 25: 3.1 Transporting

Hrx-om-i051 chapter 3 transporting and installation hrz series 3.1 transporting 3-1 chapter 3 transporting and installation 3.1 transporting this system is heavy, which poses potential danger at transportation. When transporting this system, the following safety precautions should be observed to pre...

Page 26: 3.1.1

Hrx-om-i051 chapter 3 transporting and installation 3.1 transporting hrz series 3-2 3.1.1 transporting with forklift figure 3-1 transport with forklift this system is heavy, and requires a forklift to safely move it. forklift insertion positions are on either left or right side of this system. A...

Page 27: 3.1.2

Hrx-om-i051 chapter 3 transporting and installation hrz series 3.2 installation 3-3 3.1.2 transporting with caster 3.2 installation this system is heavy, which requires assistance for this work. Exercise caution and look out for sloped surfaces such as ramps, etc. Do not grab piping on the back of t...

Page 28: 3.2.1

Hrx-om-i051 chapter 3 transporting and installation 3.2 installation hrz series 3-4 3.2.1 installation conditions system installation is not allowed outside or in the conditions described below. Potential system malfunction and damage may occur if disregarded. Clean room specifications are not appli...

Page 29: 3.2.2

Hrx-om-i051 chapter 3 transporting and installation hrz series 3.2 installation 3-5 3.2.2 installation location and maintenance work area this system does not have ventilating hole on the both right and left sides. Although this can be installed directly contacting to walls or devices, installation ...

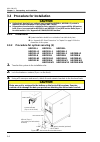

Page 30: 3.3.1

Hrx-om-i051 chapter 3 transporting and installation 3.3 procedure for installation hrz series 3-6 anti-seismic bracket is an optional part (except for hrz008-l, hrz008-l1), which is required for the installation of this system (hrz-tk002). preparation of anchor bolts suitable for floor material ...

Page 31: 3.3.3

Hrx-om-i051 chapter 3 transporting and installation hrz series 3.3 procedure for installation 3-7 3.3.3 procedure for system securing (2) hrz008-l hrz008-l1 adjust and secure the adjustable feet of this system to secure the anti-seismic bracket. 1. Transfer this system to the installation site. 2. A...

Page 32: 3.3.4

Hrx-om-i051 chapter 3 transporting and installation 3.3 procedure for installation hrz series 3-8 3.3.4 wiring installation power cable the power cables are to be prepared under your responsibility, referring to the following table. Table 3-1 power cable and main breaker (this system) item hrz001-...

Page 33

Hrx-om-i051 chapter 3 transporting and installation hrz series 3.3 procedure for installation 3-9 selection of the breaker for the customer ’s equipment (primary side) hrz001-l hrz002-l hrz004-l hrz001-l1 hrz002-l1 hrz004-l1 hrz001-l2 hrz002-l2 hrz004-l2 hrz008-l2 hrz001-h hrz002-h hrz004-h hrz008...

Page 34

Hrx-om-i051 chapter 3 transporting and installation 3.3 procedure for installation hrz series 3-10 hrz008-l hrz008-l1 hrz010-ws hrz010-w1s hrz010-w2s figure 3-8 breaker operating characteristics curve current (% to the capacity of the main breaker of this product) min o p e ra ti n g t im e 4h 2h 1h...

Page 35: 3.3.5

Hrx-om-i051 chapter 3 transporting and installation hrz series 3.3 procedure for installation 3-11 m a i f r screw breaker cover breaker front panel screw front main breaker off off 3.3.5 procedures for wiring installation 1. Turn off the power breaker on customer side (primary side), and then use t...

Page 36

Hrx-om-i051 chapter 3 transporting and installation 3.3 procedure for installation hrz series 3-12 5. Loosen the cap and insert the power cable from the power cable access. 6. Connect the communication cables with p1 and p2. [tips] see “table 3-1 power cable and main breaker (this system)” on page 3...

Page 37: 10.

Hrx-om-i051 chapter 3 transporting and installation hrz series 3.3 procedure for installation 3-13 7. Connect the power cables to the breaker terminal. Be sure to use a phillips screwdriver. See table 3-1 on page 3-8 for recommended torque. 8. Connect the grounding terminal (m8) of the power cable t...

Page 38: 3.3.6

Hrx-om-i051 chapter 3 transporting and installation 3.3 procedure for installation hrz series 3-14 3.3.6 installation of circulating fluid and facility water piping pipe diameter table 3-3 pipe diameter pipe diameter recommended torque (material: ss* vs ss) facility water inlet rc1/2 28 to 30n • m...

Page 39

Hrx-om-i051 chapter 3 transporting and installation hrz series 3.3 procedure for installation 3-15 procedure for piping installation secure the pipe coupling section with a pipe wrench, and provide proper tightening to the pipe. recommended piping installation table 3-4 recommended pipe no. Name...

Page 40

Hrx-om-i051 chapter 3 transporting and installation 3.3 procedure for installation hrz series 3-16.

Page 41: 4.1 Pre-Check

Hrx-om-i051 chapter 4 system startup and shutdown hrz series 4.1 pre-check 4-1 chapter 4 system startup and shutdown 4.1 pre-check check the following items prior to starting up the system. 4.1.1 installation condition make sure that the system is installed in a horizontal position. No heavy object ...

Page 42: 4.3.1

Hrx-om-i051 chapter 4 system startup and shutdown 4.3 supply of circulating fluid hrz series 4-2 4.3 supply of circulating fluid 4.3.1 preparation of circulating fluid when the circulating fluid is a 60% ethylene glycol aqueous solution always check the concentration of the circulating fluid. wh...

Page 43: 4.3.2

Hrx-om-i051 chapter 4 system startup and shutdown hrz series 4.3 supply of circulating fluid 4-3 4.3.2 supply of circulating fluid remove the circulating fluid fill cap, and fill the circulating fluid until it reaches its specified level. The circulating fluid specified level is a range between “hig...

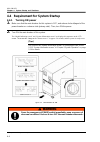

Page 44: 4.4.1

Hrx-om-i051 chapter 4 system startup and shutdown 4.4 requirement for system startup hrz series 4-4 4.4 requirement for system startup 4.4.1 turning on power 1. Make sure that the main breaker for this system is off, and release lockout/tagout of the power breaker on customer side (primary side). Th...

Page 45: 4.4.2

Hrx-om-i051 chapter 4 system startup and shutdown hrz series 4.5 system startup and shutdown 4-5 4.4.2 circulating fluid temperature setting from the “setting screen” on the lcd screen, set the circulating fluid at any temperature. See section 5.4 “examples of system operation” in “chapter 5 system ...

Page 46

Hrx-om-i051 chapter 4 system startup and shutdown 4.5 system startup and shutdown hrz series 4-6.

Page 47

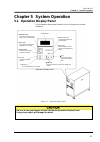

Hrx-om-i051 chapter 5 system operation hrz series 5.1 operation display panel 5-1 chapter 5 system operation 5.1 operation display panel use the operation display panel located in front of the system for the basic operations. Figure 5-1 operation display panel be sure to use your fingers only to ope...

Page 48

Hrx-om-i051 chapter 5 system operation 5.2 flow chart of operation screen hrz series 5-2 5.2 flow chart of operation screen figure 5-2 flow chart of operation screen [tips] with the press of the [sel] key, the screen is swi tched to the “menu screen 1” regardless of the screen status. Table 5-1 desc...

Page 49: 5.3 Operation Screen

Hrx-om-i051 chapter 5 system operation hrz series 5.3 operation screen 5-3 5.3 operation screen 5.3.1 model indication screen figure 5-3 model indication screen the “model indication screen” is displayed upon power-on of this system. This screen remains on for approx. 20 seconds and is automatically...

Page 50: 5.3.3

Hrx-om-i051 chapter 5 system operation 5.3 operation screen hrz series 5-4 5.3.3 status screen 2 figure 5-5 status screen 2 table 5-4 status screen 2 no. Item descriptions 1 temp pv discharge temperature of the circulating fluid (a value derived according to the offset *1 if applied) 2 temp sp set c...

Page 51: 5.3.5

Hrx-om-i051 chapter 5 system operation hrz series 5.3 operation screen 5-5 5.3.5 status screen 4 figure 5-7 status screen 4 table 5-6 status screen 4 no. Item descriptions 1 temp pv discharge temperature of the circulating fluid 2 temp sp set circulating fluid temperature 3 > displays the band/ready...

Page 52: 5.3.7

Hrx-om-i051 chapter 5 system operation 5.3 operation screen hrz series 5-6 5.3.7 setting screen figure 5-9 setting screen this screen enables the setting of temp sp value. Not available if the communication mode is in “ser remote” *1 . Table 5-8 setting screen no. Item setting range 1 temp sp hrz□□□...

Page 53: 5.3.8

Hrx-om-i051 chapter 5 system operation hrz series 5.3 operation screen 5-7 5.3.8 mode selection screen figure 5-10 mode selection screen this screen enables the selection of the communication mode. The procedures for system start/stop and temp sp value setting may vary with the communication mode. O...

Page 54

Hrx-om-i051 chapter 5 system operation 5.3 operation screen hrz series 5-8 this screen enables the setting of set values. Table 5-10 initial setting screen no. Item setting range descriptions 1 temp band 1.0 to 5.0°c *1 allows the selection of the band width for temp sp. 2 temp ready 10 to 480sec *1...

Page 55: 5.3.11 Option Screen

Hrx-om-i051 chapter 5 system operation hrz series 5.3 operation screen 5-9 5.3.10 maintenance screen figure 5-12 maintenance screen table 5-11 maintenance screen no. Item setting 1 valve open the solenoid valve is opened forcefully. Close the solenoid valve is closed forcefully. [tips] available onl...

Page 56

Hrx-om-i051 chapter 5 system operation 5.3 operation screen hrz series 5-10 5.3.12 alarm display screen figure 5-14 alarm display screen in the event of an error in this system, the current screen is switched to the alarm display screen to display the relevant alarm code. And message. The alarm disp...

Page 57: 5.4.1

Hrx-om-i051 chapter 5 system operation hrz series 5.4 examples of system operation 5-11 5.4 examples of system operation 5.4.1 example 1: circulating fluid set temperature is changed from 23.0°c to 34.1°c. Figure 5-16 change of set temperature from 25.0°c to 34.1°c 1. Press the [sel] key to displ ay...

Page 58

Hrx-om-i051 chapter 5 system operation 5.4 examples of system operation hrz series 5-12 4. Use the arrow keys ([▲], [▼], [ ]) to change the temperature to 34.1°c. [▲] key: used to add one value on which the cursor is placed. [▼] key: used to subtract one value on which the cursor is placed. [ ] key:...

Page 59: 5.4.2

Hrx-om-i051 chapter 5 system operation hrz series 5.4 examples of system operation 5-13 5.4.2 example 2: communication mode is switched from “dio remote” to “local”. Figure 5-22 switching of communication mode from “dio remote” to “local” 1. Press the [sel] key to display the “menu screen 1”. Figure...

Page 60: 5.4.3

Hrx-om-i051 chapter 5 system operation 5.4 examples of system operation hrz series 5-14 5.4.3 example 3: alarm signal of contact signal is changed from “n/a” to “alarm1”. Figure 5-27 change of alarm signal of contact signal from “n/a” to “alarm1” 1. Press the [sel] key to display the “menu screen 1”...

Page 61

Hrx-om-i051 chapter 5 system operation hrz series 5.4 examples of system operation 5-15 5. Use the arrow keys ([▲], [▼]) to select “alarm1”. Figure 5-32 initial setting screen 3: alarm1 6. Press the [ent] key. “out” flashes again, and the selection takes effect. Figure 5-33 initial setting screen 3:...

Page 62

Hrx-om-i051 chapter 5 system operation 5.4 examples of system operation hrz series 5-16.

Page 63: Troubleshooting

Hrx-om-i051 chapter 6 error message and troubleshooting hrz series 6.1 error message 6-1 chapter 6 error message and troubleshooting 6.1 error message the following are to be performed in the event of an error in this system. The “alarm” lamp comes on. Alarm buzzer comes on. The “alarm display scree...

Page 64: 6.2 Troubleshooting

Hrx-om-i051 chapter 6 error message and troubleshooting 6.2 troubleshooting hrz series 6-2 6.2 troubleshooting the procedure for error recovery varies with alarm types. Alarm code.01 to 20, 22, 24, 25: eliminate the error cause. Press the [reset] key on the operation display panel or power cycle the...

Page 65

Hrx-om-i051 chapter 6 error message and troubleshooting hrz series 6.2 troubleshooting 6-3 table 6-1 troubleshooting (2/2) code error message system condition cause remedies 12 return low flow flt stop the flow rate of the circulating fluid falls short of 6l/min. Check that the external valve is ope...

Page 66

Hrx-om-i051 chapter 6 error message and troubleshooting 6.2 troubleshooting hrz series 6-4.

Page 67

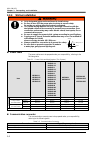

Hrx-om-i051 chapter 7 system maintenance hrz series 7.1 water quality management 7-1 chapter 7 system maintenance 7.1 water quality management table 7-1 water quality standards for fresh water (tap water) substance facility water spec. Circulating water spec. Standards ph (25°c) 6.5 to 8.2 6.0 to 8....

Page 68: 7.2.1

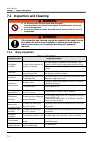

Hrx-om-i051 chapter 7 system maintenance 7.2 inspection and cleaning hrz series 7-2 7.2 inspection and cleaning 7.2.1 daily inspection table 7-2 daily inspection inspection item inspection method installation condition check of the condition of system installation no heavy object is placed on this s...

Page 69: 7.2.2

Hrx-om-i051 chapter 7 system maintenance hrz series 7.3 storage 7-3 7.2.2 quarterly inspection table 7-3 quarterly inspection inspection item inspection method circulating fluid circulating fluid is to be drained for check. Fluid should be free of particles, moisture *1 and foreign substances. For e...

Page 70: 7.3.1

Hrx-om-i051 chapter 7 system maintenance 7.3 storage hrz series 7-4 7.3.1 draining of circulating fluid out of tank 1. Prepare the container for circulating fluid recovery at the back of this system. 2. Connect the drain hoses to the main and sub tank drain ports each. Insert the tip of the hose int...

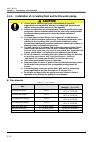

Page 71: 7.3.2

Hrx-om-i051 chapter 7 system maintenance hrz series 7.3 storage 7-5 plug circulating fluid supply facility water outlet circulating fluid return plug rear drain pan port plug facility water inlet main tank drain port sub tank drain port 6. Upon completion of fluid draining, close the valves of the m...

Page 72

Hrx-om-i051 chapter 7 system maintenance 7.4 periodic replacement parts hrz series 7-6 2. Remove facility water piping. Remove the joints such as unions if present. 3. Drain the facility water using the facility water inlet port. 7.4 periodic replacement parts replacement of consumables listed in th...

Page 73: Chapter 8 Appendix

Hrx-om-i051 chapter 8 appendix hrz series 8.1 specification 8-1 chapter 8 appendix 8.1 specification 8.1.1 system specification specification for fluorinated fluid (low temperature) table 8-1 specification for fluorinated fluid (low temperature) model hrz001-l hrz002-l hrz004-l hrz008-l cooling me...

Page 74

Hrx-om-i051 chapter 8 appendix 8.1 specification hrz series 8-2 specification for fluorinated fluid (high temperature) table 8-2 specification for fluorinated fluid (high temperature) model hrz001-h hrz002-h hrz004-h hrz008-h cooling method water cooled refrigerant cooling capacity *1 (50hz/60hz) ...

Page 75

Hrx-om-i051 chapter 8 appendix hrz series 8.1 specification 8-3 specification for fluorinated fluid (wide temperature) table 8-3 specification for fluorinated fluid (wide temperature) model hrz002-w hrz008-w cooling method water cooled refrigerant cooling capacity *1 (50hz/60hz) kw 2.0 (at 20°c) 8...

Page 76

Hrx-om-i051 chapter 8 appendix 8.1 specification hrz series 8-4 specification for ethylene glycol solution (low temperature) table 8-4 specification for ethylene glycol aqueous solution (low temperature) model hrz001-l1 hrz002-l1 hrz004-l1 hrz008-l1 cooling method water cooled refrigerant cooling ...

Page 77

Hrx-om-i051 chapter 8 appendix hrz series 8.1 specification 8-5 specification for ethylene glycol solution (high temperature) table 8-5 specification for ethylene glycol aqueous solution (high temperature) model hrz001-h1 hrz002-h1 hrz004-h1 hrz008-h1 cooling method water cooled refrigerant coolin...

Page 78

Hrx-om-i051 chapter 8 appendix 8.1 specification hrz series 8-6 specification for ethylene glycol solution (wide temperature) table 8-6 specification for ethylene glycol aqueous solution (wide temperature) model hrz002-w1 hrz008-w1 cooling method water cooled refrigerant cooling capacity *1 (50hz/...

Page 79

Hrx-om-i051 chapter 8 appendix hrz series 8.1 specification 8-7 specification for water (low temperature) table 8-7 specification for water (low temperature) model hrz001-l2 hrz002-l2 hrz004-l2 hrz008-l2 cooling method water cooled refrigerant cooling capacity *1 (50hz/60hz) kw 1.0 (at 20°c) 2.0 (...

Page 80

Hrx-om-i051 chapter 8 appendix 8.1 specification hrz series 8-8 specification for fluorinated fluid (wide temperature with inverter) table 8-8 specification for fluorinated fluid (wide temperature with inverter) model hrz010-ws cooling method water cooled refrigerant cooling capacity *1 (50hz/60hz...

Page 81

Hrx-om-i051 chapter 8 appendix hrz series 8.1 specification 8-9 specification for ethylene glycol solution (low temperature with inverter) table 8-9 specification for ethylene glycol solution (low temperature with inverter) model hrz010-w1s cooling method water cooled refrigerant cooling capacity ...

Page 82

Hrx-om-i051 chapter 8 appendix 8.1 specification hrz series 8-10 specification for water (low temperature with inverter) table 8-10 specification for water (low temperature with inverter) model hrz010-w2s cooling method water cooled refrigerant cooling capacity *1 (50hz/60hz) kw 9.0 (at 20°c) oper...

Page 83: 8.1.2

Hrx-om-i051 chapter 8 appendix hrz series 8.1 specification 8-11 8.1.2 communication specification this section provides the general outline of communications utilized in this system. For detail specification, we provide a separate system manual “communication specification”, which is available thro...

Page 84

Hrx-om-i051 chapter 8 appendix 8.1 specification hrz series 8-12 serial rs-485 table 8-12 serial rs-485 item specification connector no. P2 connector type (this system) d-sub9p female connector standard eia rs485 protocol modicon modbus circuit block diagram internal circuit this system your syste...

Page 85: 8.1.3

Hrx-om-i051 chapter 8 appendix hrz series 8.1 specification 8-13 8.1.3 alarm signal selection user can designate one alarm signal for contact signal. See section 5.3.9 “initial setting screen” for signal selecting. The following table presents the setting-alarm relationship. The alarm signal is turn...

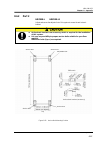

Page 86: 8.2 Outer Dimensions

Hrx-om-i051 chapter 8 appendix 8.2 outer dimensions hrz series 8-14 8.2 outer dimensions 8.2.1 part 1 hrz001-h hrz001-h1 hrz002-h hrz002-h1 figure 8-1 outer dimensions 8.2.2 part 2 hrz001-l hrz002-l hrz004-l hrz008-l2 hrz001-l1 hrz002-l1 hrz004-l1 hrz008-h hrz001-l2 hrz002-l2 hrz004-l2 hrz008-h1 hrz...

Page 87: 8.2.3

Hrx-om-i051 chapter 8 appendix hrz series 8.2 outer dimensions 8-15 8.2.3 part 3 hrz008-l hrz008-l1 figure 8-3 outer dimensions top left back front.

Page 88: 8.3 Flow Chart

Hrx-om-i051 chapter 8 appendix 8.3 flow chart hrz series 8-16 8.3 flow chart 8.3.1 part 1 hrz001-h hrz002-h hrz004-h hrz008-h hrz001-h1 hrz002-h1 hrz004-h1 hrz008-h1 hrz002-w hrz008-w hrz002-w1 hrz008-w1 hrz010-ws hrz010-w1s hrz010-w2s figure 8-4 flow chart facility water circuit circulating fluid c...

Page 89: 8.3.2

Hrx-om-i051 chapter 8 appendix hrz series 8.3 flow chart 8-17 8.3.2 part 2 hrz001-l hrz002-l hrz004-l hrz008-l hrz001-l1 hrz002-l1 hrz004-l1 hrz008-l1 hrz001-l2 hrz002-l2 hrz004-l2 hrz008-l2 figure 8-5 flow chart facility water circuit circulating fluid circuit compressor refrigerant pressure gauge ...

Page 90: 8.4 Offset Function

Hrx-om-i051 chapter 8 appendix 8.4 offset function hrz series 8-18 8.4 offset function potential deviations in temperature between this system and your system may be concerned depending on the installation environment. The offset function falling into three types (mode1 to 3) is assigned to calibrat...

Page 91: 8.4.1

Hrx-om-i051 chapter 8 appendix hrz series 8.4 offset function 8-19 8.4.1 example of offset function when the discharge temperature of the circulating fluid is at 30°c, heat is dissipated by 1°c to allow the circulating fluid in your system to be 29°c. Under the above condition, the following process...

Page 92

Hrx-om-i051 chapter 8 appendix 8.4 offset function hrz series 8-20 when mode2 is selected with offset value set at -1°c, temp pv and communication data express “29°c” (circulating fluid discharge temp. Value + offset value) that agrees with the temperature of the circulating fluid in your system. ...

Page 93: 8.5 Band/ready Function

Hrx-om-i051 chapter 8 appendix hrz series 8.5 band/ready function 8-21 8.5 band/ready function sets band to temp sp value, and notifies temp pv value reaches within band range by the operation display panel or the communication. See section “5.3.9 initial setting screen” on page 5-7, “5.3.11 option ...

Page 94: 8.6.1

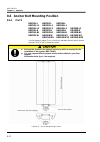

Hrx-om-i051 chapter 8 appendix 8.6 anchor bolt mounting position hrz series 8-22 8.6 anchor bolt mounting position 8.6.1 part 1 hrz001-l hrz002-l hrz004-l hrz001-l1 hrz002-l1 hrz004-l1 hrz001-l2 hrz002-l2 hrz004-l2 hrz008-l2 hrz001-h hrz002-h hrz004-h hrz008-h hrz001-h1 hrz002-h1 hrz004-h1 hrz008-h1...

Page 95: 8.6.2

Hrx-om-i051 chapter 8 appendix hrz series 8.6 anchor bolt mounting position 8-23 8.6.2 part 2 hrz008-l hrz008-l1 adjust and secure the adjuster foot of this system to secure the anti-seismic bracket. Figure 8-12 anchor bolt mounting position anchor bolt anchor bolt adjustable foot top anchor bolt an...

Page 96: 8.7 Compliance

Hrx-om-i051 chapter 8 appendix 8.7 compliance hrz series 8-24 8.7 compliance this system conforms to the following standards. Table 8-14 compliance ce marking emc directive 2004/108/ec low voltage directive 2006/95/ec machinery directive 2006/42/ec sematech s2-93, s8-95 semi s2-0703, s8-0701, f47-02...

Page 97: 8.8

Hrx-om-i051 chapter 8 appendix hrz series 8.8 thermo chiller daily inspection sheet 8-25 8.8 thermo chiller daily inspection sheet t o c o n firm d a ily ins p e c tion it e m o n t h e t he rmo c hil ler , s ee “ t a b le 7 -2 d a ily i n s p e c tion ” in “7 .2 .1 d a ily ins p e c tion ” of “ c h...

Page 98: Product Warranty

Product warranty 1. Warranty if a failure is observed in our thermo chiller, repair shall be provided in accordance with the warranty period and preconditions defined below at smc’s option. Repair involves the inspection and/or replacement and/or modification of a defective part. Removed parts shall...