- DL manuals

- Suzuki

- Automobile

- GRAND VITARA 1999

- Owner's Manual

Suzuki GRAND VITARA 1999 Owner's Manual

Important

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the words

WARNING, CAUTION and NOTE have special meanings. Pay special attention to the messages highlighted by

these signal words.

WARNING:

Indicates a potential hazard that could result in death or injury.

CAUTION:

Indicates a potential hazard that could result in vehicle damage.

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

WARNING:

This service manual is intended for authorized Suzuki dealers and qualified service mechanics only.

Inexperienced mechanics or mechanics without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the mechanic and may render the vehicle unsafe for the driver

and passengers.

WARNING:

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

• If the air bag system and another vehicle system both need repair, Suzuki recommends that the air

bag system be repaired first, to help avoid unintended air bag system activation.

• Do not modify the steering wheel, instrument panel or any other air bag system component (on or

around air bag system components or wiring). Modifications can adversely affect air bag system

performance and lead to injury.

• If the vehicle will be exposed to temperatures over 93°C (200°F) (for example, during a paint baking

process), remove the air bag system components (air bag (inflator) modules, forward sensor(s),

SDM and/or seat belt pretensioners) beforehand to avoid component damage or unintended activa-

tion.

Summary of GRAND VITARA 1999

Page 1

Important warning/caution/note please read this manual and follow its instructions carefully. To emphasize special information, the words warning, caution and note have special meanings. Pay special attention to the messages highlighted by these signal words. Warning: indicates a potential hazard th...

Page 2: Foreword

Foreword this manual contains only different service information of the following applicable model as compared with sq416/sq420/sq625 service manual. Applicable model: grand vitara xl-7 therefore, whenever servicing the above applicable model, consult this manual first. And for any section, item or ...

Page 4: Table Of Contents

Table of contents general information transmission, clutch and differential 0a 7a1 general information 0a 0b 7b1 maintenance and lubrication 0b manual transmission 7a1 7c1 heating and air conditioning automatic transmission 7b1 1a 7d heater and ventilation 1a clutch 7c1 1b 7e air conditioning 1b tra...

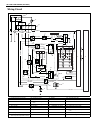

Page 6: Section 0A

General information 0a-1 0a section 0a general information contents precautions......................................................0a-2 precaution for vehicles equipped with a supplemental restraint (air bag) system ...........................................0a-2 diagnosis............................

Page 7: Precautions

0a-2 general information precautions precaution for vehicles equipped with a sup- plemental restraint (air bag) system diagnosis • when troubleshooting air bag system, be sure to follow “diagnosis” in section 10b. Bypassing these proce- dures may result in extended diagnostic time, incorrect diagnos...

Page 8

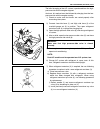

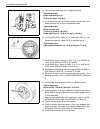

General information 0a-3 servicing and handling warning: many of service procedures require disconnection of “air bag” fuse and all air bag (inflator) module(s) from initiator circuit to avoid an accidental deployment. Driver and passenger air bag (inflator) modules • for handling and storage of a l...

Page 9

0a-4 general information warning: sdm • during service procedures, be very careful when handling a sensing and diagnostic module (sdm). Never strike or jar the sdm. Never power up the air bag system when the sdm is not rigidly attached to the vehicle. All sdm and mounting bracket fasteners must be c...

Page 10

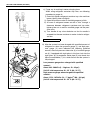

General information 0a-5 caution: • even when the accident was light enough not to cause air bags to activate, be sure to inspect sys- tem parts and other related parts according to instructions under “repair and inspection required after an accident” in section 10b. • when servicing parts other tha...

Page 11: Identification Information

0a-6 general information identification information vehicle identification number the vehicle body number is on the left side of instrument panel and punched on the chassis inside the tire housing on the right front side..

Page 12

General information 0a-7 engine identification number the number is punched on the cylinder block. Engine identification number specification transmission identification number the a/t manufacture’s identification number is located on the transmission case as shown. However, the m/t identification n...

Page 13

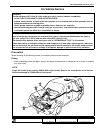

0a-8 general information warning, caution and information labels the figure below shows main labels among others that are attached to vehicle component parts. When servicing and handling parts, refer to warning/caution instructions printed on labels. If any warning/caution label is found stained or ...

Page 14: Section 0B

Maintenance and lubrication 0b-1 0b section 0b maintenance and lubrication contents maintenance schedule .................................. 0b-2 maintenance schedule under normal driving conditions ........................................ 0b-2 maintenance recommended under severe driving conditions ...

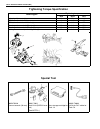

Page 15: Maintenance Schedule

0b-2 maintenance and lubrication maintenance schedule maintenance schedule under normal driving conditions note: • this interval should be judged by odometer reading or months, whichever comes first. • this table includes service as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km ...

Page 16

Maintenance and lubrication 0b-3 interval km ( × 1,000) 15 30 45 60 75 90 miles ( × 1,000) 9 18 27 36 45 54 months 12 24 36 48 60 72 chassis and body 6-1. Clutch (pedal and fluid level) – i – i – i 6-2. Brake discs and pads (thickness, wear, damage) i i i i i i brake drums and shoes (wear, damage) –...

Page 17

0b-4 maintenance and lubrication maintenance recommended under severe driving conditions if the vehicle is usually used under the conditions corresponding to any severe condition code given below, it is recommended that applicable maintenance operation be performed at the particular interval as give...

Page 18: Maintenance Service

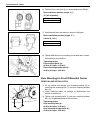

Maintenance and lubrication 0b-5 maintenance service engine and emission control item 1-1 drive belt inspection and replacement water pump and generator drive belt inspec- tion 1) disconnect negative (–) cable at battery. 2) inspect belt for cracks, cuts, deformation, wear and cleanli- ness. If any ...

Page 19

0b-6 maintenance and lubrication power steering pump and/or a/c compressor drive belts (if equipped) inspection 1) disconnect negative (–) cable at battery. 2) inspect belt for cracks, cuts, deformation, wear and cleanli- ness. If any defect exists, replace. Check belt for tension. If belt tension i...

Page 20

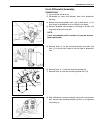

Maintenance and lubrication 0b-7 1) drain engine oil by removing drain plug. 2) after draining oil, wipe drain plug clean. Reinstall drain plug, and tighten it securely as specified below. Tightening torque engine oil drain plug (a) : 50 n·m (5.0 kg-m, 36.5 lb-ft) 3) loosen oil filter by using oil f...

Page 21

0b-8 maintenance and lubrication 6) replenish oil until oil level is brought to full level mark on dipstick. (oil pan and oil filter capacity). The filler inlet is at the top of the cylinder head cover. It is recommended to use engine oil of se, sf, sg, sh or sj grade. Note: select the appropriate o...

Page 22: Section 1A

Heater and ventilation 1a-1 1a section 1a heater and ventilation contents general description ....................................... 1a-2 rear duct..................................................... 1a-3 warning: for vehicles equipped with supplement restraint (air bag) system: • service on and a...

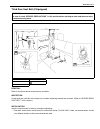

Page 23: General Description

1a-2 heater and ventilation general description the heater, an in and out air selectable-type hot water heater, is so constructed that it is possible to assure an agreeable ventilation at all times by providing the ventilator air outlets at the center and both sides (right and left) of the instrumen...

Page 24

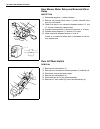

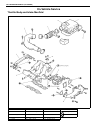

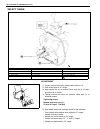

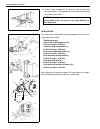

Heater and ventilation 1a-3 rear duct removal 1) disconnect negative (–) cable at battery. 2) remove front and second seats. 3) remove console box. 4) take off carpet till rear duct is totally exposed. 5) remove rear duct. Installation reverse removal sequence to install rear duct. 1. Heater unit 2....

Page 25

1a-4 heater and ventilation.

Page 26: Section 1B

Air conditioning (optional) 1b-1 1b section 1b air conditioning (optional) contents general description ....................................... 1b-3 refrigerant type .......................................... 1b-3 refrigerant flow of air conditioning system 1b-3 major components and location ..........

Page 27

1b-2 air conditioning (optional) charging .................................................... 1b-22 on-vehicle service ...................................... 1b-25 precaution.................................................. 1b-25 piping ..................................................... 1b-25 h...

Page 28: General Description

Air conditioning (optional) 1b-3 general description refrigerant type whether the a/c in the vehicle being serviced uses hfc-134a (r-134a) or cfc-12 (r-12) is indicated on label on the com- pressor. Also, it can be checked by the shape of the service (charge) valve. Refrigerant flow of air condition...

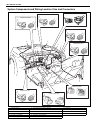

Page 29

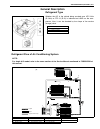

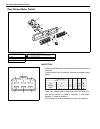

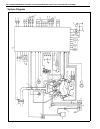

1b-4 air conditioning (optional) major components and location [a] : dual a/c model 6. Receiver/dryer 13. Suction pipe 20. Ventilation air [b] : single a/c model 7. Front expansion valve 14. Discharge pipe 21. Rear a/c air 1. Front cooling unit 8. Heater unit 15. Recirculation air 22. Room air 2. Fr...

Page 30

Air conditioning (optional) 1b-5 [a] : dual a/c lh steering model 4. Condenser 11. Low pressure charge valve [b] : dual a/c rh steering model 5. Sight glass 12. Floor liquid pipe [c] : single a/c lh steering model 6. Refrigerant (dual) pressure sensor 13. Floor suction pipe [d] : single a/c rh steer...

Page 31: Diagnosis

1b-6 air conditioning (optional) diagnosis general main a/c system (front a/c system) condition possible cause correction cool air does not come out (a/c system does not operative) no refrigerant perform recover, evacuation and charging. Fuse blown check “ig meter”, “rear defg” and “a/c” fuses, and ...

Page 32

Air conditioning (optional) 1b-7 cool air does not come out or insuffi- cient cooling (a/c sys- tem normal operative) insufficient or excessive charge of refrigerant check charge of refrigerant. Refrigerant leak in system check system for leaks. Condenser clogged check condenser. A/c evaporator clog...

Page 33

1b-8 air conditioning (optional) rear a/c system condition possible cause correction cool air dose not come out (rear blower motor normal operative) solenoid valve relay faulty check solenoid valve relay, and then replace if necessary solenoid valve faulty check solenoid valve, and then replace if n...

Page 34

Air conditioning (optional) 1b-9 quickly checking of refrigerant charge (if equipped with sight glass) the following procedure can be used for quickly checking whether the a/c system has a proper charge of refrigerant or not. 1) run engine at fast idle. 2) operate a/c at the following conditions for...

Page 35

1b-10 air conditioning (optional) performance diagnosis 1) confirm that vehicle and environmental conditions are as fol- lows. • vehicle is not exposed to direct sun. • ambient temperature is within 15 - 35 °c (59 - 95 °f). 2) make sure that high pressure valve (1) and low pressure valve (2) of mani...

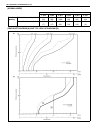

Page 36

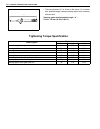

Air conditioning (optional) 1b-11 9) check for each pressure of low side and high side if it is within shaded range of graph. If each gauge reading is out of specified pressure, correct defective part referring to “performance diagnosis table”. Example : 10) check inlet port temperature-to-outlet po...

Page 37

1b-12 air conditioning (optional) performance diagnosis table high pressure gauge low pressure gauge thermometer at center duct condition possible cause correction pressure high (“a” area of high side graph) refrigerant overcharged recharge. Expansion valve frozen or clogged check expansion valve. C...

Page 38

Air conditioning (optional) 1b-13 detail diagnosis table (at ambient temperature within 30 - 35 °c (85 - 95 °f)) condition possible cause correction manifold gauge mpa (kg/cm 2 ) (psi) detail lo hi 0.23 - 0.35 (2.3 - 3.5) (33 - 50) 1.4 - 1.75 (14 - 17.5) (200 - 249) normal condition – – negative pre...

Page 39

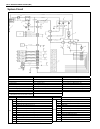

1b-14 air conditioning (optional) wiring circuit acg lt grn pnk pnk blk orn blk yel/grn red/blk blk/wht blu/wht pnk/blk pnk/grn red/blk wht/red yel/grn yel/blu a/c red/blu red/blu red/blk blk blu/orn blu/wht blu/wht pnk pnk/blu blk pnk/wht yel/blk gry/wht grn/blk blk/wht red/blk yel/grn blk blk blk ...

Page 40

Air conditioning (optional) 1b-15 inspection of a/c controller and its circuits a/c controller (1) and its circuits can be checked at a/c controller wiring couplers by measuring voltage. Voltage check 1) remove a/c controller (1) from vehicle referring to “a/c controller” in this section. 2) remove ...

Page 41

1b-16 air conditioning (optional) system circuit terminal arrangement of a/c controller terminal arrangement of ecm a: to “front blow” fuse 1. Front blower motor relay 6. Dual (refrigerant) pressure switch 11. Condenser cooling fan motor b: to “rear defg” fuse 2. Front blower motor 7. A/c thermistor...

Page 42

Air conditioning (optional) 1b-17 a/c controller voltage values table terminal wire circuit measurement ground normal value condition ac-a-1 blk/ wht controller main power supply ground to engine (fig b) 10 – 14 v ignition switch on with engine stopped ac-a-2 blk/ yel controller main ground ground t...

Page 43

1b-18 air conditioning (optional) terminal wire circuit measurement ground normal value condition ac-b-2 wht/ blk a/c evaporator temperature sensor (a/c evaporator ther- mistor) input ground to engine (fig b) 1.8 v (3520 Ω) a/c evaporator temperature sen- sor temperature at approx. 15 °c (59 °f) wit...

Page 44

Air conditioning (optional) 1b-19 refrigerant recovery, evacuation and charging operation procedure for charging a/c with refrigerant warning: • your eyes should not be exposed to refrigerant (liquid). Any liquid refrigerant-134a escaping by accident shows a temperature as low as approx. –6 °c (21.2...

Page 45

1b-20 air conditioning (optional) recovery note: • when discharging refrigerant out of a/c system, always recover it by using refrigerant recovery and recycling equipment (1). Discharging it into atmo- sphere would cause adverse effect to environments. • when handling recovery and recycling equipmen...

Page 46

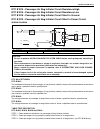

Air conditioning (optional) 1b-21 evacuating evacuating procedure 1) connect high charging hose (1) and low charging hose (2) of manifold gauge set (3) respectively as follows: high charging hose (1) → high pressure charging valve (4) on discharge hose low charging hose (2) → low pressure charging v...

Page 47

1b-22 air conditioning (optional) checking system for pressure leaks after completing the evacuation, close manifold gauge high pres- sure valve (hi) and low-pressure valve (lo) and wait 10 minutes. Verify that low-pressure gauge reading has not changed. Charging caution: if the gauge reading moves ...

Page 48

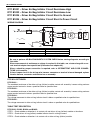

Air conditioning (optional) 1b-23 the initial charging of the a/c system is performed from the high- pressure side with the engine stopped. And next, this method must be followed by charging from the low- pressure side with the engine running. 1) check to make sure that hoses are routed properly aft...

Page 49

1b-24 air conditioning (optional) c) purge any air existing in center charging hose when using refrigerant container tap valve, use following procedure to purge air. I) once fully tighten refrigerant container tap valve and then loosen (open) plate nut slightly. Ii) open low pressure valve of manifo...

Page 50: On-Vehicle Service

Air conditioning (optional) 1b-25 on-vehicle service precaution when servicing air conditioning system, the following rules must be observed. Piping • when connecting hoses and pipes, apply a few drops of compressor oil (refrigerant oil) to seats of coupling nuts and o-ring. Warning: should refriger...

Page 51

1b-26 air conditioning (optional) • never use heat for bending pipes. When bending a pipe, try to make its bending radius as slight as possible. • keep internal parts of air conditioning free from moisture and dirt. When disconnecting any line from system, install a blind plug or cap to the fitting ...

Page 52

Air conditioning (optional) 1b-27 replenishing compressor oil when replacing air conditioning parts with new ones, it is neces- sary to replenish oil by the amount supposedly remaining in each part. When changing gas only when it is unavoidable to change gas without replacing any com- ponent part fo...

Page 53

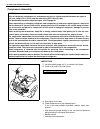

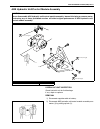

1b-28 air conditioning (optional) rear a/c unit (rear a/c evaporator) removal 1) disconnect negative (–) cable at battery. 2) recover refrigerant by using recovery and recycling equip- ment. Be sure to follow the instruction manual for the equip- ment. The amount of compressor oil removed must be me...

Page 54

Air conditioning (optional) 1b-29 4) loosen floor suction pipe and floor liquid pipe mounting bolt (1). 5) remove rear a/c no.1 duct (1). 6) disconnect rear a/c unit wire couplers (2). 7) remove rear a/c unit mounting bolts (3), and then remove rear a/c unit (4). Inspection check the following. • cl...

Page 55

1b-30 air conditioning (optional) removal 1) remove rear a/c unit referring to “rear a/c unit” in this section. 2) disconnect solenoid valve connector (1). 3) loosen solenoid valve bracket mounting screws (2). 4) remove rear liquid pipe and rear suction pipe bolt (1), and then disconnect rear liquid...

Page 56

Air conditioning (optional) 1b-31 inspection 1) connect battery positive (+) cable to terminal “b” and battery negative (–) cable to terminal “c” as shown. 2) using ohmmeter, check continuity between terminal “a” and terminal “b” at specified temperature as shown. Rear a/c evaporator temperature con...

Page 57

1b-32 air conditioning (optional) solenoid valve removal 1) remove rear a/c unit referring to “rear a/c unit” in this section. 2) disconnect solenoid valve connector (1). 3) loosen solenoid valve flared nuts (2). 4) remove solenoid valve bracket mounting screws (3), and then remove rear liquid pipe ...

Page 58

Air conditioning (optional) 1b-33 rear blower motor assembly removal 1) remove solenoid valve referring to “solenoid valve” in this section. 2) disconnect rear blower motor coupler (1). 3) remove rear blower motor assembly (2) from rear a/c unit (3). Inspection 1) check continuity between two termin...

Page 59

1b-34 air conditioning (optional) rear blower motor relay and solenoid valve relay inspection 1) disconnect negative (–) cable at battery. 2) remove rear blower motor relay (1) and/or solenoid valve relay (2) from vehicle. 3) check that there is no continuity between terminal “c” and “d”. If there i...

Page 60

Air conditioning (optional) 1b-35 inspection • check rear a/c main switch for each terminal-to-terminal continuity. If check results are not specified, replace rear a/c main switch. Installation reverse removal procedure for installation. Rear blower motor resistor removal 1) remove rear a/c unit re...

Page 61

1b-36 air conditioning (optional) rear blower motor switch inspection • check rear blower motor switch for each terminal-to-terminal continuity. If check results are not specified, replace rear blower motor switch. • check rear blower motor switch bulb come on when con- nect battery positive (+) cab...

Page 62

Air conditioning (optional) 1b-37 rear a/c no.1 and no.2 duct rear a/c no.1 duct removal 1) remove rear a/c unit referring to “rear a/c unit” in this section. 2) remove rear a/c no.1 duct (1). Installation reverse removal procedure to install rear a/c no.1 duct (1). Rear a/c no.2 duct caution: never...

Page 63

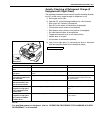

1b-38 air conditioning (optional) compressor assembly inspection 1) install manifold gauge set (1) as shown in the figure. 2) close hi (4) and lo (5) side valves. 3) run engine at fast idle. 4) check compressor for the following items. If any of the above checks indicated a defect, repair com- press...

Page 64

Air conditioning (optional) 1b-39 removal 1) run engine at idle with a/c on for 10 minutes. 2) disconnect negative (–) cable at battery. 3) recover refrigerant from refrigeration system using recovery and recycling equipment. 4) remove p/s pump referring to step 4) to 7) of “removal” under “p/s pump...

Page 65

1b-40 air conditioning (optional) installation reverse removal procedure to install compressor assembly not- ing the following instructions. • if compressor was replaced, pour new compressor oil with the same amount as that drained from compressor. Refer to “replenishing compressor oil” in this sec-...

Page 66

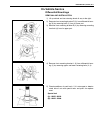

Air conditioning (optional) 1b-41 magnet clutch inspection check the following items. • check no sigh of compressor oil leakage • check magnet clutch pulley bearing for noise and grease leakage. • check magnet clutch operation as follows : a) connect battery (1) and ammeter (2) to compressor (3) as ...

Page 67

1b-42 air conditioning (optional) 5) using special tool, remove circlip. Special tool (a) : 09900-06107 6) remove magnet clutch lead wire clamp screw, and remove magnet clutch read wire ground terminal. 7) remove magnet clutch with puller. 8) remove circlip using special tool. Special tool (a) : 099...

Page 68

Air conditioning (optional) 1b-43 4) install magnet clutch (1). A) set magnet clutch squarely over clutch installation boss. B) place special tool onto clutch bearing. Ensure that edge rests only on inner race of bearing. Special tool (a) : 09991-06010 c) install new circlip. 5) adjust clearance bet...

Page 69: Required Service Materials

1b-44 air conditioning (optional) required service materials tightening torque specification special tools material recommended suzuki product (part number) use compressor oil (refrigerant oil) compressor oil (nd-oil8, 250 cc) (99000-27080) • o-ring • each component fastening part tightening torque ...

Page 70: Section 3A

Front end alignment 3a-1 3a section 3a front end alignment contents general information ........................................3a-1 alignment service data (without load) .........3a-1 on-vehicle service ......................................... 3a-1 reference information ..............................

Page 71

3a-2 front end alignment.

Page 72: Section 3B1

Power steering (p/s) system 3b1-1 3b1 section 3b1 power steering (p/s) system contents general description ......................................3b1-2 power steering (p/s) pump ........................3b1-2 diagnosis .......................................................3b1-2 power steering pump dr...

Page 73: General Description

3b1-2 power steering (p/s) system general description power steering (p/s) pump power steering (p/s) pump specification : the specification of this power steering pump is the same as the specification of the same section in the service manual mentioned in this manual except for data of relieved pres...

Page 74

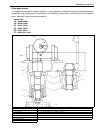

Power steering (p/s) system 3b1-3 hydraulic pressure in p/s circuit hydraulic pressure check 1) after cleaning joint of high pressure hose and p/s pump thoroughly, disconnect hose from pump and install special tool (oil pressure gauge, attachment and hose). Special tool (a) : 09915-77410 (b) : 09915...

Page 75

3b1-4 power steering (p/s) system 5) check relief pressure. A) increase engine speed to about 1500 r/min (rpm). Close gauge valve gradually while watching pressure increase indicated by gauge and take reading of relief pressure (maximum hydraulic pressure). When it is higher than specified values, p...

Page 76: Section 3C1

Air bag steering wheel and column 3c1-1 3c1 section 3c1 air bag steering wheel and column contents general description ..................................... 3c1-2 diagnosis ...................................................... 3c1-3 inspection and repair required after accident .......................

Page 77: General Description

3c1-2 air bag steering wheel and column general description this double tube type steering column has the following three important features in addition to the steering func- tion: • the column is energy absorbing, designed to compress in a front-end collision. • the ignition switch and lock are mou...

Page 78: Diagnosis

Air bag steering wheel and column 3c1-3 diagnosis for diagnosis of the steering wheel and steering column, refer to section 3. For diagnosis of the air bag system, refer to section 10b. Inspection and repair required after accident after an accident, whether the air bag has been deployed or not, be ...

Page 79

3c1-4 air bag steering wheel and column steering column removal 1) disconnect negative (–) cable at battery. 2) disable air bag system. Refer to “disabling air bag system” under “service precautions” in section 10b. 3) remove steering wheel and contact coil and combination switch assembly, if necess...

Page 80

Air bag steering wheel and column 3c1-5 6) remove steering upper shaft upper joint bolt (1) and nut (2) and disconnect steering upper shaft upper joint removing in arrow direction in the figure. 7) remove steering column (1) mounting bolts (2 pieces) (2) and nuts (2 pieces) (3). 8) if equipped with ...

Page 81

3c1-6 air bag steering wheel and column 3) install steering column assembly (1) with contacting upper side of lower bracket slits to mounting bolts. Tighten steering column lower mounting nuts (3) first and then upper mount- ing bolts (2) to specified torque. Tightening torque steering column mounti...

Page 82

Air bag steering wheel and column 3c1-7 steering upper shaft assembly removal 1) turn steering wheel so that vehicle’s front tires are at straight-ahead position. 2) turn ignition switch to “lock” position and remove key. 3) make alignment marks (3) on shaft joint (2) and shaft (upper shaft assembly...

Page 83

3c1-8 air bag steering wheel and column inspection check steering shaft damage and operation referring to check steering column and steering upper shaft for accident damage later in this section. Installation 1) be sure that front tires and steering wheel are in straight ahead position. 2) install s...

Page 84

Air bag steering wheel and column 3c1-9 6) install steering upper shaft upper joint bolt (2) and nut (1). Tighten steering upper shaft upper joint nut (1) to specified torque. Tightening torque steering upper shaft upper joint nut (a) : 23 n·m (2.3 kg-m, 17.0 lb-ft) steering lower shaft assembly rem...

Page 85

3c1-10 air bag steering wheel and column installation 1) be sure that front wheels and steering wheel are in straight ahead position. 2) align flat part “a” of lower shaft assembly (1) with bolt hole “b” of shaft joint as shown in the figure. Then insert shaft joint (1) into lower shaft assembly (2)...

Page 86

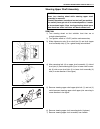

Air bag steering wheel and column 3c1-11 checking steering column and steering upper shaft for accident damage • check that 2 capsules are attached to steering column bracket securely. Check clearance between capsules and steering column bracket. Clearance should be 0 mm (0 in.) on both sides. If fo...

Page 87

3c1-12 air bag steering wheel and column • take measurement “b” as shown in the figure. If it is shorter than specified length, replace steering upper shaft assembly with new one. Steering upper shaft assembly length “b” : 419.0 ± 1.0 mm (16.50 ± 0.04 in.) tightening torque specification “b” fasteni...

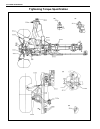

Page 88: Section 3D

Front suspension 3d-1 3d section 3d front suspension contents on-vehicle service......................................... 3d-1 suspension control arm/bushings .............. 3d-1 tightening torque specification .................. 3d-2 on-vehicle service suspension control arm/bushings installation f...

Page 89

3d-2 front suspension tightening torque specification.

Page 90: Section 3E

Rear suspension 3e-1 3e section 3e rear suspension contents on-vehicle service......................................... 3e-1 rear axle shaft and wheel bearing ............ 3e-1 rear axle shaft inner oil seal ..................... 3e-5 rear axle housing ....................................... 3e-5 ti...

Page 91

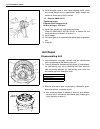

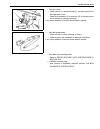

3e-2 rear suspension 2) remove circlip from axle shaft. 3) in order to remove retainer ring (1) from axle shaft (3), grind with a grinder two portion (2) of bearing retainer ring as illus- trated till it becomes thin. 4) break with a chisel (1) the thin ground sensor rotor and retainer ring, and it ...

Page 92

Rear suspension 3e-3 6) remove stud bolt(s) (1) by using hydraulic press (2). Installation install removed parts in reverse order of removal procedure, not- ing the following. 1) aligning serrations between new stud bolt(s) (1) and flange (4), install new stud bolt(s) (1) by tightening nut (2) as sh...

Page 93

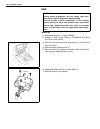

3e-4 rear suspension 5) apply grease “a” to axle shaft inner oil seal lip as shown in the figure. “a” : grease 99000-25010 6) apply water tight sealant “b” to mating surfaces of brake back plate and rear axle hub (2). “b” : water tight sealant 99000-31110 7) install rear axle shaft to rear axle hous...

Page 94

Rear suspension 3e-5 rear axle shaft inner oil seal installation 1) using special tool drive in oil seal until it contacts oil seal pro- tector in axle housing. Special tool (a) : 09924-74510 (b) : 09944-88210 “a” : grease 99000-25010 “b” : sealant 99000-31110 2) for procedure hereafter, refer to st...

Page 95: Required Service Material

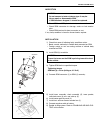

3e-6 rear suspension 5) apply thread lock cement to thread of propeller shaft flange bolt if reused. Install propeller shaft to joint flange aligning match marks and torque flange nuts to specification. “a” : cement 99000-32110 tightening torque propeller shaft nut (a) : 60 n·m (6.0 kg-m, 43.5 lb-ft...

Page 96: Special Tool

Rear suspension 3e-7 special tool 09921-57810 09924-74510 09926-88310 09927-18411 counter shaft holder bush remover handle oil seal installer universal puller 09942-15510 09943-35512 09944-88210 sliding hammer brake drum remover bearing installer.

Page 97

3e-8 rear suspension.

Page 98: Section 3F

Wheels and tires 3f-1 3f section 3f wheels and tires contents general description ....................................... 3f-1 tires ............................................................. 3f-1 wheels ......................................................... 3f-1 general description tires this...

Page 99

3f-2 wheels and tires.

Page 100: Section 4A2

Front drive shaft/shaft bearing, oil seal 4a2-1 4a2 section 4a2 front drive shaft/shaft bearing, oil seal contents on-vehicle service....................................... 4a2-2 drive shaft ................................................. 4a2-2 required service material ..............................

Page 101: On-Vehicle Service

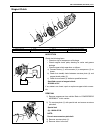

4a2-2 front drive shaft/shaft bearing, oil seal on-vehicle service drive shaft assembly 1) fully apply joint grease to wheel side joint. Use joint grease in the tube included in spare part. “a” : joint grease (about 85- 95 g (3.0 - 3.4 oz) (yellow)) 2) fit wheel side boot (1) on shaft. Fill up insid...

Page 102

Front drive shaft/shaft bearing, oil seal 4a2-3 6) install circlip (1) by using snap ring plier. 7) apply grease to entire surface of cage. Use joint grease in tube included in spare part. 8) insert cage into outer race and fit circlip (1) into groove of outer race. 9) apply grease in tube included ...

Page 103: Required Service Material

4a2-4 front drive shaft/shaft bearing, oil seal required service material material recommended suzuki product (part number) use lithium grease suzuki super grease a (99000-25010) • drive shaft oil seal • wheel spindle part of differential side drive shaft (rh) sealant sealing compound 366e (99000-31...

Page 104: Section 4B

Propeller shafts 4b-1 4b section 4b propeller shafts contents general description ....................................... 4b-1 on-vehicle service......................................... 4b-2 propeller shaft ............................................. 4b-2 tightening torque specification ............

Page 105: On-Vehicle Service

4b-2 propeller shafts on-vehicle service propeller shaft for the descriptions other than those mentioned below, refer to the same item in the same section of the service manual men- tioned in the foreword of this manual. Installation use the following specification to torque universal joint flange n...

Page 106: Section 5

Brakes 5-1 5 section 5 brakes contents diagnosis .......................................................... 5-2 diagnosis table ............................................. 5-2 warning: for vehicles equipped with supplemental restraint (air bag) system: • service on and around the air bag system co...

Page 107: Diagnosis

5-2 brakes diagnosis diagnosis table for the item not found in this column, refer to the same item of the same section in the service manual men- tioned in the foreword of this manual. Condition possible cause correction brake warning light turns on after engine start parking brake applied release p...

Page 108: Section 5A

Brakes pipe/hose/master cylinder 5a-1 5a section 5a brakes pipe/hose/master cylinder contents general description ....................................... 5a-2 master cylinder assembly............................ 5a-2 on-vehicle service......................................... 5a-3 front brake hose/p...

Page 109: General Description

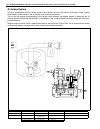

5a-2 brakes pipe/hose/master cylinder general description master cylinder assembly the master cylinder has two pistons and three piston cups. Its hydraulic pressure is produced in the primary (“a” in the figure below) and secondary (“b”) chambers. The hydraulic pressure produced in the primary chamb...

Page 110: On-Vehicle Service

Brakes pipe/hose/master cylinder 5a-3 on-vehicle service front brake hose/pipe removal 1) raise and suitably support vehicle. Remove tire and wheel. This operation is not necessary when removing pipes connecting master cylinder and flexible hose. 2) clean dirt and foreign material from both hose end...

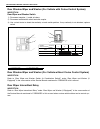

Page 111

5a-4 brakes pipe/hose/master cylinder for rh steering vehicle [d]: view d 1. E-ring [a]: clamp a 2. Flexible hose [b]: clamp b 3. Hose washer [c]: clamp d 4. Hose bolt t: top side 5. Brake caliper f: front side 6. 2 way joint.

Page 112

Brakes pipe/hose/master cylinder 5a-5 for lh steering vehicle [d]: view d 1. E-ring [a]: clamp a 2. Flexible hose [b]: clamp b 3. Hose washer [d]: clamp d 4. Hose bolt t: top side 5. Brake caliper f: front side 6. 2 way joint.

Page 113

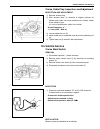

5a-6 brakes pipe/hose/master cylinder master cylinder reservoir removal 1) disconnect reservoir lead wire at coupler. 2) clean outside of reservoir (1). 3) take out fluid with syringe or such. 4) remove reservoir stopper (3). 5) remove reservoir (1). Installation 1) when using new grommets, lubricat...

Page 114

Brakes pipe/hose/master cylinder 5a-7 master cylinder assembly removal 1) disconnect reservoir lead wire (1) at coupler. 2) clean around reservoir cap (2) and take out fluid with syringe or such. 3) disconnect brake pipes from master cylinder (3) and abs actuator (4). Inspection inspect distance “a”...

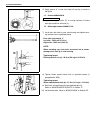

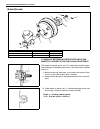

Page 115

5a-8 brakes pipe/hose/master cylinder brake booster clearance between booster piston rod and master cylinder piston check and adjustment the length of booster piston rod (1) is adjusted to provide speci- fied clearance “0” between piston rod (1) end and master cylinder piston (2). 1) before measurin...

Page 116

Brakes pipe/hose/master cylinder 5a-9 4) if measured depth is out of above specifications, adjust to specifications below by turning adjusting screw of piston rod. Special tool (f) : 09952-16021 depth “d” of piston rod for adjustment : 16.3 – 16.6 mm (0.642 – 0.653 in.).

Page 117: Special Tool

5a-10 brakes pipe/hose/master cylinder tightening torque specification special tool fastening part tightening torque n•m kg-m lb-ft brake flexible hose bolt (brake caliper/2 way joint) 23 2.3 17.0 brake hose / pipe bracket bolt 10 1.0 7.5 abs actuator bracket bolt 10 1.0 7.5 master cylinder attachin...

Page 118: Section 5C

Parking and rear brake 5c-1 5c section 5c parking and rear brake contents general description ....................................... 5c-2 drum brake assembly ................................. 5c-2 on-vehicle service......................................... 5c-3 parking brake cable ....................

Page 119: General Description

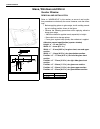

5c-2 parking and rear brake general description drum brake assembly the drum brake assembly has a self shoe clearance adjusting system so that drum-to-shoe clearance is main- tained appropriate at all times. Rear brake is a drum type. It uses leading trailing operation when brake pedal is depressed ...

Page 120: On-Vehicle Service

Parking and rear brake 5c-3 on-vehicle service parking brake cable brake drum inspection brake drum inspect drum for cleanliness. Check wear of its braking surface by measuring its inside diameter. Whenever brake drums are removed, they should be thoroughly cleaned and inspected for cracks, scores, ...

Page 121

5c-4 parking and rear brake cracked, scored, or grooved drum a cracked, drum is unsafe for further service and must be replaced. Do not attempt to weld a cracked drum. Smooth up any slight scores. Heavy or extensive scoring will cause excessive brake lining wear and it will probably be neces- sary t...

Page 122

Parking and rear brake 5c-5 wheel cylinder installation for the details, refer to the same item of the same section in the service manual mentioned in the foreword of this manual not- ing the following points. • take off bleeder plug cap from brake pipe and connect pipe (or pipes) to wheel cylinder ...

Page 123

5c-6 parking and rear brake 4) tighten brake back plate nuts to specified torque. Tightening torque brake back plate nut (a) : 50 n·m (5.0 kg-m, 36.5 lb-ft) 5) install wheel cylinder, and tighten wheel cylinder bolts and brake pipe flare nut (or nuts) to specified torque. Tightening torque wheel cyl...

Page 124

Parking and rear brake 5c-7 tightening torque specification fastening part tightening torque n•m kg-m lb-ft wheel cylinder bleeder plug 7.5 0.75 5.5 parking brake lever bolt 23 2.3 17.0 wheel cylinder bolt 13.5 1.35 10.0 brake pipe flare nut 16 1.6 12.0 brake back plate nut 50 5.0 36.5 wheel nut 100...

Page 125

5c-8 parking and rear brake.

Page 126: Section 5E2

Antilock brake system (abs) 5e2-1 5e2 section 5e2 antilock brake system (abs) contents general description ..................................... 5e2-3 components/parts location ....................... 5e2-3 abs hydraulic unit/control module assembly......................................................

Page 127

5e2-2 antilock brake system (abs) sensor circuit or sensor ring ................. 5e2-22 dtc c1031 (dtc 31), dtc c1032 (dtc 32) – right-rear wheel speed sensor circuit or sensor ring ................. 5e2-22 dtc c1035 (dtc 35), dtc c1036 (dtc 36) – left-rear wheel speed sensor circuit or sensor ring...

Page 128: General Description

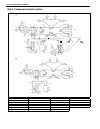

Antilock brake system (abs) 5e2-3 general description components/parts location the abs (antilock brake system) controls the fluid pressure applied to the wheel cylinder of each brake from the master cylinder so that each wheel is not locked even when hard braking is applied. This abs has also the f...

Page 129

5e2-4 antilock brake system (abs) abs hydraulic unit/control module assembly abs control module is a component of abs hydraulic unit/control module assembly and has the following functions. Self-diagnosis function abs control module diagnoses conditions of the system compo- nent parts (whether or no...

Page 130: Diagnosis

Antilock brake system (abs) 5e2-5 diagnosis to ensure that the trouble diagnosis is done accurately and smoothly, observe “precautions in diagnosing trou- bles” and follow “abs diagnostic flow table”. Precautions in diagnosing troubles • if the vehicles was operated in any of the following ways, abs...

Page 131

5e2-6 antilock brake system (abs) abs diagnostic flow table refer to the following pages for the details of each step. Step action yes no 1 1) perform “customer complaint analysis”. 2) perform “problem symptom confirmation”. 3) perform “diagnostic trouble code check, record and clearance”. Is there ...

Page 132

Antilock brake system (abs) 5e2-7 1) malfunction analysis a) customer complaint analysis record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of such a questionnaire form as shown below will facilitate collecting information to th...

Page 133

5e2-8 antilock brake system (abs) b) problem symptom confirmation check if what the customer claimed in “customer questionnaire” is actually found in the vehicle and if that symptom is found, whether it is identified as a failure. (this step should be shared with the cus- tomer if possible.) check w...

Page 134

Antilock brake system (abs) 5e2-9 abs warning lamp check 1) turn ignition switch on. 2) check that abs warning lamp (1) comes on for about 2 sec- onds and then goes off. If any faulty condition is found, advance to diagnostic flow table-a, b, c or d. Ebd warning lamp (brake warning lamp) check 1) tu...

Page 135

5e2-10 antilock brake system (abs) diagnostic trouble code (dtc) check (using abs warning lamp) 1) perform abs warning lamp check described above. 2) using service wire (4), connect diagnosis switch terminal (2) of monitor coupler (1) to ground (3). 3) turn ignition switch on. 4) read flashing of ab...

Page 136

Antilock brake system (abs) 5e2-11 diagnostic trouble code (dtc) check (using suzuki scan tool) 1) after setting cartridge for abs to suzuki scan tool, connect suzuki scan tool to data link connector. Special tool (a) : suzuki scan tool 2) turn ignition switch on. 3) read dtc according to instructio...

Page 137

5e2-12 antilock brake system (abs) 4) repeat disconnecting and reconnecting of service wire between diagnosis and ground terminals 5 times or more at about 1sec. Interval within 10 seconds. 5) turn ignition switch off and disconnect service wire from monitor coupler. 6) perform “driving test” (step ...

Page 138

Antilock brake system (abs) 5e2-13 c1022 22 rf wheel speed sensor circuit or sensor ring c1026 26 lf c1032 32 rr c1036 36 lr c1041 41 rf inlet solenoid valve circuit c1042 42 outlet solenoid valve circuit c1045 45 lf inlet solenoid valve circuit c1046 46 outlet solenoid valve circuit c1055 55 rear i...

Page 139

5e2-14 antilock brake system (abs) system circuit 1. Battery 11. Abs fail-safe transistor (solenoid valve transistor) 21. To ecm and sdm (if equipped) 2. Main fuses 12. Abs pump motor transistor 22. Stop lamp 3. Ignition switch 13. Pump motor 23. Stop lamp switch 4. Circuit fuses 14. Solenoid valves...

Page 140

Antilock brake system (abs) 5e2-15 table-a abs warning lamp circuit check – lamp does not come “on” at ignition switch on circuit description operation (on/off) of abs warning lamp is controlled by abs control module through lamp driver module in combination meter. If the antilock brake system is in...

Page 141

5e2-16 antilock brake system (abs) table-b abs warning lamp circuit check – lamp comes “on” steady refer to table – a for system circuit diagram and circuit description. Inspection step action yes no 1 perform diagnostic trouble code check. Is there any dtc (including code no.12, no codes on suzuki ...

Page 142

Antilock brake system (abs) 5e2-17 table-c abs warning lamp circuit check – the lamp flashes continuously while ignition switch is on circuit description when diagnosis switch terminal is shorted or connected to the ground with ignition switch on, diagnosis trouble code (dtc) is indicated by flashin...

Page 143

5e2-18 antilock brake system (abs) table-d code (dtc) is not outputted even with diagnosis switch terminal connected to ground circuit description when diagnosis switch terminal is connected to ground with ignition switch turned on, the abs control module outputs diagnostic trouble code by flashing ...

Page 144

Antilock brake system (abs) 5e2-19 table-e ebd warning lamp (brake warning lamp) check – lamp comes “on” steady circuit description ebd warning lamp (brake warning lamp) is controlled by parking brake switch, brake fluid level switch and abs control module/hydraulic unit assembly through lamp driver...

Page 145

5e2-20 antilock brake system (abs) dtc c1015 (dtc 15) – g sensor circuit and 4wd lamp circuit description g sensor while a vehicle is at stop or running, if the potential difference between the sensor signal terminal “e136-11” and the sensor ground terminal “e136-13” is not within the specified volt...

Page 146

Antilock brake system (abs) 5e2-21 inspection step action yes no 1 1) turn ignition switch on. Does 4wd lamp turn on when 4wd switch turns on? Go to step 2. Replace bulb or repair its circuit. 2 1) ignition switch off. 2) check for proper connection to ecm (pcm) and 4wd switch. 3) if ok, then check ...

Page 147

5e2-22 antilock brake system (abs) dtc c1021 (dtc 21), dtc c1022 (dtc 22) – right-front wheel speed sensor circuit or sensor ring dtc c1025 (dtc 25), dtc c1026 (dtc 26) – left-front wheel speed sensor circuit or sensor ring dtc c1031 (dtc 31), dtc c1032 (dtc 32) – right-rear wheel speed sensor circu...

Page 148

Antilock brake system (abs) 5e2-23 inspection step action yes no 1 1) disconnect applicable abs wheel speed sensor coupler with ignition switch off. 2) measure resistance between terminals of abs wheel speed sensor. Refer to “front wheel speed sen- sor” and/or “rear wheel speed sensor” in this secti...

Page 149

5e2-24 antilock brake system (abs) dtc c1041 (dtc 41) – right-front inlet solenoid circuit dtc c1045 (dtc 45) – left-front inlet solenoid circuit dtc c1055 (dtc 55) – rear inlet solenoid circuit dtc c1042 (dtc 42) – right-front outlet solenoid circuit dtc c1046 (dtc 46) – left-front outlet solenoid ...

Page 150

Antilock brake system (abs) 5e2-25 dtc c1057 (dtc 57) – power source circuit description the abs control module monitors the power source voltage at terminal “e136-18”. When the power source volt- age becomes extremely high or low, this dtc will be set. As soon as the voltage rises or lowers to the ...

Page 151

5e2-26 antilock brake system (abs) dtc c1061 (dtc 61) – abs pump motor circuit description the abs control module monitors the voltage at monitor terminal of pump motor circuit constantly with the igni- tion switch turned on. It sets this dtc when the voltage at the monitor terminal does not become ...

Page 152

Antilock brake system (abs) 5e2-27 dtc c1063 (dtc 63) – abs fail-safe relay circuit description abs control module monitors the voltage at the terminal of solenoid circuit constantly with ignition switch turned on. Also, immediately after ignition switch is turned on, perform initial check as follow...

Page 153

5e2-28 antilock brake system (abs) dtc c1071 (dtc 71) – abs control module description this dtc will be set when an internal malfunction is detected in the abs control module. Inspection 1. Abs hydraulic unit/control module assembly 3. Abs pump motor 5. Abs hydraulic unit/control module connector 2....

Page 154: On-Vehicle Service

Antilock brake system (abs) 5e2-29 on-vehicle service precautions when connector are connected to abs hydraulic unit/control module assembly, do not disconnect connectors of sensors and turn ignition switch on. Then dtc will be set in abs control mod- ule. Abs hydraulic unit operation check (using s...

Page 155

5e2-30 antilock brake system (abs) 9) perform following checks with help of another person. 10) brake pedal (1) should be depressed. A) ignition switch turned to on position by one person. B) wheel should be turned by another person’s hand. At this time, check that: • operation sound of solenoid is ...

Page 156

Antilock brake system (abs) 5e2-31 abs hydraulic unit/control module assembly hydraulic unit inspection check hydraulic unit for fluid leakage. If any, repair or replace. Removal 1) disconnect negative cable at battery. 2) disconnect abs hydraulic unit/control module assembly con- nector (1) by pull...

Page 157

5e2-32 antilock brake system (abs) 3) using special tool, loosen flare nuts (1) and disconnect brake pipes (2) from abs hydraulic unit/control module assembly (3). Special tool 09950-78220 4) remove three bolts and take out abs hydraulic unit/control module assembly (1) from bracket using flat end r...

Page 158

Antilock brake system (abs) 5e2-33 rear sensor rotor (retainer ring) removal 1) remove rear axle shaft assembly. Refer to “rear axle shaft” in section 3e. 2) in order to remove sensor rotor (retainer ring) (2) from shaft (1), grind with a grinder one part “a” of the sensor rotor (retainer ring) as s...

Page 159: Special Tool

5e2-34 antilock brake system (abs) tightening torque specification special tool fastening part tightening torque n•m kg-m lb-ft brake pipe flare nut : (a) 16 1.6 11.5 abs hydraulic unit bolt : (b) 9 0.9 6.5 abs hydraulic unit bracket bolt : (c) 10 1.0 7.5 wheel speed sensor bolt (front) : (d) 23 2.3...

Page 160

Antilock brake system (abs) 5e2-35 tech 2 kit (suzuki scan tool) (see note b.) note: a. This kit includes the following items and substitutes for the tech 2 kit. 1. Storage case, 2. Operator’s manual, 3. Tech 1a, 4. Dlc cable, 5. Test lead/probe, 6. Power source cable, 7. Dlc cable adapter, 8. Self-...

Page 161

5e2-36 antilock brake system (abs).

Page 162: Section 6-1

Engine general information and diagnosis (h27 engine) 6-1-1 6-1 section 6-1 engine general information and diagnosis (h27 engine) contents general information ...................................... 6-1-3 statement of cleanliness and care ............ 6-1-3 general information on engine service ........

Page 163

6-1-2 engine general information and diagnosis (h27 engine) table a-4 malfunction indicator lamp check – mil does not flash or just remains on even with grounding diagnosis switch terminal (vehicle with monitor connector) ................................... 6-1-45 table a-5 ecm (pcm) power and groun...

Page 164: General Information

Engine general information and diagnosis (h27 engine) 6-1-3 general information statement of cleanliness and care an automobile engine is a combination of many machined, honed, polished and lapped surfaces with tolerances that are measured in the thousands of an millimeter (ten thousands of inch). A...

Page 165

6-1-4 engine general information and diagnosis (h27 engine) • when disconnecting couplers, don’t pull wire harness but make sure to hold coupler itself. With lock type coupler, be sure to unlock before disconnection. Attempt to disconnect coupler without unlocking may result in damage to coupler. Wh...

Page 166

Engine general information and diagnosis (h27 engine) 6-1-5 fuel pressure relief procedure after making sure that engine is cold, relief fuel pressure as fol- lows. 1) place transmission gear shift lever in “neutral” (shift selector lever to “p” range for a/t vehicle), set parking brake, and block d...

Page 167: Engine Diagnosis

6-1-6 engine general information and diagnosis (h27 engine) engine diagnosis general description this vehicle is equipped with an engine and emission control system which are under control of ecm (pcm). The engine and emission control system in this vehicle are controlled by ecm (pcm). Ecm (pcm) has...

Page 168

Engine general information and diagnosis (h27 engine) 6-1-7 warm-up cycle a warm-up cycle means sufficient vehicle operation such that the coolant temperature has risen by at least 22°c (40°f) from engine starting and reaches a minimum temperature of 70 °c (160 °f). Driving cycle a “driving cycle” c...

Page 169

6-1-8 engine general information and diagnosis (h27 engine) priority of freeze frame data ecm (pcm) has 4 frames where the freeze frame data can be stored. The first frame stores the freeze frame data of the malfunction which was detected first. However, the freeze frame data stored in this frame is...

Page 170

Engine general information and diagnosis (h27 engine) 6-1-9 on-board diagnostic system (vehicle with monitor connector) ecm diagnosis troubles which may occur in the area including the following parts when the ignition switch is on and the engine is running, and indicates the result by turning on of...

Page 171

6-1-10 engine general information and diagnosis (h27 engine) data link connector (dlc) dlc (1) is in compliance with saej1962 in its installation posi- tion, the shape of connector and pin assignment. K line of iso 9141 is used for suzuki scan tool to communicate with ecm (pcm), abs control module a...

Page 172

Engine general information and diagnosis (h27 engine) 6-1-11 engine diagnostic flow table refer to following pages for the detail of each step. Step action yes no 1 customer complaint analysis 1) perform customer complaint analysis. Was customer complaint analysis performed? Go to step 2. Perform cu...

Page 173

6-1-12 engine general information and diagnosis (h27 engine) step 1. Customer complaint analysis record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of such an inspection form will facilitate collecting information to the point r...

Page 174

Engine general information and diagnosis (h27 engine) 6-1-13 step 2. Diagnostic trouble code (dtc)/freeze frame data check first, check dtc, referring to “diagnostic trouble code check” in this section. If dtc is indicated, record dtc and freeze frame data. After that clear dtc referring to “diagnos...

Page 175

6-1-14 engine general information and diagnosis (h27 engine) step 6. And 7. Rechecking and record of dtc refer to “dtc check” in this section for checking procedure. Step 8. Engine basic inspection and engine diagnosis table perform basic engine check according to the “engine basic inspection flow t...

Page 176

Engine general information and diagnosis (h27 engine) 6-1-15 step 9. Troubleshooting for dtc based on the dtc indicated in step 6 or 7 and referring to the applicable dtc diag. Flow table in this section, locate the cause of the trouble, namely in a sensor, switch, wire harness, connector, actuator,...

Page 177

6-1-16 engine general information and diagnosis (h27 engine) malfunction indicator lamp (mil) check 1) turn on ignition switch (but the engine at stop) and check that mil (1) lights. If mil does not light up, go to “diagnostic flow table a-1” for troubleshooting. 2) start engine and check that mil t...

Page 178

Engine general information and diagnosis (h27 engine) 6-1-17 [without using suzuki scan tool] (vehicle with monitor connector) 1) check malfunction indicator lamp referring to “malfunction indicator lamp check” in this section. 2) with the ignition switch off position, disconnect suzuki scan tool if...

Page 179

6-1-18 engine general information and diagnosis (h27 engine) [without using scan tool] 1) turn the ignition switch off position. 2) disconnect battery negative cable for specified time below to erase diagnostic trouble code stored in ecm memory and reconnect it. Time required to erase dtc: diagnosti...

Page 180

Engine general information and diagnosis (h27 engine) 6-1-19 p0133 ho2s circuit slow response (bank 1 - sensor 1) response time of ho2s-1 output volt- age between rich and lean is longer than specification. 2 driving cycles not applicable p0135 ho2s heater circuit malfunc- tion (bank 1 - sensor 1) t...

Page 181

6-1-20 engine general information and diagnosis (h27 engine) p0174 fuel system too lean (bank 2) short term fuel trim or total fuel trim (short and long terms added) is larger than specification for specified time or longer. (fuel trim toward rich side is large.) 2 driving cycles not applicable p017...

Page 182

Engine general information and diagnosis (h27 engine) 6-1-21 for a/t system (refer to section 7b1 for diagnosis) p0505 idle air control system mal- function difference between desired idle speed and actual idle speed continues to exceed specified value for longer than specified time. 2 driving cycle...

Page 183

6-1-22 engine general information and diagnosis (h27 engine) for immobilizer control system (refer to section 8g for diagnosis) p0753 (no.61) (no.62) shift solenoid a (#1) electrical monitor signal off is detected when shift solenoid a (#1) is on or monitor signal on is detected when it is off. 1 dr...

Page 184

Engine general information and diagnosis (h27 engine) 6-1-23 fail-safe table when any of the following dtcs is detected, ecm (pcm) enters fail-safe mode as long as malfunction continues to exist but that mode is canceled when ecm (pcm) detects normal condition after that. Dtc no. Trouble area fail s...

Page 185

6-1-24 engine general information and diagnosis (h27 engine) scan tool data as the data values given below are standard values estimated on the basis of values obtained from the normally operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in good condi- ti...

Page 186

Engine general information and diagnosis (h27 engine) 6-1-25 inj pulse width b2 at specified idle speed with no load after warming up. 2.0 – 3.3 msec ✱ at 2500 r/min with no load after warming up. 2.2 – 3.2 msec throttle pos (absolute throttle posi- tion) with ignition switch on/warmed up engine sto...

Page 187

6-1-26 engine general information and diagnosis (h27 engine) pnp signal (transmis- sion range switch) (for 4- a/t) with ignition switch on, selector lever in “p” or “n” position p/n range ✱ with ignition switch on, selector lever in “r”, “d”, “2” or “l” position d range fuel tank level ignition swit...

Page 188

Engine general information and diagnosis (h27 engine) 6-1-27 scan tool data definitions coolant temp (engine coolant temp., °c/°f) it is detected by engine coolant temp. Sensor. Intake air temp (°c/°f) it is detected by intake air temp. Sensor. Desire idle (desired idle speed rpm) the desired idle s...

Page 189

6-1-28 engine general information and diagnosis (h27 engine) tp sensor volt (tp sensor output voltage, v) throttle position sensor reading provides throttle valve opening information in the from of voltage. O2s b1 s1 (ho2s bank 1 sensor 1 output voltage, v) / o2s b2 s1 (ho2s bank 2 sensor 1 output v...

Page 190

Engine general information and diagnosis (h27 engine) 6-1-29 egr valve (%) this parameter indicates opening rate of egr valve which controls the amount of egr flow. A/c switch (on/off) on : command for operation being output from a/c amplifier to compressor. Off : command for operation not being out...

Page 191

6-1-30 engine general information and diagnosis (h27 engine) shift sol #2 con/mon (shift solenoid #2, b command/monitor, on/off) con-on : on command being output to shift solenoid #2, b. Con-off : on command not being output. Mon-on : electricity being passed to shift solenoid #2, b. Mon-off : elect...

Page 192

Engine general information and diagnosis (h27 engine) 6-1-31 engine diagnosis table perform troubleshooting referring to following table when ecm (pcm) has detected no dtc and no abnormality has been found in visual inspection and engine basic inspection previously. Condition possible cause correcti...

Page 193

6-1-32 engine general information and diagnosis (h27 engine) improper engine idling or engine fails to idle faulty spark plug spark plugs in section 6f2. Faulty ignition coil with ignitor ignition coil in section 6f2. Fuel pressure out of specification “diag. Flow table b-3” in this section. Engine ...

Page 194

Engine general information and diagnosis (h27 engine) 6-1-33 surges (engine power varia- tion under steady throttle or cruise. Feels like the vehicle speeds up and down with no change in the accelerator pedal.) defective spark plug (excess carbon deposits, improper gap, and burned electrodes, etc.) ...

Page 195

6-1-34 engine general information and diagnosis (h27 engine) poor gasoline mileage faulty spark plug (improper gap, heavy depos- its, and burned electrodes, etc.) spark plugs in section 6f2. Fuel pressure out of specification “diag. Flow table b-3” in this section. Faulty tp sensor, ect sensor or ma...

Page 196

Engine general information and diagnosis (h27 engine) 6-1-35 engine noise (note : before check- ing the mechanical noise, make sure the followings : ignition timing is properly adjusted, specified spark plug is used, specified fuel is used.) faulty hydraulic valve lash adjuster hydraulic valve lash ...

Page 197

6-1-36 engine general information and diagnosis (h27 engine) inspection of pcm (ecm) and its circuits pcm (ecm) and its circuits can be checked at pcm (ecm) wiring couplers by measuring voltage and resistance. Voltage check 1) remove pcm (ecm) cover from bracket referring to pcm (ecm) removal. 2) ch...

Page 198

Engine general information and diagnosis (h27 engine) 6-1-37 terminal circuit normal voltage condition e61-1 power source for co adjusting resistor (if equipped) 10 – 14 v ignition switch on e61-2 power source for back up 10 – 14 v ignition switch on and off e61-3 – – – e61-4 cruise control module (...

Page 199

6-1-38 engine general information and diagnosis (h27 engine) e61-22 a/c condenser fan motor relay (if equipped) 10 – 14 v ignition switch on, a/c not oper- ated and engine coolant temp. : less than 113°c, 235°f e61-23 fuel pump relay 0 – 2.5 v for 3 sec. After ignition switch on or while engine runn...

Page 200

Engine general information and diagnosis (h27 engine) 6-1-39 c51-3-9 throttle position sensor 0.5 – 1.2 v ignition switch on, throttle valve at idle position 3.4 – 4.7 v ignition switch on, throttle valve at full open position c51-3-10 mass air flow sensor 1.0 – 1.6 v ignition switch on and engine s...

Page 201

6-1-40 engine general information and diagnosis (h27 engine) c51-1-10 a/t input speed sensor (–) (a/t vehicle) about 2.5 v ignition switch on c51-1-11 a/t input speed sensor (+) (a/t vehicle) about 2.5 v ignition switch on c51-1-12 camshaft position sensor 1 deflects between 0 – 1 v and 4 – 6 v igni...

Page 202

Engine general information and diagnosis (h27 engine) 6-1-41 c51-2-1 fuel injector no.2 10 – 14 v ignition switch on c51-2-2 fuel injector no.1 c51-2-3 – – – c51-2-4 heater of ho2s-1 (bank 1) (if equipped) 10 – 14 v ignition switch on 0 – 2 v at specified idle speed after engine warmed up c51-2-5 he...

Page 203

6-1-42 engine general information and diagnosis (h27 engine) resistance check 1) disconnect couplers (1) from ecm/pcm with ignition switch off. 2) check resistance between each pair of terminals of discon- nected couplers (1) as listed in following table. Caution: never touch terminals of ecm/pcm it...

Page 204

Engine general information and diagnosis (h27 engine) 6-1-43 table a-1 malfunction indicator lamp circuit check – lamp does not come “on” or dims at ignition switch on (but engine at stop) wiring diagram circuit description when the ignition switch is turned on, ecm causes the main relay to turn on ...

Page 205

6-1-44 engine general information and diagnosis (h27 engine) table a-2 malfunction indicator lamp circuit check – lamp remains “on” after engine starts wiring diagram/circuit description refer to table a-1. Inspection 2 ecm power and ground circuit check : does engine start? Go to step 3. Go to “tab...

Page 206

Engine general information and diagnosis (h27 engine) 6-1-45 table a-3 malfunction indicator lamp check – mil flashes at ignition switch on (vehicle with monitor connector) wiring diagram/circuit description refer to table a-1. Troubleshooting table a-4 malfunction indicator lamp check – mil does no...

Page 207

6-1-46 engine general information and diagnosis (h27 engine) table a-5 ecm (pcm) power and ground circuit check – mil doesn’t light at ignition switch on and engine doesn’t start though it is cranked up wiring diagram circuit description when the ignition switch is turned on, the main relay turns on...

Page 208

Engine general information and diagnosis (h27 engine) 6-1-47 inspection step action yes no 1 main relay operating sound check : is operating sound of main relay heard at igni- tion switch on? Go to step 5. Go to step 2. 2 fuse check : is main “fi” fuse in good condition? Go to step 3. Check for shor...

Page 209

6-1-48 engine general information and diagnosis (h27 engine) dtc p0100 (dtc no.33, 34) mass air flow circuit malfunction wiring diagram dtc detecting condition and trouble area 1. Main fuse 2. Main relay 3. Ecm/pcm 4. Mass air flow sensor dtc detecting condition trouble area any one of the following...

Page 210

Engine general information and diagnosis (h27 engine) 6-1-49 dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze frame data by using scan tool and run engine at idle speed for 20 sec. Or more. 3) check dtc ...

Page 211

6-1-50 engine general information and diagnosis (h27 engine) dtc p0110 (dtc no.23, 25) intake air temp. (iat) circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and cl...

Page 212

Engine general information and diagnosis (h27 engine) 6-1-51 troubleshooting step action yes no 1 was “engine diag. Flow table” per- formed? Go to step 2. Go to “engine diag. Flow table” in this section. 2 check iat sensor and its circuit : 1) connect scan tool with ignition switch off. 2) turn igni...

Page 213

6-1-52 engine general information and diagnosis (h27 engine) dtc p0115 (dtc no.14, 15) engine coolant temp. Circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clea...

Page 214

Engine general information and diagnosis (h27 engine) 6-1-53 troubleshooting step action yes no 1 was “engine diag. Flow table” per- formed? Go to step 2. Go to “engine diag. Flow table” in this section. 2 check ect sensor and its circuit : 1) connect scan tool with ignition switch off. 2) turn igni...

Page 215

6-1-54 engine general information and diagnosis (h27 engine) dtc p0120 (dtc no.21, 22) throttle position circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear d...

Page 216

Engine general information and diagnosis (h27 engine) 6-1-55 troubleshooting step action yes no 1 was “engine diag. Flow table” per- formed? Go to step 2. Go to “engine diag. Flow table”. 2 check tp sensor and its circuit. 1) connect scan tool to dlc with ignition switch off and then turn ignition s...

Page 217

6-1-56 engine general information and diagnosis (h27 engine) dtc p0121 throttle position circuit range/performance problem wiring diagram/circuit description refer to dtc p0120. Dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. ...

Page 218

Engine general information and diagnosis (h27 engine) 6-1-57 troubleshooting fig. For steps 4 and 5 step action yes no 1 was “engine diag. Flow table” performed? Go to step 2. Go to “engine diag. Flow table” in this section. 2 is there a dtc related to tp sensor (dtc p0120)? Go to applicable dtc dia...

Page 219

6-1-58 engine general information and diagnosis (h27 engine) dtc p0130 (dtc no.13) ho2s-1 (bank 1) circuit malfunction or no activity detected wiring diagram dtc detecting condition and trouble area 1. Ho2s heater relay 2. Ecm (pcm) 3. Ho2s-1 (bank-1) note: for vehicle with monitor connector, dtc wi...

Page 220

Engine general information and diagnosis (h27 engine) 6-1-59 dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze frame data by using scan tool and start engine. 3) increase vehicle speed to 55 km/h (35 mph)...

Page 221

6-1-60 engine general information and diagnosis (h27 engine) fig. For step 2 dtc p0133 ho2s-1 (bank 1) circuit slow response wiring diagram/circuit description refer to dtc p0130. Dtc detecting condition and trouble area dtc confirmation procedure refer to dtc p0130. Troubleshooting 4 short term fue...

Page 222

Engine general information and diagnosis (h27 engine) 6-1-61 dtc p0135 ho2s-1 (bank 1) heater circuit malfunction wiring diagram refer to dtc p0130. Dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool with ignition switch off. 2) turn on ignition switch and clear...

Page 223

6-1-62 engine general information and diagnosis (h27 engine) fig. For step 3 4 ho2s heater control circuit check : 1) with ignition switch off, install ho2s heater relay. 2) with ignition switch on leaving engine off, check voltage between c51-2-4 and ground. Is the voltage 10 – 14 v? Substitute a k...

Page 224

Engine general information and diagnosis (h27 engine) 6-1-63 dtc p0136 ho2s-2 (bank 1) circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1. Ho2s heater relay 2. Ecm (pcm) 3. Ho2s-2 (bank-1) dtc detecting condition trouble area dtc will set when an...

Page 225

6-1-64 engine general information and diagnosis (h27 engine) 1) connect scan tool with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze frame data in ecm memory by using scan tool and start engine. 3) increase vehicle speed to 55 km/h (40 mph) or more. 4) keep dr...

Page 226

Engine general information and diagnosis (h27 engine) 6-1-65 dtc p0141 ho2s-2 (bank 1) heater circuit malfunction wiring diagram refer to dtc p0136. Dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool with ignition switch off. 2) turn on ignition switch and clear...

Page 227

6-1-66 engine general information and diagnosis (h27 engine) troubleshooting fig. For step 2, 3 step action yes no 1 was “engine diag. Flow table” per- formed? Go to step 2. Go to “engine diag. Flow table” in this section. 2 ho2s-2 heater check : 1) disconnect ho2s-2 coupler with ignition switch off...

Page 228

Engine general information and diagnosis (h27 engine) 6-1-67 dtc p0150 (dtc no.26) ho2s-1 (bank 2) circuit malfunction or no activity detected wiring diagram dtc detecting condition and trouble area 1. Ho2s heater relay 2. Ecm (pcm) 3. Ho2s-1 (bank-2) note: for vehicle with monitor connector, dtc wi...

Page 229

6-1-68 engine general information and diagnosis (h27 engine) dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze frame data by using scan tool and start engine. 3) increase vehicle speed to 55 km/h (35 mph)...

Page 230

Engine general information and diagnosis (h27 engine) 6-1-69 fig. For step 2 dtc p0153 ho2s-1 (bank 2) circuit slow response wiring diagram/circuit description refer to dtc p0150. Dtc detecting condition and trouble area dtc confirmation procedure refer to dtc p0150. Troubleshooting 4 short term fue...

Page 231

6-1-70 engine general information and diagnosis (h27 engine) dtc p0155 ho2s-1 (bank 2) heater circuit malfunction wiring diagram refer to dtc p0150. Dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool with ignition switch off. 2) turn on ignition switch and clear...

Page 232

Engine general information and diagnosis (h27 engine) 6-1-71 fig. For step 2, 3 4 ho2s heater control circuit check : 1) with ignition switch off, install ho2s heater relay. 2) with ignition switch on leaving engine off, check voltage between c51-2-4 and ground. Is the voltage 10 – 14 v? Substitute ...

Page 233

6-1-72 engine general information and diagnosis (h27 engine) dtc p0156 ho2s-2 (bank 2) circuit malfunction wiring diagram dtc detecting condition and trouble area dtc confirmation procedure 1. Ho2s heater relay 2. Ecm (pcm) 3. Ho2s-2 (bank-2) dtc detecting condition trouble area dtc will set when an...

Page 234

Engine general information and diagnosis (h27 engine) 6-1-73 1) connect scan tool with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze frame data in ecm memory by using scan tool and start engine. 3) increase vehicle speed to 55 km/h (40 mph) or more. 4) keep dr...

Page 235

6-1-74 engine general information and diagnosis (h27 engine) dtc p0161 ho2s-2 (bank 2) heater circuit malfunction wiring diagram refer to dtc p0156. Dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool with ignition switch off. 2) turn on ignition switch and clear...

Page 236

Engine general information and diagnosis (h27 engine) 6-1-75 troubleshooting fig. For step 2, 3 step action yes no 1 was “engine diag. Flow table” per- formed? Go to step 2. Go to “engine diag. Flow table” in this section. 2 ho2s-2 heater check : 1) disconnect ho2s-2 coupler with ignition switch off...

Page 237

6-1-76 engine general information and diagnosis (h27 engine) dtc p0171/p0172 fuel system too lean/rich (bank 1) dtc detecting condition and possible cause dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze...

Page 238

Engine general information and diagnosis (h27 engine) 6-1-77 troubleshooting step action yes no 1 was “engine diag. Flow table” per- formed? Go to step 2. Go to “engine diag. Flow table” in this section. 2 is there dtc (s) other than “dtc p0171/ p0172”? Go to applicable dtc flow table. Go to step 3....

Page 239

6-1-78 engine general information and diagnosis (h27 engine) dtc p0174/p0175 fuel system too lean/rich (bank 2) dtc detecting condition and possible cause dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, pending dtc and freeze...

Page 240

Engine general information and diagnosis (h27 engine) 6-1-79 troubleshooting step action yes no 1 was “engine diag. Flow table” per- formed? Go to step 2. Go to “engine diag. Flow table” in this section. 2 is there dtc (s) other than “dtc p0174/ p0175”? Go to applicable dtc flow table. Go to step 3....

Page 241

6-1-80 engine general information and diagnosis (h27 engine) dtc p0300/p0301/p0302/p0303/p0304/p0305/p0306 random misfire/cylinder 1 misfire/cylinder 2 misfire/cylinder 3 misfire/cylinder 4 misfire detected/cyl- inder 5 misfire detected/cylinder 6 misfire detected system description ecm (pcm) measur...

Page 242

Engine general information and diagnosis (h27 engine) 6-1-81 troubleshooting step action yes no 1 was “engine diag. Flow table” per- formed? Go to step 2. Go to “engine diag. Flow table” in this section. 2 ignition system inspection : 1) check spark plug and ignition spark of cylin- der where misfir...

Page 243

6-1-82 engine general information and diagnosis (h27 engine) dtc p0325 (dtc no.43) knock sensor circuit malfunction circuit description dtc detecting condition and trouble area dtc confirmation procedure 1) connect scan tool to dlc with ignition switch off. 2) turn on ignition switch and clear dtc, ...

Page 244

Engine general information and diagnosis (h27 engine) 6-1-83 troubleshooting fig. For steps 2 and 3 step action yes no 1 was “engine diag. Flow table” per- formed? Go to step 2. Go to “engine diag. Flow table” in this section. 2 knock sensor and its circuit check : 1) with engine running, check volt...

Page 245