- DL manuals

- Tandberg Data

- Storage

- LTO-3

- User's Reference Manual

Tandberg Data LTO-3 User's Reference Manual

Summary of LTO-3

Page 1

Autoloader lto3 – user reference manual rev. 1.01 tandberg data page 1 of 79 2u autoloader 6.4 ® lto3 user reference manual document no: docsp 301283 date: aug., 2005.

Page 2

Warnings precautions autoloader lto3 – user reference manual rev. 1.01 tandberg data page 2 of 79 product overview product name p/n description lto3 autoloader 6.4 8330 7071 00 1 drive & 8 slots, 2u, accessories product name description scsi cable terminator power cord (1x eu version, 1x us version)...

Page 3

Warnings precautions autoloader lto3 – user reference manual rev. 1.01 tandberg data page 3 of 79 service & support information: europe tandberg data gmbh feldstr. 81 d-44141 dortmund germany phone: 0049 – (0)231 – 5436 142 fax: 0049 – (0)231 – 5436 143 usa inostor inc. (a tandberg data company ) 13...

Page 4: 1 Warnings

Warnings precautions autoloader lto3 – user reference manual rev. 1.01 tandberg data page 4 of 79 1 warnings ! ! Important all safety and operating instructions should be read before this product is operated, and should be retained for future reference. This unit has been engineered and manufactured...

Page 5

Warnings precautions autoloader lto3 – user reference manual rev. 1.01 tandberg data page 5 of 79 1.1 precautions n do not use oil, solvents, gasoline, paint thinners or insecticides on the unit. N do not expose the unit to moisture, to temperatures higher than 60 °c (140 °f) or to extreme low tempe...

Page 6

Warnings user guide autoloader lto3 – user reference manual rev. 1.01 tandberg data page 6 of 79 1.3 user guide this specification describes the functional, performance, and environmental specifications of the autoloader. Contents of this user reference manual n quick start guide n features and phys...

Page 7: 2 Contents

Contents autoloader lto3 – user reference manual rev. 1.01 tandberg data page 7 of 79 2 contents 1 warnings ................................ ............................................................................................ 4 1.1 precautions ...................................................

Page 8

Contents autoloader lto3 – user reference manual rev. 1.01 tandberg data page 8 of 79 8.5 configuration ............................................................................................................ 36 8.6 operation .........................................................................

Page 9

Contents autoloader lto3 – user reference manual rev. 1.01 tandberg data page 9 of 79 12.4 environmental specifications ..................................................................................... 70 12.4.1shock and vibration ....................................................................

Page 10: 3 Tables

Tables autoloader lto3 – user reference manual rev. 1.01 tandberg data page 1 0 of 79 3 tables table 1 autoloader features................................................................................................ ... 15 table 2 scsi interface ......................................................

Page 11: 4 Figures

Figures autoloader lto3 – user reference manual rev. 1.01 tandberg data page 1 1 of 79 4 figures figure 1 ac line cord, scsi terminator .................................................................................... 12 figure 2 power switch .........................................................

Page 12: 5 Quick Start Guide

Quick start guide autoloader lto3 – user reference manual rev. 1.01 tandberg data page 1 2 of 79 5 quick start guide defaults note: the following defaults have been set at the factory. Ldr scsi id 0 drv scsi id 5 operating mode sequential figure 1 ac line cord, scsi terminator 1. Install ac line cor...

Page 13

Quick start guide autoloader lto3 – user reference manual rev. 1.01 tandberg data page 1 3 of 79 figure 3 operator panel 5. Press any button on the operator panel to change to interaction mode. 6. Choose the "go offline" menu and press . 7. Choose the "commands" menu and press . 8. Choose "import", ...

Page 14

Features and physical description equipment description autoloader lto3 – user reference manual rev. 1.01 tandberg data page 1 4 of 79 6 features and physical description 6.1 equipment description the autoloader provides automated data storage, archival, backup, and retrieval for a range of systems,...

Page 15

Features and physical description features autoloader lto3 – user reference manual rev. 1.01 tandberg data page 1 5 of 79 6.2 features the autoloader includes the following features: n a carousel encircles the tape drive and positions the specified cartridge slot in front of the tape drive. A roboti...

Page 16

Features and physical description component descriptions autoloader lto3 – user reference manual rev. 1.01 tandberg data page 1 6 of 79 6.3 component descriptions the following sections describe the major components of the autoloader. Front panel components figure 5 front panel components ( 1 ) cart...

Page 17

Features and physical description component descriptions autoloader lto3 – user reference manual rev. 1.01 tandberg data page 1 7 of 79 back panel components figure 6 back panel components ( 1 ) scsi connectors the autoloader has two wide scsi connectors for connecting the autoloader and tape drive ...

Page 18

Features and physical description component descriptions autoloader lto3 – user reference manual rev. 1.01 tandberg data page 1 8 of 79 tape drive the autoloader contains one tape drive. The tape drive can sustain a maximum data transfer rate of 280 mb per second (compressed) and can store up to 800...

Page 19

Features and physical description component descriptions autoloader lto3 – user reference manual rev. 1.01 tandberg data page 1 9 of 79 data cartridges the tape drive reads and writes to lto tape data cartridges. The capacity and transfer rates are listed in 0. Caution wrong tapes! Damages of the ta...

Page 20: 7 Installation and Setup

Installation and setup installing the optional remote management unit (rmu) autoloader lto3 – user reference manual rev. 1.01 tandberg data page 2 0 of 79 7 installation and setup this chapter describes: n installing the optional remote management unit (rmu) n installing the optional bar code reader...

Page 21

Installation and setup installing the optional bar code reader (bcr) autoloader lto3 – user reference manual rev. 1.01 tandberg data page 2 1 of 79 figure 8 location of the protective coveri ng for the rmu rail 3. Align the lan card in the rails and insert into the unit. 4. Fix the unit with the sup...

Page 22

Installation and setup installing the optional bar code reader (bcr) autoloader lto3 – user reference manual rev. 1.01 tandberg data page 2 2 of 79 7.2.3 mounting instructions: caution electro static discharge! Destruction of the esd sensitive components. Please touch unit cover or rear panel before...

Page 23

Installation and setup installing the optional bar code reader (bcr) autoloader lto3 – user reference manual rev. 1.01 tandberg data page 2 3 of 79 7.2.4 configuration of the barcode reader 1. Enable barcode reader through the operator panel. Select menu item configuration/barcode reader and set bcr...

Page 24

Installation and setup installing the autoloader as a desktop unit autoloader lto3 – user reference manual rev. 1.01 tandberg data page 2 4 of 79 7.3 installing the autoloader as a desktop unit warning weights on the autoloader! Destruction of the autoloader's chassis. The autoloader should not be s...

Page 25

Installation and setup installing the autoloader in a rack autoloader lto3 – user reference manual rev. 1.01 tandberg data page 2 5 of 79 7.4 installing the autoloader in a rack you have to install the autoloader into a standard 19-inch rack. Required tools: n phillips screwdriver, size 2 n torx wre...

Page 26

Installation and setup installing the autoloader in a rack autoloader lto3 – user reference manual rev. 1.01 tandberg data page 2 6 of 79 3. Install the cage clip-nuts (for racks with square mounting holes) from the back side of each rail. Figure 13 attaching cage cilp nuts to a rack with square hol...

Page 27

Installation and setup installing the autoloader in a rack autoloader lto3 – user reference manual rev. 1.01 tandberg data page 2 7 of 79 7.4.3 install the rack front mount brackets on the autoloader 1. Determine on which side of the autoloader the rack mount brackets will be attached (see figure 15...

Page 28

Installation and setup running library verify test autoloader lto3 – user reference manual rev. 1.01 tandberg data page 2 8 of 79 7.4.5 connecting power 1. Connect the pcc cable (included with your rack mount kit) to the rear of the autoloader. 2. Connect the other end of the pcc cable to your rack’...

Page 29

Installation and setup connecting the autoloader to the server autoloader lto3 – user reference manual rev. 1.01 tandberg data page 2 9 of 79 7.6 connecting the autoloader to the server the autoloader has to be attached to a scsi/lvd system. Cabling is required for the tape drive interface and the r...

Page 30

Operation and maintenance general guidelines autoloader lto3 – user reference manual rev. 1.01 tandberg data page 3 0 of 79 8 operation and maintenance this chapter describes the requirements for using the autoloader, including information about: n general guidelines n powering on the system n power...

Page 31

Operation and maintenance powering on the sys tem autoloader lto3 – user reference manual rev. 1.01 tandberg data page 3 1 of 79 if the autoloader detects that a cartridge is loaded when it first comes alive, the following status will be displayed on the operator panel: drive loaded 12345 -78 seq in...

Page 32

Operation and maintenance using the operator panel and menu options autoloader lto3 – user reference manual rev. 1.01 tandberg data page 3 2 of 79 the 4 leds (1-4) are updated during power up and reset sequences. Upon power up or software reset, the autoloader will illuminate all leds as soon as pow...

Page 33

Operation and maintenance operational modes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 3 3 of 79 ( 6 ) enter, button [ ↵ ] it is used in interaction mode. Push the enter button to go to a sub menu or to force a robotic action. ( 7 ) next, button [+] it is used in interactio...

Page 34

Operation and maintenance operational modes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 3 4 of 79 8.4.3 sequential mode in sequential mode the media exchanger is no longer visible on t he scsi bus. Cartridge replacements are initiated by an ‘unload’ command sent to the drive...

Page 35

Operation and maintenance operational modes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 3 5 of 79 8.4.6 menu structure and options ocp user interaction mode go online (inv. Status) any key commands (inv. Status) information (inv. Status) cancel enter configuration (inv. Stat...

Page 36

Operation and maintenance configuration autoloader lto3 – user reference manual rev. 1.01 tandberg data page 3 6 of 79 8.5 configuration for most installations, the default configuration of the autoloader does not need to be changed. For further information see thinstor ® plus lto3 autoloader – oper...

Page 37

Operation and maintenance performing autoloader and tape drive autoloader lto3 – user reference manual rev. 1.01 tandberg data page 3 7 of 79 8.7.2 bulk exchange the menu item bulk exchange was designed to make the autoloader more user friendly. This item enables a user to import or export a specifi...

Page 38

Operation and maintenance performing autoloader and tape drive autoloader lto3 – user reference manual rev. 1.01 tandberg data page 3 8 of 79 note: the tape drive can also report its cleaning requirements to the application software. Your application may notify you when the tape drive needs cleaning...

Page 39

Operation and maintenance shipping autoloader lto3 – user reference manual rev. 1.01 tandberg data page 3 9 of 79 performing routine maintenance and service the autoloader requires no routine maintenance. If necessary, you can use touch-up paint on the housing. Touch -up paint is available for cover...

Page 40

Troubleshooting and diagnostics general guidelines autoloader lto3 – user reference manual rev. 1.01 tandberg data page 4 0 of 79 9 troubleshooting and diagnostics 9.1 general guidelines the autoloader includes features to support troubleshooting and diagnostic operations. If an autoloader error occ...

Page 41

Troubleshooting and diagnostics determining a problem autoloader lto3 – user reference manual rev. 1.01 tandberg data page 4 1 of 79 9.2.1 viewing drive error codes via the ocp 1. From the ocp, press enter to access the information menu. 2. Press next to access drive info. 3. Press next or previous ...

Page 42

Troubleshooting and diagnostics determining a problem autoloader lto3 – user reference manual rev. 1.01 tandberg data page 4 2 of 79 2. Check if air flows from the rear fan? Yes: n proceed with step 3. No: n from serial port hyperterminal session, select fct command. N if fan remains off, replace re...

Page 43

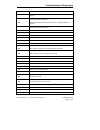

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 4 3 of 79 9.4 error messages and error codes this chapter describes error codes and associated sub codes of the autoloader. The codes should be used for analyzing failu...

Page 44

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 4 4 of 79 ddd:hh:mm:ss:hh ddd: days hh: hours mm: minutes ss: seconds hh: 1/100 second the time stamp is set at zero at system start up. The complete error log can be p...

Page 45

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 4 5 of 79 19h scsi bus type changed to lvd 1ah invalid cleaning cartridge 1bh invalid upgrade tape 1ch cleaning requested 1dh-1fh reserved 9.4.5 recovered errors 20h – ...

Page 46

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 4 6 of 79 42h slot empty during cartridge loading 43h cleaning tape expired 44h cleaning failed 45h-4fh reserved 9.4.7 illegal request errors 50h – 6fh error code descr...

Page 47

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 4 7 of 79 69h bad sequence number 6ah wrong checksum 6bh command unspecified 6ch configuration problem: no bar code reader installed 6dh flash image does not fit boot c...

Page 48

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 4 8 of 79 9.4.10 robotic control errors 81h – 8fh error code description recommended action 81h invalid internal command error. This error indicates that the robotic re...

Page 49

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 4 9 of 79 9.4.11 function errors 90h – 9fh error code description recommended action 90h mechanical initialization failure. The robotic wasn’t able to get into its safe...

Page 50

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 5 0 of 79 9.4.12 low level axis errors a0h – afh error code description recommended action a0h belt axis error. Error during cartridge carrier movement (position not fo...

Page 51

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 5 1 of 79 9.4.13 electronic hardware errors b0h – b9h error code description recommended action b0h rom error. A defective rom was detected. Retry operation, after seve...

Page 52

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 5 2 of 79 9.4.15 barcode errors c0h – cfh error code description recommended action c0h library verify test. Autoloader has detected different reading results according...

Page 53

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 5 3 of 79 14h end pattern missing 15h drive busy – command rejected 16h general drive error 17h byte stuffing error 18h command negative acknowledged 21h carrier state ...

Page 54

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 5 4 of 79 41h slider home error. Slider home position not reached. 42h slider forwa rd positioning error. Slider position in forward direction not reached. 43h slider c...

Page 55

Troubleshooting and diagnostics error messages and error codes autoloader lto3 – user reference manual rev. 1.01 tandberg data page 5 5 of 79 91h no drive activity after the load operation 92h timeout while loading cartridge 93h no drive activity after the unload operation 94h timeout while unloadin...

Page 56

Troubleshooting and diagnostics access protocol autoloader lto3 – user reference manual rev. 1.01 tandberg data page 5 6 of 79 c drive needs to be cleaned drive determines that it needs to be cleaned. This condition clears when drive has been cleaned. H reserved for future use j reserved for future ...

Page 57: 10 Analysis Procedures

Analysis procedures power/external fan analysis autoloader lto3 – user reference manual rev. 1.01 tandberg data page 5 7 of 79 10 analysis procedures 10.1 power/external fan analysis if the autoloader does not power on: 1. Ensure power cord is plugged in at the autoloader and at the electrical outle...

Page 58

Analysis procedures bcr analysis autoloader lto3 – user reference manual rev. 1.01 tandberg data page 5 8 of 79 10.3 bcr analysis if the server (host) has reported inventory problems relating to inability to read bar code labels, or, if some or all of the cartridge labels are not being displayed on ...

Page 59

Scsi interface specification cable and terminator requirements autoloader lto3 – user reference manual rev. 1.01 tandberg data page 5 9 of 79 11 scsi interface specification the autoloader has a standard scsi interface. This chapter provides requirements and specifications for the scsi interface, in...

Page 60

Scsi interface specification scsi communications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 6 0 of 79 scsi cable length the maximum allowable cable length for a low-voltage differential scsi bus, including all internal and external cables, is specified as follows: if you ha...

Page 61

Scsi interface specification scsi communications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 6 1 of 79 11.2.1 scsi messages the initiator and the target use the scsi message system to manage the physical path. The following table lists the messages supported by the autoloa d...

Page 62

Scsi interface specification scsi communications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 6 2 of 79 bus device reset 0ch the initiator instructs the autoloader to reset all of its current i/o operations for all initiators. The autoloader releases the scsi bus into the bus...

Page 63

Scsi interface specification scsi communications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 6 3 of 79 mode sense (10 bytes) 5ah reports its operating mode parameters to the initiator. Move medium (12 bytes) a5h moves a cartridge from one location to another. Position to ele...

Page 64

Scsi interface specification scsi communications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 6 4 of 79 status bytes after the autoloader executes a command, it issues a status byte to the initiator to indicate whether the command completed successfully. The following table d...

Page 65

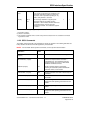

Scsi interface specification elements and element addresses autoloader lto3 – user reference manual rev. 1.01 tandberg data page 6 5 of 79 11.3 elements and element addresses 11.3.1 elements elements are the locations in the autoloader that can accept a cartridge. The autoloader includes three types...

Page 66

Scsi interface specification elements and element addresses autoloader lto3 – user reference manual rev. 1.01 tandberg data page 6 6 of 79 figure 21 default element addresses (identical to the element indexes number element description element address element index 1 cartridge slot 1 1h 1 2 cartridg...

Page 67: 12 Product Specifications

Product specifications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 6 7 of 79 12 product specifications this chapter provides the following information: n size and weight n performance specifications n power specifications n environmental specifications n shipping specificati...

Page 68

Product specifications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 6 8 of 79 autoloader self-test times each time the autoloader is powered on, it performs a power-on self-test (post). Post includes a self-test of the control electronics, initialization of the mechanical com...

Page 69

Product specifications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 6 9 of 79 12.3 power specifications ac power the autoloader has automatic ac input voltage selection and accepts the input voltages shown in the following table. It is capable of continuous operation when the...

Page 70

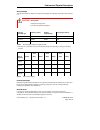

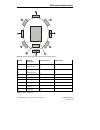

Product specifications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 7 0 of 79 12.4 environmental specifications specification operating 1 ) storage 2) or non- operating 3) transportation 4 ) ambient temperature range +10 °c to +35 °c (+50 °f to +95 °f) –40 °c to +60 °c (–40 °...

Page 71

Product specifications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 7 1 of 79 12.4.1 shock and vibration the autoloader meets the shock and vibration criteria described in the following sections. Shock specifications the autoloader will operate normally after experiencing sho...

Page 72

Product specifications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 7 2 of 79 transportation 3 ) according bdt wn-72077 swept sine applied during non -operation 6 ) 5 to 500 to 5 hz table 17 vibration specifications 1) a 0.3 g rms random vibration spectrum is applied to the b...

Page 73

Product specifications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 7 3 of 79 12.6 safety and regulatory agency compliance this section describes the autoloader's compliance with safety and regulatory agency standards: ! ! Important to comply with the following regulations an...

Page 74

Product specifications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 7 4 of 79 radiated and conducted radio frequency emissions (emi) the autoloader meets the require ments for radiated and conducted emissions as defined by the following standards: n fcc rules and regulations,...

Page 75

Product specifications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 7 5 of 79 power frequency magnetic field immunity the autoloader complies with en 61000-4 -8:1995, electromagnetic compatibility (emc), part 4: testing and measurement techniques, section 8: power frequency m...

Page 76

Product specifications autoloader lto3 – user reference manual rev. 1.01 tandberg data page 7 6 of 79 ce notice marking by the symbol ce indicates compliance of this tape library to the emc (electromagnetic compatibility) directive of the european community. Such marking is indicative that this tape...

Page 77: 13 Index

Index autoloader lto3 – user reference manual rev. 1.01 tandberg data page 7 7 of 79 13 index a ac power cord specifications...................................68 specifications...........................................68 acces protocol............................................55 accessories.........

Page 78

Index autoloader lto3 – user reference manual rev. 1.01 tandberg data page 7 8 of 79 error code descript ion ......................................42 log example ............................................42 media related ...........................................57 messages and codes ...............

Page 79

Index autoloader lto3 – user reference manual rev. 1.01 tandberg data page 7 9 of 79 q quick start ................................ ..................11 r rack installation ................................ .........24 rack mount kit...................................... 14, 18 regulations .............