TANDBERG SDLT220-320 INTEGRATION Manual

Summary of SDLT220-320 INTEGRATION

Page 1

Tandberg super dlt tm design & intergration guide revision 1 june 2002 - 432588-01.

Page 2

Sdlt 220 and sdlt 320 design & integration guide copyright copyright © 2002 by tandberg data. All rights reserved. Document origination: oslo, norway. Trademarks quantum, the quantum logo, dlttape, the dlttape logo, super dlttape and the super dlttape logo are trademarks of quantum corporation regis...

Page 3

Sdlt 220 and sdlt 320 design & integration guide revision history all revisions made to this document are listed below in chronological order. Document release date summary of changes a april 29, 2002 initial release..

Page 4

Sdlt 220 and sdlt 320 design & integration guide.

Page 5: Ta Bl E of Contents

Ta bl e of contents chapter 1 introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 purpose and scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 referenced documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

Table of contents recording media specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15 environmental requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16 temperature and humidity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17 air...

Page 7

Table of contents electromagnetic field specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 electromagnetic emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 electromagnetic interference susceptibility . . . . . . . . . . . . . . . . . . . 5-3 conduct...

Page 8

Table of contents insertion depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3 cartridge insertion force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3 insertion velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 9: List Of Tables

List of tables chapter 1 introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 table 1-1. Typographical conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 chapter 2 general drive specifications . . . . . . . . . . ....

Page 10

List of tables table 4-1. Sdlt 220/320 steady state temperatures: embedded bezel . . . . . . . . . . . . . . . . . . . . . . .4-7 table 4-2. Sdlt 220/320 steady state temperatures: library bezel . . . . . . . . . . . . . . . . . . . . . . . . . .4-8 table 4-3. Sdlt 320 versus sdlt 220 with embedded ...

Page 11: List Of Figures

List of figures chapter 1 introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 chapter 2 general drive specifications . . . . . . . . . . . . . . . . 2-1 figure 2-1. Sdlt 220/320 drive system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 12

List of figures figure 6-3. Loader connector (internal version shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9 figure 6-4. Termpwr connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 13: Introduction

Chapter 1 introduction 1.1 purpose and scope the purpose of this design and integration guide is to provide detailed information that may be helpful to refer to as you integrate the sdlt 220 and sdlt 320 cartridge tape systems into larger systems. The sdlt 220 and sdlt 320 cartridge tape systems, su...

Page 14: 1.2

Chapter 1: introduction 1.2 referenced documents • super dlttape™ interactive library interface specification • super dlt product manual (432589 rev. 01 or later) • super dlt scsi interface guide (432614 rev. 01 or later) 1.3 related documents • dlt script tool user guide.

Page 15: 1.4

Chapter 1: introduction 1.4 structure of this manual • chapter 1, introduction, is the chapter you are currently reading. • chapter 2, general drive specifications, provides a basic product description of the sdlt 220/320 tape drive, and the drive specifications such as dimensions and tolerances, fu...

Page 16: 1.5

Chapter 1: introduction 1.5 conventions this manual uses the following conventions to designate specific elements: 1.6 for more information the web site http://www.Superdlttape.Com includes much valuable information about sdlt systems; or to locate very specific product-related information, visit ht...

Page 17: 1.7

Chapter 1: introduction 1.7 reader comments tandberg data is committed to providing the best products and service. We we encourage your comments, suggestions, and corrections for this manual. Please send all comments to: tandberg data asa p.O. Box 134 kjelsås n-0411 oslo norway 1.8 tandberg diagnost...

Page 18

Chapter 1: introduction.

Page 19: 2.1 Product Description

2.1 product description figure 2-1. Sdlt 220/320 drive system internal drive external drive the tandberg super dlttape™ system is a highly scalable platform designed for multiple product generations. It is a follow-on to the dlttape product family, which is the industry standard for mid-range unix a...

Page 20: 2.2

Chapter 2: general drive specifications 2.2 sdlt product features sdlt tape drives offer the following product features: • a streaming tape drive that uses half-inch wide digital linear tape (dlt) media. • standard 5.25-inch full-height form factor to simplify integration into system and tape librar...

Page 21

Chapter 2: general drive specifications 2.2.1 sdlt 220/320 library tape drive interface the library tape drive interface (for sdlt drives) is an rs-422 serial port set to 9600 baud, 8 bits per character, no parity, and 2 stop bits. All data sent to or from the library tape drive interface consists o...

Page 22: 2.3

Chapter 2: general drive specifications 2.3 dimensions and tolerances the following figures show the physical specifications of the sdlt 220/3220 tape drive. Figure 2-3. Combination side and bottom view of sdlt tape drive n ote : tape cartridge insertion and ejection distances are shown in figure 8-...

Page 23

Chapter 2: general drive specifications figure 2-4. Rear view of sdlt 220/320 tape drive (dimensions) figure 2-5. Rear view of sdlt 220/320 tape drive (connectors).

Page 24

Chapter 2: general drive specifications figure 2-6. Front views of sdlt 220/320 tape drive.

Page 25: 2.4

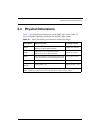

Chapter 2: general drive specifications 2.4 physical dimensions table 2-1 provides physical dimensions for the sdlt tape system. Table 2-2 shows acceptable operating orientations for the sdlt tape system. Table 2-1. Sdlt 220/320 physical dimensions and shipping weight description internal version ta...

Page 26

Chapter 2: general drive specifications table 2-2. Proper and acceptable tape drive orientations orientation looks like this typical (top side up) left side down right side down.

Page 27: 2.5

Chapter 2: general drive specifications 2.5 reliability tandberg data and its employees and suppliers are committed to providing quality products. The sdlt tape drive system is a very reliable electromechanical device. 2.5.1 positive engagement tape leader buckling mechanism this buckling mechanism ...

Page 28: 2.5.4 Data Integrity

Chapter 2: general drive specifications 2.5.3 load and unload cycles load and unload cycles are rated at 15,000 for the cartridge itself. Table 2-3 shows the number of load and unload cycles and tape insertions an sdlt drive can perform before it needs to be replaced. 2.5.4 data integrity sdlt data ...

Page 29: 2.6

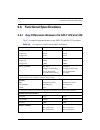

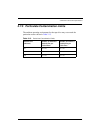

Chapter 2: general drive specifications 2.6 functional specifications 2.6.1 key differences between the sdlt 220 and 320 table 2-5 compares important features in the sdlt 220 and sdlt 320 products. Table 2-5. A comparison of sdlt 220 and sdlt 320 features parameter sdlt 220 sdlt 320 capacity compres...

Page 30

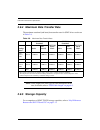

Chapter 2: general drive specifications 2.6.2 sdlt 220/320 performance data table 2-6 provides performance data for the sdlt tape system. Note: for a comparison of sdlt 220/320 storage capacities, refer to section 2.6.1, “key differences between the sdlt 220 and 320” on page 2-11 . Table 2-6. Sdlt 2...

Page 31

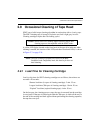

Chapter 2: general drive specifications 2.6.3 backward-read compatibility transfer rates both the sdlt 220 and sdlt 320 drives feature an optional backward-read compatibility (brc) mode. When in brc mode, the drives are capable of reading dlttape iv tapes with dlt4000, dlt7000, dlt8000, and dlt 1 fo...

Page 32: 2.6.5 Storage Capacity

Chapter 2: general drive specifications 2.6.4 maximum data transfer rate the maximum sustained (and burst) data transfer rates for sdlt drives are shown in table 2-8 . N ote : cable lengths and cable type can limit attainable transfer rate; for details, refer to “scsi cable length” on page 6-5 . 2.6...

Page 33

Chapter 2: general drive specifications 2.6.6 recording media specifications the following tables provide specifications for super dlttape i media. Basic media specifications for the super dlttape i are shown in table 2-9 . Operating, storage, and shipping environment limits for the dlttape iv cartr...

Page 34: 2.7

Chapter 2: general drive specifications 2.7 environmental requirements the sdlt tape drive operates in environments that include general offices and workspaces with systems capable of maintaining standard comfort levels. The following sections provide the operating, non-operating, storage and shippi...

Page 35

Chapter 2: general drive specifications 2.7.1 temperature and humidity the ambient operating environment for the tape drive may not exceed the limits shown in table 2-11 . (the specifications shown in the table are valid for both the internal and tabletop tape drives.) 2.7.2 air flow requirements ad...

Page 36: 2.7.4 Altitude

Chapter 2: general drive specifications 2.7.3 storage and shipment the ambient storage and shipment environment for the tape drive may not exceed the limits shown in table 2-12 . (the specifications shown in the table are valid for both the internal and tabletop tape drives.) 2.7.4 altitude both the...

Page 37

Chapter 2: general drive specifications 2.7.5 particulate contamination limits the ambient operating environment for the tape drive may not exceed the particulate counts shown in table 2-13 . Table 2-13. Particulate contamination limits particle size (microns) number of particles ≥ particle size per...

Page 38: 2.8

Chapter 2: general drive specifications 2.8 shock and vibration specifications the following tables provide non-operating and operating shock and vibration specifications for the sdlt system. Table 2-14. Non-operating shock specifications (unpackaged) shock (unpackaged) pulse shape square wave ½ sin...

Page 39

Chapter 2: general drive specifications table 2-16. Non-operating vibration specifications vibration (unpackaged) type sine sweep frequency range 5 - 500 - 5 hz upward and downward sweep acceleration level 0.02" da 1.0 g between 5 and 31 hz (crossover) between 31 and 500 hz (crossover) application x...

Page 40

Chapter 2: general drive specifications table 2-17. Operating shock and vibration specifications shock pulse shape ½ sine pulse peak acceleration 10 g duration 10 ms application x,y,z axes, twice in each axis (once in each direction) vibration type sine sweep frequency range 5 - 500 - 5 hz upward an...

Page 41: 2.9

Chapter 2: general drive specifications 2.9 occasional cleaning of tape head sdlt uses a built-in tape cleaning algorithm in conjunction with a cleaning tape. The sdlt cleaning tape is housed in a plastic case, and is light gray in color. Cleaning cartridges expire after 20 cleaning cycles. A yellow...

Page 42

Chapter 2: general drive specifications 2.9.2 error reporting (for cleaning) n ote : use the sdlt cleaning tape if cleaning is indicated through your backup software or when the yellow alert light is on. Do not clean the drive unless the drive specifically indicates cleaning is necessary. How the ta...

Page 43

Chapter 2: general drive specifications how tapealert returns cleaning status an eeprom parameter named enacleanta enables tapealert reporting of cleaning status. The general status packet contains one flag that conveys cleaning information for the drive; it is: • clean now the clean now flag will b...

Page 44

Chapter 2: general drive specifications 2.9.3 front panel cleaning light the cleaning required (yellow) led on the front panel indicates to the operator that cleaning is needed. This feature is enabled by the eeprom parameter enacleanlight. The location of the cleaning required led (and other front ...

Page 45: Electrical Specifications

Chapter 3 electrical specifications 3.1 current and power requirements table 3-1 on page 3-2 lists the current and power requirements for both versions of the tape system (internal and tabletop). The tabletop version requires ac power. The highest current (and power) is drawn during the native write...

Page 46

Chapter 3: electrical specifications table 3-1. Current and power specifications mode 5 v current (a) maxpk 1 maxrms 2 typ 3 12 v current (a) maxpk 1 maxrms 2 typ 3 dc power (w) max 4 typ 5 ac power (w) max 6 typ 7 standby / idle 3.2 3.0 2.9 0.6 0.5 0.4 20 19 34 29 media loading / unloading 3.8 3.1 ...

Page 47: 3.2

Chapter 3: electrical specifications 3.2 power supply tolerances one of the functions of the power supply is to transform the ac power to dc, and to step the voltage down from 115/220 vac to 5 vdc and 12 vdc. 3.2.1 voltage tolerances voltage tolerances are: • 5 vdc ± 5% • 12 vdc ± 5% 3.2.2 dc voltag...

Page 48

Chapter 3: electrical specifications 3.2.4 supply transient voltage allowable power supply transient voltage is: • 5 volt rail – 60 mv (peak to peak) • 12 volt rail – 1.6 v (peak to peak)..

Page 49: Thermal Specifications

Chapter 4 thermal specifications 4.1 over temperature condition this chapter presents the results of extensive experimentation and measurements of drive temperatures, and the resultant impact on sdlt 220/320 drive performance. An overtemp condition is defined to be when the calculated tape path temp...

Page 50: 4.2

Chapter 4: thermal specifications if a scsi command is aborted as a result of the over-temperature condition, the drive returns status of: hardware error, warning — specified temperature exceeded (04h, 0bh, 01h). 4.2 air flow measurements air flow is measured in the location shown in figure 4-1 . At...

Page 51: 4.3

Chapter 4: thermal specifications 4.3 thermal measurement locations the electronics interface module (eim) comprises two boards: the integrated controller module (icm) board, and the host interface module (him) board. Temperatures are measured on the icm board in the locations shown in figure 4-2 , ...

Page 52

Chapter 4: thermal specifications figure 4-2. Icm board thermal measurement locations hifn xez coldfire hydra (back) mac front thermal sensor rear thermal sensor 3.3 – 5.0v voltage regulator.

Page 53

Chapter 4: thermal specifications figure 4-3. Him board thermal measurement location qlogic.

Page 54: 4.4

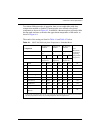

Chapter 4: thermal specifications figure 4-4. Tape path thermal measurement locations 4.4 sdlt 220/320 thermal profile this section lists the temperature of key module components and media at the extremes of the sdlt 220/320 operating specification as well as at room temperature. Both styles of beze...

Page 55

Chapter 4: thermal specifications to evaluate different modes of operation, data was recorded either with data compression enabled or disabled. Thermocouples were affixed to key board components as shown in figure 4-2 . In addition, a thermocouple was placed within the tape path enclosure to monitor...

Page 56: Sdlt 320

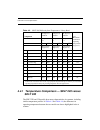

Chapter 4: thermal specifications 4.4.1 temperature comparison — sdlt 220 versus sdlt 320 the sdlt 220 and 320 models have many characteristics in common, including similar temperature profiles. In table 4-3 and table 4-4 , the differences in operating temperature between the two models are shown hi...

Page 57

Chapter 4: thermal specifications embedded bezel this section lists empirical temperature data from measurements taken while using the embedded bezel. Results show certain components running hotter in 320 mode than 220 mode. The hifn (compression chip) runs slightly hotter, and the hydra chips (read...

Page 58

Chapter 4: thermal specifications library bezel this section lists empirical temperature data from measurements taken while using the library bezel. Again, the results show similar components running hotter in 320 mode than 220 mode. The hifn (compression chip) is slightly hotter and the hydra chips...

Page 59: Regulatory Requirements

Chapter 5 regulatory requirements regulatory requirements that apply to the sdlt tape system include: • safety • electromagnetic emissions • acoustic. 5.1 safety regulations this section lists the safety regulations that the sdlt tape system meets or exceeds, such as ul, csa, en/iec, and “gs” mark. ...

Page 60

Chapter 5: regulatory requirements 5.1.2 safety requirements safety requirements include: • ul1950: information technology including electrical business equipment • csa c22.2 #220: information technology including electrical business equipment • en60950/iec 950: information technology including elec...

Page 61: 5.2

Chapter 5: regulatory requirements 5.2 electromagnetic field specifications tandberg data sdlt tape drives are electrical devices; as such, this equipment generates, uses, and may emit radio frequency energy. The drives may emit energy in other frequencies, as well, as discussed in the following sub...

Page 62: 5.2.4 Radiated Emissions

Chapter 5: regulatory requirements 5.2.3 conducted emissions limits for class b equipment are in the frequency range from 0.15 to 30 mhz. 5.2.4 radiated emissions limits of radiated interference field strength, in the frequency range from 30 mhz to 1000 mhz at a test distance of 10 meters, are liste...

Page 63

Chapter 5: regulatory requirements 5.2.5 susceptibility and esd limits the following tables list radiated, magnetic radiated, and conducted susceptibility and esd failure level limits for the tape system. N ote : proper esd protection must be observed when handling tandberg data tape drive products....

Page 64: 5.3

Chapter 5: regulatory requirements 5.3 acoustic noise emissions the following table provides the tape system’s acoustic noise emission levels, both as noise power and sound pressure. Table 5-6. Acoustic noise emissions, nominal acoustics – preliminary declared values per iso 9296 and iso 7779/en2777...

Page 65: Scsi And Controller

Chapter 6 scsi and controller interface specification 6.1 scsi interface type the sdlt drive is available in either of two possible scsi interface versions; these versions provide three possible scsi interface types: • multimode single-ended (mse) card provides one of two interfaces low voltage diff...

Page 66: 6.2

Chapter 6: scsi and controller interface specification 6.2 setting the scsi id each device on the scsi bus must have a unique scsi id address assigned to it. For specific recommendations for assigning scsi ids, refer to the system or scsi controller documentation. Internal drives can be configured f...

Page 67

Chapter 6: scsi and controller interface specification table 6-1. Scsi id address selections scsi id jumper across pins: 9-10* 7-8 5-6 3-4 1-2 0 1 0 0 0 0 1 1 0 0 0 1 2 1 0 0 1 0 3 1 0 0 1 1 4 1 0 1 0 0 5 (default) 0 0 0 0 0 6 1 0 1 1 0 7 1 0 1 1 1 8 1 1 0 0 0 9 1 1 0 0 1 10 1 1 0 1 0 11 1 1 0 1 1 1...

Page 68: 6.3

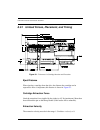

Chapter 6: scsi and controller interface specification 6.3 hardware (connectors) the scsi interface is made available via the back panel of the drive, as shown in figure 6-1 and figure 6-2 below. Figure 6-1. Connectors on the back panel figure 6-2. Back panel connector locations (drawn to scale) con...

Page 69: 6.4

Chapter 6: scsi and controller interface specification 6.4 scsi stub lengths the scsi interface resides on the host interface module (him). Quantum provides two versions, namely: • lvd (50-84004-01) • hvd (50-84008-01) the longest recorded stub lengths on the latest version of each style of pcb are ...

Page 70: 6.6

Chapter 6: scsi and controller interface specification 6.6 power on self test when power is applied to the tape system, the system performs a power on self test (post). Post completes in approximately ten seconds. While post is running, the tape system responds busy to scsi commands. The tape system...

Page 71

Chapter 6: scsi and controller interface specification prevent/allow media removal 500 milliseconds read 1 hour read block limits 500 milliseconds read buffer 3 minutes read position 500 milliseconds receive diagnostics 500 milliseconds release unit 500 milliseconds request sense 500 milliseconds re...

Page 72: 6.8

Chapter 6: scsi and controller interface specification 6.8 scsi and power connectors this section describes how to use the connectors that are provided on the back of the sdlt tape drive. The arrangement of these connectors is shown in figure 6-1 on page 6-4 . 6.8.1 power the pin orientation for the...

Page 73: 6.9

Chapter 6: scsi and controller interface specification 5. Attach the power cables to the drive. Check the scsi cable and termination connections and ensure that they are attached correctly and seated firmly. 6.9 loader/library controller interface the loader connector (for library tape drive interfa...

Page 74

Chapter 6: scsi and controller interface specification table 6-5. 8-pin loader connector pin assignments signal name pin number pin number signal name ground 1 5 send_to_loader_h rec_from_loader_h 2 6 send_to_loader_l rec_from_loader_l 3 7 ground ground 4 8 loader_present_l table 6-6. Mse and se mod...

Page 75

Chapter 6: scsi and controller interface specification ground 21 55 -atn ground 22 56 ground ground 23 57 -bsy ground 24 58 -ack ground 25 59 -rst ground 26 60 -msg ground 27 61 -sel ground 28 62 -c/d ground 29 63 -req ground 30 64 -i/o ground 31 65 -db(8) ground 32 66 -db(9) ground 33 67 -db(10) gr...

Page 76

Chapter 6: scsi and controller interface specification table 6-7. Mse lvd mode scsi connector pin assignments signal name pin number pin number signal name +db(12) 1 35 -db(12) +db(13) 2 36 -db(13) +db(14) 3 37 -db(14) +db(15) 4 38 -db(15) +db(p1) 5 39 -db(p1) +db(0) 6 40 -db(0) +db(1) 7 41 -db(1) +...

Page 77

Chapter 6: scsi and controller interface specification +db(8) 31 65 -db(8) +db(9) 32 66 -db(9) +db(10) 33 67 -db(10) +db(11) 34 68 -db(11) table 6-8. Hvd mode scsi connector pin assignments signal name pin number pin number signal name +db(12) 1 35 -db(12) +db(13) 2 36 -db(13) +db(14) 3 37 -db(14) +...

Page 78

Chapter 6: scsi and controller interface specification +ack 23 57 -ack +rst 24 58 -rst +msg 25 59 -msg +sel 26 60 -sel +c/d 27 61 -c/d +req 28 62 -req +i/o 29 63 -i/o ground 30 64 ground +db(8) 31 65 -db(8) +db(9) 32 66 -db(9) +db(10) 33 67 -db(10) +db(11) 34 68 -db(11) table 6-9. 4-pin power connec...

Page 79: 6.10 Configuring The Drive

Chapter 6: scsi and controller interface specification 6.10 configuring the drive configure the internal drive for termpwr or wide/narrow scsi. 6.10.1 termpwr a scsi bus must be terminated at each end of the bus. All signals not defined as reserved, ground, or termpwr shall be terminated exactly onc...

Page 80

Chapter 6: scsi and controller interface specification.

Page 81: Updating The Firmware

Chapter 7 updating the firmware 7.1 updating the code when you need to update the firmware in a drive, you can do it either of two ways: • build a firmware image tape; this tape can be used in either a manual firmware update or in a library setting. • update the firmware over the scsi bus. Both of t...

Page 82

Chapter 7: updating the firmware 7.1.2 making a fup/cup tape sdlt update is a tool that allows you to update a drive’s firmware (using the scsi bus), or to create a code update (cup/fup) tape for an sdlt drive. Sdlt update is available on tandberg data’s web site, http://www.Tandberg.Com. Follow the...

Page 83

Chapter 7: updating the firmware n ote : the firmware upgrade will fail the microcode update process if the firmware personalities do not match; this will be noted in the history log, along with the reason for the failure. 7. Wait several minutes for the update process to complete. The amber and gre...

Page 84: 7.2

Chapter 7: updating the firmware 7.2 code update using the library tape drive interface the library tape drive interface (for sdlt) enables updating the policy/servo firmware with a new version—that is to say, image—via tape update. Follow these steps: 1. Make certain the drive contains no cartridge...

Page 85

Chapter 7: updating the firmware 7.2.1 firmware (code) update troubleshooting this section lists common behaviors that you may notice as you update the tape drive’s firmware. For example: • updating the same revision if a code update is requested and the code revision being updated is the same as th...

Page 86

Chapter 7: updating the firmware.

Page 87: Insertion And Extraction

Chapter 8 insertion and extraction guidelines 8.1 applicable library commands the following lists of commands are provided for customers who are using library interface commands to communicate with the drive. N ote : use the attention command to poll the status of the drive; once the status is obtai...

Page 88: 8.1.2 Unloading

Chapter 8: insertion and extraction guidelines 8.1.2 unloading these commands pertain to unloading the cartridge: • attention • eject • unload • unload and eject • disable eject on scsi unload • enable eject on scsi unload • disable auto tape thread • enable auto tape thread..

Page 89: 8.2

Chapter 8: insertion and extraction guidelines 8.2 loading a tape cartridge complete this subsection to load a tape cartridge into the front of the tape drive. Because this subsection of the manual refers to some of the front panel leds and controls, it describes the process for manually loading a t...

Page 90

Chapter 8: insertion and extraction guidelines hold time for loading (dwell time) when loading the cartridge into the drive, the maximum time that the picker should hold the cartridge is 250ms (0.25 second). If a longer hold time is used, buckling and possible reel driver engagement problems could o...

Page 91: 8.3

Chapter 8: insertion and extraction guidelines 8.3 unloading a tape cartridge complete this subsection to unload a tape cartridge. Because this subsection of the manual refers to some of the front panel leds and controls, it describes the process for manually unloading a tape cartridge. 1. Press the...

Page 92

Chapter 8: insertion and extraction guidelines 8.3.1 unload forces, placement, and timing figure 8-1. Tolerances for cartridge insertion and extraction eject distance when ejecting a cartridge from the drive, the distance the cartridge can be expected to move is important; this distance is shown in ...

Page 94

W w w. T a n d b e r g . C o m tandberg data asa, kjelsåsv. 161, p.O. Box 134 kjelsås, n-0411 oslo, norway tel: +47 22 18 90 90. Fax: +47 22 18 95 50. Sales-no@tandberg.Com tandberg data gmbh, feldstraße 81, d-44141 dortmund, germany tel: +49 231 5436 0. Fax: +49 231 5436 111. Sales-de@tandberg.Com ...