- DL manuals

- TANDBERG

- Other

- SDLT220-320 INTEGRATION

- Product Manual

TANDBERG SDLT220-320 INTEGRATION Product Manual

Summary of SDLT220-320 INTEGRATION

Page 1

Tandberg super dlt tm product manual revision 2 june 2002 - 432589-01.

Page 2

Sdlt 220 and sdlt 320 product manual copyright copyright © 2002 by tandberg data.. All rights reserved. Trademarks quantum, the quantum logo, dlttape, the dlttape logo, super dlttape and the super dlttape logo are trademarks of quantum corporation registered in the u.S.A. And other countries. Laser ...

Page 3

Sdlt 220 and sdlt 320 product manual revision history revision date (yymmdd) summary of changes 422216-01 020610 initial release.

Page 4

Sdlt 220 and sdlt 320 product manual user manual statements for class a equipment (internal tape system) this equipment generates, uses, and may emit radio frequency energy. The equipment has been tested and found to comply with the limits for a class a digital device, pursuant to part 15 of the fcc...

Page 5

Sdlt 220 and sdlt 320 product manual user manual statements for class b equipment (tabletop tape system) this equipment has been tested and found to comply with the limits for a class b digital device, pursuant to part 15 of the fcc rules. These limits are designed to provide reasonable protection a...

Page 6

Sdlt 220 and sdlt 320 product manual from device to device and needs to be obtained from the emc (electromagnetic compatibility) group or product manager. This class b digital apparatus complies with canadian ices-003. Cet appareil numérique de la classe b est conforme à la norme nmb-003 du canada..

Page 7: Table Of Contents

Table of contents chapter 1 introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 purpose and scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 referenced documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 8

Table of contents sdlt cartridge tape module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10 key differences between the sdlt 220 and the sdlt 320 . . . . . . . . 2-11 tandberg data diagnostics tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12 tapealert . . . . . . . ...

Page 9

Table of contents installing the internal tape drive. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10 securing the internal tape drive . . . . . . . . . . . . . . . . . . . . . . . . 4-11 connecting the internal drive cables. . . . . . . . . . . . . . . . . . . . . 4-12 configuring and inst...

Page 10

Table of contents scsi signal definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9 signal bus timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10 chapter 7 regulatory compliance . . . . . . . . . . . . . . . . . . . . 7-1 safety re...

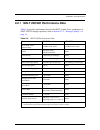

Page 11: List Of Tables

List of tables chapter 1 introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 table 1-1. Typographical conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 chapter 2 sdlt 220/320 product information . . . . . . . . ....

Page 12

List of tables chapter 4 installing your tape drive . . . . . . . . . . . . . . . . . . 4-1 table 4-1. Scsi id address selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9 table 4-2. Mse and se mode scsi connector pin assignments . . . . . ....

Page 13: List Of Figures

List of figures chapter 1 introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 chapter 2 sdlt 220/320 product information . . . . . . . . . . . 2-1 figure 2-1. Sdlt 220/320 drive system (photographs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 fig...

Page 14

List of figures chapter 7 regulatory compliance . . . . . . . . . . . . . . . . . . . . 7-1 appendix a sdlt i tape cartridge . . . . . . . . . . . . . . . . . . . . . A-1 figure a-1. End view of sdlt i cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 15: Introduction

Chapter 1 introduction 1.1 purpose and scope this product manual is a comprehensive source of information about the sdlt 220 and sdlt 320 cartridge tape drive systems; it describes both the internal and tabletop versions of the super dlttape™ tape system. This manual is also intended to serve as an ...

Page 16: 1.2

Chapter 1: introduction 1.2 referenced documents • super dlt scsi interface guide (432614 rev. 01 or later) • super dlt design and integration guide (432588 rev. 01 or later) • super dlttape™ interactive library interface specification 1.3 related documents • dlt script tool user guide 1.4 structure...

Page 17

Chapter 1: introduction • appendix a, sdlt i cartridge, provides tape cartridge information for the sdlt i cartridge including handling and inspection procedures, information on the write-protect switch, and how to load and unload a tape cartridge. • appendix b, dlt iv cartridge, includes the cartri...

Page 18: 1.5

Chapter 1: introduction 1.5 conventions this manual uses the following conventions to designate specific elements: 1.6 for more information the web site http://www.Superdlttape.Com includes much valuable information about sdlt systems; or to locate very specific product-related information, visit ht...

Page 19: 1.7

Chapter 1: introduction 1.7 reader comments tandberg data is committed to providing the best products and service. We encourage your comments, suggestions, and corrections for this manual. Please send all comments to: tandberg data asa p.O. Box 134 kjelsas n-0411 norway.

Page 20

Chapter 1: introduction.

Page 21: Sdlt 220/320 Product

Chapter 2 sdlt 220/320 product information this chapter describes the features of the tandberg data super dlttape system. This chapter covers the following topics: • “overview” describes basic features of the system. • “sdlt 220/320 product features” lists key features of the sdlt family of tape dri...

Page 22: 2.2

Chapter 2: sdlt 220/320 product information provides 160 gb of storage capacity with a transfer speed of 16mb/second (native). To view a succinct comparison of the two models, refer to “key differences between the sdlt 220 and the sdlt 320” on page 2-11 . For detailed engineering specifications (for...

Page 23: 2.3 Sdlt 220/320 Technology

The sdlt system ( figure 2-1 and figure 2-2 ) is based on laser guided magnetic recording•••• (lgmr) technology. Lgmr provides a unique combination of the best optical and magnetic technologies, which results in dramatically higher capacities by substantially increasing the number of recording track...

Page 24

Chapter 2: sdlt 220/320 product information figure 2-2. Sdlt 220/320 drive system (cad diagram in perspective) 2.3.2 pivoting optical servo pivoting optical servo (pos) is a optically-encoded servo system, which combines high-density magnetic read/write data recording with laser servo guiding. The p...

Page 25: Likelihood

Chapter 2: sdlt 220/320 product information 2.3.4 advanced partial response maximum likelihood improving on partial response maximum likelihood (prml) technology, tthe advanced prml channel technology was developed with to bring new levels of performance and capacity to high-performance linear tape ...

Page 26: 2.4

Chapter 2: sdlt 220/320 product information 2.4 sdlt 220/320 modular design sdlt is designed as a total system. The system includes a complex interaction of a number of important components including such items as the tape path, tape heads, media, cartridge, and host interface. Sdlt is organized int...

Page 27: 2.4.1 Data Control Module

Chapter 2: sdlt 220/320 product information the only two modules that are field replaceable. Customer adjustments to the tcm, dcm, or eim are not allowed, and will void the drive’s warranty. 2.4.1 data control module the data control module (dcm) contains several of the functions and features of lgm...

Page 28: 2.4.2 Tape Control Module

Chapter 2: sdlt 220/320 product information 2.4.2 tape control module the tape control module (tcm) implements the functions required to buckle and unbuckle the tape and control the tape motion. The tcm consists of a variety of components: • tcm pcba (printed circuit board assembly) • base plate • c...

Page 29: 2.4.3 Front Panel Module

Chapter 2: sdlt 220/320 product information cartridge receiver assembly reverses the process and automatically ejects the tape a fixed distance from the front of the drive. There is no longer a manual lock and release handle to operate when loading and unloading the cartridge. This “soft load” capab...

Page 30

Chapter 2: sdlt 220/320 product information 2.4.4 electronic interface module the electronic interface module (eim) is the electronic heart of the sdlt system. It provides the main control function for the system and the interface from the system to the host computer. The eim provides the advanced p...

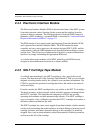

Page 31: 2.5

Chapter 2: sdlt 220/320 product information 2.5 key differences between the sdlt 220 and the sdlt 320 table 2-1 compares important features in the sdlt 220 and the sdlt 320 products. Table 2-1. A comparison of sdlt 220 and sdlt 320 features parameter sdlt 220 sdlt 320 capacity compressed ‡ uncompres...

Page 32: 2.6

Chapter 2: sdlt 220/320 product information 2.6 tandberg data diagnostics tools tandberg data frequently provides new and updated tools to use with its tape drives. For example: all tools are available on the tandberg data’s web site, http://www.Tandberg.Com. New tools and utilities get added freque...

Page 33: 2.7

Chapter 2: sdlt 220/320 product information 2.7 tapealert sdlt drives are delivered with tapealert features built in. The internal sdlt firmware constantly monitors the device’s hardware and media, checking for errors and potential difficulties. Any problems identified are flagged on the scsi log ...

Page 34

Chapter 2: sdlt 220/320 product information.

Page 35: Drive Specifications

Chapter 3 drive specifications this chapter describes various specifications that apply to the tandberg super dlttape system, which include: • “product specifications” provides the product specifications for the sdlt 220/320 tape drives. • “functional specifications” provides the functional specific...

Page 36: 3.1.1 Interface Type

Chapter 3: drive specifications 3.1.1 interface type the sdlt drive is available in either of two possible scsi interface versions; these versions provide three possible scsi interface types: • multimode single-ended (mse) provides one of two interfaces: ! Low voltage differential (lvd) running at 8...

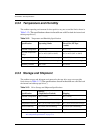

Page 37: 3.1.3 Storage Capacity

Chapter 3: drive specifications 3.1.3 storage capacity table 3-2 provides native and compressed capacity ranges for the sdlt i tape cartridge: in accordance with industry practice, a typical compression ratio of 2:1 is quoted. Actual compression ratios achieved depend on the redundancy and type of d...

Page 38: 3.1.5 Data Integrity

Chapter 3: drive specifications 3.1.5 data integrity sdlt data transfer errors are extremely rare; data integrity for the overall tape system is shown in table 3-3 . Table 3-3. Data transfer error rates error type frequency error rates recoverable read 6 bytes read detected, unrecoverable read 17 bi...

Page 39

Chapter 3: drive specifications 3.1.6 maximum data transfer rate the maximum sustained (and burst) data transfer rates for sdlt drives are shown in table 3-4 . N ote : cable lengths and cable type can limit attainable transfer rate; for details, refer to a separate document, super dlt design and int...

Page 40: 3.1.7 Reliability (Mtbf)

Chapter 3: drive specifications 3.1.7 reliability (mtbf) mean time between failures (mtbf) for the overall tape system is projected to be 250,000 hours. Head life is a minimum of 30,000 tape motion hours and an average of 50,000 tape motion hours. Media durability is 1,000,000 passes. N ote : tandbe...

Page 41

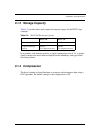

Chapter 3: drive specifications 3.2.1 sdlt 220/320 performance data table 3-6 provides performance data for the sdlt system. For a comparison of sdlt 220/320 storage capacities, refer to section 3.1.3, “storage capacity” on page 3-3 . Table 3-6. Sdlt 220/320 performance data feature sdlt 220 sdlt 32...

Page 42

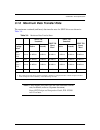

Chapter 3: drive specifications 3.2.2 shock and vibration specifications the following tables provide non-operating and operating shock and vibration specifications for the sdlt system. Table 3-7. Non-operating shock specifications (unpackaged) shock (unpackaged) pulse shape square wave ½ sine pulse...

Page 43

Chapter 3: drive specifications table 3-9. Non-operating vibration specifications vibration (unpackaged) type sine sweep frequency range 5 - 500 - 5 hz upward and downward sweep acceleration level 0.02" da 1.0 g between 5 and 31 hz (crossover) between 31 and 500 hz (crossover) application x,y,z axes...

Page 44

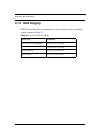

Chapter 3: drive specifications 3.2.3 current and power requirements table 3-11 on page 3-11 lists the current and power requirements for both versions of the tape system (internal and tabletop). The tabletop version requires ac power. The highest current (and power) is drawn during the native write...

Page 45

Chapter 3: drive specifications table 3-11. Current and power specifications mode 5 v current (a) maxpk 1 maxrms 2 typ 3 12 v current (a) maxpk 1 maxrms 2 typ 3 dc power (w) max 4 typ 5 ac power (w) max 6 typ 7 standby / idle 3.2 3.0 2.9 0.6 0.5 0.4 20 19 34 29 media loading / unloading 3.8 3.1 2.9 ...

Page 46

Chapter 3: drive specifications 3.2.4 tape system recording method the sdlt 220 tape system uses the partial response maximum likelihood (prml) 32/33 encoding method for reading/writing sdlt format. The sdlt 320 tape system uses the prml 32/33 encoding method for reading/ writing sdlt 320 and 220 fo...

Page 47: 3.3

Chapter 3: drive specifications 3.3 environmental specifications the sdlt 220/320 tape drive operates in environments that include general offices and workspaces with systems capable of maintaining standard comfort levels. The following subsections provide the environmental specifications for the sd...

Page 48

Chapter 3: drive specifications 3.3.2 temperature and humidity the ambient operating environment for the tape drive may not exceed the limits shown in table 3-12 . (the specifications shown in the table are valid for both the internal and tabletop tape drives .) 3.3.3 storage and shipment the ambien...

Page 49: 3.3.4 Altitude

Chapter 3: drive specifications 3.3.4 altitude both the internal and tabletop tape drives operate in normal pressures from –500 to 10,000 feet when operated within the ambient operating environments specified in “temperature and humidity” on page 3-14 . The drive will operate to 30,000 feet for temp...

Page 50

Chapter 3: drive specifications table 3-15. Super dlttape i media specifications description specifications width 0.5 in. Magnetic coating 300 nm metal particle length 1800 feet (1765 feet usable) coercivity 1800 oe cartridge dimensions 4.1 in x 4.1 in x 1.0 in shelf life 30 years min. @ 20 °c & 40%...

Page 51

Chapter 3: drive specifications 3.4.1 backward-read compatibility transfer rates both the sdlt 220 and 320 drives feature an optional backward-read compatibility (brc) mode. When in brc mode, the drives are capable of reading dlttape iv tapes with dlt4000, dlt7000, dlt8000, and dlt 1 /vs80 formats. ...

Page 52

Chapter 3: drive specifications.

Page 53

Chapter 4 installing your tape drive this chapter describes how to install the internal tape drive into a system. This includes configuration jumper settings, connector pin assignments, installation instructions, power and signal cabling descriptions, and operating instructions. This chapter also in...

Page 54: 4.1

Chapter 4: installing your tape drive 4.1 safety, handling, and esd protection inappropriate or careless handling of tape systems may result in damage to the product. Follow the precautions and directions to prevent damaging the tape system. In addition, follow the pre-installation guidelines to ens...

Page 55: 4.1.2 Handling

Chapter 4: installing your tape drive 4.1.2 handling damage to the tape system can occur as the result of careless handling, vibration, shock, or electrostatic discharge (esd). For more details about esd, refer to “electrostatic discharge protection” on page 4-4 . Follow these guidelines to avoid da...

Page 56

Chapter 4: installing your tape drive 4.1.3 electrostatic discharge protection several electrical components of the tape system are sensitive to static electricity and electrostatic discharge (esd). Even a static buildup or discharge that is too slight to feel can be sufficient to destroy or degrade...

Page 57

Chapter 4: installing your tape drive 4.2 pre-installation guidelines before you begin, check the contents of the box, record the applicable numbers, check for scsi controller and cable compatibility, and confirm software and operating system compatibility. Finally, check the drive to make sure it i...

Page 58: 4.3

Chapter 4: installing your tape drive 4.3 configuring and installing an internal tape drive this section provides information for configuring and installing a tape drive into a system. See “configuring and installing a tabletop drive” for information on configuring and installing a tabletop tape dri...

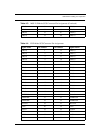

Page 59

Chapter 4: installing your tape drive 4.3.1 setting the internal drive scsi id each device on the scsi bus must have a unique scsi id address assigned to it. For specific recommendations for assigning scsi ids, refer to the system or scsi controller documentation. Internal drives can be configured f...

Page 60

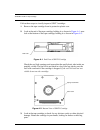

Chapter 4: installing your tape drive figure 4-1. Connectors on the back panel figure 4-2. Back panel connector locations (drawn to scale) controller diag port (8 pin) (diagnostic use only) configuration jumper (omit jumper on pins 1-2 to enable wide scsi) scsi id jumper block (no jumpers on this bl...

Page 61

Chapter 4: installing your tape drive table 4-1. Scsi id address selections scsi id jumper across pins: 9-10* 7-8 5-6 3-4 1-2 0 1 0 0 0 0 1 1 0 0 0 1 2 1 0 0 1 0 3 1 0 0 1 1 4 1 0 1 0 0 5 (default) 0 0 0 0 0 6 1 0 1 1 0 7 1 0 1 1 1 8 1 1 0 0 0 9 1 1 0 0 1 10 1 1 0 1 0 11 1 1 0 1 1 12 1 1 1 0 0 13 1 ...

Page 62

Chapter 4: installing your tape drive 4.3.2 configuring the internal drive for termpwr a scsi bus must be terminated at each end of the bus. All signals not defined as reserved, ground, or termpwr shall be terminated exactly once at each end of the bus. At least one device must supply terminator pow...

Page 63

Chapter 4: installing your tape drive figure 4-4. Sdlt 220/320 — two views (front + side + top and back + side + top) securing the internal tape drive this section describes how to mount and secure the drive in the system. N ote : in some system configurations it may be more convenient to connect th...

Page 64

Chapter 4: installing your tape drive 2. Using four #6-32 unc-2b screws, secure the tape drive in the bay or chassis. Figure 4-5. Internal drive mounting locations – side and bottom views connecting the internal drive cables the three connectors on the back of the internal sdlt drive that are discus...

Page 65

Chapter 4: installing your tape drive pin assignments for the three possible scsi connectors are listed in a series of tables: multimode single-ended (mse) single ended (se) mode in table 4-2 on page 4-14 , mse low voltage differential (lvd) mode in table 4-3 on page 4-16 , and high voltage differen...

Page 66

Chapter 4: installing your tape drive figure 4-6. Connectors on the back panel (drawn to scale) table 4-2. Mse and se mode scsi connector pin assignments signal name pin number pin number signal name ground 1 35 -db(12) ground 2 36 -db(13) ground 3 37 -db(14) ground 4 38 -db(15) ground 5 39 -db(p1) ...

Page 67

Chapter 4: installing your tape drive diffsens 16 50 ground termpwr 17 51 termpwr termpwr 18 52 termpwr reserved 19 53 reserved ground 20 54 ground ground 21 55 -atn ground 22 56 ground ground 23 57 -bsy ground 24 58 -ack ground 25 59 -rst ground 26 60 -msg ground 27 61 -sel ground 28 62 -c/d ground...

Page 68

Chapter 4: installing your tape drive table 4-3. Mse lvd mode scsi connector pin assignments signal name pin number pin number signal name +db(12) 1 35 -db(12) +db(13) 2 36 -db(13) +db(14) 3 37 -db(14) +db(15) 4 38 -db(15) +db(p1) 5 39 -db(p1) +db(0) 6 40 -db(0) +db(1) 7 41 -db(1) +db(2) 8 42 -db(2)...

Page 69

Chapter 4: installing your tape drive +db(8) 31 65 -db(8) +db(9) 32 66 -db(9) +db(10) 33 67 -db(10) +db(11) 34 68 -db(11) table 4-4. Hvd mode scsi connector pin assignments signal name pin number pin number signal name +db(12) 1 35 -db(12) +db(13) 2 36 -db(13) +db(14) 3 37 -db(14) +db(15) 4 38 -db(1...

Page 70

Chapter 4: installing your tape drive +msg 25 59 -msg +sel 26 60 -sel +c/d 27 61 -c/d +req 28 62 -req +i/o 29 63 -i/o ground 30 64 ground +db(8) 31 65 -db(8) +db(9) 32 66 -db(9) +db(10) 33 67 -db(10) +db(11) 34 68 -db(11) table 4-4. Hvd mode scsi connector pin assignments (continued).

Page 71

Chapter 4: installing your tape drive table 4-5. 4-pin power connector pin assignments pin number signal name 1 +12 vdc 2 ground (+12v return) 3 ground (+5v return) 4 +5 vdc table 4-6. 8-pin loader connector pin assignments signal name pin number pin number signal name ground 1 5 send_to_loader_h re...

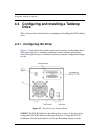

Page 72: 4.4

Chapter 4: installing your tape drive 4.4 configuring and installing a tabletop drive this section provides instructions for configuring and installing the sdlt tabletop drive. 4.4.1 configuring the drive figure 4-7 shows the location of the controls and connectors for the tabletop drive. This model...

Page 73

Chapter 4: installing your tape drive desired scsi id. The top button increases the id number, the bottom button decreases the id number. Termpwr the termpwr setting for the tabletop drive is preconfigured at the factory according to specific customer requirements. Termpwr is not selectable on-site....

Page 74

Chapter 4: installing your tape drive 4. Align the appropriate scsi cable to its matching connector on the drive. Carefully connect the cable, to avoid bending or damaging the connector pins. Check the scsi cable and termination connections and ensure that they are attached correctly and seated firm...

Page 75: 4.5

Chapter 4: installing your tape drive figure 4-8. Ac power cord connector types the power supply of the tabletop unit has an auto-sensing feature; no adjustment or switch setting changes are required for different ac sources. Refer to figure 4-7 and figure 4-8 . Connect one end of the ac cord into t...

Page 76

Chapter 4: installing your tape drive.

Page 77: Using Your Tape Drive

Chapter 5 using your tape drive this chapter describes how to start using your tape drive system. This includes making a trial back-up, cleaning the tape mechanism, and various troubleshooting information. This chapter also includes information on the leds and buttons on the front panel of the syste...

Page 78: 5.1

Chapter 5: using your tape drive 5.1 power on self test when power is applied to the tape system, the system performs a power on self test (post). Post completes in approximately ten seconds. While post is running, the tape system responds busy to scsi commands. The tape system also responds to vari...

Page 79: 5.3

Chapter 5: using your tape drive n ote : you can review specific instructions for loading a tape cartridge in appendix a, “sdlt i tape cartridge,” and appendix b, “dlt iv tape cartridge.” 5.3 overwriting 320-formatted cartridges in a 220 drive this section describes what happens when a 320-formatted...

Page 80: 5.4

Chapter 5: using your tape drive 5.4 updating the firmware when you need to update the firmware in a drive, you can do it either of two ways: • build a firmware image tape; this tape can be used in either a manual firmware update or in a library setting. • update the firmware over the scsi bus. Both...

Page 81

Chapter 5: using your tape drive 5.4.2 making a fup/cup tape sdlt update is a tool that allows you to update a drive’s firmware (using the scsi bus), or to create a code update (cup/fup) tape for an sdlt drive. Sdlt update is available on tandberg data’s web site, http://www.Tandberg.Com. Follow the...

Page 82

Chapter 5: using your tape drive n ote : the firmware upgrade will fail the microcode update process if the firmware personalities do not match; this will be noted in the history log, along with the reason for the failure. 7. Wait several minutes for the update process to complete. The amber and gre...

Page 83: 5.5

Chapter 5: using your tape drive 5.5 cleaning the tape mechanism this section discusses the sdlt cleaning tape, maintenance considerations, and important compatibility issues you need to be aware of. N ote : use the sdlt cleaning tape if cleaning is indicated through your backup software or when the...

Page 84

Chapter 5: using your tape drive 5.5.2 when to use the cleaning tape sdlt uses a built-in tape cleaning algorithm in conjunction with a cleaning tape. The sdlt cleaning tape is housed in a plastic case, and is light gray in color. A yellow led (light) located on the front bezel of the tape drive ind...

Page 85: Drive

Chapter 5: using your tape drive 5.5.5 loading the cleaning tape into a tabletop drive n ote : to use the cleaning cartridge in an autoloader or library drive, refer to your owner’s manual. Follow these steps to load an sdlt cleaning tape into an sdlt tabletop drive: 1. Insert the cleaning cartridge...

Page 86: 5.6

Chapter 5: using your tape drive 5.6 front panel controls and leds all controls and leds are located on the tape drive’s front panel. See figure 5-1 on page 5-11 for details. Control and led functionality are described in table 5-2 and table 5-3 . Use these controls and leds to operate the tape syst...

Page 87

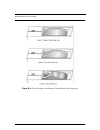

Chapter 5: using your tape drive figure 5-1. Sdlt 220 and sdlt 320 front panels (a comparison) sdlt 220 sdlt 320

Page 88

Chapter 5: using your tape drive table 5-3. Front panel led/control functionality led/button symbol led color description write protect led (left on sdlt 220) or drive density led (left on sdlt 320) amber for the sdlt 320 drive, this led functions as the “drive density indicator” led; for the sdlt 2...

Page 89: 5.7

Chapter 5: using your tape drive 5.7 troubleshooting the following subsections provide troubleshooting information that might be helpful should the system fail its power-on self text (post). Refer to the tape cartridge appendices in this manual ( appendix a, “sdlt i tape cartridge” and appendix b, “...

Page 90

Chapter 5: using your tape drive system does not recognize the tape system. (cont.) scsi bus may not be terminated correctly. If tape system is last or only device on bus (except for adapter), make sure terminator is installed on tape system. If tape system is not the last or only device on the bus,...

Page 91

Chapter 5: using your tape drive 5.7.2 over temperature condition an overtemp condition is defined to be when the calculated tape path temp = 52 degrees c. When this condition is detected, the tape is rewound, unloaded, and ejected from the drive. (as long as the drive is not mounted in a tape autom...

Page 92

Chapter 5: using your tape drive.

Page 93: Scsi Description

Chapter 6 scsi description this chapter covers the following topics: • “scsi overview” introduces the scsi specification. • “scsi-2 commands” lists the scsi-2 commands implemented by sdlt 220/320. • “scsi-3 commands” lists the scsi-3 commands implemented by sdlt 220/320. • “parity” defines the meani...

Page 94

Chapter 6: scsi description important features of scsi-2 implementation include the following: • efficient peer-to-peer i/o bus with up to 15 devices • asynchr onous transfer rates that d epend only on d evice implementation and c able length • logica l addr essing for all da ta blocks (rather than ...

Page 95: 6.2

Chapter 6: scsi description 6.2 scsi-2 commands ansi classifies scsi commands as mandatory, optional, or vendor-specific. The mandatory and optional scsi-2 commands implemented for the drives are summarized in table 6-1 . Table 6-1. Implemented ansi scsi-2 commands command code class description era...

Page 96

Chapter 6: scsi description read buffer 3ch optional used in conjunction with the write buffer command as a diagnostic function for testing target memory and the integrity of the scsi bus. This command does not alter the medium. Read position 34h optional reports the current position of the logical ...

Page 97: 6.3

Chapter 6: scsi description 6.3 scsi-3 commands ansi classifies scsi commands as mandatory, optional, or vendor-specific. The mandatory and optional scsi-3 commands implemented for the drives are summarized in table 6-2 . Table 6-2. Implemented ansi scsi-3 commands command code class description per...

Page 98: 6.4

Chapter 6: scsi description 6.4 parity parity is a method of generating redundant information that can be used to detect errors in stored or transmitted data. Data transmitted across the scsi interface is protected by redundant parity bits: • one bit for the 8-bit narrow scsi implementation • two bi...

Page 99

Chapter 6: scsi description table 6-3. Ansi signal sources signals bus phase bsy sel c/d i/o msg req ack atn db(7–0) db (p) db(15-8) db (p1) bus free none none none none none none arbitration all winner none none s id s id selection i&t init none init init init reselection i&t targ targ init targ ta...

Page 100: 6.5.2 Scsi Ids

Chapter 6: scsi description 6.5.2 scsi ids scsi permits a maximum of 16 devices (the host adapter is considered one device) when using wide scsi. Each scsi device has a unique scsi id assigned to it. This scsi id provides an address for identifying the device on the bus. On the drive, the scsi id is...

Page 101

Chapter 6: scsi description 6.6.1 scsi signal definitions table 6-4 lists the scsi bus signals. Table 6-4. Scsi-2 bus signal definitions signal definition ack (acknowledge) a signal driven by the initiator as an acknowledgment of receipt of data from a target or as a signal to a target indicating wh...

Page 102: 6.6.2 Signal Bus Timing

Chapter 6: scsi description 6.6.2 signal bus timing the ansi scsi-2 standard defines the scsi bus timing values listed in table 6-5 . Table 6-5. Scsi bus timing values timing description value description arbitration delay 2.4 µ s minimum time a scsi device waits from asserting bsy for arbitration u...

Page 103

Chapter 6: scsi description disconnection delay 200 µ s minimum time that a drive waits after releasing bsy before participating in an arbitration when honoring a disconnect message from the initiator. Hold time 45 ns minimum time added between the assertion of req or ack and changing the data lines...

Page 104

Chapter 6: scsi description.

Page 105: Regulatory Compliance

Chapter 7 regulatory compliance this chapter describes various regulations that apply to the quantum super dlttape system, which include: • “safety regulations” describes compliance with various standards published by international safety organizations. • “electromagnetic field specifications” descr...

Page 106: 7.1.2 Safety Requirements

Chapter 7: regulatory compliance 7.1.2 safety requirements safety requirements include: • ul1950: information technology including electrical business equipment • csa950 c22.2 no. 950: information technology including electrical business equipment • en60950/iec 950: information technology including ...

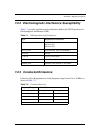

Page 107: 7.2.3 Conducted Emissions

Chapter 7: regulatory compliance 7.2.2 electromagnetic interference susceptibility table 7-1 provides regulations and certifications held by the sdlt tape drive for electromagnetic interference (emi). 7.2.3 conducted emissions limits for class b equipment are in the frequency range from 0.15 to 30 m...

Page 108: 7.2.4 Radiated Emissions

Chapter 7: regulatory compliance 7.2.4 radiated emissions limits of radiated interference field strength, in the frequency range from 30 mhz to 1000 mhz at a test distance of 10 meters, are listed in table 7-3 . Table 7-3. Radiated emissions frequency range quasi-peak limits db (µv/m) class a class ...

Page 109

Chapter 7: regulatory compliance 7.2.5 susceptibility and esd limits the following tables list radiated, magnetic radiated, and conducted susceptibility and esd failure level limits for the tape system. Table 7-4. Radiated, magnetic radiated, and conducted susceptibility type specifications comments...

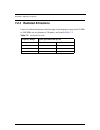

Page 110: 7.3

Chapter 7: regulatory compliance 7.3 acoustic noise emissions the following table provides the tape system’s acoustic noise emission levels, both as noise power and sound pressure. Table 7-6. Acoustic noise emissions, nominal acoustics – preliminary declared values per iso 9296 and iso 7779/en27779 ...

Page 111: Sdlt I Tape

Appendix a sdlt i tape cartridge from the outside, the sdlt i cartridge looks very similar to the dlt iv cartridges. The basic geometry, write protection switch, and label space are unchanged from the dlt iv cartridge. This simplifies the integration of sdlt into existing operating environments and ...

Page 112

Appendix a: sdlt i tape cartridge a.1 tape cartridge handling guidelines ensure that your tape backup solution performs reliably by following the general handling guidelines described here: • always keep each tape cartridge in its protective plastic case when it is not in the tape drive. • when carr...

Page 113

Appendix a: sdlt i tape cartridge • avoid unnecessary opening of the cartridge door; this may expose the tape to contamination or physical damage. • do not use graphite pencils, water-soluble felt pens, or other debris-producing writing instruments on your labels. Never erase a label — replace it. •...

Page 114

Appendix a: sdlt i tape cartridge follow these steps to visually inspect a sdlt i cartridge: 1. Remove the tape cartridge from its protective plastic case. 2. Look at the end of the tape cartridge, holding it as shown in figure a-1 ; now look at the bottom of the tape cartridge, holding it as shown ...

Page 115

Appendix a: sdlt i tape cartridge 4. Finally, check for proper operation of the tape cartridge’s write-protect switch ( figure a-3 ). This sliding switch, located on the end of the tape cartridge used for the tape label, should snap smartly back and forth, and the orange tab should be visible when t...

Page 116

Appendix a: sdlt i tape cartridge when a tape cartridge is loaded in the drive and the tape cartridge’s write-protect switch is moved to its write-protected position (to the left as you face the label/ switch side of the tape cartridge), the drive turns on its write-protect indicator led immediately...

Page 117

Appendix a: sdlt i tape cartridge a.4 loading a tape cartridge complete this subsection to load a tape cartridge into the front of the tape drive; refer to figure a-4 as needed. 1. Insert the cartridge. 2. Push the cartridge fully into the tape drive. The drive status led blinks to show that the tap...

Page 118: Cartridges

Appendix a: sdlt i tape cartridge a.5 unloading a tape cartridge complete this subsection to unload a tape cartridge; refer to figure a-4 on page a-7 as needed. 1. Press the eject button (or issue an appropriate system software command); the drive completes any active writing of data to the tape. Th...

Page 119

Appendix a: sdlt i tape cartridge once a 320-formatted cartridge has become ready in an sdlt 220 drive, the drive will report density code 00h (unknown format ) on any valid mode sense command. If write commands are given to a ready 320-formatted cartridge in an sdlt 220 drive, the write commands wi...

Page 120

Appendix a: sdlt i tape cartridge.

Page 121: Dlt Iv Tape

Appendix b dlt iv tape cartridge the sdlt drive is backward compatible; it ensures backward read compatibility of dlt iv cartridges in the sdlt drive. Data backed up using a dlt iv cartridge in a dlt 8000, dlt 7000, dlt 4000 or dlt/vs80 drive will be retrievable using sdlt-based drives. By following...

Page 122

Appendix b: dlt iv tape cartridge b.1 tape cartridge handling guidelines ensure that your tape backup solution performs reliably by following both the general handling guidelines described in this subsection. • always keep each tape cartridge in its protective plastic case when it is not in the tape...

Page 123

Appendix b: dlt iv tape cartridge • avoid unnecessary opening of the cartridge door; this may expose the tape to contamination or physical damage. • do not use graphite pencils, water-soluble felt pens, or other debris-producing writing instruments on your labels. Never erase a label—replace it. • m...

Page 124

Appendix b: dlt iv tape cartridge follow these steps to visually inspect a dlt cartridge: 1. Remove the tape cartridge from its protective plastic case. 2. Look at the tape cartridge to check for any obvious cracks or other physical damage. Look for broken or missing parts. 3. Gently shake the tape ...

Page 125

Appendix b: dlt iv tape cartridge 6. Ensure that the tape leader within the tape cartridge is in the correct position. To do this, open the tape cartridge door by holding the dlt cartridge as shown in figure b-3 . Figure b-3. Dlt tape leader loop in its correct position 7. On the right side corner o...

Page 126

Appendix b: dlt iv tape cartridge figure b-4. Tape cartridges with damage visible during visual inspection.

Page 127

Appendix b: dlt iv tape cartridge b.3 tape cartridge write-protect switch each tape cartridge has a write-protect switch ( figure b-5 ) that can be used to prevent accidental erasure of data. Since the dlt iv cartridge is a read-only cartridge when used in the sdlt drive, the write-protect switch in...

Page 128

Appendix b: dlt iv tape cartridge b.4 loading a tape cartridge complete this subsection to load a tape cartridge into the front of the tape drive; refer to figure b-6 as needed. 1. Insert the cartridge. Push the cartridge fully into the tape drive. N ote : if you have loaded a dlt iv cartridge into ...

Page 129

Appendix b: dlt iv tape cartridge any command that attempts to write to the medium (write, write filemarks, erase) will return check condition status. The sense key will be set to data protect (7) and the asc/ascq will be set to “cannot write medium - incompatible format” (30/05). No update of the t...

Page 130

Appendix b: dlt iv tape cartridge.

Page 131: Glossary

Glossary a ac alternating current. Access (v.) to read, write, or update information on a storage medium, such as tape. (n.) the operation of reading, writing, or updating stored information. Access time the interval between the time a request for data is made by the system and the time the data is ...

Page 132

Glossary b backup a copy of a file, directory, or volume on a separate storage device from the original, for the purpose of retrieval in case the original is accidentally erased, damaged, or destroyed. Bad data block a block that cannot reliably hold data because of a media flaw or damaged format ma...

Page 133

Glossary c cache specialized ram used as a buffer between a fast cpu or i/o channel and storage which has a relatively slow access time (e.G., tape or diskette), to avoid slowing down the former. Cartridge receiver at tape insertion, the cartridge receiver assembly is responsible for guiding the tap...

Page 134

Glossary d data compression a process that reduces the amount of storage space required to hold a particular block of data. Data transfer speed and total tape capacity are affected by the data compression achieved. In accordance with industry practice, a typical compression ratio is 2:1 of data stor...

Page 135

Glossary e f eeprom electronically-erasable programmable read-only memory. An integrated circuit memory chip that can store programs and data in a non-volatile state. These devices, which are used to store firmware in dlt and sdlt drives, can be erased and reprogrammed with new data. Eim electronic ...

Page 136

Glossary g h gb gigabyte. A unit of measure equal to 1000 megabytes (mb) or 1,073,741,824 bytes. Gslink global storage link. This sdlt feature allows you to quickly diagnose the integrity of the drive using an infrared (wireless) communication connector located on the front panel of the tape drive. ...

Page 137

Glossary i j k l icm integrated controller module. This board is one of two boards that make up the eim. The icm contains the main controller and servo micro-processor, the custom-designed sdlt asics, and the cache memory. Iec international electrotechnical commission, an international standards org...

Page 138

Glossary m n p mb megabyte. A unit of measure equal to 1 million bytes. Metal particle (mp) tape a magnetic recording media in which a flexible base is coated with a mixture of magnetic particles and a bonding agent. Mrc heads magneto resistive cluster heads. A cluster of small, cost- effective magn...

Page 139

Glossary q r s qez an asic (application specific integrated circuit) for the sdlt. Restore to replace data on the hard drive with data obtained from another media device. San storage area network. Scsi small computer system interface. An american national standards institute (ansi) standard for the ...

Page 140

Glossary t take-up reel the reel inside every dlttape drive onto which dlttape media is wound. The in-the-drive take-up reel enables dlttape systems to operate using a single-reel cartridge and thereby pack more tape and data into every cartridge. Tapealert a firmware feature that monitors and retur...

Page 141

Glossary u x ul underwriters laboratory; a united states safety organization. Unformatted capacity the total number of usable byes on the media, including the space that will be required later to record location, boundary definitions, and timing information. (see also native capacity.) xez an asic (...

Page 142

W w w. T a n d b e r g . C o m tandberg data asa, kjelsåsv. 161, p.O. Box 134 kjelsås, n-0411 oslo, norway tel: +47 22 18 90 90. Fax: +47 22 18 95 50. Sales-no@tandberg.Com tandberg data gmbh, feldstraße 81, d-44141 dortmund, germany tel: +49 231 5436 0. Fax: +49 231 5436 111. Sales-de@tandberg.Com ...