Swingo 150e v011 / 12089-59 1624 *12089-59* ar .2 bg 14 cs .27 da .40 de .53 en .66 es .79 et .92 fi ...105 fr .118 gr 132 hr .146 hu .159 it ...172 lt ..185 lv .198 nl .211 no 224 pl ..237 pt .250 ro .263 sk .277 sl ..290 sv .303 tr .316 zh .329 ar bg cs da de en es et fi fr gr hr hu it lt lv nl no...

60 translation of the original instructions of use legend: content intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 cleaning products . . . . . . . . . . . . . . ...

61 cleaning products further documents caution: in case of malfunction or defect or after collisions or toppling over, the machine must be inspected by an authorized expert before restarting. The same applies if the machine was left outdoors, immersed in water or subjected to moisture. Caution: the ...

62 structural layout 1 handle 2 cleaning solution pump switch (on/off) (illuminat- ed) 3 suction unit motor switch (on/off) 4 main switch (on/off) 5 transport handle, front 6 tank lid unlocking 7 filter housing 8 dosing lid 9 tank lock 10 fresh water tank 11 recovery tank 12 brush pressure regulatio...

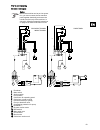

63 prior to commissioning electrical circuit diagram 1 distributor 2 main switch 3 suction switch 4 pump switch 5 cable loom for operating panel 6 cable loom, upper housing 7 pressure sensor (for pump) 8 pump or electrical valve 9 overheating protection for pump 10 distributor 11 by-pass suction mot...

64 filling the fresh water tank dosing: dosing examples: pre-cleaning attention: max. Permissible water temperature 60 °c/140 °f. Diversey recommends using cold water since hot water will adjust to the floor tem- perature as soon as it is in contact with the floor. Thus there are no advantages to th...

65 beginning work with the machine cleaning start setting the brush pressure cleaning method direct working method: scrubbing and suction in one work step. Indirect working method: applying the cleaning solution, scrubbing and suction in sev- eral work steps. Replenishing cleaning solvent attention:...

66 end of operation removing and cleaning the squeegee empty and clean the recovery tank and fresh water tank empty the recovery tank and fresh water tank • switch off the water pump. The cleaning solution supply is stopped. • allow the suction unit to run further so that the remaining water will be...

67 cleaning the recovery tank and fresh water tank wash out the motor protection filter washing out the filter housing and the float cleaning the sponge and pump protection filter cleaning / replacing the sponge filter replacing pump protection filter cleaning / replacing the brush roller replacing ...

68 cleaning the brush housing installing/replacing the brush roller cleaning the transport wheels cleaning the machine storing / parking the machine (not in operation) service, maintenance and care the maintenance of the machine is a prerequisite for impec- cable operation and a long service life. S...

69 malfunctions technical data accessories malfunction possible causes troubleshooting page machine without function no power supply • insert the plug into the mains sock- et. Machine is switched off • switch on the main switch 62 power supply cord defect • contact your service partner motor does no...

70 transport disposal machine dimensions the dimensions are in centimeters! Notice: transport the machine in upright position. Notice: make sure that the machine is lashed and secured in the transport vehicle. Notice: after withdrawal from service, the machine and accessory parts must be adequately ...