- DL manuals

- Taylor

- Freezer

- 104

- Operator's Manual

Taylor 104 Operator's Manual

Summary of 104

Page 1

Operator’s manual model 104 batch freezer original operating instructions 053064- m 8/13/08 (original publication) (updated 8/3/15).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on data plate: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e 2008 carrier ...

Page 3: Table Of Contents

Table of contents model 104 table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Site p...

Page 4

Table of contents model 104 table of contents - page 2 section 7 important: operator checklist 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . During cleaning and sanitizing 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Troubleshooting bacterial ...

Page 5: Section 1

1 model 104 to the installer 131122 section 1 to the installer the following information has been included in the manual as safety and regulatory guidelines. For complete installation instructions, please see the installation checklist. Installer safety in all areas of the world, equipment should be...

Page 6

2 to the installer model 104 130319 air cooled units do not obstruct air intake and discharge openings: air cooled units require a minimum of 3” (76 mm) of clearance around all sides of the freezer to allow for adequate air flow across the condenser(s). Failure to allow adequate clearance can reduce...

Page 7

3 model 104 to the installer 130930 60 cycle units this equipment is supplied with a 3- wire cord and grounding type plug, for connection to a single phase, 60 cycle, branch circuit supply. This unit must be plugged into a properly grounded receptacle. Permanent wiring may be employed, if required b...

Page 8: Section 2

4 to the operator model 104 131122 section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to give you dependable operation. The taylor model 104 batch ice cream freezer, when properly operated and cared for, will produce a consistent quality product. ...

Page 9: Section 3

5 model 104 safety 130319 section 3 safety we, at taylor company, are concerned about the safety of the operator at all times when they are coming in contact with the unit and its parts. Taylor makes every effort to design and manufacture built- in safety features to protect both operators and servi...

Page 10

6 safety model 104 130319 this unit is provided with an equipotential grounding lug that is to be properly attached to the rear of the frame by the authorized installer. The installation location is marked by the equipotential bonding symbol (5021 of iec 60417-1) on both the removable panel and the ...

Page 11: Section 4

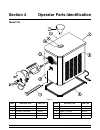

7 model 104 operator parts identification section 4 operator parts identification model 104 figure 1 item description part no. 1 funnel 034252 2 panel- side left 051039 3 cover a.- mix inlet x24948 4 panel- rear 051040 5 panel- side right 051038 item description part no. 6 gasket- base pan 049420 7 ...

Page 12

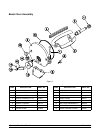

8 operator parts identification model 104 beater door assembly figure 2 item description part no. 1 seal- drive shaft 032560 2 shaft- beater 033498 3 beater assembly x33417 4 blade- scraper 7- 1/4” l 033277 5 o- ring 5- 7/16 od x 5- 1/4 033276 6 door a.- partial x37710 7 pin a.- pivot 1- 3/4 grip x3...

Page 13

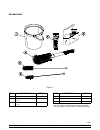

9 model 104 operator parts identification 110825 accessories figure 3 item description part no. 1 pail-6 qt 023348 2 brush-mix pump body 3” x 7 ” 023316 3 brush-rear bearing 1” x 2” 013071 item description part no. 4 brush-draw valve 1-1/2” 014753 5 lubricant-taylor 4 oz. 047518 6 sanitizer-stera sh...

Page 14: Section 5

10 important: to the operator model 104 section 5 important: to the operator figure 4 item description 1 control switch 2 orange dial light 3 timer control 4 door hinge control switch (item 1) when the control switch is placed in the auto mode and the timer is adjusted to the desired setting, the re...

Page 15

11 model 104 important: to the operator timer control (item 3) the model 104 uses a timer control to operate the compressor and determine the viscosity of the product. After the desired amount of product has been added to the freezing cylinder, turn the timer for the amount of refrigeration required...

Page 16: Section 6

12 operating procedures model 104 section 6 operating procedures the model 104 is a small 3 quart (2.9 liter) capacity ice cream freezer. It has been designed to produce a rich tasting, nominal overrun ice cream product that can be drawn off and placed in a hardening cabinet or flash freezer. Overru...

Page 17

13 model 104 operating procedures step 3 place the plastic scraper blades on the beater, making sure one end of the blade is up against the notch at the front of the beater. Figure 8 holding the beater and blades securely, slide the beater into the freezing cylinder about one- third of the way in. L...

Page 18

14 operating procedures model 104 align the hole in the draw arm over the stem on the freezer door and push down. Make sure the draw arm fits into the depression in the draw plate. Figure 13 screw the stem cap over the stem that protrudes from the draw arm. Once snug, tighten one step further to ali...

Page 19

15 model 104 operating procedures step 7 secure the freezer door hinge by installing the pivot pin. Figure 19 step 8 slide the drip pan into the hole in the front panel. Figure 20 sanitizing step 1 prepare two quarts (1.9 liters) of an approved 100 ppm sanitizing solution (example: kay- 5r or stera-...

Page 20

16 operating procedures model 104 140717 pour the sanitizing solution into the funnel and allow it to flow into the freezing cylinder. Figure 23 step 3 put the control switch into the eject position. This will cause the sanitizing solution in the freezing cylinder to be agitated. Allow it to agitate...

Page 21

17 model 104 operating procedures step 3 set the timer for the time required for the batch. Allow the unit to operate until the buzzer sounds and the refrigeration system automatically cycles off. Figure 27 step 4 place the control switch in the auto position. Remove the funnel and close the mix inl...

Page 22

18 operating procedures model 104 step 3 draw off one pint of frozen product, and with a straight edge, level off the top. Figure 31 step 4 place the pint of product on the scale and read the overrun directly off of the scale. Figure 32 step 5 if the scale does not have overrun graduations, then wei...

Page 23

19 model 104 operating procedures 140717 step 4 put the control switch into the off position. Holding a pail beneath the ejection port, open the draw arm and drain the water from the freezing cylinder. Close the draw arm. Repeat these procedures until the rinse water being drawn from the freezing cy...

Page 24

20 operating procedures model 104 step 4 thoroughly brush clean all disassembled parts in the cleaning solution, making sure all lubricant and mix film is removed. Place the cleaned parts on a clean dry surface to air dry. Step 5 return to the freezer with a small amount of cleaning solution. With t...

Page 25: Section 7

21 model 104 important: operator checklist section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The following check points s...

Page 26: Section 8

22 troubleshooting guide model 104 section 8 troubleshooting guide problem probable cause remedy page ref. 1. Poor ejection. A. Over refrigeration. A. Use less time to run the batch. - - b. Inadequate pre- charge b. Increase the pre- charge. - - c. The beater is rotating counterclockwise. C. Contact...

Page 27: Section 9

23 model 104 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 4 months every 6 months annually qty. Drive shaft seal x 1 scraper blades x minimum 2 freezer door o- ring x 1 draw plate o- ring x 1 white bristle brush, 3” x 7” inspect & replace if n...

Page 28

24 limited warranty on equipment model 104 131122 section 10 limited warranty on equipment taylor company limited warranty on freezers taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor-branded freezer equipment a...

Page 29

25 model 104 limited warranty on equipment 3. Replacement of wear items designated as class “000” parts in the taylor operator’s manual. 4. External hoses, electrical power supplies, and machine grounding. 5. Parts not supplied or designated by taylor, or damages resulting from their use. 6. Return ...

Page 30: Section 11

26 limited warranty on parts model 104 131122 section 11 limited warranty on parts taylor company limited warranty on taylor genuine parts taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor genuine replacement com...

Page 31

27 model 104 limited warranty on parts limited warranty exceptions this limited warranty does not cover: 1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new parts. 2. Normal maintenance, clean...

Page 32

28 limited warranty on parts model 104 limitation of warranty this limited warranty is exclusive and is in lieu of all other warranties, conditions and/or remedies under the law, including any implied warranties or conditions of merchantability or fitness for a particular purpose. The original owner...