- DL manuals

- Taylor

- Freezer

- 340

- Operating Instructions Manual

Taylor 340 Operating Instructions Manual

Summary of 340

Page 1

Models 340, 341, 342 slush freezers operating instructions 028764--m 1/97.

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e january, ...

Page 3: Table Of Contents

Table of contents models 340, 341, 342 table of contents ______________________________________________________________________________ section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Water connections 1 . . . . . . . . . . . . . ....

Page 4

Models 340, 341, 342 table of contents notes:.

Page 5: Section 1

1 models 340, 341, 342 to the installer 050307 section 1 to the installer this machine is designed for indoor use only. Do not install the machine in an area where a water jet could be used to clean or rinse the machine. Failure to follow this instruction may result in serious electrical shock. Wate...

Page 6: Section 2

2 models 340, 341, 342 to the operator 061211 section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to provide dependable operation. The taylor slush models 340, 341, and 342, when properly operated and cared for, will produce a consistent quality pr...

Page 7: Section 3

3 models 340, 341, 342 safety 061211 section 3 safety we at taylor are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both you and the service ...

Page 8: Section 4

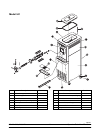

4 models 340, 341, 342 operator parts identification 020729 section 4 operator parts identification 13 11 1 2 3 5 4 6 7 8 12 9 r 10 model 340 item description part no. 1 cover a.-hopper x38458 2 gasket-hopper cover 038375 3 tube-feed 015176-9 4 skirt-air flow 049069 5 pan-drip 19-1/2 long 035034 6 t...

Page 9

5 models 340, 341, 342 operator parts identification 020729 4 1 2 3 5 6 7 4 9 9 10 11 8 12 r 12 13 14 model 341 item description part no. 1 cover a.-hopper x38458 2 gasket-hopper cover 038375 3 tube-feed 015176-9 4 panel-upper side (left/right) 024576 5 pan-drip 035034 6 tray-drip 013690 7 shield-sp...

Page 10

6 models 340, 341, 342 operator parts identification 020729 4 11 15 5 1 2 3 6 7 14 10 12 13 11 9 16 8 r model 342 item description part no. 1 cover a.-hopper x38458 2 gasket-hopper cover 038375 3 tube-feed 015176-9 4 panel-upper left side 028700 5 pan-drip 027503 6 tray-drip 014533 7 shield-splash 0...

Page 11

7 models 340, 341, 342 operator parts identification 040826 models 340, 341, 342 beater door assembly 2 1 6 7 8 9 10 11 12 13 15 16 17 3 4 5 14 18 19 item description part no. 1 door a.-partial x39248 2 handle a.-draw-slush x25124 3 valve-draw 047734 4 valve a.-handle pin x25929 5 o-ring-1 od x .139...

Page 12

8 models 340, 341, 342 operator parts identification 071017 accessories lu be r 2 3 6 4 5 7 1 8 048260 s s tera heen sanitizer & cleaner (milkstone remover) g r e e n l a b e l kay-5 sanitizer/cleaner ® caution keep out of reach of children for institutional use only 1 oz (28.4 g) 9 item description...

Page 13: Section 5

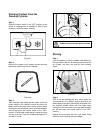

9 models 340, 341, 342 important: to the operator section 5 important: to the operator figure 1 item description 1 control switch 2 consistency control 3 indicator light -- “add mix” symbol definitions to better communicate in the international arena, the words on many of our operator switches and b...

Page 14: Section 6

10 models 340, 341, 342 operating procedures section 6 operating procedures the model 341 has been selected to illustrate the pictured step-by-step operating procedures for the models contained in this manual. Each unit has a 20 quart (18.9 liter) mix hopper and the freezing cylinder holds 7 quarts ...

Page 15

11 models 340, 341, 342 operating procedures 020807 step 3 if the blades are in good condition, install the scraper blade clip over the scraper blade. Place the rear scraper blade over the rear holding pin (knife edge to the outside). Holding the blade on the beater, turn it over and install the fro...

Page 16

12 models 340, 341, 342 operating procedures insert the draw valve into the door, leaving approximately 1/2” of the valve sticking out the top of the door. Figure 9 rotate the draw valve so the flats on the top of the draw valve are perpendicular to the door face. Figure 10 insert the ice buster thr...

Page 17

13 models 340, 341, 342 operating procedures slide the white, plastic front bearing onto the bearing hub, making certain that the flanged end of the bearing is resting against the freezer door. Do not lubricate the door gasket or front bearing. Figure 14 step 6 install the freezer door. Place the fr...

Page 18

14 models 340, 341, 342 operating procedures 071017 step 10 lay the hopper gasket and feed tube in the bottom of the mix hopper. Figure 19 step 11 (optional rack assembly) complete the assembly by inserting the flavor bottles into the rack assembly on the front of the machine. Figure 20 sanitizing s...

Page 19

15 models 340, 341, 342 operating procedures step 5 place an empty mix pail beneath the door spout and move the draw handle to the right. Draw off all the sanitizing solution. When the sanitizer stops flowing from the door spout, move the draw handle to the left and place the control switch in the “...

Page 20

16 models 340, 341, 342 operating procedures step 3 place the control switch in the “auto” position. When the unit cycles off, the product will be at serving viscosity. Figure 28 step 4 place the hopper cover into position. Figure 29 step 5 (optional flavor rack assembly) to make a refreshing slush ...

Page 21

17 models 340, 341, 342 operating procedures draining product from the freezing cylinder step 1 place the control switch in the “off” position as far ahead of cleaning time as possible to allow frozen product to soften for easier cleaning. Figure 31 step 2 remove the hopper cover, gasket, and air tu...

Page 22

18 models 340, 341, 342 operating procedures 071017 cleaning step 1 prepare two gallons (7.6 liters) of an approved clean- ing solution (examples: stera--sheenr or kay-5r). Use warm water and follow the manufac- turer’s specifications. Step 2 pour the two gallons (7.6 liters) of cleaning solution in...

Page 23

19 models 340, 341, 342 operating procedures 071017 disassembly make sure control switch is in the “off” position. Failure to do so may cause injury from electrocution or hazardous moving parts . Step 1 remove the torque arm, handscrews, freezer door, torque rotor, beater assembly, scraper blades, a...

Page 24: Section 7

20 models 340, 341, 342 important: operator checklist 051214 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The follow...

Page 25

21 models 340, 341, 342 important: operator checklist winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is subject to freezing conditions. Disconnect the freezer from...

Page 26: Section 8

22 models 340, 341, 342 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product is being dispensed with the draw valve opened. A. Improper mixing of product. A. Carefully follow the directions for mixing the product. -- -- b. There is a mix low con...

Page 27

23 models 340, 341, 342 troubleshooting guide problem probable cause remedy page ref. 4. The walls of the freezing cylinder are scored. A. Broken beater pins. A. Repair or replace the beater assembly. -- -- b. The gear unit is out of alignment. B. Contact service technician. -- -- c. The beater asse...

Page 28

24 models 340, 341, 342 troubleshooting guide problem probable cause remedy page ref. 9. The guide bearing is missing. A. The guide bearing is stuck in the drive shaft. A. Remove the guide bearing from the hole in the drive shaft. -- -- 10. There is excessive leakage from the door spout. A. There is...

Page 29: Section 9

25 models 340, 341, 342 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually qty. Drive shaft o-ring x 1* drive shaft seal x 1* scraper blade inspect & replace if necessary minimum 2* torque rotor o-ring x 1* guide bearing x 1* freez...

Page 30: Section 10

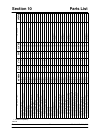

Section 10 parts list + available separately 26 parts list models 340, 341, 342 020729 de s cri p t io n part num be r 340 qty . 341 qty . 342 qty . W arr. Cl as s re m arks part s up da t e ad apt o r a. --c aster x 18915 4 4 103 a r m a .-- a nt ic ip a tor m e cha ni ca l x 29556 1 1 2 103 a r m ...

Page 31

27 + available separately models 340, 341, 342 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r + r el a y --st ar t --c o m pr esso r 048765 1 1 2 103 208/ 230- 60- 1 + c a p a c it o r --r u n -- 20u f /370v 023606 1 2 103 115- 60- ...

Page 32

+ available separately 28 parts list models 340, 341, 342 de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r hood 023263 1 103 hub --5 /8 b ore s p li t 027815 1 1 2 103 g ear pu ll e y k it a .-- t une up *s lu s h * x 39969 1 1 2 000 bear in g -...

Page 33

29 + available separately models 340, 341, 342 parts list 071015 de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r pa n e l a .-- s id e x 44855 1 103 pa n e l a .-- s id e lo w e r x 24397 2 103 p an el --r ear 013637 1 103 p a n e l- -r e a r *...

Page 34

+ available separately 30 parts list models 340, 341, 342 040823 de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r s p r in g --e x t e n s io n .375x .025x 2. 25 029310 1 1 2 103 spr in g --t o r q u e* bl u e * 029259 1 1 2 103 spr in g --t o r...

Page 35

31 + available separately models 340, 341, 342 parts list 040823 de s cri p t io n part num be r 340 qty . 341 qty . 342 qty . W arr. Cl as s re m arks part s up da t e w a ter c ooled accum ul a to r --co pper 2” di a 10 ”l g 047062 1 1 2 103 bl o w er --1 00 c f m 012796 -- 1 1 103 br ac ket --m o...

Page 36

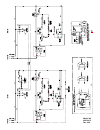

Models 340/341 049359 rev. 3/06.

Page 37

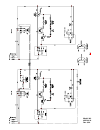

Model 341 049359--33 rev. 3/06.

Page 38

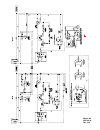

Model 340/341 049359--40 rev. 3/06.

Page 39

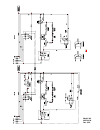

Model 341 049359--58 rev. 3/06.

Page 40

Model 342 052720--27 rev. 3/06.

Page 41

Model 342 052720--33 rev. 3/06.

Page 42

Model 342 052720--40 rev. 3/06.

Page 43

Model 342 052720--58 rev. 3/06.