- DL manuals

- Taylor

- Freezer

- 340

- Original operating instructions

Taylor 340 Original operating instructions

Summary of 340

Page 1

Models 340, 341, 342 remote auto fill slush freezers original operating instructions 028764rf 1/97 (original publication) (updated 7/13/11).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e january, ...

Page 3: Table Of Contents

Table of contents models 340, 341, 342 table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

Models 340, 341, 342 table of contents table of contents -- page 2 section 7 important: operator checklist 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . During cleaning and sanitizing 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Troubleshootin...

Page 5: Section 1

1 models 340, 341, 342 to the installer 110105 section 1 to the installer the following are general installation instructions. For complete installation details, please see the checkout card. Installer safety in all areas of the world, equipment should be installed in accordance with existing local ...

Page 6

2 models 340, 341, 342 to the installer 110105 water connections (water cooled units only) an adequate cold water supply with a hand shut-off valve must be provided. On the underside of the base pan, two 3/8” i.P.S. (for single-head units) or two 1/2” i.P.S. (for double-head units) water connections...

Page 7

3 models 340, 341, 342 to the installer 110105 s stationary appliances which are not equipped with a power cord and a plug or another device to disconnect the appliance from the power source must have an all-pole disconnecting device with a contact gap of at least 3 mm installed in the external inst...

Page 8: Section 2

4 models 340, 341, 342 to the operator 110105 section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to provide dependable operation. The taylor slush models 340, 341, and 342, when properly operated and cared for, will produce a consistent quality pr...

Page 9: Section 3

5 models 340, 341, 342 safety 110413 section 3 safety we, at taylor company, are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both you and th...

Page 10

6 models 340, 341, 342 safety 110105 s do not allow untrained personnel to operate this machine. S do not operate the freezer unless all service panels and access doors are restrained with screws. S do not remove any internal operating parts (examples: freezer door, beater, scraper blades, etc.) unl...

Page 11: Section 4

7 models 340, 341, 342 operator parts identification 091102 section 4 operator parts identification model 340 item description part no. 1 cover a.-hopper x38458 2 gasket-hopper cover 038375 3 tube-feed 015176-9 4 panel-rear 047008 5 louver-side top 051192 6 panel-right side 047007 7 leg-4” 013458 it...

Page 12

8 models 340, 341, 342 operator parts identification 091102 model 341 item description part no. 1 cover a.-hopper x38458 2 gasket-hopper cover 038375 3 tube-feed 015176-9 4 louver-side--top 051192 5 panel-upper side (left/right) 024576 6 panel-rear 013637 7 panel a.-lower side (left/right) x24397 8 ...

Page 13

9 models 340, 341, 342 operator parts identification 091102 model 342 item description part no. 1 cover a.-hopper x38458 2 gasket-hopper cover 038375 3 tube-feed 015176-9 4 louver-side top 051191 5 panel-upper right side 028701 6 panel-rear 017563 7 panel a.-lower right side x44855 *8 trim--rear cor...

Page 14

10 models 340, 341, 342 operator parts identification 091102 models 340, 341, 342 beater door assembly item description part no. 1 door a.-partial x39248-ser 2 handle a.-draw-slush blk x47384 3 valve-draw 047734 4 pin a.-valve handle x25929 5 o-ring-1 od x .139 w 032504 6 buster-ice 047735 7 o-ring-...

Page 15

11 models 340, 341, 342 operator parts identification 110620 accessories item description part no. 1 kit a.-tune up x39969 2 brush-rear bearing 013071 3 brush-double ended 013072 4 brush-mix pump body 023316 5 lubricant-taylor lube 047518 6 brush-draw valve 013073 item description part no. 7 cap-res...

Page 16: Section 5

12 models 340, 341, 342 important: to the operator section 5 important: to the operator figure 1 item description 1 control switch 2 consistency control 3 indicator light -- “add mix” symbol definitions to better communicate in the international arena, the words on many of our operator switches and ...

Page 17: Section 6

13 models 340, 341, 342 operating procedures section 6 operating procedures the model 341 has been selected to illustrate the pictured step-by-step operating procedures for the models contained in this manual. Each unit has a 20 quart (18.9 liter) mix hopper and the freezing cylinder holds 7 quarts ...

Page 18

14 models 340, 341, 342 operating procedures 020807 step 3 if the blades are in good condition, install the scraper blade clip over the scraper blade. Place the rear scraper blade over the rear holding pin (knife edge to the outside). Holding the blade on the beater, turn it over and install the fro...

Page 19

15 models 340, 341, 342 operating procedures insert the draw valve into the door, leaving approximately 1/2” of the valve sticking out the top of the door. Figure 9 rotate the draw valve so the flats on the top of the draw valve are perpendicular to the door face. Figure 10 insert the ice buster thr...

Page 20

16 models 340, 341, 342 operating procedures slide the white, plastic front bearing onto the bearing hub, making certain that the flanged end of the bearing is resting against the freezer door. Do not lubricate the door gasket or front bearing. Figure 14 step 6 install the freezer door. Place the fr...

Page 21

17 models 340, 341, 342 operating procedures 080602 step 10 lay the hopper gasket and feed tube in the bottom of the mix hopper. Figure 19 step 11 (optional rack assembly) complete the assembly by inserting the flavor bottles into the rack assembly on the front of the machine. Figure 20 sanitizing s...

Page 22

18 models 340, 341, 342 operating procedures step 5 place an empty mix pail beneath the door spout and move the draw handle to the right. Draw off all the sanitizing solution. When the sanitizer stops flowing from the door spout, move the draw handle to the left and place the control switch in the “...

Page 23

19 models 340, 341, 342 operating procedures 110713 figure 28 step 4 place the hopper cover into position. Figure 29 step 5 (optional flavor rack assembly) to make a refreshing slush product, add the desired flavor to the bottom of the cup by pressing the pump handle of the flavor bottle. Move the d...

Page 24

20 models 340, 341, 342 operating procedures 110620 draining product from the freezing cylinder step 1 place the control switch in the “off” position as far ahead of cleaning time as possible to allow frozen product to soften for easier cleaning. Figure 31 step 2 remove the hopper cover, gasket, and...

Page 25

21 models 340, 341, 342 operating procedures 080602 cleaning step 1 prepare an approved 100 ppm cleaning solution (examples: 2--1/2 gal. [9.5 liters] of kay--5r or 2 gal. [7.6 liters] of stera--sheenr). Use warm wa- ter and follow the manufacturer’s specifications. Step 2 pour the cleaning solution ...

Page 26

22 models 340, 341, 342 operating procedures 071017 disassembly make sure control switch is in the “off” position. Failure to do so may cause injury from electrocution or hazardous moving parts . Step 1 remove the torque arm, handscrews, freezer door, torque rotor, beater assembly, scraper blades, a...

Page 27: Section 7

23 models 340, 341, 342 important: operator checklist 110620 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The follow...

Page 28

24 models 340, 341, 342 important: operator checklist 080213 winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is subject to freezing conditions. Disconnect the freez...

Page 29: Section 8

25 models 340, 341, 342 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product is being dispensed with the draw valve opened. A. Improper mixing of product. A. Carefully follow the directions for mixing the product. -- -- b. There is a mix low con...

Page 30

26 models 340, 341, 342 troubleshooting guide problem probable cause remedy page ref. 4. The walls of the freezing cylinder are scored. A. Broken beater pins. A. Repair or replace the beater assembly. -- -- b. The gear unit is out of alignment. B. Contact service technician. -- -- c. The beater asse...

Page 31

27 models 340, 341, 342 troubleshooting guide problem probable cause remedy page ref. 9. The guide bearing is missing. A. The guide bearing is stuck in the drive shaft. A. Remove the guide bearing from the hole in the drive shaft. -- -- 10. There is excessive leakage from the door spout. A. There is...

Page 32: Section 9

28 models 340, 341, 342 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually qty. Drive shaft o-ring x 1* drive shaft seal x 1* scraper blade inspect & replace if necessary minimum 2* torque rotor o-ring x 1* guide bearing x 1* freez...

Page 33: Section 10

Section 10 parts list 29 + available separately models 340, 341, 342 parts list 081113 hp 62 340 & 341 j51 13655/ up ,342 j5092092/ up , copeland com p ressor - 340- j9026004 (230- 60- 1) , 340- j9073064 (230- 50- 1) , 341- j90112199/ up, 342- j8071822/ up de s cri p t io n part num be r 340 qty . 3...

Page 34

+ available separately 30 parts list models 340, 341, 342 de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r boot- c apaci t or in sulati ng 031314 1 1 000 capaci t or- run- 10 uf/ 370v 033047 1 1 103 m o to r- blo w er- 208/ 230v 50/ 60 046536- 2...

Page 35

31 + available separately models 340, 341, 342 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r +capaci t or- run 15uf/ 370v 027087 1 1 1 103 115v 60hz 1 ph - 0341( b/ x) 000 h8109393- j4113102 +capaci t or- s tart 340- 408uf/ 165v 04...

Page 36

+ available separately 32 parts list models 340, 341, 342 de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r decal- dec- taylor 021872 1 1 1 000 340 & 341 - p ri o r to j7010000 decal- troubleshooti n g 038374 1 1 1 000 deflector- blow er- exhaust...

Page 37

33 + available separately models 340, 341, 342 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r hub- 5 /8 bore spli t 027815 1 1 2 103 gear pulley - use w / o ld style 010840 pulley knob- a dj ustment 014499 1 1 2 103 +screw -adj u st...

Page 38

+ available separately 34 parts list models 340, 341, 342 de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r panel a. -s id e l ow er x24397- ser 2 1 panel- r ear 013637 1 103 panel- servi ce *341* 013638- sp1 1 103 panel- u pper si de *410- 15* 0...

Page 39

35 + available separately models 340, 341, 342 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r solenoi d -p ull 030202- 12 1 1 2 103 115v solenoi d -p ull 030202- 27 1 1 2 103 230v spri n g -extensi o n .375x. 025x2. 25 029310 1 1 2 ...

Page 40

+ available separately 36 parts list models 340, 341, 342 de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r w a te r c oole d accumulator- c opper 2" di a 10" lg 047062 1 1 2 103 blow er- 100 cfm 012796- 1 1 103 +guard- blow er 022505 1 1 103 bra...

Page 41

37 + available separately models 340, 341, 342 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r compressor r s80c1e- tfd- 224 (c opeland) 051958- 58 1 1 2 512 380- 415v 50hz 3 n di ag ram -w iri ng *340- 341- 342* 049359- 40 1 1 000 2...

Page 42

+ available separately 38 parts list models 340, 341, 342 de s cri p t io n part s up da t e re m arks w arr. Cl as s 342 qty . 341 qty . 340 qty . Part num be r pulley- ak64- 5/ 8 007538 1 1 2 103 gear pulley- ak34- 5/ 8 016055 1 1 2 103 mot o r shi e ld- s w itch *445* 024175 1 2 starter- 1 p hase...

Page 43

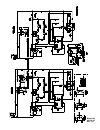

Models 340/341 049361 rev. 7/11.

Page 44

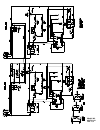

Model 342 052721--27 rev. 7/11.

Page 45

Model 342 052721--33 rev. 7/11.