- DL manuals

- Taylor

- Freezer

- 702

- Operating Instructions Manual

Taylor 702 Operating Instructions Manual

Summary of 702

Page 1

Models 702/741/772 soft serve freezers operating instructions 028759-m 6/97 (original publication) (updated 6/15/11).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e june, 199...

Page 3: Table Of Contents

Table of contents models 702/741/772 table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

Models 702/741/772 table of contents table of contents -- page 2 priming 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Closing procedure 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5: Section 1

1 models 702/741/772 to the installer 110616 section 1 to the installer the following are general installation instructions. For complete installation details, please see the checkout card. Installer safety in all areas of the world, equipment should be installed in accordance with existing local co...

Page 6

2 to the installer models 702/741/772 110616 air cooled units do not obstruct air intake and discharge openings: the model 702 requires a minimum of 6” (152 mm) of clearance around both sides of the freezer. Install the deflector on the right side of the unit and place the back of the unit against t...

Page 7

3 models 702/741/772 to the installer 110616 s stationary appliances which are not equipped with a power cord and a plug or another device to disconnect the appliance from the power source must have an all-pole disconnecting device with a contact gap of at least 3 mm installed in the external instal...

Page 8

4 to the installer models 702/741/772 110616 refrigerant in consideration of our environment, taylor proudly uses only earth friendly hfc refrigerants. The hfc refrigerant used in this unit is r404a. This refrigerant is generally considered non-toxic and non-flammable, with an ozone depleting potent...

Page 9: Section 2

5 models 702/741/772 to the operator 110616 section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to give you dependable operation. The taylor freezer, when properly operated and cared for, will produce a consistent quality product. Like all mechanic...

Page 10: Section 3

6 safety models 702/741/772 110616 section 3 safety we, at taylor company, are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built--in safety features to protect both the operato...

Page 11

7 models 702/741/772 safety 110616 s do not allow untrained personnel to operate this machine. S do not operate the freezer unless all service panels and access doors are restrained with screws. S do not remove any internal operating parts (examples: freezer door, beater, scraper blades, etc.) unles...

Page 12: Section 4

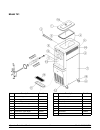

8 operator parts identification models 702/741/772 section 4 operator parts identification model 702 item description part no. 1 cover a.-hopper x38458 1a knob-hopper cover 025429 2 tube-feed-ss-5/32 hole 028967-2 3 panel-rear 047008 4 panel-side 702 right 050928 5 pan-drip 13-1/4 long 039027 6 pane...

Page 13

9 models 702/741/772 operator parts identification model 702 door assembly item description part no. 1 seal-drive shaft 032560 2 shaft-beater 033498 3 beater a.-4 qt.-1 pin support x49490 4 bearing-front 013116 5 gasket-door 5.177 id x 5.9380 016672 6 decal-lift plate front 015200 7 valve a.-draw x1...

Page 14

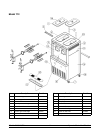

10 operator parts identification models 702/741/772 model 741 item description part no. 1 cover a.-hopper-standard x38458 1a knob-hopper cover 025429 2 gasket-hopper cover-20 qt. 038375 3 pan-drip - 11-5/8 long 027503 4 tube-feed-ss 028967-3 5 panel-rear 013637 6 panel-side- upper right 028707 7 pan...

Page 15

11 models 702/741/772 operator parts identification model 772 item description part no. 1 cover a.-hopper-insulated x39291 1a knob-hopper cover 025429 2 stud-nose cone 022822 3 pan-drip 11-5/8 long 027503 4 tube-feed-ss 028967-3 5 louver-side 017471 6 panel-upper side right 028701 7 caster-swivel-5/...

Page 16

12 operator parts identification models 702/741/772 models 741 & 772 door assembly item description part no. 1 seal-drive shaft 032560 2 shaft-beater 033498 3 beater a.-7 qt.-1 pin support x46233 4 bearing-front 013116 5 gasket-door 5.177 id x 5.9380 016672 6 decal-lift plate front 015200 7 valve a....

Page 17: Section 5

13 models 702/741/772 important: to the operator section 5 important: to the operator indicator light “mix low” the models 702, 741, and 772 are equipped with a “mix low” light located on the front of the machine. When the light begins to flash, it indicates that the mix hopper has a low supply of m...

Page 18

14 important: to the operator models 702/741/772 080324 thermistor control the viscosity (thickness) of the product is controlled by a temperature sensing device called the thermistor. To achieve a thicker product, turn the control clockwise, and turn the control counterclockwise to achieve a thinne...

Page 19: Section 6

15 models 702/741/772 operating procedures section 6 operating procedures the model 702 has been selected to show you the pictured step-by-step operating procedures for all models contained in this manual. These models, for practical purposes of operation, are the same. They all store 20 quarts (18....

Page 20

16 operating procedures models 702/741/772 note: to prevent costly damage, the hole in the scraper blade must fit securely over the pin. If the blades are in good condition, place the rear scraper blade over the rear holding pin on the beater, knife edge to the outside. Holding the rear blade on the...

Page 21

17 models 702/741/772 operating procedures 110616 rotate the draw valve bracket to the left. Center it into position by raising the draw arm and placing it into the slotted groove of the draw valve bracket. Figure 13 step 5 snap the design cap over the end of the door spout. Figure 14 step 6 lay the...

Page 22

18 operating procedures models 702/741/772 step 3 while the solution is flowing into the freezing cylinder, brush clean the hopper. While cleaning the mix hopper, take particular care in brushing the mix level sensing probe on the rear wall of the hopper, the mix inlet hole, the hopper gasket, and t...

Page 23

19 models 702/741/772 operating procedures priming prime the machine as close to the time of first product draw as possible. Step 1 place a mix pail beneath the door spout and raise the draw arm. Pour two gallons (7.6 liters) of fresh mix into the hopper and allow it to flow down into the freezing c...

Page 24

20 operating procedures models 702/741/772 110616 draining product from the freezing cylinder step 1 place the control switch in the “off” position. Step 2 remove the hopper cover, the hopper gasket, and the mix feed tube. Take these parts to the sink for cleaning. Step 3 if local health codes permi...

Page 25

21 models 702/741/772 operating procedures 080324 repeat these steps for the second freezing cylinder on the model 772. Step 4 remove the front drip tray and the splash shield. Brush cleaning step 1 prepare a sink with an approved cleaning solution (ex- amples: kay-5r or stera--sheenr). Use warm wat...

Page 26: Section 7

22 important: operator checklist models 702/741/772 110616 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by federal, state, or local regulatory agencies, and must be followed accordingly. If the...

Page 27

23 models 702/741/772 important: operator checklist 080324 j 6. Dispose of o-rings and seals if they are worn, torn, or fit too loosely, and replace with new ones. J 7. Follow all lubricating procedures as outlined in “assembly”. J 8. Check the condensers for accumulation of dirt and lint. Dirty con...

Page 28: Section 8

24 troubleshooting guide models 702/741/772 section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product being dispensed with the draw valve open and the control switch in auto. A. The freezer door is installed upside down. A. Install the door correctly. 16 b. There is a fre...

Page 29

25 models 702/741/772 troubleshooting guide problem probable cause remedy page ref. 3. The product appears too soft. (cont’d.) h. Product is broken down from overbeating. H. Draw off some product to allow fresh product to enter the freezing cylinder. -- -- 4. The mix in the hopper is too cold. A. Th...

Page 30

26 troubleshooting guide models 702/741/772 problem probable cause remedy page ref. 8. Excessive mix leakage into the rear drip pan. (cont’d.) d. The drive shaft works forward. D. Call service technician to correct. -- -- e. The seal is installed inside-out on the drive shaft. E. Install correctly. ...

Page 31: Section 9

27 models 702/741/772 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 4 months every 6 months annually scraper blade x drive shaft seal x drive shaft o-ring x freezer door gasket x front bearing x draw valve o-ring x white bristle brush, 3” x 7” ...

Page 32: Section 10

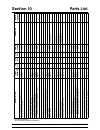

Section 10 parts list + available separately shr (separate hopper refrigeration) 28 parts list models 702/741/772 de s cri p t io n part num be r 702 qty . 741 qty . 772 qty . W arr. Cl as s re m arks part s up da t e accumula tor --copper 2” di a 10” 047602 1 103 adapt or a. --caster x18915 4 4 103...

Page 33

29 + available separately shr (separate hopper refrigeration) models 702/741/772 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 772 qty . 741 qty . 702 qty . Part num be r com p ressor l63b562bbcb b ri st ol 048727 --27e 1 s/ n k 5010000 & u p +cap aci to r --run 30uf/ 370v 0...

Page 34

+ available separately shr (separate hopper refrigeration) 30 parts list models 702/741/772 de s cri p t io n part s up da t e re m arks w arr. Cl as s 772 qty . 741 qty . 702 qty . Part num be r +knob --a lumi num 027422 1 1 2 103 cover a. --hopper --std x38458 --ser 1 1 103 includes k nob knob --m...

Page 35

31 + available separately shr (separate hopper refrigeration) models 702/741/772 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 772 qty . 741 qty . 702 qty . Part num be r hood 023285 1 103 hood 023263 1 103 ki t a .-- m ot or --f a n x62253 --27 1 1 1 103 ki t a .-- t une up...

Page 36

+ available separately shr (separate hopper refrigeration) 32 parts list models 702/741/772 de s cri p t io n part s up da t e re m arks w arr. Cl as s 772 qty . 741 qty . 702 qty . Part num be r louver --si de 051 191 2 103 017471 lubri c ant --t ay lor 4 oz. 047518 1 1 1 000 man --o per 700 dual m...

Page 37

33 + available separately shr (separate hopper refrigeration) models 702/741/772 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 772 qty . 741 qty . 702 qty . Part num be r pla t e --d ec --si ngle --rocker sw it ch 022604 1 1 103 pla t e --d ec --tw in --rocker sw it ch 02260...

Page 38

+ available separately shr (separate hopper refrigeration) 34 parts list models 702/741/772 de s cri p t io n part s up da t e re m arks w arr. Cl as s 772 qty . 741 qty . 702 qty . Part num be r sw it ch a. --dra w *632 --710 --31 --41 -- x51242 --ser 1 2 103 arm a .-- dra w val ve x28874 1 2 103 b...

Page 39

35 + available separately shr (separate hopper refrigeration) models 702/741/772 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 772 qty . 741 qty . 702 qty . Part num be r va lv e --a ccess --1/ 4m fl x 3/ 8o d s 053565 2 103 s/ n k 1060000 & u p replaces 043232 va lv e --a c...

Page 40

+ available separately shr (separate hopper refrigeration) 36 parts list models 702/741/772 de s cri p t io n part s up da t e re m arks w arr. Cl as s 772 qty . 741 qty . 702 qty . Part num be r 50hz bel t --ax46 023027 2 000 bel t --ax38 023873 2 000 replaces 023874 -- effecti v e 5/ 17/ 98 bel t ...

Page 41

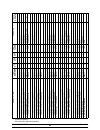

Model 702 063149--27 6/15/11.

Page 42

Model 702 063149--33 6/15/11.

Page 43

Model 741 063287--27 6/15/11.

Page 44

Model 741 063287--33 6/15/11.

Page 45

Model 741 063287--40 6/15/11.

Page 46

Model 772 063357--27 6/15/11.

Page 47

Model 772 063357--33 6/15/11.