- DL manuals

- Taylor

- Freezer

- 8756

- Operator's Manual

Taylor 8756 Operator's Manual

Summary of 8756

Page 1

Operator's manual model 8756 single stage pump soft serve freezer original operating instructions 069071-m 11/15/10 (original publication) (updated 8/14/14).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: fax: e-mail: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: ...

Page 3: Table Of Contents

Model 8756 table of contents table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Site ...

Page 4

Table of contents model 8756 table of contents - page 2 closing procedure 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Draining product from the freezing cylinder 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rinsing 30 . ....

Page 5: Section 1

1 model 8756 to the installer 131220 section 1 to the installer the following information has been included in the manual as safety and regulatory guidelines. For complete installation instructions, please see the installation checklist. Installer safety in all areas of the world, equipment should b...

Page 6

2 model 8756 to the installer water connections (water cooled units only) an adequate cold water supply must be provided with a hand shut-off valve. On the underside of the base pan, two 3/8” i.P.S. (for single-head units) or two 1/2” i.P.S. (for double-head units) water connections for inlet and ou...

Page 7

3 model 8756 to the installer 131220 s supply cords used with this unit shall be oil-resistant, sheathed flexible cable not lighter than ordinary polychloroprene or oth- er equivalent synthetic elastomer-sheathed cord (code designation 60245 iec 57) in- stalled with the proper cord anchorage to reli...

Page 8: Section 2

4 model 8756 to the operator 131220 section 2 to the operator the unit you have purchased has been carefully engineered and manufactured to give you dependable operation. This unit, when properly operated and cared for, will produce a consistent quality product. Like all mechanical products, it will...

Page 9: Section 3

5 model 8756 safety 131220 section 3 safety we, at taylor company, are concerned about the safety of the operator at all times when they are coming in contact with the unit and its parts. Taylor makes every effort to design and manufacture built-in safety features to protect both operators and servi...

Page 10

6 model 8756 safety 131220 do not use a water jet to clean or rinse the unit. Failure to follow these instructions may result in serious electrical shock. S do not allow untrained personnel to operate this unit. S do not operate the unit unless all service panels and access doors are restrained with...

Page 11: Notes

7 model 8756 safety notes :.

Page 12: Section 4

8 model 8756 operator parts identification section 4 operator parts identification figure 1.

Page 13

9 model 8756 operator parts identification 8756 parts identification item description part no. 1 panel a.-front x22879 2 stud-nose cone 068410 3 bolt-carriage 012347 4 panel a.-lower side (r & l) x23956 5 panel-upper side left 028599 6 hood 048526 7 panel-upper rear 022015 8 panel-lower rear 023598 ...

Page 14

10 model 8756 operator parts identification beater door assembly figure 2 item description part no. 1 handle a.-draw adj x55096 1a handle-adjustable 028804 1b screw-adjustment 055092 1c o-ring-1/4 od x .070w 50 015872 1d nut-5/16-24 finished hex 029639-blk 2 rod a.-pivot-short x22388 3 o-ring-3/8 od...

Page 15

11 model 8756 operator parts identification air/mix pump assembly item description part no. 1 cap-pump 021276-9 2 pin-retaining 021276-8 *3 pump a.-soft serve complete x22345 3a cylinder a.-pump 022345-1 3b pin-retaining 021276-8 3c piston 021276-2 3d ring-check 2” od x 1/2 020050 3e o-ring 2-1/8 od...

Page 16

12 model 8756 operator parts identification 140814 accessories figure 4 item description part no. 1 brush-mix pump body 023316 2 brush-pressure switch 027647 3 brush set-lvb 050103 4 brush-feed tube 021101 5 brush-double ended 013072 6 brush-rear bearing 013071 item description part no. 7 brush-draw...

Page 17: Section 5

13 model 8756 important: to the operator section 5 important: to the operator figure 5 item description 1 power switch (toggle) 2 reset switch 3 mix refrigeration control 4 standby key 5 wash key item description 6 auto key 7 pump key 8 mix low indicator 9 mix out indicator.

Page 18

14 model 8756 important: to the operator symbol definitions to better communicate in the international arena, the words on many of our operator switches and buttons have symbols to indicate their functions. Your taylor equipment is designed with these international symbols. = auto = on = off = mix r...

Page 19

15 model 8756 important: to the operator wash when the wash key is pressed, the light comes on, indicating beater motor operation. The standby or auto modes must be cancelled first to activate the wash mode. Auto when the auto key is pressed, the light comes on, indicating the main refrigeration sys...

Page 20: Section 6

16 model 8756 operating procedures section 6 operating procedures the model 8756 has two freezing cylinders. The size of each freezing cylinder is 3.4 quarts (3.2 liters). Mix is stored in the lower front refrigerated compartment and is pumped up to the freezing cylinder by an air/mix pump. Duplicat...

Page 21

17 model 8756 operating procedures step 2 install the drive shaft through the rear shell bearing in the freezing cylinder and engage the hex end firmly into the gear box coupling. Be sure the drive shaft fits into the drive coupling without binding. Figure 8 step 3 check the scraper blades for any n...

Page 22

18 model 8756 operating procedures step 6 place the large rubber gaskets in the grooves on the back side of the freezer door. Figure 12 step 7 slide the white plastic front bearings over the baffle rods. Make certain that the flanged end of the bearing is resting against the freezer door. Do not lub...

Page 23

19 model 8756 operating procedures step 11 with the door seated on the freezer studs, install the short handscrews on the bottom and the long handscrews on the top. Tighten the handscrews equally in a criss-cross pattern until the door is snug. Figure 17 step 12 slide the two o-rings into the groove...

Page 24

20 model 8756 operating procedures step 15 slide the fork of each draw handle into the slot of the draw valves, starting from the right. Slide the long pivot pin through the right and middle draw handles. Secure the left draw handle with the short pivot pin. Figure 21 note: this unit features adjust...

Page 25

21 model 8756 operating procedures air/mix pump assembly this model 8756 uses a single-stage pump. The purpose of the pump is to transfer specific amounts of air and mix to the freezing cylinder. Step 1 assemble the piston by sliding the check band and the o-ring into the grooves on the piston. Do n...

Page 26

22 model 8756 operating procedures step 5 insert the piston, air orifice end first, into the pump body and push upward. Figure 30 note: the drive hole in the piston must be visible through the hole in the pump body. Figure 31 step 6 slide the two check bands and the two o-rings into the grooves on t...

Page 27

23 model 8756 operating procedures step 8 slide the o-ring into the groove on the mix inlet fitting and lubricate the o-ring. Figure 34 step 9 insert the mix inlet fitting into the hole in the base of the liquid valve body. Figure 35 step 10 secure the pump parts in position by sliding the keeper pi...

Page 28

24 model 8756 operating procedures step 12 to secure the air/mix pump, place the pump collar over the pump body. (the cross holes of the pump collar will be on top.) figure 38 align the drive hole in the piston to the ball crank of the motor reducer. At the same time, align the locating pin on the f...

Page 29

25 model 8756 operating procedures sanitizing step 1 prepare a pail of approved 100 ppm sanitizing solu- tion (examples: 2-1/2 gal. [9.5 liters] of kay-5r or 2 gal. [7.6 liters] of stera-sheenr). Use warm water and follow the manufacturer's specifications. Step 2 place the pail of sanitizing solutio...

Page 30

26 model 8756 operating procedures step 8 press the pump key. A light will illuminate, indicating that the air/mix pump is operating. This action will cause the sanitizing solution to be pumped through the air/mix pump and out through the pressure line. After approximately 15 seconds, press the pump...

Page 31

27 model 8756 operating procedures step 12 when a steady stream of sanitizing solution is flowing from the prime plug hole in the bottom of the freezer door, press the pump key. This will de-activate pump operation. Push down the prime plug and allow the beater to agitate for 5 minutes. Figure 51 st...

Page 32

28 model 8756 operating procedures priming step 1 place the mix tank and the cover in the mix cabinet. Step 2 insert the prongs of the mix probe inside the mix tank. Connect the mix probe in the socket receptacle. Figure 54 step 3 place the free end of the suction line into the mix tank. Figure 55 s...

Page 33

29 model 8756 operating procedures step 7 when a steady stream of mix is flowing from the prime plug hole in the bottom of the freezer door, press the pump key to stop operation. Figure 58 step 8 once the stream of mix stops flowing from the prime plug hole, push down the prime plug. Rinse the prime...

Page 34

30 model 8756 operating procedures draining product from the freezing cylinder step 1 press the auto and mix ref keys to cancel freezer operation. Step 2 open the mix cabinet door and remove the mix storage cover, the mix tank cover, the mix tank, and the mix probe. Step 3 if local health codes perm...

Page 35

31 model 8756 operating procedures step 5 place an empty pail beneath the door spout. Raise the prime plug and press the wash and pump keys. Figure 62 step 6 when a steady stream of rinse water is flowing from the prime plug hole in the bottom of the freezer door, open the draw valve and drain all t...

Page 36

32 model 8756 operating procedures step 6 place an empty pail beneath the door spout. Raise the prime plug and press the wash and pump keys. Figure 66 step 7 when a steady stream of solution is flowing from the prime plug hole in the bottom of the freezer door, open the draw valve and draw off the r...

Page 37

33 model 8756 operating procedures brush cleaning step 1 prepare a sink with an approved cleaning solution (examples: kay-5r or stera-sheenr). Use warm water and follow the manufacturer's specifications. If an approved cleaner other than kay-5r or sterar-sheen is used, dilute it according to the lab...

Page 38: Section 7

34 model 8756 important: operator checklist section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by federal, state, or local regulatory agencies, and must be followed accordingly. If the unit has a “st...

Page 39

35 model 8756 important: operator checklist j 7. If your machine is air cooled, check the condensers for accumulation of dirt and lint. Dirty condensers will reduce the efficiency and capacity of the machine. Condensers should be cleaned monthly with a soft brush. Never use screwdrivers or other met...

Page 40: Section 8

36 model 8756 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product is being dispensed. A. Low on mix. The mix out light is on. A. Add mix to the mix tank and press the auto key. 28 b. The power switch is in the off position. B. Place the power s...

Page 41

37 model 8756 troubleshooting guide problem probable cause remedy page ref. 2. Insufficient mix in the freezing cylinder. (cont'd.) d. Missing, defective, or no lubrication on the mix inlet fitting o-ring. D. Replace or evenly lubricate the o-ring on the mix inlet fitting. 23 / 41 e. The pump motor ...

Page 42

38 model 8756 troubleshooting guide problem probable cause remedy page ref. 4. Product is too soft. A. Worn scraper blades. A. Replace scraper blades regularly. 41 b. Dirty condensers or air filters on air cooled units. B. Clean monthly. 35 c. Inadequate water supply on water cooled units. C. Check ...

Page 43

39 model 8756 troubleshooting guide problem probable cause remedy page ref. 8. Excessive mix leakage into the rear drip pan. A. Worn or missing drive shaft seal. A. Install or replace the seal. 16/ 41 b. Improper lubrication of the drive shaft. B. Lubricate properly. 16 c. Worn rear shell bearing. C...

Page 44

40 model 8756 troubleshooting guide problem probable cause remedy page ref. 12. The machine will not operate in the auto mode. A. The machine is unplugged. A. Plug the machine into the wall receptacle. - - - b. The circuit breaker is off or the fuse is blown. B. Turn the breaker on or replace the fu...

Page 45: Section 9

41 model 8756 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually scraper blades x drive shaft seal x freezer door gasket x front bearing x beater shoes x draw valve o-rings x prime plug o-rings x air/mix pump o-rings x check rings ...

Page 46

42 model 8756 limited warranty on equipment 131220 section 10 limited warranty on equipment taylor company limited warranty on freezers taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor-branded freezer equipment ...

Page 47

43 model 8756 limited warranty on equipment 3. Replacement of wear items designated as class “000” parts in the taylor operator’s manual. 4. External hoses, electrical power supplies, and machine grounding. 5. Parts not supplied or designated by taylor, or damages resulting from their use. 6. Return...

Page 48: Section 11

44 model 8756 limited warranty on parts 131220 section 11 limited warranty on parts taylor company limited warranty on taylor genuine parts taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor genuine replacement co...

Page 49

45 model 8756 limited warranty on parts limited warranty exceptions this limited warranty does not cover: 1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new parts. 2. Normal maintenance, clea...

Page 50

46 model 8756 limited warranty on parts limitation of warranty this limited warranty is exclusive and is in lieu of all other warranties, conditions and/or remedies under the law, including any implied warranties or conditions of merchantability or fitness for a particular purpose. The original owne...

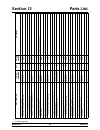

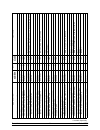

Page 51: Section 12

Section 12 parts list 47 model 8756 parts list + available separately de s cri p t io n p art num be r qty . W arr. Cl as s re m arks adaptor- p ump- cabi net 024259 2 103 beari n g- rear shell- ni ckel 031324 2 000 +gui de- dri p seal 028992 2 000 +nut- brass beari n g 028991 2 000 +w asher- beari ...

Page 52

48 parts list model 8756 + available separately de s cri p t io n re m arks w arr. Cl as s qty . P art num be r cap- desi g n -1 .010" id -6 po in t 014218 3 000 cap- pump 021276- 9 2 103 caster- s w v -3 /4 -1 0 s t. 3i n w heel 021279 2 103 caster- 3 " s w v 3/ 4- 10 stm w /b rake 030307 2 103 com...

Page 53

49 model 8756 parts list + available separately de s cri p t io n re m arks w arr. Cl as s qty . P art num be r decal- door- 3 spout- t w in t w ist 021521 1 000 decal- in st- c ln- c ab 024735 1 000 decal- mi x t ank- w rong 038750 2 000 decal- troubleshoot 038374 1 000 di agram- w iri ng 037807- 3...

Page 54

50 parts list model 8756 + available separately de s cri p t io n re m arks w arr. Cl as s qty . P art num be r fi tti ng- inlet 013087 2 103 funnel- mi x 036637 2 103 fuse- 15 amp c artri d ge 027582 4 000 fuse- .063a- 250v- 5 x20m m 051272 2 103 fuse- 15 amp c artri d ge 027582 2 000 gasket- cab m...

Page 55

51 model 8756 parts list + available separately de s cri p t io n re m arks w arr. Cl as s qty . P art num be r ki t a. -draw valve *t w in ss* x56200- 3 1 gasket- d oor ht 4" -d ouble 048926 2 seal- dri ve shaft 032560 2 ki t a. -beater- f ront shoes x50350 2 beari ng- front- shoe 050348 2 shoe- f ...

Page 56

52 parts list model 8756 140814 + available separately de s cri p t io n re m arks w arr. Cl as s qty . P art num be r nut- stud *long 034382 2 103 nut- stud *short 034383 2 103 o r if ic e 023425- 50 2 103 +o -r in g -13/ 16 o d x .103w 019330 2 000 pai l- 10 q t . 013163 2 000 pan a. -dri p x22811...

Page 57

53 model 8756 parts list + available separately de s cri p t io n re m arks w arr. Cl as s qty . P art num be r ri ng- check 2 in o d x 1/ 2 020050 6 000 +cap- pump 021276- 9 2 103 +pi n -r etai ni ng 021276- 8 2 103 relay- 3 p o l e- 20a- 208/ 240 50/ 60 066795- 33 2 103 relay- dpdt 100ua t o 7 a 1...

Page 58

54 parts list model 8756 + available separately de s cri p t io n re m arks w arr. Cl as s qty . P art num be r s w it c h a .-d r a w *t w in t w is t x38921 1 103 arm- sw it ch- draw -left 038649 1 103 arm- sw it ch- draw -ri ght 038650 1 103 bracket a. -sw itch x38252 1 103 e- ri ng 1/ 4 032190 2...

Page 59

55 model 8756 parts list + available separately de s cri p t io n re m arks w arr. Cl as s qty . P art num be r tri m a. -s helf x24813 1 103 below dri p t ray t r im a .-s id e x22424 2 103 tri m -b ottom m ix door 024826 1 103 tri m -f ront left 024824- sp 1 103 tri m -f ront ri ght 024825 1 103 t...

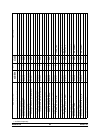

Page 60

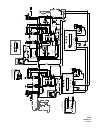

8756 037807-33 11/12/13 brn draw switch blk red blk brn red grn/yel mix hopper temp membrane switches brn blk grn/yel brn blk blk mix low mix shk.Temp/ viscosity colder dip switch up = off 1-comp 5 2-comp 10 3-btr 5 4-btr 10 5-fan 2 6-stby dis 7-interval 8-interval switch interval 7 8 time off off o...