- DL manuals

- Taylor

- Freezer

- C708

- Operating Instructions Manual

Taylor C708 Operating Instructions Manual

Summary of C708

Page 1

Models c708 & c716 heat treatment soft serve freezer operating instructions 059061--m 1/03/05.

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e december,...

Page 3: Table Of Contents

Models c708 & c716 table of contents table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Water connections (water cooled units only) 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air cooled units 1 . . . ....

Page 4

Table of contents models c708 & c716 table of contents - page 2 section 7 important: operator checklist 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . During cleaning and sanitizing 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Troubleshooting b...

Page 5

1 models c708 & c716 to the installer do not install these machines in an area where a water jet could be used. Failure to follow this instruction may result in serious electrical shock. Water connections (water cooled units only) an adequate cold water supply must be provided with a hand shut-off v...

Page 6: Section 2

2 models c708 & c716 to the operator 050816 section 2 to the operator your freezers have been carefully engineered and manufactured to give you dependable operation. These units, when properly operated and cared for, will produce a consistent quality product. Like all mechanical products, they will ...

Page 7: Section 3

3 models c708 & c716 safety section 3 safety we at taylor company are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both you and the service t...

Page 8: Section 4

4 models c708 & c716 operator parts identification section 4 operator parts identification model c708 figure 1 item description part no. 1 panel-side-left 056963 2 pan-drip 11-5/8 long 027503 3 pin-retaining-hopper cvr 043934 4 cover-hopper *black 053809-1 5 blade a.-agitator x56591 6 pump a.-mix si...

Page 9

5 models c708 & c716 operator parts identification.

Page 10

6 models c708 & c716 operator parts identification model c708 single spout door and beater assembly figure 3 item description part no. 1 handle a.-draw-welded x56246 2 nut-stud-black 2.563“ 058764 3 door a.-w/baffle x57332-ser 4 valve a.-draw x55820 5 o-ring-draw valve-s.S. 014402 6 pin-handle-ss 05...

Page 11

7 models c708 & c716 operator parts identification model c716 door and beater assembly figure 4 item description part no. 1 handle a.-draw-welded x56421-1 2 nut-stud-black 3.250 long 058765 3 nut-stud*black 2.563 long 058764 4 door a.-3spt*ht*lg baf x59923-ser 5 pin-handle-twin 059894 6 gasket-door ...

Page 12

8 models c708 & c716 operator parts identification x57029-xx pump a. - mix simplified (model c708).

Page 13

9 models c708 & c716 operator parts identification x57029-xx pump a. - mix simplified (model c716).

Page 14

10 models c708 & c716 operator parts identification accessories figure 7 item description part no. 1 sanitizer-kay 5 case 125 041082 2 tool-o-ring removal 048260-wht 3 tool-shaft-drive-pump- hopper 0457167 4 lubricant-taylor hi-perf 048232 item description part no. 5 pail-mix 10 qt. 013163 * kit a.-...

Page 15

11 models c708 & c716 operator parts identification brush kit assembly x44127.

Page 16: Section 5

12 models c708 & c716 important: to the operator section 5 important: to the operator c708 c716 figure 9 item description 1 power switch 2 liquid crystal display 3 keypads 4 mix out indicator 5 standby indicator 6 mix low indicator 7 select key 8 service menu key 9 brush clean counter 10 arrow key(s...

Page 17

13 models c708 & c716 important: to the operator 050628 symbol definitions to better communicate in the international arena, symbols have replaced words on many of our operator switches, function, and fault indicators. Your taylor equipment is designed with these international symbols. The following...

Page 18

14 models c708 & c716 important: to the operator 050628 if the beater motor is turning properly, touch the wash symbol to cancel the cycle. Touch the auto symbol to resume normal operation. If the freezer shuts down again, contact your authorized service technician. Air/mix pump reset mechanism this...

Page 19

15 models c708 & c716 important: to the operator 050628 system data system data is protected separately from the rest of the data in memory. System data includes variables that change frequently such as the mode the machine is in, lockout status, serving counters, fault codes, and others. While syst...

Page 20

16 models c708 & c716 important: to the operator 050628 power switch on when the power switch is placed in the on position, the control panel touch keys become operative. The fluorescent display will be either blank or indicate that the unit has been cleaned. Unit cleaned international models only: ...

Page 21

17 models c708 & c716 important: to the operator 050628 if the heat treatment cycle fails, the screen will display a failure message and return the freezer to the standby mode. Always comply with local guidelines for the maximum number of days allowed between brush clean cycles. (see the manager’s m...

Page 22

18 models c708 & c716 important: to the operator 050628 following are the variable messages for soft lock failures that appear on the second line of the screen. Power switch off power switch was in the off position. Mix out present there was a mix out condition present. Auto or standby off the machi...

Page 23

19 models c708 & c716 important: to the operator 050628 manager’s menu the manager’s menu is used to enter the operator function displays. To access the menu, touch the center of the cone symbol on the control panel. The arrow symbols, the sel symbol and the cone symbol will be lit when the access c...

Page 24

20 models c708 & c716 important: to the operator 050628 auto start time standby mode brush clean cycle mix level audible fault description lockout history heat cycle summary heat cycle data system information current conditions selecting “exit from menu” will exit the manager’s menu and the return t...

Page 25

21 models c708 & c716 important: to the operator 050628 the auto heat time screen allows the manager to set the time of day in which the heat treatment cycle will start. Auto heat time 00:00 change > exit to set the auto heat time, touch the up arrow symbol to move the arrow to “change”. Then touch ...

Page 26

22 models c708 & c716 important: to the operator 050628 the following message will be displayed if the brush clean cycle option is selected when the machine is not in a brush clean state. Brush clean cycle no changes allowed press any key change the number of days between brush clean intervals by us...

Page 27

23 models c708 & c716 important: to the operator 050628 the lockout history screen displays a history of the last 40 soft locks, hard locks, brush clean dates, or aborted heat cycles. Page numbers are indicated in the upper right hand corner. Page 1 always contains the most recent failure. Lockout h...

Page 28

24 models c708 & c716 important: to the operator 050628 the heat cycle summary screen displays the hours since the last heat cycle, the hours since the product temperature was above 150_f (65.6_c), and the number of heat cycles completed since the last brush clean date. Heat cycle summary hrs since ...

Page 29

25 models c708 & c716 important: to the operator 050628 pf power failure in hc a power failure caused the heat phase, cool phase, or total cycle time to exceed the maximum allowed time. If a power failure occurs, but the heat treatment cycle does not fail, an asterisk(*) will appear on the third lin...

Page 30: Section 6

26 models c708 & c716 operating procedures section 6 operating procedures the c708 stores mix in a hopper and has a 3.4 quart (3.2 liter) capacity freezing cylinder with a single spout door. The c716 stores mix in two hoppers and has two 3.4 quart (3.2 liter) capacity freezing cylinders with a three...

Page 31

27 models c708 & c716 operating procedures use extreme caution when handling the beater assembly. The scraper blades are very sharp and may cause injury. Step 6 before installing the beater assembly, check the scraper blades for any nicks or signs of wear. If any nicks are present, or if the blades ...

Page 32

28 models c708 & c716 operating procedures freezer door assembly the assembly of the c708 freezer door is different from the c716 freezer door. Please follow the appropriate instructions for your machine. Model c708 freezer door assembly step 1 place the door gasket into the groove on the back of th...

Page 33

29 models c708 & c716 operating procedures model c708 freezer door assembly (cont’d.) step 5 insert the baffle rod through the beater in the freezing cylinder. With the door seated on the freezer studs, install the handscrews, with the longer ones on top. Tighten equally in a criss-cross pattern to ...

Page 34

30 models c708 & c716 operating procedures model c716 freezer door assembly step 1 place the door gaskets into the grooves on the back of the freezer door. Step 2 slide the front bearings over the baffle rods. The flanged edges should be against the door. Do not lubricate the gaskets or bearings. St...

Page 35

31 models c708 & c716 operating procedures to increase the flow rate, turn the adjustment screw clockwise. To decrease the flow rate, turn the adjustment screw counter- clockwise. Step 9 snap the design caps over the bottom of the door spouts. Step 10 slide the two rear drip trays into the holes in ...

Page 36

32 models c708 & c716 operating procedures step 4 insert the piston into the retaining pin hole end of the pump cylinder. (see figure 33.) 15123 figure 33 step 5 assemble the valve cap. Slide the o-ring into the groove of the valve cap. Do not lubricate the o-ring. (see figure 34.) 15109 figure 34 s...

Page 37

33 models c708 & c716 operating procedures step 9 secure the pump parts in position by sliding the retaining pin through the cross holes located at one end of the pump cylinder. (see figure 38.) 15113 figure 38 note: the head of the retaining pin should located at the top of the pump when installed....

Page 38

34 models c708 & c716 operating procedures step 13 slide the large black o-ring and the two smaller black o-rings into the grooves on the drive shaft. Thoroughly lubricate the o-rings and shaft. Do not lubricate the hex end of the shaft. (see figure 42.) figure 42 step 14 install the hex end of the ...

Page 39

35 models c708 & c716 operating procedures step 4 install the pump assembly at the rear of the mix hopper. To position the pump on the drive hub, align the drive hole in the piston with the drive crank of the drive shaft. Secure the pump in place by slipping the pump clip over the collar of the pump...

Page 40

36 models c708 & c716 operating procedures step 13 place the agitator on the agitator drive shaft housing. (see figure 48.) 12182 figure 48 note: if agitator should stop turning during normal operation, with sanitized hands, remove agitator from agitator drive shaft housing and brush clean with sani...

Page 41

37 models c708 & c716 operating procedures daily closing procedures this procedure must be performed once daily! The function of the heat treatment cycle is to destroy bacteria by raising the temperature of the mix in the freezing cylinder and the hopper to a specified temperature for a specified pe...

Page 42

38 models c708 & c716 operating procedures step 10 remove, clean and reinstall all drip pans. (see figure 52.) figure 52 step 11 using a clean, sanitized towel, wipe down the freezer door, front panel, the area around the bottom of the freezer door, and any other areas that demonstrate a build-up of...

Page 43

39 models c708 & c716 operating procedures step 3 using a clean, sanitized towel, wipe down the freezer door, front panel, the area around the bottom of the freezer door, and any other areas that demonstrate a build-up of either moisture or food substance. Install the front drip tray and splash shie...

Page 44

40 models c708 & c716 operating procedures step 3 when the flow of product stops, touch the wash and pump symbols , cancelling the wash and pump modes. Close the draw valve. Step 4 remove the locking clip, mix feed tube, pump clip and the assembled air/mix pump. Repeat these steps for the other side...

Page 45

41 models c708 & c716 operating procedures step 7 once the cleaning solution stops flowing from the door spout, close the draw valve and touch the wash symbol , cancelling the wash mode. Repeat these steps on the other side of the model c716. Disassembly note: failure to remove the parts specified b...

Page 46

42 models c708 & c716 operating procedures brush cleaning step 1 prepare two gallons (7.6 liters) of an approved 100 ppm cleaning/sanitizing solution (example: kay-5r). Use warm water and follow the manufacturer’s specifications. Make sure all brushes provided with the freezer are available for brus...

Page 47: Section 7

43 models c708 & c716 important: operator checklist 050808 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The followin...

Page 48

44 models c708 & c716 important: operator checklist winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is subject to freezing conditions. Disconnect the freezer from t...

Page 49: Section 8

45 models c708 & c716 important: operator checklist section 8 troubleshooting guide problem probable cause remedy page ref. 1. Soft lock message appears on display. A. More than 24 hours since the last heat cycle. A. The freezer must go through a heat cycle every 24 hours. The freezer must now be di...

Page 50

46 models c708 & c716 important: operator checklist problem probable cause remedy page ref. 2. Hard lock message appears on display. A. Brush clean interval exceeded. (programmable from 2 - 14 days.) a. The freezer must be disassembled and brush cleaned within 24 hours when the counter indicates one...

Page 51

47 models c708 & c716 important: operator checklist problem probable cause remedy page ref. 6. The product is too soft. A. Draw rate is set too fast. A. Adjust draw rate of 5 to 7 1/2 oz. (142 g. To 213 g.) of product by weight in 10 seconds. 14 7. The product is too thick. A. Freezing cylinder not ...

Page 52

48 models c708 & c716 important: operator checklist problem probable cause remedy page ref. 13. Excessive mix leakage into the long drip pan. A. The seal on drive shaft is improperly lubricated or worn. A. Lubricate properly or replace the seal. 26 b. The seal is installed inside-out on the drive sh...

Page 53: Section 9

49 models c708 & c716 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually scraper blade x drive shaft seal x freezer door gasket x front bearing x front beater shoes x draw valve o-ring x mix feed tube o-ring x pump o-ring x pump va...

Page 54: Section 10

Section 10 parts list 50 parts list models c708 & c716 de s cri p t io n p art num be r c708 qty . C716 qty . W arr. Cl as s re m arks p art s up dat e actuator a. -draw s w itch x62401 1 103 adator -m ix in let -ss -r ed 054825 1 2 103 beari n g -front -shoe 050348 1 2 000 +shoe -front h eli x *f r...

Page 55

51 models c708 & c716 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r brush -draw valve 1” od x 2 ”x 17” 013073 1 1 000 brush -draw valve 1 -1/ 2” o d x 14” 014753 1 1 000 b r u s h -m ixp u m pb o d y -3 ” x7 ” w h 023316 1 1 000 brush -1/...

Page 56

52 parts list models c708 & c716 de s cri p t io n p art s up dat e re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r +capaci t or -run 40m f/ 440v 036049 1 103 ” +capaci t or -s tart 216 -259uf/ 330v 048908 1 103 ” +relay -s tart -c ompressor 051957 -4 0 1 103 ” compressor c s20k6e -tfd...

Page 57

53 models c708 & c716 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r +beari n g -front -shoe 050348 2 000 +decal -d oor -3 spout -t w in t w ist 062239 1 000 +gasket -d oor ht 4” -d ouble 048926 2 000 +handle a .- draw -w e lded *c 602* x5...

Page 58

54 parts list models c708 & c716 de s cri p t io n p art s up dat e re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r nut -a gi tator belt h ousi ng *h 043574 1 2 103 m a g n et a. -a g itato r* c708* x57341 1 2 103 magnet a. -a gi tator -i nner x41733 1 2 103 screw -8 -32x3/ 16 allen se...

Page 59

55 models c708 & c716 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r o -ri ng 1/ 2 id x .139w 048632 4 000 gasket -s im pli f ie d p ump valve 053527 2 000 ri ng -check -f eed -t ube 056524 2 000 ki t a .- draw valve c716 x56200 -1 8 1 000...

Page 60

56 parts list models c708 & c716 de s cri p t io n p art s up dat e re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r motor a .- agi t ator x56586 -0 3 1 103 cap -agi t ator housi n g *c708 056589 1 103 body -a gi tator h ousi ng *c 708 056588 1 103 m a g n et a. -a g itato r* c708* x573...

Page 61

57 models c708 & c716 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r panel -r ear *c 706* 056077 1 103 5/ 24/ 2004 & u p panel -r ear *c 708* 056966 1 103 6/ 27/ 02 to 5/ 28/ 04 panel -s id e -left *c 708* 056963 1 103 panel a. -f il ter -...

Page 62

58 parts list models c708 & c716 de s cri p t io n p art s up dat e re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r +connector -p rogrami n g s hunt 040084 -001 1 103 pcb a .- in terface -hot g as -c 602 x59485 2 212 +chi p -softw are m ix level x40799 2 103 pi n -retai n in g -hopper ...

Page 63

59 models c708 & c716 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r sani t iz er kay -5 125 packets 041082 1 1 000 shaft a .- dri ve -m ix pump -h opper x41947 1 2 103 o -ri ng -1 -3 /4 o d x .139w 008904 1 2 000 crank -dri ve -h opper mi...

Page 64

60 parts list models c708 & c716 de s cri p t io n p art s up dat e re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r spri n g -return -l eft -self c lose 041660 1 103 spri n g -return -r ig ht -self c lose 041661 1 103 sw it ch -l ever -spdt -10a -125 -250v 028889 2 103 sw it ch a. -dua...

Page 65

61 models c708 & c716 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r tray -parts -barrel -3. 4 q t t w ist 045755 1 103 tray -parts -barrel -3. 4 q t -17” ht 045756 1 000 tray -parts -p ump -si mpli fi ed ss 056525 1 2 000 tri m -c o rner ...

Page 66

62 parts list models c708 & c716 de s cri p t io n p art s up dat e re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r bracket -valve -w /c *c 708* 058440 1 nnn condenser -w c -coax 047540 -1 1 103 condenser -w c -coax 047540 1 103 guard -blow er 022505 1 103 fan -5 b lade 7 ” push 30d 01...

Page 67

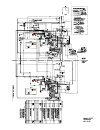

Model c708 057010-27 rev. 1/05.

Page 68

Model c708 057010-33 rev. 1/05.

Page 69

Model c708 057010-40 rev. 1/05.

Page 70

Model c708 057010-58 rev. 1/05.

Page 71

Model c716 059900-27 rev. 6/05.

Page 72

Model c716 059900-33 rev. 6/05.

Page 73

Model c716 059900-40 rev. 6/05.

Page 74

Model c716 059900-58 rev. 6/05.