- DL manuals

- Taylor

- Freezer

- C708

- Operator's Manual

Taylor C708 Operator's Manual

Summary of C708

Page 1

Operator's manual model c708 & c716 heat treatment soft serve freezers original operating instructions 059061-m january, 2005 (original publication) (updated 12/23/13).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e 2005 carr...

Page 3: Table Of Contents

Models c708 & c716 table of contents table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

Table of contents models c708 & c716 table of contents - page 2 rinsing 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hopper cleaning 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: Section 1

1 models c708 & c716 to the installer 131121 section 1 to the installer the following information has been included in the manual as safety and regulatory guidelines. For complete installation instructions, please see the installation checklist. Installer safety in all areas of the world, equipment ...

Page 6

2 models c708 & c716 to the installer 101027 air cooled units do not obstruct air intake and discharge openings: model c708: requires a minimum of 6” (152 mm) of clearance on both sides and 0” in the rear of the unit. Model c716: requires a minimum of 3” (76 mm) of clearance on all sides. Install th...

Page 7

3 models c708 & c716 to the installer 130809 s stationary appliances which are not equipped with a power cord and a plug or another device to disconnect the appliance from the power source must have an all-pole disconnecting device with a contact gap of at least 3 mm installed in the external instal...

Page 8: Section 2

4 models c708 & c716 to the operator 131121 section 2 to the operator your freezers have been carefully engineered and manufactured to give you dependable operation. These units, when properly operated and cared for, will produce a consistent quality product. Like all mechanical products, they will ...

Page 9: Section 3

5 models c708 & c716 safety 130225 section 3 safety we, at taylor company, are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both you and the ...

Page 10

6 models c708 & c716 safety 130304 s do not allow untrained personnel to operate this machine. S do not operate the freezer unless all service panels and access doors are restrained with screws. S do not remove any internal operating parts (example: freezer door, beater, scraper blades, etc.) unless...

Page 11: Notes:

7 models c708 & c716 safety notes:.

Page 12: Section 4

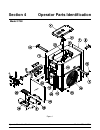

8 models c708 & c716 operator parts identification section 4 operator parts identification model c708 figure 1.

Page 13

9 models c708 & c716 operator parts identification 110506 model c708 exploded view parts identification item description part no. 1 panel-side-left 056963 2 pan-drip 11-5/8 long 027503 3 pin-retaining-hopper cvr 043934 4 kit a.-cover-hopper x65368 5 blade a.-agitator x56591 6 pump a.-mix simplified ...

Page 14

10 models c708 & c716 operator parts identification 130129 model c716 figure 2.

Page 15

11 models c708 & c716 operator parts identification 120409 model c716 exploded view parts identification item description part no. 1 kit a.-cover-hopper x67061-as 2 blade a.-agitator x56591 3 panel-rear 064258-ser 4 pan-drip 7.875 059737 5 pump a.-mix simplified x57029-14 6 panel-side-right 059907 7...

Page 16

12 models c708 & c716 operator parts identification model c708 single spout door and beater assembly figure 3 item description part no. 1 handle a.-draw-welded x56246 2 nut-stud-black 2.563“ 058764 3 door a.-w/baffle x57332-ser 4 valve a.-draw x55820 5 o-ring-draw valve-s.S. 014402 6 pin-handle-ss 0...

Page 17

13 models c708 & c716 operator parts identification 120409 model c716 door and beater assembly figure 4 item description part no. 1 handle a.-draw-welded x56421-1 2 o-ring-1/4 od x .070w 50 015872 3 screw-adjustment-5/16-24 056332 4 door a.-3spt*ht*lg baf x59923-ser 5 pin-handle-twin 059894 6 gasket...

Page 18

14 models c708 & c716 operator parts identification 120221 x57029-xx pump a. - mix simplified (models c708 & c716) figure 5 item description part no. 1 - 7 pump assembly - mix simplified soft serve x57029-xx* 1 cylinder-pump-hopper-ss 057943 2 pin a.-retaining x55450 3 piston 053526 4 o-ring 2-1/8” ...

Page 19

15 models c708 & c716 operator parts identification 110516 accessories figure 6 item description part no. 1 sanitizer-stera sheen *see note 2 tool-o-ring removal 048260-wht 3 tool-shaft-drive-pump- hopper 057167 4 lubricant-taylor hi-perf 048232 item description part no. 5 pail-mix 10 qt. 013163 ** ...

Page 20

16 models c708 & c716 operator parts identification 100507 brush a.-package-ht x44127 figure 7 item description part no. 1 black bristle brush 013071 2 double end brush 013072 3 white bristle brush 1” x 2” 013073 4 white bristle brush 1-1/2” x 3” 014753 5 white bristle brush 1/2 x 3 033059 item desc...

Page 21: Section 5

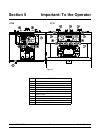

17 models c708 & c716 important: to the operator section 5 important: to the operator c708 c716 figure 8 item description 1 power switch 2 liquid crystal display 3 keypads 4 mix out indicator 5 standby indicator 6 mix low indicator 7 select key 8 service menu key 9 brush clean counter 10 arrow key(s...

Page 22

18 models c708 & c716 important: to the operator 100507 symbol definitions to better communicate in the international arena, symbols have replaced words on many of our operator switches, function, and fault indicators. Your taylor equipment is designed with these international symbols. The following...

Page 23

19 models c708 & c716 important: to the operator 110817 reset mechanism the reset button is located in the service panel on the left side of the c708. The reset buttons are located in the back panel of the c716. A reset button protects the beater motor from an overload condition. Should an overload ...

Page 24

20 models c708 & c716 important: to the operator 050628 initializing language note: if there is a language initialization fault, the machine will force a language selection prior to the initializing sequence. The standard menu led's should light, as if it were in a menu. If a language has been selec...

Page 25

21 models c708 & c716 important: to the operator 050628 power switch off after the safety timeout has been completed and the power switch is off, the following screen is displayed. Power switch off - = - = - = - = - = - unit cleaned power switch on when the power switch is placed in the on position,...

Page 26

22 models c708 & c716 important: to the operator 121008 to comply with health codes, heat treatment system freezers must complete a heat treatment cycle daily and must be disassembled and brush cleaned according to the frequency specified by your federal, state, or local regulatory agencies. Please ...

Page 27

23 models c708 & c716 important: to the operator 050628 soft lock if a heat treatment cycle has not been initiated within the last 24 hours, a soft lock failure will occur. A soft lock allows the operator to correct the cause of the soft lock. The operator has the option of either starting another h...

Page 28

24 models c708 & c716 important: to the operator 050628 to restore the message that identified the reason for the soft lock, turn the power switch off for five seconds, and then return the power switch to the on position. The original message with the reason for the soft lock will be displayed. Heat...

Page 29

25 models c708 & c716 important: to the operator 120321 manager menu options touch the arrow symbols to move up or down through the menu. Select a menu option by touching the sel symbol. Exit the menu program by selecting exit from menu or touch the cone symbol. The following menu options are listed...

Page 30

26 models c708 & c716 important: to the operator enter the correct month, day, and year. Then touch the sel symbol to advance to the daylight saving time (dst) screen. Daylight saving time enabled > enable disable pressing the up or down arrow symbols will move the arrow to “enable” or “disable”. Pr...

Page 31

27 models c708 & c716 important: to the operator auto start time the auto start time option allows the manager to set the time of day at which the machine automatically enters the auto mode from the standby mode. The machine must be in the standby mode without a freezer lock condition in order to au...

Page 32

28 models c708 & c716 important: to the operator 070412 touch the sel symbol to display the next fault found or return to the manager menu if no other faults exist. Touching the sel symbol any time faults are displayed will clear the faults, if corrected, upon returning to the menu screen. Listed be...

Page 33

29 models c708 & c716 important: to the operator 051025 power fail in h/c - a power failure occurred during the heat treatment cycle. Mix low failure - the mix level in the hopper is too low for a successful heat cycle. Beater ovld h/c - the overload tripped for the beater motor. Brl therm fail - th...

Page 34

30 models c708 & c716 important: to the operator the third screen shows the right side (r) of the freezer. The top line of these screens shows the hopper (h) and barrel (b) temperatures recorded at the end of the heat treat cycle and indicates the side (l or r) of the freezer. The remaining lines in...

Page 35

31 models c708 & c716 important: to the operator 120227 system information the system information is displayed on three separate screens. The first screen contains the control and software version installed in the machine. Software version c708 control uvc version x.Xx > next touch the sel symbol to...

Page 36: Section 6

32 models c708 & c716 operating procedures section 6 operating procedures the c708 stores mix in a hopper and has a 3.4 quart (3.2 liter) capacity freezing cylinder with a single spout door. The c716 stores mix in two hoppers and has two 3.4 quart (3.2 liter) capacity freezing cylinders with a three...

Page 37

33 models c708 & c716 operating procedures use extreme caution when handling the beater assembly. The scraper blades are very sharp and may cause injury. Step 6 before installing the beater assembly, check the scraper blades for any nicks or signs of wear. If any nicks are present, or if the blades ...

Page 38

34 models c708 & c716 operating procedures freezer door assembly the assembly of the c708 freezer door is different from the c716 freezer door. Please follow the appropriate instructions for your machine. Model c708 freezer door assembly step 1 place the door gasket into the groove on the back of th...

Page 39

35 models c708 & c716 operating procedures model c708 freezer door assembly (cont'd.) step 5 insert the baffle rod through the beater in the freezing cylinder. With the door seated on the freezer studs, install the handscrews, with the longer ones on top. Tighten equally in a criss-cross pattern to ...

Page 40

36 models c708 & c716 operating procedures model c716 freezer door assembly step 1 place the door gaskets into the grooves on the back of the freezer door. Step 2 slide the front bearings over the baffle rods. The flanged edges should be against the door. Do not lubricate the gaskets or bearings. St...

Page 41

37 models c708 & c716 operating procedures to increase the flow rate, turn the adjustment screw clockwise. To decrease the flow rate, turn the adjustment screw counter- clockwise. Step 9 snap the design caps over the bottom of the door spouts. Step 10 slide the two rear drip trays into the holes in ...

Page 42

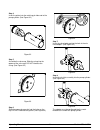

38 models c708 & c716 operating procedures step 4 insert the piston into the retaining pin hole end of the pump cylinder. (see figure 32.) figure 32 step 5 assemble the valve cap. Slide the o-ring into the groove of the valve cap. Do not lubricate the o-ring. (see figure 33.) figure 33 step 6 slide ...

Page 43

39 models c708 & c716 operating procedures 120209 step 9 secure the pump parts in position by sliding the retaining pin through the cross holes located at one end of the pump cylinder. (see figure 37.) figure 37 note: the head of the retaining pin should located at the top of the pump when installed...

Page 44

40 models c708 & c716 operating procedures 080617 step 13 slide the large black o-ring and the two smaller black o-rings into the grooves on the drive shaft. Thoroughly lubricate the o-rings and shaft. Do not lubricate the hex end of the shaft. (see figure 41.) figure 41 step 14 install the hex end ...

Page 45

41 models c708 & c716 operating procedures 100507 step 4 install the pump assembly at the rear of the mix hopper. To position the pump on the drive hub, align the drive hole in the piston with the drive crank of the drive shaft. Secure the pump in place by slipping the pump clip over the collar of t...

Page 46

42 models c708 & c716 operating procedures 120209 step 13 place the agitator on the agitator drive shaft housing. (see figure 47.) figure 47 note: if agitator should stop turning during normal operation, with sanitized hands, remove agitator from agitator drive shaft housing and brush clean with san...

Page 47

43 models c708 & c716 operating procedures 080222 daily closing procedures this procedure must be performed once daily! The function of the heat treatment cycle is to destroy bacteria by raising the temperature of the mix in the freezing cylinder and the hopper to a specified temperature for a speci...

Page 48

44 models c708 & c716 operating procedures 080222 step 10 remove, clean and reinstall all drip pans. (see figure 51.) figure 51 step 11 using a clean, sanitized towel, wipe down the freezer door, front panel, the area around the bottom of the freezer door, and any other areas that demonstrate a buil...

Page 49

45 models c708 & c716 operating procedures 121008 step 3 using a clean, sanitized towel, wipe down the freezer door, front panel, the area around the bottom of the freezer door, and any other areas that demonstrate a build-up of either moisture or food substance. Install the front drip tray and spla...

Page 50

46 models c708 & c716 operating procedures 100507 step 3 when the flow of product stops, touch the wash and pump symbols , cancelling the wash and pump modes. Close the draw valve. Properly dispose of the mix. (see figure 55.) figure 55 step 4 remove the locking clip, mix feed tube, pump clip and th...

Page 51

47 models c708 & c716 operating procedures 121008 step 4 touch the wash symbol . This will cause the cleaning solution in the freezing cylinder to come in contact with all areas of the freezing cylinder. Step 5 place an empty pail beneath the door spout(s). Step 6 open the draw valve on the freezer ...

Page 52

48 models c708 & c716 operating procedures 080617 brush cleaning step 1 prepare an approved 100 ppm cleaning solution (examples: 2-1/2 gal. [9.5 liters] of kay-5r or 2 gal. [7.6 liters] of stera-sheenr). Use warm wa- ter and follow the manufacturer's specifications. Make sure all brushes provided wi...

Page 53: Section 7

49 models c708 & c716 important: operator checklist 121008 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by your federal, state or local regulatory agencies and must be followed accordingly. Ple...

Page 54

50 models c708 & c716 important: operator checklist 080222 j 7. If your machine is water cooled, check the water lines for kinks or leaks. Kinks can occur when the machine is moved back and forth for cleaning or maintenance purposes. Deteriorated or cracked water lines should be replaced only by an ...

Page 55: Section 8

51 models c708 & c716 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. Soft lock message appears on display. A. More than 24 hours since the last heat cycle. A. The freezer must go through a heat cycle every 24 hours. The freezer must now be disassembl...

Page 56

52 models c708 & c716 troubleshooting guide problem probable cause remedy page ref. 2. Hard lock message appears on display. A. Brush clean interval exceeded. A. The freezer must be disassembled and brush cleaned within 24 hours when the counter indicates one day remaining. 22 b. A barrel or hopper ...

Page 57

53 models c708 & c716 troubleshooting guide problem probable cause remedy page ref. 6. The product is too soft. A. Draw rate is set too fast. A. Adjust draw rate of 5 to 7 1/2 oz. (142 g. To 213 g.) of product by weight in 10 seconds. 19 7. The product is too thick. A. Freezing cylinder not primed c...

Page 58

54 models c708 & c716 troubleshooting guide problem probable cause remedy page ref. 13. Excessive mix leakage into the long drip pan. A. The seal on drive shaft is improperly lubricated or worn. A. Lubricate properly or replace the seal. 32 b. The seal is installed inside-out on the drive shaft. B. ...

Page 59: Section 9

55 models c708 & c716 parts replacement schedule 130227 section 9 parts replacement schedule part description every 3 months every 6 months annually every 4 years door a. X scraper blade x drive shaft seal x freezer door gasket x front bearing x front beater shoes x draw valve o-ring x mix feed tube...

Page 60

56 models c708 & c716 limited warranty on equipment 131121 section 10 limited warranty on equipment taylor company limited warranty on freezers taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor-branded freezer eq...

Page 61

57 models c708 & c716 limited warranty on equipment 3. Replacement of wear items designated as class “000” parts in the taylor operator’s manual. 4. External hoses, electrical power supplies, and machine grounding. 5. Parts not supplied or designated by taylor, or damages resulting from their use. 6...

Page 62: Section 11

58 models c708 & c716 limited warranty on parts 131121 section 11 limited warranty on parts taylor company limited warranty on taylor genuine parts taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor genuine replac...

Page 63

59 models c708 & c716 limited warranty on parts limited warranty exceptions this limited warranty does not cover: 1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new parts. 2. Normal maintenan...

Page 64

60 models c708 & c716 limited warranty on parts limitation of warranty this limited warranty is exclusive and is in lieu of all other warranties, conditions and/or remedies under the law, including any implied warranties or conditions of merchantability or fitness for a particular purpose. The origi...

Page 65: Section 12

Section 12 parts list 61 models c708 & c716 parts list 131223 de s cri p t io n p art num be r c708 qty . C716 qty . W arr. Cl as s re m arks accumulator- c opper 2" di a 10" 047062 1 2 103 actuator a. -draw s w itch * x69835 1 103 s/ n m 1104867 & u p actuator a. -draw s w itch x62401 1 103 s/ n m ...

Page 66

62 parts list models c708 & c716 de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r boot- valve- expansi on 027137 2 000 hopper txv boot- insulati n g- epr 062048 4 000 bottle- w ash- p lasti c 044818 1 000 brush a .- package- ht x44127 1 1 000 brush- rear brg 1 "d x 2 "...

Page 67

63 models c708 & c716 parts list de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r com p ressor l64a113bbca 048259- 27e 1 2 512 s/ n k 7112082 & u p - 208- 230v 60hz 1 ph - b ri sto l +capaci t or- run 25uf/ 440v 037431 1 2 103 +capaci t or- s tart 189- 227uf/ 33 033044...

Page 68

64 parts list models c708 & c716 de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r +valve a. -draw *c602* x55820 1 103 +o -r in g -7/ 8 o d x .103w 014402 3 000 door a. -3 spt* h t* lg baf* w /o prg x59923- ser 1 103 +decal- d oor- 3 spout- t w in t w ist 062239 1 000 +...

Page 69

65 models c708 & c716 parts list de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r gu a r d -p o we r s wi t c h 034830 1 1 103 g u id e a .-d r ip p a n x28863 1 103 g u id e a .-d r ip p a n -m ix p u m p x48228 2 103 gui d e a .- dri p pan- l eft x59910 1 103 g u id ...

Page 70

66 parts list models c708 & c716 de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r ho usi n g a .- ag it ato r *c 708* x56586- 03 1 103 bo dy- a g itato r h o u si ng *c 708* 056588 1 103 cap- ag it ato r ho usi n g *c708* 056589 1 103 2/ 1/ 2012 replaces 056589- j magn...

Page 71

67 models c708 & c716 parts list de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r o -ri ng -11/ 16o dx. 103w -r ed 016132 2 000 o -ri ng -2 -1 /8 o d x .139w -#225 020051 2 000 o -ri ng 1/ 2 id x .139w 048632 2 000 gasket- s im pli f ie d p ump valve 053527 1 000 ri ng...

Page 72

68 parts list models c708 & c716 de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r label- c k m tr rotate- c w -eng/ spn 020090 1 1 000 208- 230v 60hz 3 ph label- d oor- m ove part 032749 1 1 000 label- r eset- m ix pmp 044452 1 1 000 label- s w -pow e r- off/ on- symbo...

Page 73

69 models c708 & c716 parts list de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r panel a. -f ront- u pper *c 708* x57017 1 103 s/ n k 4087456 & p ri o r panel a- si de- r ig ht *c 707* x57871 1 103 to p a ir di scharg e u se x57869 panel- s id e- left *c 708* 056963 1...

Page 74

70 parts list models c708 & c716 de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r +cable- ri bbon- 14c- 3 "l -s il /s il 056864 1 103 pcb a .- in terface *c712- c717* x62101- ser * 103 plate a .- dec s /n k606 & p ri or - m ay substi t ute w ith 063925- ser chi p- so f...

Page 75

71 models c708 & c716 parts list de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r gasket- s im pli f ie d p ump valve 053527 2 2 000 o -ri ng -2 -1 /8 o d x .139w -#225 020051 1 4 000 p in a .-r e t a in in g x55450 1 2 103 +pi n -c otter- hai r pi n- 1/ 8di a 044731 1...

Page 76

72 parts list models c708 & c716 de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r strai n er- c one m esh 1/ 2 o df 062299 2 4 000 sw it ch a. -draw *c706* x56147 1 103 arm a .- draw *c706* x56253 1 103 e- ri ng 3/ 16 .335 o .D. 049178 1 000 in sulato r- sw it ch 1/ 64...

Page 77

73 models c708 & c716 parts list de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r sw it ch- reed* d oor in terlock* 6 056771 1 1 103 s/ n k 7085360 & u p - see in terlo c k a .- do o r sw it ch- reed *d oor in terlock* 056249 103 s/ n k 7072606 & p ri or - beater in te...

Page 78

74 parts list models c708 & c716 131223 de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r valve- in let p ress. Reg 1 2 see ki t a .- valve- epr x57009- 3 valve- outlet press. Reg 1 2 see ki t a .- valve- o p r x 57008- 3 +boot- insulati n g- valve- sol 080523 1 2 valve...

Page 79

75 models c708 & c716 parts list de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r o -ri ng -3 /4 o d x .103w 015835 2 000 pi n a .- coax pump *h t* ss* x36950 2 103 pi ston- c oax p ump *aaa* w h it e 041480 2 103 poppet- rubber- b lack 022473 2 000 ri ng- check 1- 1/ ...

Page 80

76 parts list models c708 & c716 de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r ri ng- check 2 in o d x 1/ 2 020050 2 4 000 seal- a ir in let f itti ng 045327 1 2 000 spri n g- tapered 1- 7/ 8l 022456 1 2 103 tube a. -m ix in let- hopper pum x45318 1 2 103 b & c coax...

Page 81

77 models c708 & c716 parts list de s cri p t io n re m arks w arr. Cl as s c716 qty . C708 qty . P art num be r body a. -c oax valve- ht- ss- x50352- j 2 103 j1 coax pump cyli nder a .- pump *h t* mcd* ss x44755 2 103 o -ri ng -1 -5 /8 o d x .103w -# 050356 2 000 j1 coax pump o -ri ng -2 -1 /8 o d ...

Page 82

78 parts list models c708 & c716 de s cri p t io n c708- 58 c708- 40 c708- 35 c708- 29 p art no . Cap- valve body ss 056874- 8 1 cap- valve body ss 056874- 10 1 com p ressor l63a113dbla 048259- 33 1 1 com p ressor l63a113bbka 048259- 40 1 com p ressor l63a113dbea 048259- 58 1 di ag ram -w iri ng *c ...

Page 83

79 models c708 & c716 parts list c716 - 5 0 h z : c71635fw 0 0 220- 240v 50hz 3 ph ro hs co m p li ant, c 71639r000 200v 50/ 60hz 3 ph, c 71640fw 0 0 220- 240v 50hz 1 ph ro hs co m p li ant, c 71658fw 0 0 380- 415v 50hz 3 n~( 4 w ire) r o h s c o m pli ant, c 71660f925 220/ 380v 60hz 3 ph- 4 w ire d...

Page 84

80 parts list models c708 & c716 de s cri p t io n c716- -5 8 c716- 40 c716- 39 c716- 35 p art no . Mot o r- 2 .0 h p 017650- 33 motor- reducer- servi ce 036955- 34s pulley- 2ak27 x .625- .6265 011545 2 2 2 pulley- 2ak22- 7/ 8 019987 relay- start- compressor 038146 2 starter- 3 p hase 4 t o 6 .5 amp...

Page 85

81 models c708 & c716 parts list de s cri p t io n w arr cl as s c716- 58 mc d c716- 58 mc d n o cup c716- 58 st d p art no . Harness- w ire- syr- h eaters* c60 068342- 40 2 2 103 heater- s tri p -175w -240v 042782 2 2 103 ho lder a. -l id *5472* x42811 1 1 103 j a r- syrup* p lasti c *s hallow 0365...

Page 86

82 parts list models c708 & c716 131223 de s cri p t io n p art num be r c708 qty . C716 qty . W arr. Cl as s re m arks wa te r c oole d : c70827r000 208- 230v 60hz 1 ph w /c s td, c 71627r000 208- 230v 60hz 1 ph w /c s td accumulator- c opper 2" di a 13" 053377 1 103 bracket a. -m ounti n g c onden...

Page 87

Model c708 057010-27 5/13.

Page 88

Model c708 057010-33 5/13.

Page 89

Model c708 057010-40 5/13.

Page 90

Model c708 057010-58 5/13.

Page 91

Model c716 059900-27 5/13.

Page 92

Model c716 059900-33 5/13.

Page 93

Model c716 059900-40 5/13.

Page 94

Model c716 059900-58 5/13.