- DL manuals

- Taylor

- Freezer

- C902

- Operating Instructions Manual

Taylor C902 Operating Instructions Manual

Summary of C902

Page 1

Model c902 frozen beverage freezer operating instructions 055544--m 2/08/02.

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e february,...

Page 3: Table Of Contents

Model c902 table of contents table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Site ...

Page 4

Table of contents model c902 table of contents -- page 2 rinsing 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hopper cleaning 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5: Section 1

1 model c902 to the installer 081208 section 1 to the installer the following are general installation instructions. For complete installation details, please see the check out card. Installer safety in all areas of the world, equipment should be installed in accordance with existing local codes. Pl...

Page 6

2 model c902 to the installer 081204 air cooled units air cooled units require a minimum of 3” (76 mm) of air clearance on all sides and employs two 3” air deflectors on the rear of the unit. This is required to allow for adequate air flow across the condenser(s). Failure to allow adequate clearance...

Page 7

3 model c902 to the installer 081204 refrigerant in consideration of our environment, taylor proudly uses only earth friendly hfc refrigerants. The hfc refrigerant used in this unit is r404a. This refrigerant is generally considered non-toxic and non-flammable, with an ozone depleting potential (odp...

Page 8: Section 2

4 model c902 to the operator 081204 section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to give you dependable operation. The taylor model c902, when properly operated and cared for, will produce a consistent quality product. Like all mechanical pr...

Page 9: Section 3

5 model c902 safety 081204 section 3 safety we at taylor company are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built--in safety features to protect both you and the service t...

Page 10

6 model c902 safety 081204 s do not allow untrained personnel to operate this machine. S do not operate the freezer unless all service panels and access doors are restrained with screws. S do not remove any internal operating parts (examples: freezer door, beater, scraper blades, etc.) unless all co...

Page 11: Section 4

7 model c902 operator parts identification section 4 operator parts identification item description part no. 1 lens-decorative 055347 2 panel a.-side-left x55733-ser 3 cover-hopper 055164 4 panel a.-rear x55655 5 panel a.-side-right x55734-ser item description part no. 6 panel-front-upper 055675 7 p...

Page 12

8 model c902 operator parts identification beater door assembly item description part no. 1 knob-draw valve-black 047358 2 screw-1/4-20x9/16 thumb 047632 3 plate-draw spout mntg 049275 4 spout-door zero waste 049276 5 o-ring-2.375 od x 1/16w 046830 6 spring-comp.845x.055x3.5- 047357 7 valve-draw*zer...

Page 13

9 model c902 operator parts identification accessories item description part no. 1 sanitizer kay-5 125 pkts 041082 2 lubricant-taylor 4 oz. 047518 3 kit a.-tune up x55457 4 pail-mix 10 qt. 013163 5 brush-rear brg 1in.Dx2in.L 013071 6 brush-double ended 013072 item description part no. 7 brush-draw v...

Page 14: Section 5

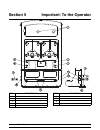

10 model c902 important: to the operator section 5 important: to the operator item description 1 viscosity adjustment (behind panel) 2 indicator light--mix low 3 indicator light--mix out 4 label--wash/off/auto (left side) 5 control switch--wash/off/auto item description 6 flavor cards 7 power switch...

Page 15

11 model c902 important: to the operator symbol definitions to better communicate in the international arena, the words on many of our operator switches and keys have symbols to indicate their functions. Your taylor equipment is designed with these international symbols. The following chart identifi...

Page 16: Section 6

12 model c902 operating procedures section 6 operating procedures the model c902 freezer is designed to produce slush product at the desired thickness. This unit has two 3.2 quart (3.0 liter) freezing cylinders. We begin our instructions at the point where we enter the store in the morning and find ...

Page 17

13 model c902 operating procedures install the blades on the beater assembly. Be sure the holes in the blades are securely positioned over the beater pins. Figure 5 holding the beater securely, slide the beater into the freezing cylinder. Align the hole at the rear of the beater with the flats on th...

Page 18

14 model c902 operating procedures step 6 align the tabs on the beater bearing with the slot in the front of the beater. Insert the beater bearing into the front of the beater. Figure 9 step 7 insert the door bearing into the beater bearing. Do not lubricate the door bearing. Figure 10 repeat these ...

Page 19

15 model c902 operating procedures insert the draw valve and spring into the door spout until the threaded end of the shaft passes through the hole in the end of the door spout. Thread the draw valve knob onto the end of the draw valve shaft. Figure 13 place the door spout seal o--ring into the groo...

Page 20

16 model c902 operating procedures step 9 install the upper front plastic panel onto the freezer. Figure 18 step 10 install the freezer door. Position the door on the freezer studs at the front of the freezing cylinder. Press the door firmly into place. Figure 19 note: the torque rotor will protrude...

Page 21

17 model c902 operating procedures 081204 step 13 slide the long drip pan into the hole in the front panel. Figure 22 step 14 install the lower plastic panel, front drip tray and splash shield beneath the door spouts. Figure 23 step 15 install the magnetic translight lens into the plastic upper fron...

Page 22

18 model c902 operating procedures step 5 place the control switch in the off position. Place an empty mix pail beneath the door spout. Open the draw valve and draw off all of the sanitizing solution. When the sanitizer stops flowing from the door spout, close the draw valve. Figure 26 repeat these ...

Page 23

19 model c902 operating procedures 081204 draining product from the freezing cylinder step 1 place the power and the control switches in the off position as far ahead of cleaning time as possible. This will allow frozen product to soften for easier cleaning. Step 2 remove the hopper cover. Step 3 if...

Page 24

20 model c902 operating procedures 070809 disassembly be sure the control switch and the power switch are in the “off” position. Failure to do so may cause injury from electrocution or hazardous moving parts. Step 1 remove the handscrews, freezer door, beater assembly, torque rotor, scraper blade an...

Page 25: Section 7

21 model c902 important: operator checklist 081204 section 7 important: operator checklist during cleaning and sanitizing: always follow local health codes. Cleaning and sanitizing schedules are governed by federal, state, or local regulatory agencies, and must be followed accordingly. If the unit h...

Page 26

22 model c902 important: operator checklist winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is to be left unheated and subject to freezing conditions. Disconnect th...

Page 27: Section 8

23 model c902 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product being dispensed. A. Control switch is in the off position. A. Place control switch in the auto position. 18 b. Improper mixing of product. B. Carefully follow directions for mixi...

Page 28

24 model c902 troubleshooting guide problem probable cause remedy page ref. 4. Product too thick. A. Inadequate mix in hopper. A. Fill hopper with mix. 18 b. Improper mixing of product. B. Carefully follow directions for mixing product. -- -- -- c. The viscosity adjustment is set incorrectly. C. Adj...

Page 29: Section 9

25 model c902 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 4 months every 6 months annually quantities to be replaced drive shaft seal x 2 drive shaft o--ring x 2 scraper blade x 2 freezer door gasket x 2 front bearing x 2 guide bearing x 2 do...

Page 30: Section 10

Section 10 parts list + available separately 26 parts list model c902 de s cri p t io n part num be r qty . W arr. Cl as s re m arks part s up da t e a r m- t o r q u e *c 902* 5- 3/ 16 lo n g 055446 2 103 b a lla s t -120v -9 w 055300- 12 2 103 115- 60- 1 bear in g -g u id e 014496 2 000 bear in g ...

Page 31

27 + available separately model c902 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r c o v e r -t o r q u e s w it c h *c 902* 055339 1 103 de ca l -i n s t -cl n hp r 019029 1 000 d e c a l- s t a t ic c l in g *c 902* s e t /3 055491 1 000 d e c a l -tr o...

Page 32

+ available separately 28 parts list model c902 de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r o -r in g -7 /8 o d x .139w 025307 2 000 beater sh aft seal -d r ive sh aft 032560 2 000 to o l -o -r in g r em o val -fr eezer 048260- w h t 1 000 k it -f l a v o r c a r ...

Page 33

29 + available separately model c902 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r p a n e l -s id e -r ig h t *c 902* x 55734- s e r 1 103 k 1114634/ up 159 p a n e l -s id e -r ig h t *c 902* x 55722 1 103 p rior to k 1114600 159 p c b a .- c o n t r o ...

Page 34

+ available separately 30 parts list model c902 de s cri p t io n part s up da t e re m arks w arr. Cl as s qty . Part num be r n u t -10- 32 mf lo c k 020983 2 000 nut -p us h o n-9 /1 6 d ia . S ha f t 051288 2 000 s c r e w -10- 32x 1 r h m z p s t e e l 004455 2 000 s p r in g-t o rque *w hi t e...

Page 35

Model c902 055350--12 rev. 8/31/01.

Page 36

Model c902 055350--40 rev. 8/31/01.