- DL manuals

- Taylor

- Welding System

- CD-i

- Operating manual

Taylor CD-i Operating manual

Summary of CD-i

Page 1

V‐4j taylor studwelding systems limited operating guide for type cd‐i capacitor discharge studwelding equipment a taylormade capacitor discharge studwelding system.

Page 2: Index

V‐4j index 2 page no. Content 3 useful information. 5 important safety information. 7 introduction to studwelding. 8 guide to external features. 10 setting up and welding. 12 weld settings. 14 weld testing. 15 parts list & exploded diagrams. 22 circuit schematic ‐ wiring. 23 declaration of conformit...

Page 3: Useful Information

V‐4j useful information 3 manufacturers details taylor studwelding systems limited commercial road dewsbury west yorkshire wf13 2bd england telephone : +44 (0)1924 452123 facsimile : +44 (0)1924 430059 email : sales@taylor‐studwelding.Com web : www.Taylor‐studwelding.Com sales direct tel : +44 (0)19...

Page 4: Useful Information

V‐4j useful information 4 further information should you require addi onal technical informa on, please contact us directly (details on previous page) or our local agent / distributor (details of agents etc. Can be obtained from us). This guide contains important informa on which is a pre‐requisite ...

Page 5

V‐4j important safety information ! 5 protect yourself and others ! Read and understand these safety notes. 1. Electrical no por on of the outer cover of the welding controller should be removed by anyone other than suitably qualified personnel and never whilst mains power is connected. Always discon...

Page 6

V‐4j important safety information ! 6 4. Maintenance all cables must be inspected regularly to ensure that no danger exists from worn or damaged insula on or from unsound electrical connec ons. Special note should be made of the cables close to the pistol, where maximum wear occurs. As well as produ...

Page 7

V‐4j introduction to studwelding 7 introduction the complete range of taylor studwelding systems capacitor discharge units are compact, portable stud welding equipment's. The units are specifically designed to enable a small diameter range of ferrous and non‐ferrous weld studs to be welded to light g...

Page 8

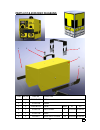

V‐4j guide to external features 8 front panel 1. Carrying handle 2. Welding voltage display 3. Welding voltage control knob 4. Ventillation holes ! Do not obstruct ! 5. Welding earth panel connector 6. Green led ‐ indicates ready to weld 7. Amber led ‐ indicates unit is charging 8. Red led ‐ indicat...

Page 9

V‐4j guide to external features 9 back panel 1. Rating/serial plate 4. Main fuse 2. On/off switch 5. Mains inlet ‐ iec socket or 3. Ventillation fan/grille ‐ ! Do not obstruct ! Fixed cable (see inset) options available important notes ! Due to the power requirements and electromagne c emissions pro...

Page 10: Setting Up And Welding

V‐4j setting up and welding 10 set up the control unit at the place of work, ensuring that the mains switch is in the off posi on. Ensure that this is done in line with the notes and safety recommenda ons on pages 5 and 6 of this manual. Plug the controller into the correct mains ac supply. The cont...

Page 11: Setting Up And Welding

V‐4j setting up and welding 11 connect the welding pistol control cable to the panel mounted socket on the controller. Note that the cable end plug and panel moun ng socket are keyed to prevent incorrect fi ng. Push the plug firmly home and twist the locking ring clockwise to secure the plug in posi o...

Page 12: Weld Settings

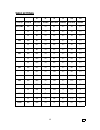

V‐4j weld settings 12 this page and the following are intended as a guide to se ng your machine. The se ngs outlined in the table are only intended as a star ng point. It is possible that the se ngs will give sa sfactory results without adjustment, but in reality the quality of the welding results i...

Page 13: Weld Settings

V‐4j weld settings 13 i8 i8 i9 i9 i10 i10 stud Ø stud m voltage spring voltage spring voltage spring m2.5/m3 ms 75 2½ 45 2½ 35 2½ ss 75 2½ 45 2½ 35 2½ al 80 2½ 50 2½ 35 2½ m4 ms 85 2½ 60 2½ 40 2½ ss 85 2½ 60 2½ 40 2½ al 90 3½ 65 3½ 45 3½ m5 ms 105 2½ 75 2½ 65 2½ ss 110 2½ 85 2½ 65 2½ al 110 3½ 80 3½...

Page 14: Weld Testing

V‐4j weld testing 14 visual examina on of weld quality can, even with limited experience, provide a useful quality assessment. In such a check the presence of a small even witness of weld material around the base of the stud flange a er welding should be ensured. Poor welds are indicated by excess me...

Page 15

V‐4j parts list & exploded diagrams 15 1 2 3 4 5 6 item no. Off part no. Description 1 10 z200‐05‐008 screw 2 1 70‐105‐014 handle 3 2 z105‐08‐025 screw 4 1 70‐105‐237 logo sticker 5 1 70‐105‐230 cover 6 1 see inset model ident sticker model lh rh i8 70‐105‐238 70‐105‐239 i9 70‐105‐240 70‐105‐241 i10...

Page 16

V‐4j parts list & exploded diagrams 16 see pages 22 to 24 for a breakdown of the capacitor bank see page 20 for a breakdown see page 21 for a breakdown of the baseplate of the back panel.

Page 17

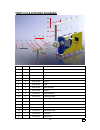

V‐4j parts list & exploded diagrams 17 item no. Off part no. Description 1 1 81‐104‐030 knob 2 1 81‐104‐032 knob cap 3 2 z200‐03‐010 screw 4 1 70‐102‐025 panel control socket 5 1 70‐105‐231 control panel overlay 6 1 70‐105‐227 baseplate 7 4 z200‐03‐006 screw 8 4 z610‐03‐000 washer 9 1 70‐105‐220 dis...

Page 18

V‐4j parts list & exploded diagrams 18 item no. Off part no. Description 1 1 70‐105‐294 fan 2 1 70‐105‐229 back panel 3 1 70‐105‐244 serial/rating plate 4 1 70‐102‐018 fan guard 5 1 70‐105‐270 on/off switch 6 4 z650‐03‐000 rivet 7 4 z200‐05‐012 screw 8 1 70‐102‐085 fuseholder 9 1 70‐105‐236 fuse 10 ...

Page 19

V‐4j parts list & exploded diagrams 19 item no. Off part no. Description 1 1 70‐105‐221 main pcb 2 5 z600‐03‐000 washer 3 5 z200‐03‐006 screw 4 5 70‐105‐228 mounting pillar 5 1 70‐105‐226 warning sticker 6 1 70‐105‐247 capacitor 8 1 70‐105‐245 wiring harness (not shown) 7 1 70‐105‐219 resistor 1 2 3...

Page 20

V‐4j parts list & exploded diagrams 20 item no. Off part no. Description 1 1 z200‐05‐008 screw 2 1 na diode lead 3 2 z605‐10‐000 washer 4 1 70‐105‐225 socket link bar 5 2 z510‐10‐000 locknut 6 4 z105‐05‐045 screw 7 5 z615‐05‐000 spring washer 8 5 z600‐05‐000 washer 9 1 70‐105‐224 positive busbar 10 ...

Page 21

V‐4j parts list & exploded diagrams 21 item no. Off part no. Description 1 6 z205-04-016 screw 2 4 z515-05-000 nut 3 4 z615-05-000 spring washer 4 4 z605-05-999 washer 5 4 70-105-139 capacitor screw 6 # 70-105-258 insulator 7 # 70-105-259 insulator 1 8 2 9 3 10 4 11 5 12 6 13 7 item no. Off part no....

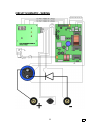

Page 22

V‐4j circuit schematic ‐ wiring 22.

Page 23: Ec Declaration

V‐4j ec declaration signed: david taylor managing director responsible party name : taylor studwelding systems ltd address : commercial road dewsbury west yorkshire uk wf13 2bd in accordance with the following direc ves : 93/68/eec the ce marking direc ve 2014/35/eu the low voltage direc ve 2014/30/...