- DL manuals

- TDK-Lambda

- Power Supply

- Z+ series

- User manual

TDK-Lambda Z+ series User manual

Summary of Z+ series

Page 1

Programmable dc power supplies 200w/400w/600w/800w in 2u built-in usb, rs-232 & rs-485 interface optional interface: lxi compliant lan ieee488.2 scpi (gpib) multi-drop isolated analog programming series user manual.

Page 2: User Manual

User manual series this manual covers models: z10-20 z20-10 z36-6 z60-3.5 z100-2 z10-40 z20-20 z36-12 z60-7 z100-4 programmable dc power supplies 200w/400w built-in usb, rs-232 & rs-485 interface ia710-04-01c.

Page 3

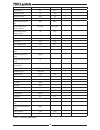

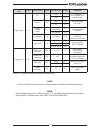

Conc en tr ation values of to xic and hazar dous substanc es/elemen ts (wt%) not es lead (p b) 0.1wt% m er cur y (hg) 0.1wt% cadmium ( cd) 0.1wt% he xa valen t chr omium (c r6+) 0.1wt% polybr omina ted biphen yls (pbb) 0.1wt% polybr omina ted diphen yl ethers (pbde) 0.1wt% case o o o o o o plastic p...

Page 6

Table of contents regulatory notices ..............................................................................................11 safety instructions..............................................................................................11 chapter 1: general information 1.1 user manual con...

Page 7

3.9.3 wire termination ..................................................................................................................................................... 35 3.9.4 noise and impedance effects .............................................................................................

Page 8

5.3.5.1 setting the protection delay ........................................................................................................................ 55 5.3.6 over temperature protection ............................................................................................................

Page 9

7.7.1 data format ................................................................................................................................................................. 78 7.7.2 end of message ...................................................................................................

Page 10

8.6.2 wave execution via communication pc ................................................................................................. 116 8.6.3 wave execution via front panel ................................................................................................................... 116...

Page 11

Warranty this tdk-lambda product is warranted against defects in materials and workmanship for a period of five years from date of shipment. During the warranty period, tdk-lambda will, at it’s option, either repair or replace products which prove to be defective. Limitation of warranty the warranty...

Page 12

11 regulatory notices fcc notice this device complies with part 15 of the fcc rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired op...

Page 13

12 caution: z + series units are not authorized for use as critical component in nuclear control systems, life support systems or equipment for use in hazardous environments without the express written approval of the managing director of tdk-lambda. Vorsicht: die geräte der z + serie sind ohne ausd...

Page 14

13 parts substitutions & modifications parts substitutions and modifications are by authorized tdk-lambda service personnel only. For repairs or modifications, the instrument must be returned to tdk-lambda service facility. Auswechseln und verÄnderung von bauteilen das auswechseln sowie die veränder...

Page 15

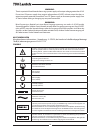

14 maschinenlaerm maschinenlaerm informations - verordnung - 3. Gpsgv, der hoechste schalldruckpegel betraegt 70 db(a) oderweniger gemass en iso7779. Symbols caution, risk of danger. Instruction manual symbol. The instrument will be marked with this symbol when it is necessary for the user to refer ...

Page 16

15 chapter 1: general information 1.1 user manual content this user's manual contains the operating instructions, installation instructions and specifications of the z + series 200w and 400w power supply series. The instructions refer to the standard power supplies, including the built-in usb and rs...

Page 17

16 1.2.4 multiple output power system the z + series power supplies series can be configured into a programmable power system of up to 31 units using the built-in usb or rs232/rs485 communication port in the power supply and the rs485 linking cable provided with each power supply. In a lan system, e...

Page 18

17 caution: observe all torque guidelines within this manual. Over torque may damage unit or accessories. Such damage is not covered under manufacturers warranty. 1.3 accessories 1.3.1 general accessories are delivered with the power supply or separately upon ordering, the list below shows the possi...

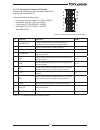

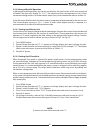

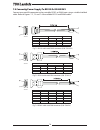

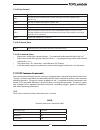

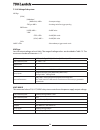

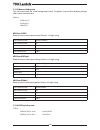

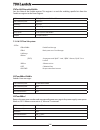

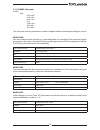

Page 19: 1 Z

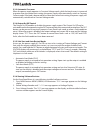

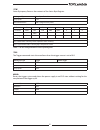

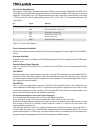

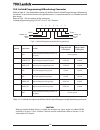

18 chapter 2: specifications 2. 1 z + 20 0 s er ies s pe ci fic at io ns model z 10-20 20-10 36-6 60-3.5 100-2 1. R at ed output v oltage(*1) v 10 20 36 60 100 2. R at ed output cur ren t (*2) a 20 10 6 3.5 2 3. R at ed output po w er w 200 200 216 210 200 const ant v ol ta ge mode v 10-20 20-10 36-...

Page 20: 1 Z

19 2. 1 z + 20 0 s er ies s pe ci fic at io ns model z 10-20 20-10 36-6 60-3.5 100-2 1. R at ed output v oltage(*1) v 10 20 36 60 100 2. R at ed output cur ren t (*2) a 20 10 6 3.5 2 3. R at ed output po w er w 200 200 216 210 200 const ant v ol ta ge mode v 10-20 20-10 36-6 60-3.5 100-2 1. M ax. Li...

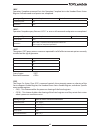

Page 21: 200 Series Specific

20 z + 200 series specific ations input char ac teristics v 10-20 20-10 36-6 60-3.5 100-2 1. I nput v oltage/fr eq . (*3) --- 85~265v ac c on tinuous , 47~63h z, single phase 2. M aximum i nput cur ren t 100/200v ac (*18) --- 2.65/1.30 2.61/1.28 2.71/1.34 2.68/1.32 2.54/1.26 3. P ow er f ac tor ( ty...

Page 22: 200 Series Specific

21 z + 200 series specific ations input char ac teristics v 10-20 20-10 36-6 60-3.5 100-2 1. I nput v oltage/fr eq . (*3) --- 85~265v ac c on tinuous , 47~63h z, single phase 2. M aximum i nput cur ren t 100/200v ac (*18) --- 2.65/1.30 2.61/1.28 2.71/1.34 2.68/1.32 2.54/1.26 3. P ow er f ac tor ( ty...

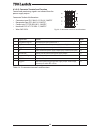

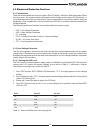

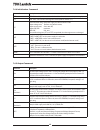

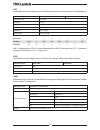

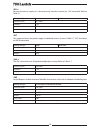

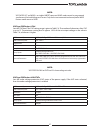

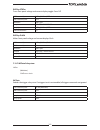

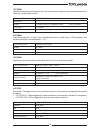

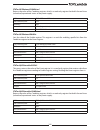

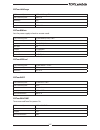

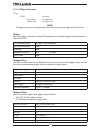

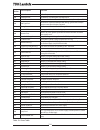

Page 23: 2 Z

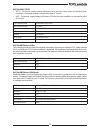

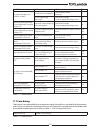

22 2. 2 z + 40 0 s er ies s pe ci fic at io ns model z 10-40 20-20 36-12 60-7 100-4 1. R at ed output v oltage(*1) v 10 20 36 60 100 2. R at ed output cur ren t (*2) a 40 20 12 7 4 3. R at ed output po w er w 400 400 432 420 400 const ant v ol ta ge mode v 10-40 20-20 36-12 60-7 100-4 1. M ax. Line ...

Page 24: 2 Z

23 2. 2 z + 40 0 s er ies s pe ci fic at io ns model z 10-40 20-20 36-12 60-7 100-4 1. R at ed output v oltage(*1) v 10 20 36 60 100 2. R at ed output cur ren t (*2) a 40 20 12 7 4 3. R at ed output po w er w 400 400 432 420 400 const ant v ol ta ge mode v 10-40 20-20 36-12 60-7 100-4 1. M ax. Line ...

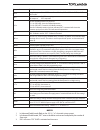

Page 25: 400 Series Specific

24 z + 400 series specific ations input char ac teristics v 10-40 20-20 36-12 60-7 100-4 1. I nput v oltage/fr eq . (*3) --- 85~265v ac c on tinuous , 47~63h z, single phase 2. M aximum i nput cur ren t 100/200v ac (*18) --- 5.05/2.47 4.98/2.45 5.25/2.57 5.10/2.50 4.80/2.37 3. P ow er f ac tor ( typ...

Page 26: 400 Series Specific

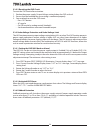

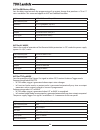

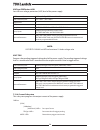

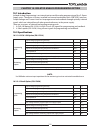

25 2. 3 s up pl em en tal c ha ra ct er is ti cs the supplemen tal char ac ter istics g iv e t ypical but non- w ar ran ted per for manc e char ac ter istics . The supplemen tal char ac ter istics ar e useful in assessing applica tions f or the po w er supply . Sev er al k inds of supplemen tal char...

Page 27

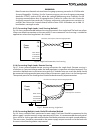

26 2.4 z200w/400w outline drawing.

Page 28

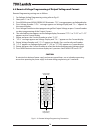

27 2.5 z200w/400w optional ieee, isolated analog interface outline drawing.

Page 29

28 2.6 z200w/400w front panel output binding post outline drawing.

Page 30

29 chapter 3: installation 3.1 general this chapter contains instructions for initial inspection, preparation for use and repackaging for shipment. Connection to pc, setting the communication port and linking z + power supplies are described in chapter 7. Note: z + power supplies generate magnetic f...

Page 31

30 3.5 location, mounting and cooling this power supply is fan cooled. The air intake is at the front panel and the exhaust is at the rear panel. Upon installation allow cooling air to reach the front panel ventilation inlets. Allow minimum 10cm (4”) of unrestricted air space at the front and the re...

Page 32

31 1 local (-) sense 2 (-) sense 3 (+) sense 4 local (+) sense fig.3-3: sense connector default connection plug p/n: ipd1-02-d-k (samtec) 2. Ensure that the protection of output bus-bars or of output connector is mounted and properly assembled for power supplies when the output voltage exceed 42.4vd...

Page 33

32 3.8.3 constant voltage check 1. Turn on the output by pressing out push-button so the out led illuminates. 2. Observe the power supply volt display and rotate the voltage encoder. Ensure that the output voltage varies while the volt encoder is rotated. The minimum control range is from zero to th...

Page 34

33 3.8.7 foldback check warning: there is a potential shock hazard when checking a power supply with output voltage greater than 42.4v. Observe proper safety procedures during the checking. Warnung: beim einsatz eines netzteils mit einer nenn-ausgangsspannung von mehr als 42.4v besteht stromschlagge...

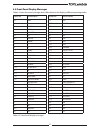

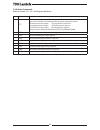

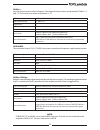

Page 35

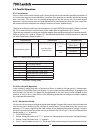

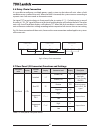

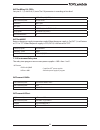

34 wire size awg resistivity ohm/1000ft maximum length in feet to limit voltage drop to 1v or less 5a 10a 20a 50a 14 2.526 80 40 20 8 12 1.589 120 60 30 12 10 0.9994 200 100 50 20 8 0.6285 320 160 80 32 6 0.3953 500 250 125 50 4 0.2486 800 400 200 80 2 0.1564 1200 600 300 125 0 0.0983 2000 1000 500 ...

Page 36

35 3.9.3 wire termination the wires should be properly terminated with terminals securely attached. Do not use non terminated wires for load connection at the power supply. Caution: when local sensing, a short from +ls or +s to -v or -s or -ls, will cause damage to the power supply. Reversing the se...

Page 37

36 caution: ensure that the load wiring mounting hardware does not short the output terminals. Heavy connecting cables must have some form of strain relief to prevent loosening the connections or bending the bus-bars. 10v to 100v models refer to fig.3-4 for connection of the load wires to the power ...

Page 38

37 3.9.7 connecting single loads, local sensing (default) fig.3-6 shows recommended load and sensing connections for a single load. The local sense lines shown are default connections at the rear panel j2 sense connector. Local sensing is suitable for applications where load regulation is less criti...

Page 39

38 3.9.10 multiple load connection with distribution terminals if remotely located output distribution terminals are used, the power supply output terminals should be connected to the distribution terminals by a pair of twisted and/or shielded wires. Each load should be separately connected to the r...

Page 40

39 3.10 local and remote sensing the rear panel j2 sense connector is used to configure the power supply for local or remote sensing of the output voltage. Refer to fig.3-10 for sense connector location. 3.10.2 local sensing the power supply is shipped with the rear panel j2 sense connector wired fo...

Page 41

40 3.10.3 remote sensing warning: there is a potential shock hazard at the sense point when using power supply with an output voltage greater than 42.4v. Ensure that the connections at the load end are shielded to prevent accidental contact with hazardous voltages. Warning: do not operate the power ...

Page 42

41 chapter 4: front/rear panel controls and connectors 4.1 introduction the z + power supply series has a full set of controls, indicators and connectors that allow the user to set up and operate the unit. Before starting to operate the unit, please read the following sections for an explanation of ...

Page 43

42 no. Control/indicator description section 1 ac power switch ac on/off control 2 current display 4 digit 7-segment led display. Normally displays the output current. In preview mode, the display indicates the program setting of output current. 3 voltage display 4 digit 7-segment led display. Norma...

Page 44

43 4.3 rear panel connectors refer to fig.4-2 and table 4-2 for description of the rear panel connectors. No. Connection description section 1 ac input connector iec320-16 type connector 2 dc output bus-bar bus-bars for 10v to 100v models. Use m6 or 1/4” screws. 3.9.9 3 analog control and signals. J...

Page 45

44 warning: terminals 7, 9 and 12 of j1 are connected internally to the negative sense(-s) potential of the power supply. Do not attempt to bias any of these terminals relative to the negative sense. Use the isolated programming interface option to allow control from a programming source at a differ...

Page 46

45 fig.4-3: j1 connector terminals and functions table 4-3: j1 connector terminals and functions pin parameter specification section 1 loc/rem select input for selecting between local or remote analog programming of output voltage and output current. 6.2 2 p output for current balance in parallel op...

Page 47

46 table 4-4: j3 connector terminals and functions fig.4-4: j3 connector terminals and functions 4.3.2 j3 connector terminal and function control and monitoring signals are isolated from the power supply output. Connector technical information • connector type: ipl1-104-01-s-d-ra-k, samtec • recepta...

Page 48

47 4.4 front panel display messages table 4-5 shows the various messages that will be shown on the display in different operating modes. Display text text description display text text description abor abort mac mac ac ac §memo memory adr address off off ato auto[start] on on bad baud rate once on...

Page 49

48 4.5 navigating the main menu 4.5.1 introduction the main menu consists of three levels: subsystem, function and parameter. To enter the menu press the menu button. The menu led illuminates and the display shows the subsystem menu. Navigate by rotating the voltage encoder to scroll through the sub...

Page 50

49 4.6 navigating communication menu 4.6.1 introduction the communication menu consists of two /three levels: function level and parameter level. To navigate the communication menu press rem button. The rem led illuminates. The function menu item appears on the display. Navigate by rotating the volt...

Page 51

50 4.6.2 exiting the communication menu there are three ways to exit from rem menu: 1. Press twice on rem button. Rem led turns off. Display shows present status of power supply. 2. Press and hold rem button 3sec. Rem led turns off. Display shows present status of power supply. 3. No action for 15se...

Page 52

51 chapter 5: local operation 5.1 introduction this chapter describes the operating modes that do not require programming and monitoring the power supply via its serial communication ports. Usb or rs232/rs485 or by remote analog signals. Ensure that the rem/loc led on the front panel is off, (indica...

Page 53

52 5.2.3 automatic crossover when the power supply operates in constant voltage mode, while the load current is increased to greater than the current limit setting, the power supply will automatically switch to constant current mode. If the load is decreased to less than the current limit setting, t...

Page 54

53 5.3 alarms and protective functions 5.3.1 introduction there are several conditions that cause alarm (red led blinks). All alarms affect the output. When an alarm occurs, the respective fault will appear on the display and the alarm led illuminates. It is possible that more than one fault (alarm)...

Page 55

54 5.3.2.2 resetting the ovp circuit to reset the ovp circuit after activation: 1. Reduce the power supply output voltage setting below the ovp set level. 2. Ensure that the load and the sense wiring is connected properly. 3. Four methods to reset the ovp circuit. • press out button. • ac recycle. •...

Page 56

55 5.3.4.1 setting the foldback protection the foldback can be set when the power supply output is enabled (on) or disabled (off ). 1. Press prot button. Prot (green) led illuminates. The “o“ message appears on the voltage display. 2. Rotate voltage encoder until "fod“ message appears on voltage ...

Page 57

56 5.4 series operation power supplies of the same model can be connected in series to obtain increased output voltage. Split connection of the power supplies gives positive and negative output voltage. 5.4.1 series connection for increased output voltage two units are connected so that their output...

Page 58

57 5.4.3 remote programming in series operation programming by external voltage: the analog programming circuits of this power supply are referenced to the negative sense potential. Therefore, the circuits used to control each series connected unit must be separated and floated from each other. Refe...

Page 59

58 5.5 parallel operation 5.5.1 introduction up to six units of the same voltage and current rating can be connected in parallel to provide up to six times the output current capability. One of the units operates as a master and the remaining units are slaves. The slave units are analog programmed b...

Page 60

59 5.5.2.2 slave unit set up when slave mode is selected the power supply enters current programming mode via external voltage. Voltage and current programming setting values are set to 105% of range. During operation the slave units operate as a controlled current source following the master output...

Page 61

60 caution: make sure that the connection between - vo terminals is reliable to avoid disconnection during operation. Disconnection may cause damage to the power supply. Note: with local sensing it is important to minimize the wire length and resistance. Also the positive and negative wire resistanc...

Page 62

61 5.5.3 advanced parallel operation in advanced parallel operation the master unit displays the total current of all units connected in parallel. The slave units display “o se”. The master and slave units operate in a daisy-chain connection configuration. For further details about daisy-chain co...

Page 63

62 5.6 daisy-chain connection it is possible to configure a multiple power supply system to shut down all units when a fault condition occurs in one of the units. When the fault is removed, the system recovers according to a preset state: safe start mode or automatic restart. Set signal “so” to posi...

Page 64

63 5.7.1 external shut off function so signal serves as output shut off . It is an optically isolated signal from the power supply output. Connection to the signal is made via pin j3-5 (shut off) and pin j3-7 (ifc_com). The so pin accepts a 2.5v to 15v signal or open-short contact to disable or enab...

Page 65

64 front panel ilc setting ilc input power supply output display alarm led off - default open or short on voltage/current off on open off ena blinking short on voltage/current off table 5-5: interlock functions and settings caution: to prevent possible damage to the unit, do not connect any of the e...

Page 66

65 5.7.4 power supply ok signal ps_ok signal indicates fault condition in the power supply. It is a ttl signal output at j3-2, referenced to if_com at j3-7 (isolated interface common). When a fault condition occurs, ps_ok level is low, with maximum sink current of 1ma. When no fault condition occurs...

Page 67

66 5.9 parameter setting memory power supply has four memory configuration modes: subsystem level display function level display parameter level display description memory memo save sae 1…4 1...4 save setting in non violate memory recall rec 1…4 1...4 recall setting in non violate memory rst rst y...

Page 68

67 5.9.4 save this command saves the present state of the power supply to a specified location in memory (refer to table 5-7). Up to 4 states can be stored. Storage locations 1 through 4 are in nonvolatile memory. Save front panel setting: 1. Press menu button. Menu (green) led illuminates. “et” me...

Page 69

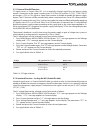

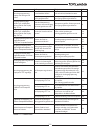

68 parameter factory default resetting last setting save & recall output status off off + + voltage set-point 0v 0v + + current set-point max 0a + + fold back mode off off + + over voltage protection ovp max max + + under voltage level/ protection mode off (uvl) off (uvl) + + under voltage level/ pr...

Page 70

69 chapter 6: remote analog programming 6.1 introduction the rear panel connector j1 allows the user to program the power supply output voltage and current limit with an analog device. J1 also provides monitoring signals for output voltage and output current. The programming range and monitoring sig...

Page 71

70 fig.6-1: j1-remote voltage programming connection output current programming output voltage programming 6.4 remote voltage programming of output voltage and current remote programming settings are as follows: 1. For voltage analog programming wiring refer to fig.6-1. 2. Short pins j1-1 to j1-7. 3...

Page 72

71 fig.6-2: j1-remote resistor programming connection 6.5 remote resistor programming of output voltage and output current for resistive programming, internal current sources, for output voltage and/or output current control, supply 1ma current through external programming resistors connected betwee...

Page 73

72 notes: 1. In remote analog mode: the output voltage cannot be set by the voltage encoder. The output voltage limit is set to 5% over the model-rated maximum value. The output current limit is set by the current encoder to 5% over the model-rated maximum value. 2. The power supply will operate wit...

Page 74

73 chapter 7: serial rs232/rs485 and usb interface 7.1 introduction this chapter describes the set-up, operation, commands and communication protocol of z + power supplies via serial communication interfaces: rs232, rs485 or usb. 7.2 configuration function level display parameter level display descr...

Page 75

74 7.2.4 baud rate setting seven optional rates are possible: 1200, 2400, 4800, 9600, 19200, 38400, 57600. 1. Press rem button. The rem led illuminates. “it” message appears on the voltage display. 2. Rotate voltage encoder until voltage display shows “bd”. 3. Press voltage encoder. Voltage disp...

Page 76

75 note: tx and rx are used for rs232 communication. Txd +/- and rxd +/- are used for rs485 communication. Refer to rs232 and rs485 cable descriptions for connection details. 1 sg 2 nc 3 rxd+ 4 txd+ 5 txd- 6 rxd- 7 tx 8 rx nc 8 nc 7 txd- 6 rxd- 5 rxd+ 4 txd+ 3 nc 2 sg 1 in out shield (connector encl...

Page 77

76 socket socket socket 08-25 connector 8 pin connector remarks pin no. Name pin no. Name 1 shield housing shield 2 tx 8 rx twisted 3 rx 7 tx pair 7 sg 1 sg fig.7-2: rs232 cable with db25 connector (p/n: z/232-25) d08-9 connector 8 pin connector remarks pin no. Name pin no. Name housing shield housi...

Page 78

77 fig.7-6: multi power supplies rs232/485 connection 7.5 rear panel usb connector a standard usb series b device connector is located on rear panel for usb control. Refer to fig.7-5 and table 7-2. Fig.7-5: usb connector 7.5.1 usb getting started power supply #1 power supply #2 power supply #3 power...

Page 79

78 7.7 gen protocol (gen series communication language) note: the address (adr n) command must return an “ok” response before any other commands are accepted. 7.7.1 data format serial data format is 8 bit, one start bit and one stop bit. No parity bit. 7.7.2 end of message the end of message is the ...

Page 80

79 error code description e01 returned when program voltage (pv) is programmed above acceptable range. Example: pv value is above '105% of supply rating' or 'pv above 95% of ovp setting'. E02 returned when programming output voltage below uvl setting. E04 returned when ovp is programmed below accept...

Page 81

80 command description pv n sets the output voltage value in volts. The range of voltage value is described in table 7-3. The maximum number of characters is 12. See the following examples for pv n format: pv 12, pv 012, pv 12.0, pv 012.00, etc... Pv? Reads the output voltage setting. Returns the st...

Page 82

81 command description out n turns the output to on or off. Recover from safe-start, ovp or fld fault. Out 1 (or out on)-turn on. Out? Returns the output on/off status string. On- output on. Off- output off. Fld n sets the foldback protection to on or off. Fld 1 (or fold on) - arms the foldback prot...

Page 83

82 note: the power supply can accept values higher by 5% than the table values, however it is not recommended to program the power supply over the rated values. Grst reset. Brings the power supply to a safe and known state: output voltage: 0v, output current: 0a, out: off, remote: rmt 1’ ast: off ov...

Page 84

83 model rated output voltage (v) minimum (v) maximum (v) 10 0.5 12.0 20 1.0 24.0 36 2.0 40.0 60 5.0 66.0 100 5.0 110 table 7-8: ovp programming range model rated output voltage (v) minimum (v) maximum (v) 10 0 9.5 20 0 19.0 36 0 34.2 60 0 57.0 100 0 95.0 table 7-9: uvl/uvp programming range model m...

Page 85

84 7.8.8 status commands refer to section 9.3.1, 9.3.2 for register definitions. # command description 1 stt? Reads the complete power supply status. Returns ascii characters representing the following data, separated by commas: mv pc pv sr mc fr example response: mv(45.201),pv(45),mc(4.3257),pc(10)...

Page 86

85 7.9 serial communication test set-up basic set-up to test serial communication operation. 1. Equipment: pc with windows hyper terminal, private edition, software installed, z + power supply, rs232 cable. 2. Pc set-up: 2.1 open hyper terminal.......................New connection. 2.2 enter a name ...

Page 87

86 7.10.4 checksum the user may optionally add a checksum to the end of the command. The checksum is "$" followed by two hex characters. If a command or a query has checksum, the response will also have one. There is no cr between the command string and the "$" sign. 7.10.5 scpi requirements the pow...

Page 88

87 7.10.8 data formats data formats description digits with an implied decimal point assumed at the right of the least-significant digit. Examples: 256 digits with an explicit decimal point. Example: .0253 digits with an explicit decimal point and an exponent. Example: 2.73e+2 extended format that i...

Page 89

88 *ese standard event status enable command. Modifies the contents of the event status enable register. Meaning and type event status enable device status command syntax *ese parameters 0 to 255 power on value 1 query syntax *ese? Parameters 3digits query syntax *esr? *psc *stb? Bit position 7 6 5 ...

Page 90

89 *opc operation complete command. Sets the operation complete bit in the standard event status register if all commands and queries are completed. Meaning and type operation complete device status command syntax *opc parameters none *opc? Operation complete query. Returns ascii ‘1’ as soon as all ...

Page 91

90 *rcl n restores the power supply to a state previously stored in memory by *sav command. Refer to table 5-7. Meaning and type recall device state command syntax *rcl parameters 1 to 4 query commands *rcl 3 query syntax none *rst this command resets the power supply to a defined state as shown in ...

Page 92

91 *stb? Status byte query. Returns the contents of the status byte register. Meaning and type status byte device status query syntax *stb? Returned parameters (register binary value) bit position 7 6 5 4 3 2 1 0 condition oper mss esb mav ques 0 0 0 (rqs) bit weight 128 64 32 16 8 4 2 1 esb = event...

Page 93

92 7.12 scpi subsystem commands subsystem commands are specific to power supply functions. They can be a single command or a group of commands. Groups are comprised of commands that extend one or more levels below the root. Commands followed by a question mark (?) take only the query form. Except as...

Page 94

93 output:pon[:state] • auto - the power supply output will return to its previous value when the latching fault condition is removed or to the stored value after ac recycle. • safe - the power supply output will remain off after the fault condition is removed or after ac recycle. Scpi command synta...

Page 98

97 note: volt:mode list and wave is an implied abort command. Wave mode cannot be programmed simultaneously for both voltage and current. Only the last sent command can be accepted as wave. Previous mode reverts to none. Voltage:protection:level sets the ovp level. The ovp setting range is given in ...

Page 99

98 voltage:protection:low sets the over voltage protection (uvp) level of the power supply. Scpi command syntax [source]:voltage:protection:low gen command syntax uvl , uvp default suffix v *rst value 0 examples volt:under:prot 2.5 volt:under:prot:lev max query syntax [source]:voltage:protection:low...

Page 100

99 current sets the output current value in amperes. The range of current values are described in tables 7-4 and 7-5. The maximum number of characters is 12. Scpi command syntax [source]:current[:level] [:immediate][:amplitude] gen command syntax pc pc? Default suffix a *rst value 0 examples curr 50...

Page 101

100 7.12.5 measure subsystem this subsystem reads the actual voltage and current. The power is a result of multiplying voltage and current measurements. Measure :current[:dc]? :voltage[:dc]? :power[:dc]? Measure:curr? Reads the measured output current. Returns a 5 digit string. Scpi command syntax m...

Page 103

102 initiate:continuous • init:cont 0 - enables the trigger subsystem only for a single trigger action. The subsystem must be enabled prior to each subsequent trigger action. • init:cont 1 - trigger system is continuously enabled and init is redundant. Scpi command syntax initiate:continuous paramet...

Page 104

103 list:curr specifies the output current points in a list. The current points are given in the command parameters, which are separated by commas. Scpi command syntax [source]:list:current {,} default suffix a examples list:curr 2.5,3.0,3.5 list:curr max,2.5,min up to 12 parameters query syntax lis...

Page 105

104 list:volt specifies the output voltage points in a list. The voltage points are given in the command parameters, which are separated by commas. Scpi command syntax [source]:list:voltage {,} default suffix v examples list:volt 2.0,2.5,3.0 list:volt max,2.5,min up to 12 parameters query syntax lis...

Page 106

105 status:operational:condition? Returns the value of the condition register, which is a read-only register that holds the real-time (unlatched) operational status of the power supply. Scpi command syntax status:operation:condition? Gen command syntax stat? Parameters none returned parameters (regi...

Page 107

106 status:questionable:enable sets the value of the enable register. This register is a mask for enabling specific bits from the condition register to the event register. Scpi command syntax status:questionable:enable gen command syntax fena nnnn parameters 0 to 32727 returned parameters (register ...

Page 109

108 7.12.11 trigger subsystem trigger [:start] run trigger delay set trigger delay :source set trigger source note: the trigger subsystem must be enabled from the initiate subsystem or no triggering action will occur. Trigger when the trigger subsystem is enabled, trig generates an immediate trigger...

Page 110

109 7.12.12 wave subsystem [source] :wave :coun :curr :load :step :store :time :volt this subsystem receives parameters to create a sloped waveform of the output voltage or current. Wave:coun sets the number of times that the list is executed before it is completed. The command accepts parameters in...

Page 112

111 7.12.13 global subsystem global commands general • power supplies acting upon global commands need not be a currently addressed supply. • all power supplies attached to the interface must be capable of accepting global commands. • no messages, opc or not busy will be returned to the host pc afte...

Page 113

112 chapter 8: advanced functions 8.1 introduction this chapter describes the advanced functions of output programmable modes. The are three programmable modes: fix, wave and list. The user can program the output transient state. The programmable modes are synchronized by input trigger (refer to sec...

Page 114

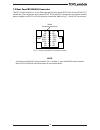

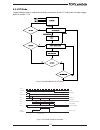

113 fig.8-4: list mode sequence example 0.01sec trig initated init:imm wtg (wait trigger) trigger event tdc trig:del 0.02 sts (step started) dwell list:dwell 0.05,0.06,0.03 stc (step complited) opc (operation complited) output list:volt 5,10,0 voltage 0.02s 0.05s 0.06s 0.03s list step auto 8.3 list ...

Page 115

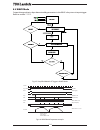

114 fig.8-5: simplified models of trigger in wave mode 0.01sec trig initated init:imm wtg (wait trigger) trigger event trd trig:del 0.02 sts (step started) time 0.03s 0.02s 0.03s wave:time 0,3,2,3 stc (step complited) opc (operation complited) wave:volt 5,10,10,0 output voltage wave:coun 2 init cont...

Page 116

115 8.5 trigger 8.5.1 input trigger trigger source can be set via: • bus - command (refer to section 7.11 *trg, 7.12 trigger) or front panel. • ext - rear panel connector j3-8 (refer to section 4.3.2). Input trigger source setting via front panel: 1. Press menu button. Menu (green) led illuminates. ...

Page 117

116 8.6.2 wave execution via communication pc 1. Load stored data insert communication command ( example: wave:load 2 ) 2. Set counter (how many times program will be repeated if step in auto mode). Insert communication command ( example: wave:coun 2 ) 3. Set trigger in source (bus for command or fr...

Page 118

117 subsystem level display function level display parameter level display description trigger setting trig init init init iit initialization (refer to command init) ready for trigger. Trig trig continue cont ena ena refer to command init:cont dis di trigger in (input trigger) tr.I bus (via softw...

Page 119

118 chapter 9: status, fault and srq registers 9.1 general this section describes various status errors (faults) and srq register structures. The registers can be read or set via the rs232/485/usb commands. Refer to fig.9-1 for the status and fault registers diagram. Lsb msb stat:oper:cond? Stat? St...

Page 120

119 9.2 power supply status structure status and fault register shows the status register structure of the power supply. The standard event, status byte, and service request enable registers and the output queue perform standard functions as defined in the ieee 488.2 standard digital interface for p...

Page 121

120 9.3.2 status register the status register sets a bit when status changes (refer to table 9-2). The bit is cleared when the condition is removed. Bit number decimal value bit symbol description 0 1 cv set high if constant voltage operation 1 2 cc set high if constant current operation 2 4 nfl no ...

Page 122

121 9.6 standard event status group 9.6.1 register functions this group consists of an event register and an enable register that are programmed by common commands. The standard event register latches events relating to interface communication status. It is a read-only register that is cleared when ...

Page 123

122 9.6.3 status byte register this register summarizes the information from all other status groups as defined in the ieee 488.2 standard digital interface for programmable instrumentation standard. The register can be read either by a serial poll or by *stb?. Both methods return the same data, exc...

Page 124

123 9.6.5 output queue the output queue is a first-in, first-out (fifo) data register that stores power supply-to-controller messages until the controller reads them. Whenever the queue holds one or more bytes, it sets the mav bit (4) of the status byte register. If too many unread error messages ar...

Page 125

124 error number error description error event 0 “no error” no error reported -100 “command error” unit receives command with unspecified error. -101 “invalid character” a character was received that is not: a-z, a-z, 0-9, ?, *, :, ;, period, space, cr, lf. -104 “data type error” ieee receives comma...

Page 126

125 chapter 10: isolated analog programming option 10.1 introduction isolated analog programming is an internal option card for analog programming of the z + power supply series. The option is factory installed and cannot be obtained with gpib (ieee) interface. Output voltage and current limit can b...

Page 127

126 10.3 isolated programming & monitoring connector refer to table 8-1 for detailed description of the rear panel isolated programming & monitoring connector. To provide the lowest noise performance, it is recommended to use shielded-twisted pair wiring. Refer to fig.8-1 for description of the conn...

Page 128

127 caution: to prevent damage to the unit, do not program the output voltage and current to higher than the power supply rating. 10.4 setup and operating instructions caution: to prevent damage to the unit, do not program the output voltage and current to higher than the power supply rating. 10.4.1...

Page 129

128 chapter 11: maintenance 11.1 introduction this chapter provides information about maintenance, calibration and troubleshooting. 11.2 units under warranty units requiring repair during the warranty period should be returned to a tdk lambda authorized service facility. Refer to the address listing...

Page 130

129 symptom check action ref. No output. All displays and indicators are blank. Is the ac power cord defective? Check continuity, replace if necessary. 3.7 is the ac input voltage within range? Check input ac voltage. Connect to appropriate voltage source. 3.6 3.7 output is present momentarily but s...

Page 131

130 11.1 einleitung dieses kapitel liefert informationen über wartung, kalibrierung und fehlersuche. 11.2 reparaturen während der garantie sollte ein gerät innerhalb der garantiezeit ausfallen, so dürfen reparaturen nur durch lambda oder autorisierte servicestellen durchgeführt werden. Die adressen ...

Page 132

131 symptom prüfung tätigkeit ref. Keine ausgangsspannung. Displays und anzeigen sind dunkel. Ist das netzkabel defekt? Falls erforderlich, netzkabel ersetzen. 3.7 ist die netzspannung innerhalb des eingangsbereiches? Netzspannung prüfen, gerät an passende versorgungsspannung anschließen. 3.6 3.7 au...

Page 133

132 user manual index a h s ac cables 16 humidity 18,20 safe start 47 ac fail 50 hyper terminal 80 safety 10 accessories 16 scpi 80 acknowledge 73 i series operation 51 address 68 identification commands 74 shield 70 auto-restart 47 shut off 52,58 initialization 75 specifications 17,19,120 b install...

Page 134

Notes.

Page 135

Notes.

Page 136

Notes.

Page 137

Notes.

Page 138

Tdk-lambda emea www.Emea.Tdk-lambda.Com innovating reliable power a d 04 12 ia 71 0-0 4-0 1c north america tdk-lambda americas inc. 3055 del sol boulevard san diego, ca 92154 u.S.A. Tel: +1-619-575-4400 fax: +1-619-575-7185 www.Us.Tdk-lambda.Com/lp uk tdk-lambda uk ltd. Kingsley avenue ilfracombe, d...