- DL manuals

- Vaillant

- Boiler

- ecoCRAFT VKK GB SERIES

- Installation And Maintenance Instructions Manual

Vaillant ecoCRAFT VKK GB SERIES Installation And Maintenance Instructions Manual

Summary of ecoCRAFT VKK GB SERIES

Page 1

For the heating engineer installation and maintenance instructions ecocraft gas condensing boiler vkk gb 806/3-e-h vkk gb 1206/3-e-h vkk gb 1606/3-e-h vkk gb 2006/3-e-h vkk gb 2406/3-e-h vkk gb 2806/3-e-h gb.

Page 2

Installation and maintenance instructions ecocraft - 0020055744_03 2 contents 1 notes on the documentation ...............................3 1.1 storage of the documents .......................................... 3 1.2 symbols used ................................................................. 3 1...

Page 3

1 notes on the documentation the following instructions are intended to help you throughout the entire documentation. Further documents apply in combination with this instal- lation and maintenance manual. We accept no liability for damage caused by a failure to observe these instructions. Documents...

Page 4

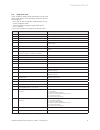

2 description of the appliance 2.1 model description appliance type designated country (designation in accordance with iso 3166) category of permit type of gas nominal heat output range p (kw) vkk gb 806/3-e-h gb (great britain) ie (ireland) i 2h g20 (natural gas e) 13.6 – 78.2 (80/60 °c) 14.1 – 80....

Page 5

2.3 intended use vaillant gas-fired condensing boilers vkk gb 806/3 -2806/3-e-h are constructed in accord- ance with state of the art technology and recognised safety regulations. Nevertheless, there is still a risk of injury or death to the user or others or of damage to the device and other proper...

Page 6

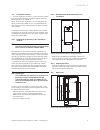

Overview of the operating controls 1 9 8 7 6 5 2 3 4 fig. 2.2 ecocraft operating controls to open the front panel, hold the recess and fold the panel out. You can now see the controls, which have the following functions (cf. Fig. 4.1): 1 display indicating the current heating flow tem- perature, the...

Page 7

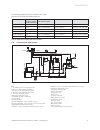

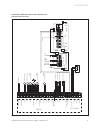

14 1 2 3 4 6 5 13 12 11 10 9 8 7 15 16 fig. 2.4 view from the left hand side key 1 fan 2 gas valve 3 supply air silencer 4 inspection opening for heat exchanger 5 supply air hose 6 siphon 7 condensate discharge 8 condensate trap/siphon connection 9 flue gas stl (optional) 10 flue gas silencer 11 con...

Page 8

3 safety instructions and regulations the appliance may only be installed by a competent qualified person registered with corgi. 3.1 safety instructions the combustion air fed to the unit must be free of chemicals e.G. Fluorine, chlorine or sulphur. Sprays, solvents or cleaning agents, paints and ad...

Page 9

Start-up the heating system must be thoroughly cleansed before use. The boiler heat exchanger is made from aluminium and any inhibitor used must be suitable for use with alu- minium. Always seek the advice of a professional water treatment company. Advice may be sought from: fernox cookson electroni...

Page 10

Bs 5854 code of practice for flues and flue structures in buildings. Bs en 12828 design of water-based heating systems. Bs 6644 specification for the installation of gas- fired hot water boilers with rated inputs between 70kw (net) and 1.8mw (net) (2nd and 3rd family gases). Bs 6880 code of practice...

Page 11

4.3 installation location • the unit should be installed in a frost-protected room. The unit can be operated in ambient temperatures be- tween approx. 4 °c and 50 °c. When selecting the installation site, the weight of the boiler including the water inside, as determined from the "technical data" ta...

Page 12

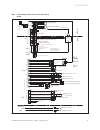

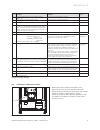

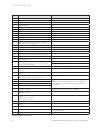

A b c d e f g fig. 4.4 appliance dimensions vkk gb 80-1606/3-e-h vkk gb 200-2806/3-e-h a 165 165 b 326 326 c 369 369 d 50 50 a 1168 1478 f 1240 1550 g 22 22 table 4.2 appliance dimensions boiler type vkk gb 806/ 3-e-h vkk gb 1206/ 3-e-h vkk gb 1606/ 3-e-h vkk gb 2006/ 3-e-h vkk gb 2406/ 3-e-h vkk gb...

Page 13

5 installation 5.1 general information on the heating system a caution! Malfunctions! Flush the heating system thoroughly before connecting the appliance! In this way, residue such as cinders, hemp, putty, rust, welding residues, coarse dirt and similar substances are removed from the pipes. Otherwi...

Page 14

5.3 gas connection the gas installation may only be carried out by a com- petent and qualified engineer. The legal directives and any local regulations for gas supply companies must be observed while doing this. The gas supply line must be constructed in accordance with the gas safety (installation ...

Page 15

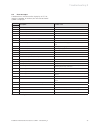

The following pumps and low loss headers are recom- mended for use with the respective boilers: boiler nominal water circulation volume for 20 k difference speed regulated high-efficiency pump 3 stage conventional pump low loss header vkk gb 806/3-e-h 3.44 item no. 0020022253 item no. 309 442 wh 95 ...

Page 16

5.6 air/flue gas installation in case you use air/flue gas pipes which are licenced to be used together with the boiler, please observe the en- closed installation instructions 0020058722. In case you use customary air/flue gas pipes, please overserve the following notes: the flue gas system must be...

Page 17

17 installation and maintenance instructions ecocraft - 0020055744_03 1 2 3 fig. 5.6 siphon key 1 siphon 2 drain hose to the neutralisation box (optional) or to the drain 3 hose from the condensate trap to the siphon d danger! Risk of poisoning from leaking flue gas! If the device is operated with a...

Page 18

Installation and maintenance instructions ecocraft - 0020055744_03 18 e danger! Danger of death from electric shock! The fan is connected to a 230 v/50 hz supply. The connection should be wired as follows: • open the front flap by lifting the silver handle strip. • unscrew the screw above the multi-...

Page 19

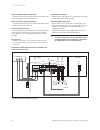

19 installation and maintenance instructions ecocraft - 0020055744_03 5.9.3 connecting electrical accessories and internal wiring mains voltage edge connector option - ext. Controller/ room thermostat 7-8-9 (analogue) option - ext. Controller/ room thermostat 3-4 (contact) bus connection (controller...

Page 20

Installation and maintenance instructions ecocraft - 0020055744_03 20 boiler circulation pump, fixed speed • connect the boiler circulation pump to the green proe plug connector on the connection rail. Boiler circulation pump, modulating • connect the boiler circulation pump additionally to the 0-10...

Page 21

21 installation and maintenance instructions ecocraft - 0020055744_03 connecting a vrc 630 control unit (controller out- side the electronics box) white white 9 c1 c2 7 8 dcf yellow af 0 red natural natural + 2 1 2 1 - blue beige yellow grey 1 1 2 1 2 1 2 2 yellow-green 1 2 white n open clo se d nat...

Page 22

Installation and maintenance instructions ecocraft - 0020055744_03 22 6 start-up initial start-up and operation of the appliance, and in- struction for the user, must be performed by a heating engineer. For subsequent installation/operation instruc- tions, see the relevant section of the operating m...

Page 23

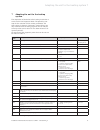

23 installation and maintenance instructions ecocraft - 0020055744_03 no. Procedure remarks tools required 1 check the gas connection pressure minimum inlet working pressure is not less than 17 mbar u-tube or digital pressure gauge 2 check whether syphon is full if necessary fill via flue gas analys...

Page 24

Installation and maintenance instructions ecocraft - 0020055744_03 24 6.3 function menu (for maintenance and service work) the function menu allows the technician to perform functional checks on individual actuators. It can always be started after a "reset" or a "mains on". After a wait of approx. F...

Page 25

25 installation and maintenance instructions ecocraft - 0020055744_03 on off check external pump? Vent hydraulics? Test burner? Check circulation pump? The internal heating pump is energised at the same time as the burner; function menu terminated. Vt target = vl max ºc 3 2 back yes back / forward b...

Page 26

Installation and maintenance instructions ecocraft - 0020055744_03 26 6.4 filling the system • flush the entire heating system thoroughly before fill- ing. Corrosion protection by water treatment in the case of heating water that has been conditioned by the addition of strongly alkaline substances, ...

Page 27

27 installation and maintenance instructions ecocraft - 0020055744_03 6.5.1 checking the connection pressure (gas flow pressure) 1 fig. 6.2 checking the gas flow pressure key 1 pressure measurement nipple proceed as follows to check the connection pressure: • remove the unit's front casing. • lift t...

Page 28

Installation and maintenance instructions ecocraft - 0020055744_03 28 • measure the co 2 content in the flue gas. Vkk gb xx6/3-e-h % co 2 at rated load % co 2 at minimum load g20 20 mbar 9.3 ± 0.2 9.0 ± 0.2 table 6.2 co 2 target values for rated and minimum load no further adjustment is required if ...

Page 29

29 installation and maintenance instructions ecocraft - 0020055744_03 h note! Adjust only in increments of 1/8 turn and wait approx. 1 minute after each adjustment until the value stabilises. After the adjustment, check the quality of combustion through the display opening: — no lifting of the flame...

Page 30

Installation and maintenance instructions ecocraft - 0020055744_03 30 6.6 checking the appliance function after installation and setting the gas ratio, perform a functional check before commissioning the appliance and handing it over to the user. Fig. 6.5 visual inspection of the appliance and the s...

Page 31

31 installation and maintenance instructions ecocraft - 0020055744_03 7 adapting the unit to the heating system the adaptation of the boiler to the heating installation is carried out in the diagnostic mode. The operating con- cept for the selection of the various parameters and their setting is sho...

Page 32

Installation and maintenance instructions ecocraft - 0020055744_03 32 7.1 setting the maximum boiler flow temperature the maximum boiler flow temperature for heating mode can be set at diagnostic point d.71, and for cylinder charging mode at d.78 (see table 9.2). 7.2 setting pump overrun time the ov...

Page 33

33 installation and maintenance instructions ecocraft - 0020055744_03 no. Procedure remarks tools 1 check the filling pressure of the heating system (button "-") top up if necessary (approx. 2.5 bar) 2 visual check for leaks in heating circuit check function of quick vent system 3 visual check of sa...

Page 34

Installation and maintenance instructions ecocraft - 0020055744_03 34 8.7 cleaning the siphon • remove the boiler casing. H note condensate can escape while the drain hoses are being pulled off. 1 2 fig. 8.2 removing the hoses • unfasten the hoses (1) and (2). 3 fig. 8.3 pulling off the clip • pull ...

Page 35

35 installation and maintenance instructions ecocraft - 0020055744_03 8.10 cleaning the burner if cleaning of the burner is necessary, the complete burner/fan unit must be dismantled. D danger! Danger of personal injury and material damage! Shut off the gas supply before dismantling the burner, as o...

Page 36

Installation and maintenance instructions ecocraft - 0020055744_03 36 8.11 checking the safety temperature limiter 1 fig. 8.9 reset button key 1 stl reset button with cover cap • switch on the mains switch. • turn the heating circuit off. • set the unit to maximum feed temperature and heat the unit ...

Page 37

37 installation and maintenance instructions ecocraft - 0020055744_03 9.2 diagnostic mode in the diagnostic mode various parameters can be read off to allow display of the operating conditions and for fault diagnosis. • press the "i" and "+" buttons simultaneously to call up the diagnostic mode. • s...

Page 38

Installation and maintenance instructions ecocraft - 0020055744_03 38 display meaning setting range and default setting for settable parameters d.34 actual speed of fan [rpm x 10] d.40 flow temperature [°c] d.41 return temperature [°c] d.43 boiler temperature d.44 actual value of ionisation current ...

Page 39

39 installation and maintenance instructions ecocraft - 0020055744_03 9.3 error messages a malfunction is indicated on the display by an "f" fol- lowed by a number. In addition, the "crossed-out flame" symbol is displayed. Fault with description possible cause no. "f.." 0 open circuit in flow sensor...

Page 40

Installation and maintenance instructions ecocraft - 0020055744_03 40 9.4 resetting the interlock after switch-off by the safety temperature limiter (stl) 1 fig. 9.1 resetting the interlock after switch-off by the stl if error code "f.20" is displayed, the safety temperature limiter (stl) has automa...

Page 41

41 installation and maintenance instructions ecocraft - 0020055744_03 10 factory customer service/ manufacturer's guarantee 10.1 vaillant service to ensure regular servicing, it is strongly recommended that arrangements are made for a maintenance agreement. Please contact vaillant service solutions ...

Page 42

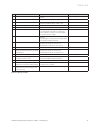

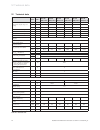

Installation and maintenance instructions ecocraft - 0020055744_03 42 12 technical data term units vkk gb 806/3-e-h vkk gb 1206/3-e-h vkk gb 1606/3-e-h vkk gb 2006/3-e-h vkk gb 2406/3-e-h vkk gb 2806/3-e-h rated heat output range for heating 80/60 kw 13.6 -78.2 21.3 -113.4 26.2 -156.5 43.1 -196.8 47...

Page 43

Term units vkk gb 806/3-e-h vkk gb 1206/3-e-h vkk gb 1606/3-e-h vkk gb 2006/3-e-h vkk gb 2406/3-e-h vkk gb 2806/3-e-h electrical equipment nominal voltage v/hz 230 / 50 max. Elec. Power consumption w 260 260 320 320 320 320 elec. Power consumption in standby w 8 level of protection ip 20 fuses fitte...

Page 44

0020055744_03 gb 112008.