- DL manuals

- Vaillant

- Boiler

- ecoCRAFT VKK GB SERIES

- Installation And Maintenance Instructions Manual

Vaillant ecoCRAFT VKK GB SERIES Installation And Maintenance Instructions Manual

Summary of ecoCRAFT VKK GB SERIES

Page 1

For the expert technician installation and maintenance instructions ecocraft gas-fired condensing boiler vkk gb 806/3-e-h vkk gb 1206/3-e-h vkk gb 1606/3-e-h vkk gb 2006/3-e-h vkk gb 2406/3-e-h vkk gb 2806/3-e-h gb.

Page 2

Installation and maintenance instructions ecocraft 0020055744_08 2 contents contents 1 notes on the documentation ...............................3 1.1 storage of the documents .......................................... 3 1.2 symbols used .................................................................

Page 3

1 notes on the documentation the following instructions are intended to help you throughout the entire documentation. Further documents apply in combination with this instal- lation and maintenance manual. We accept no liability for damage caused by a failure to observe these instructions. Documents...

Page 4

2 description of the appliance 2.1 model description unit type designated coun- try (designation in accordance with iso 3166) approval category type of gas nominal heat output range p (kw) vkk gb 806/3-e-h gb (great britain) ie (ireland) i 2h g20 (natural gas e) 14.7 – 84.1 (40/30 °c) 13.6 – 78.2 (8...

Page 5

2.4 intended use vaillant vkk gb 806/3 — 2806/3-e-h gas-fired condens- ing boilers are constructed in accordance with state of the art technology and recognised safety regulations. Nevertheless, there is still a risk of injury or death to the user or others or of damage to the device and other prope...

Page 6

Overview of the operating controls 1 9 8 7 6 5 2 3 4 fig. 2.2 ecocraft operating controls open the front flap by lifting the silver handle and fold- ing it out. You can now see the controls, which have the following functions (fig. 2.2): 1 display indicating the current heating flow tem- perature, t...

Page 7

14 1 2 3 4 6 5 13 12 11 10 9 8 7 15 16 fig. 2.4 view from the left hand side key 1 fan 2 gas fitting 3 supply air silencer 4 inspection opening for heat exchanger 5 supply air hose 6 siphon 7 condensate discharge 8 condensate trap/siphon connection 9 flue gas stl (optional) 10 flue gas silencer 11 c...

Page 8

3 safety instructions and regulations the appliance may only be installed by a competent per- son approved at the time by the health and safety ex- ecutive. 3.1 safety instructions the combustion air fed to the unit must be free of chemicals containing e.G. Fluorine, chlorine or sulphur. Sprays, sol...

Page 9

Inspection and maintenance inspection, maintenance and repair work should only be undertaken by an approved heating installation compa- ny. Inspections/maintenance work not carried out can result in damage to property and personal injury. The electrical installation must only be made by a quali- fie...

Page 10

Ige/up/1a soundness testing and purging of small low pressure industrial and commercial natural gas installations. Ige/up/10 installation of gas appliances in indus- trial and commercial premises. Part 1 flued appliances. 4 assembly the boiler is delivered in a packing unit, ready for con- nection a...

Page 11

4.3.2 recommended minimum distances for installation 500 500 300 50 fig. 4.2 recommended distances during installation (in mm) • keep to the recommended minimum distances in order to be able to carry out assembly and mainte- nance work with as little impediment as possible. 4.3.3 levelling the boile...

Page 12

5 installation 5.1 general information on the heating system a caution! Malfunctions! Flush the heating system thoroughly before connecting the appliance! In this way, residue such as cinders, hemp, putty, rust, welding res- idues, coarse dirt and similar substances are removed from the pipes. Other...

Page 13

5.3 gas connection the gas installation may only be carried out by a com- petent and qualified engineer. The legal directives and any local regulations for gas supply companies must be observed while doing this. The gas supply line must be constructed in accordance with the gas safety (installation ...

Page 14

The following pumps and low loss headers are recom- mended for use with the respective boilers: gas-fired condensing boiler nominal water circulation volume for 20 k difference speed regulated high-effi- ciency pump low loss header vkk gb 806/3-e-h 3.44 item no. 0020022253 wh 95 (item no. 306721) vk...

Page 15

5.6 air/flue gas installation should you use air/flue gas pipes which are licensed to be used together with the boiler, please observe the en- closed installation instructions 0020058722. Should you use conventional air/flue gas pipes, please note the following: the flue gas system must be suitable ...

Page 16

1 2 3 fig. 5.6 siphon key 1 siphon 2 drain hose to the neutralisation box (optional) or to the drain 3 hose from the condensate trap to the siphon d danger! Risk of poisoning from leaking flue gas! If the device is operated with an empty conden- sate siphon, there is a risk of poisoning from the esc...

Page 17

17 installation and maintenance instructions ecocraft 0020055744_08 • use the cable channel on the left hand side section for feeding the cable through the unit. A caution! Risk of malfunction! Do not use the same strain relief for the extra low voltage cable as for the mains cable! • take care to e...

Page 18

Installation and maintenance instructions ecocraft 0020055744_08 18 5.9.3 connecting electrical accessories and internal wiring ionisation electrode 4a slow-blow blue option - ext. Controller/room thermostat 3-4 (contact) charging pump heating circuit pump/ boiler circulation pump option - ext. Cont...

Page 19

19 installation and maintenance instructions ecocraft 0020055744_08 boiler circulation pump, speed regulated • connect the boiler circulation pump to the green proe connector on the terminal strip, and also the control line to the 0 — 10 v adapter box which is located at the top left of the unit, ne...

Page 20

Installation and maintenance instructions ecocraft 0020055744_08 20 5.9.4 connecting a controller connecting a vrc 430 control unit (controller out- side the electronics box) a weather-controlled outside temperature controller with modulating burner control can be used to control the heating install...

Page 21

21 installation and maintenance instructions ecocraft 0020055744_08 connecting a vrs 620, vrc 630 control unit (con- troller outside the electronics box) white white 9 c1 c2 7 8 dcf yellow af 0 red natural natural + 2 1 2 1 - blue beige yellow grey 1 1 2 1 2 1 2 2 yellow-green 1 2 white n open clo s...

Page 22

Installation and maintenance instructions ecocraft 0020055744_08 22 6 start-up the initial start-up and operation of the appliance, and instruction for the user, must be performed by a fully competent heating engineer who is currently qualified to carry out the commissioning of this appliance. Vaill...

Page 23

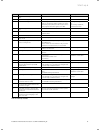

23 installation and maintenance instructions ecocraft 0020055744_08 no. Procedure remarks tools required 1 ensure boiler and system are full of water 2 check whether syphon is full if necessary fill via flue gas analysis point 3 check the entire gas route for leaks gas sensing instrument is recommen...

Page 24

Installation and maintenance instructions ecocraft 0020055744_08 24 6.3 function menu (for maintenance and service work) the function menu allows the technician to perform functional checks on individual components. It can al- ways be started after a " reset " or a " mains on ". After a wait of appr...

Page 25

25 installation and maintenance instructions ecocraft 0020055744_08 on off check external pump? Vent hydraulics? Test burner? Check circulation pump? The internal heating pump is energised at the same time as the burner; function menu terminated. Vt target = vl max ºc 3 2 back yes back / forward bac...

Page 26

Installation and maintenance instructions ecocraft 0020055744_08 26 6.4 filling the system a caution! Malfunction! Flush the heating system thoroughly before connecting the appliance! In this way you will remove residues such as welding beads, cinders, hemp, mastic, rust, coarse dirt and the like fr...

Page 27

27 installation and maintenance instructions ecocraft 0020055744_08 total heating rating total hardness at 20 l/kw for the smallest boiler heating sur- face 2) total hardness at > 20 l/kw for the smallest boiler heating surface 2) total hardness at > 50 l/kw for the smallest boiler heating surface 2...

Page 28

Installation and maintenance instructions ecocraft 0020055744_08 28 6.4.1 filling the heating side • loosen the cap on the factory-fitted automatic air vent by one or two turns. Make sure that the opening of the cap does not point towards the electronic com- ponents. • fill the installation up to a ...

Page 29

29 installation and maintenance instructions ecocraft 0020055744_08 • if you cannot correct the defects you must not start up the boiler. 6.5.2 checking the gas inlet working pressure • ensure that the gas inlet working pressure can be ob- tained with all other gas appliances in the property working...

Page 30

Installation and maintenance instructions ecocraft 0020055744_08 30 • if the measured gas flow rate lies outside the toler- ance limits specified in table 6.5, do not operate the boiler and inform the vaillant service solutions (0870 6060 777). • if the measured gas flow rate is within the tolerance...

Page 31

31 installation and maintenance instructions ecocraft 0020055744_08 7 adapting the unit to the heating system the adaptation of the boiler to the heating installation is carried out in the diagnostic mode. The operating con- cept for the selection of the various parameters and their setting is shown...

Page 32

Installation and maintenance instructions ecocraft 0020055744_08 32 diagnostic point description setting range default setting d.77 cylinder partial load (cylinder charging output limit- ing) in kw settable values in kw vkk gb 806 = 14 - 80 kw vkk gb 1206 = 22 - 120 kw vkk gb 1606 = 27 - 160 kw vkk ...

Page 33

33 installation and maintenance instructions ecocraft 0020055744_08 8 inspection and maintenance 8.1 inspection and maintenance intervals a danger! Risk of injury and risk of damage to property due to neglected maintenance! Neglected maintenance works or not observing the demanded maintenance interv...

Page 34

Installation and maintenance instructions ecocraft 0020055744_08 34 safety instructions a danger! Danger of life and limb by electric shock! The supply terminals of the boiler are under mains voltage even if the boiler main switch is off. Don’t touch the supply terminals. Protect the electronic box ...

Page 35

35 installation and maintenance instructions ecocraft 0020055744_08 if the flue gas value in maximum load needs to be ad- justed, • remove the black cover cap to reach the screw of the main throttle on gas valve (1, see fig. 8.1). • be sure that the boiler is running in p.1 for full load (see sectio...

Page 36

Installation and maintenance instructions ecocraft 0020055744_08 36 8.5 maintenance work steps • carry out proper regular maintenance once a year. No. Activity 1 check the filling pressure of the heating system (button “-”) top up if necessary (section 6.4.1). 2 check the air flue gas system for lea...

Page 37

37 installation and maintenance instructions ecocraft 0020055744_08 3 fig. 8.3 pulling off the clip • pull off the clip ( 3 , fig. 8.3). • remove the siphon and clean it. • fit the siphon in reverse sequence. • unscrew the plug from the flue gas measurement opening and fill the siphon with water thr...

Page 38

Installation and maintenance instructions ecocraft 0020055744_08 38 8.10 cleaning the burner d danger! Danger of personal injury and material damage! Shut off the gas supply before dismantling the burner, as otherwise gas can escape without control. H note the burner must be cleaned once a year. It ...

Page 39

39 installation and maintenance instructions ecocraft 0020055744_08 • open the gas valve and check for leaks up to the gas fitting. • switch the boiler on. • use a gas sensing instrument to check for leaks in the gas/air combination behind the gas fitting and along the burner gaskets. • tighten the ...

Page 40

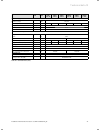

Installation and maintenance instructions ecocraft 0020055744_08 40 9 troubleshooting 9.1 status messages • press the " i " button to read the current operating sta- tus. • press the " i " button again to quit the display mode. All the parameters are summarised in the following table. Display status...

Page 41

41 installation and maintenance instructions ecocraft 0020055744_08 9.2 diagnostic mode in the diagnostic mode various parameters can be read off to allow display of the operating conditions and for fault diagnosis. • press the " i " and " + " buttons simultaneously to call up the diagnostic mode. •...

Page 42

Installation and maintenance instructions ecocraft 0020055744_08 42 display meaning setting range and default setting for settable parameters d.34 actual speed of blower [rpm x 10] d.40 flow temperature [°c] d.41 return temperature [°c] d.43 boiler temperature d.44 actual value of ionisation current...

Page 43

43 installation and maintenance instructions ecocraft 0020055744_08 9.3 error messages a malfunction is indicated on the display by an "f" fol- lowed by a number. In addition, the "crossed-out flame" symbol is displayed. Fault with description possible cause no. "f.." 0 open circuit in flow sensor 1...

Page 44

Installation and maintenance instructions ecocraft 0020055744_08 44 9.4 test programs special functions can be triggered on the appliances by activating various test programs. These programs are given in detail in the table 8.5. The test programs p.0 to p.6 will be started when "power on" is turned ...

Page 45

45 installation and maintenance instructions ecocraft 0020055744_08 10 customer service and warranty 10.1 vaillant service to ensure regular servicing, it is strongly recommended that arrangements are made for a maintenance agreement. Please contact vaillant service solutions (0870 6060 777) for fur...

Page 46

Installation and maintenance instructions ecocraft 0020055744_08 46 12 technical data term units vkk gb 806/ 3-e-h vkk gb 1206/ 3-e-h vkk gb 1606/ 3-e-h vkk gb 2006/ 3-e-h vkk gb 2406/ 3-e-h vkk gb 2806/ 3-e-h rated heat output range for heating 80/60 kw 13.6—78.2 21.3—113.4 26.2—156.5 43.1—196.8 47...

Page 47

47 installation and maintenance instructions ecocraft 0020055744_08 term units vkk gb 806/ 3-e-h vkk gb 1206/ 3-e-h vkk gb 1606/ 3-e-h vkk gb 2006/ 3-e-h vkk gb 2406/ 3-e-h vkk gb 2806/ 3-e-h electrical equipment nominal voltage v/hz 230/50 max. Elec. Power consumption w 260 260 320 320 320 320 elec...

Page 48

0020055744_08 gb 082011 - subject to alterations.