- DL manuals

- Vaillant

- Boiler

- ecoTEC plus 612

- Instructions For Installation And Servicing

Vaillant ecoTEC plus 612 Instructions For Installation And Servicing

For the installer

ecoTEC plus 612

ecoTEC plus 615

ecoTEC plus 618

ecoTEC plus 624

ecoTEC plus 630

ecoTEC plus 637

ecoTEC plus 824

ecoTEC plus 831

ecoTEC plus 837

ecoTEC pro 28

ecoTEC pro 24

Instructions for installation and servicing

ecoTEC

Wall hung room sealed fan assisted condensing boiler

GB, IE

Summary of ecoTEC plus 612

Page 1

For the installer ecotec plus 612 ecotec plus 615 ecotec plus 618 ecotec plus 624 ecotec plus 630 ecotec plus 637 ecotec plus 824 ecotec plus 831 ecotec plus 837 ecotec pro 28 ecotec pro 24 instructions for installation and servicing ecotec wall hung room sealed fan assisted condensing boiler gb, ie.

Page 2

2 contents instructions for installation and servicing ecotec 839592_12 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.1 notes on the documentation . . . . . . . . . . . . . . . . 4 1.1.1 applicable documents . . . . . . . . . . . . . . . . . . . . . . 4 1.1.2 retention of ...

Page 3

3 instructions for installation and servicing ecotec 839592_12 contents 6 functional checks (commissioning part ii). . 39 6.1 functional checks . . . . . . . . . . . . . . . . . . . . . . . . . 39 6.1.1 procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 6.1.2 heating . . . ...

Page 4

4 instructions for installation and servicing ecotec 839592_12 1 introduction 1 introduction 1.1 notes on the documentation the following information is intended to help you throughout the entire documentation. Further documents apply in combination with this installation and maintenance manual. We ...

Page 5

5 instructions for installation and servicing ecotec 839592_12 the ecotec system boiler consists of models with outputs of 12, 15, 18, 24, 30 and 37 kw. All ecotec system boilers are available in natural gas. The ecotec plus 618 and 630 are also available in lpg. 1.4 general notes the boilers have b...

Page 6

6 instructions for installation and servicing ecotec 839592_12 2 boiler specifications 2.1 technical data technical data ecotec plus ecotec pro units 824 831 837 24 28 ch heat output range 80 °c flow/60 °c return 60 °c flow/40 °c return 50 °c flow/30 °c return 40 °c flow/30 °c return 6.7 – 19.0 6.9 ...

Page 7

7 instructions for installation and servicing ecotec 839592_12 technical data ecotec plus units 612 615 618 624 630 637 ch heat output range 80 °c flow/60 °c return 60 °c flow/40 °c return 50 °c flow/30 °c return 40 °c flow/30 °c return 4.9 – 12.0 5.1 – 12.3 5.2 – 12.7 5.3 – 12.9 4.9 – 15.0 5.1 – 15...

Page 8

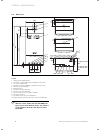

8 instructions for installation and servicing ecotec 839592_12 2.2 dimensions 24 1 20 64 2 72 0 883 12 5 100 100 440 35 35 130 180 300 ecotec plus 630: 334 ecotec plus 637, ecotec plus 837: 368 17 5 190 65 75 45 8 6 4 3 2 1 5 7 10 9 1 2 3 4 5 11 12 fig. 2.1 dimensions in mm legend: 1 heating return ...

Page 9

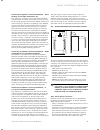

9 instructions for installation and servicing ecotec 839592_12 2.3 installation 1 2 3 4 6 5 7 8 9 14 13 11 10 12 fig. 2.2 function elements of combination boilers legend: 1 expansion vessel 2 air intake pipe 3 burner module 4 ignition electrode 5 fan 6 diverter valve with by-pass 7 pump 8 aqua-senso...

Page 10

10 instructions for installation and servicing ecotec 839592_12 3 general requirements 3.1 preliminary remarks for room sealed appliances this appliance should only be installed in conjunction with either a vaillant flue system or an alternative approved system (details of flue approval categories c...

Page 11

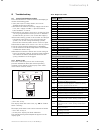

11 instructions for installation and servicing ecotec 839592_12 1 2 3 4 7 8 6 5 fig. 3.1 contents included with delivery of ecotec plus system boilers do not remove the boiler from the polystyrene base at this stage. Item quantity description 1 1 hanging bracket 2 1 boiler 3 1 bottom cover 4 4 conne...

Page 12

12 instructions for installation and servicing ecotec 839592_12 bar i f p 1 2 3 7 6 5 4 fig. 3.3 contents included with delivery of ecotec pro combi- nation boilers do not remove the boiler from the polystyrene base at this stage. Item quantity description 1 1 hanging bracket 2 1 boiler 3 2 connecti...

Page 13

13 instructions for installation and servicing ecotec 839592_12 their contractor. An existing meter should be checked to ensure that it is capable of passing the rate of gas supply required. Installation pipes should be fitted in accordance with bs 6891. In ie the current edition of is 813. Pipework...

Page 14

14 instructions for installation and servicing ecotec 839592_12 a bcd a g h, i f j b f m l l k k g g f f e a a fig. 3.8 flue termination note vertical flues must not terminate within 600 mm of an openable window, air vent or any other ventilation opening. The flue assembly shall be so placed or shie...

Page 15

15 instructions for installation and servicing ecotec 839592_12 3.10 guide to system requirements 3.10.1 water circulation system detailed recommendations for the water circulation system are given in bs 6798 and bs 5449: part 1 (for small bore and micro bore central heating systems). Pipework not f...

Page 16

16 instructions for installation and servicing ecotec 839592_12 total heating output total hardness at 20 l/kw for the smallest boiler heating surface 2) total hardness at > 20 l/kw heating surface 2) total hardness at > 50 l/kw for the smallest boiler heating surface 2) kw mol/m 3 mol/m3 mol/m 3 no...

Page 17

17 instructions for installation and servicing ecotec 839592_12 vessel volume [l] initial system pressure (bar) 1.0 1.5 pressure relief valve setting (bar) 3.0 total water content of system litres 25 2.7 3.9 50 5.4 7.8 100 10.9 15.6 125 13.6 19.5 150 16.3 23.4 175 19.1 27.3 200 21.8 31.2 225 24.5 35...

Page 18

18 instructions for installation and servicing ecotec 839592_12 4 boiler installation sequence 4.1 transporting the appliance caution! With regards to the manual handling operations, 1992 regulations, the following lift operation exceeds the recommended weight for a one man lift. General recommendat...

Page 19

19 instructions for installation and servicing ecotec 839592_12 positioning of appliance for final installation – above worktop, foreseeable obstructions etc. This appliance is deemed to be a one person lift when removed from the carton. Fit bracket securely onto wall before lifting appliance into p...

Page 20

20 instructions for installation and servicing ecotec 839592_12 4.2.2 unpack the boiler to unpack the boiler, cut both plastic carton straps, open box and lift out the polystyrene top packing. Lift the cardboard box upwards. Note care should be taken not to scratch the white surface of the boiler ca...

Page 21

21 instructions for installation and servicing ecotec 839592_12 4.5 installing the flue system • install the flue system (refer to the seperate air/flue duct installation instructions). 4.6 fitting the boiler • lift the boiler (3) up to the wall so that it is slightly above the hanging bracket (1). ...

Page 22

22 instructions for installation and servicing ecotec 839592_12 2 6 7 3 5 4 1 fig. 4.5 fitting the gas connection (example ecotec plus com- bination boiler) • fit the union nut (2) and the compression olive (3) to the gas connection pipe (1) of the boiler. • fit the union nut (6) and the compression...

Page 23

23 instructions for installation and servicing ecotec 839592_12 note flush all foreign matter from the mains supply before connecting to the boiler. • insert the seal (1) and connect the service valve (2) to the appliance cold water connection. • fit the union nut (4) and the compression olive (3) t...

Page 24

24 instructions for installation and servicing ecotec 839592_12 4.12 heating connection caution! When making final connection to the boiler, if using soldered fittings, extra care should be taken to avoid damage to isolation valves through heat transfer. 4.12.1 heating flow and return connection not...

Page 25

25 instructions for installation and servicing ecotec 839592_12 caution! To ensure fumes do not escape through the syphon of the boiler the trap must be filled with water be- fore the boiler is turned on. Therefore the discharge pipework should be installed so as not to interfere with the removal an...

Page 26

26 instructions for installation and servicing ecotec 839592_12 4.14.2 connection to the main supply fig. 4.13 opening the electronics box • remove the front case and lower the control panel. • unclip the bottom of the terminal box cover and hinge back to reveal the connection plugs. • feed the powe...

Page 27

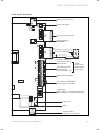

27 instructions for installation and servicing ecotec 839592_12 4.14.3 electric board layout burner cable harness hydraulic cable harness connection for external ebus controller room thermostat 24 v: connection 7, 8 and 9 no bi-directional interface (analogue only) room thermostat 230 v/50 hz (remov...

Page 28

28 instructions for installation and servicing ecotec 839592_12 x 2 bus — + 24v 7 8 9 230v l n 3 4 5 x 20 x40 x3 1 x12 x41 electronic control box aqua sensor ecotec plus only: ntc hot water outlet fan unit ignition electrode ntc flow diverter valve gas valve assembly water pressure sensor ntc return...

Page 29

29 instructions for installation and servicing ecotec 839592_12 x 2 bus 24v 7 8 9 — + 230v l n 3 4 5 x 20 x40 x3 1 x12 x41 electronic control box fan unit ignition electrode ntc flow gas valve assembly hot water contact c1/c2 water pressure sensor ntc return x 20/5 red x 20/7 black x 20/7 black x 20...

Page 30

30 instructions for installation and servicing ecotec 839592_12 4.15 controls 4.15.1 vaillant controls and accessories controller item no. Connection vrc 400 (1-circuit controller, weather-controlled) 00 2001 0843 installation in electronics box (plug-and-play) vrt 360 (room temperature controller) ...

Page 31

31 instructions for installation and servicing ecotec 839592_12 4.16 thermostatic radiator valves the boiler has a built in automatic by-pass valve making it ideal for use in systems with thermostatic radiator valves (no separate system by-pass is required). For optimum fuel economy where trv’s are ...

Page 32

32 instructions for installation and servicing ecotec 839592_12 5 commissioning part i 5.1 preliminary electrical checks check the electrical installation by carrying out short circuit, earth continuity and resistance to earth tests and a check for correct polarity. 5.2 gas supply the complete gas i...

Page 33

33 instructions for installation and servicing ecotec 839592_12 the ecotec plus combination boiler will be delivered with a filling loop. • insert the double check valve (1) of the filling pipe at the cold water shutoff valve and secure the double check valve with the spring clip (2). • to fill, fir...

Page 34

34 instructions for installation and servicing ecotec 839592_12 5.6 filling the condensate siphon 1 fig. 5.4 filling the condensate siphon danger! Note that if the boiler is run with an empty condensate trap there is a danger that fumes might escape into the room and cause poisoning. For this reason...

Page 35

35 instructions for installation and servicing ecotec 839592_12 if the boiler version corresponds to the local gas family: • proceed as described below. If the boiler version does not correspond to the local gas family: • perform the gas conversion in accordance with the gas conversion kit 002001064...

Page 36

36 instructions for installation and servicing ecotec 839592_12 boiler nominal net heat input in kw as per bs en 483 gas flow rate natural gas in m 3 /h propane in kg/h nominal + 5% - 10% nominal + 5% - 10% ecotec plus 612 12.2 1.29 1.36 1.16 0.95 1.00 0.85 ecotec plus 615 15.3 1.62 1.70 1.46 1.19 1...

Page 37

37 instructions for installation and servicing ecotec 839592_12 • connect a digital pressure gauge or u-tube manometer (2). • open the gas isolation valve of the boiler. • start the boiler by activating the test program p.1 as described in section 8.2. • in addition, ensure that maximum heat can be ...

Page 38

38 instructions for installation and servicing ecotec 839592_12 5.10 refitting the case 1 2 fig. 5.9 refitting the case • hook the top of the front casing over the lip on the top of the boiler chassis and push the bottom of the front casing into place. • ensure the spring retaining clips (2) engage ...

Page 39

39 instructions for installation and servicing ecotec 839592_12 6 functional checks (commissioning part ii) 6.1 functional checks 6.1.1 procedure after installing and checking the gas supply pressure, perform a function check before commissioning the appliance and handing over to the user. • commiss...

Page 40

40 instructions for installation and servicing ecotec 839592_12 • release water from the system until the system design pressure of 1.0 bar is attained. (the actual reading on the digital pressure gauge should ideally be 0.5 bar plus an additional pressure corresponding to the highest point of the s...

Page 41

41 instructions for installation and servicing ecotec 839592_12 7 inspection and maintenance 7.1 inspection and maintenance intervals danger! Risk of injury and risk of damage to property due to neglected inspection and maintenance! Neglected inspection and maintenance works or not observing the sta...

Page 42

42 instructions for installation and servicing ecotec 839592_12 - correctness of electrical, water and gas connections. - correctness of the water pressure. - the condition of the whole system, in particular the condition of radiator valves, evidence of leakage from the heating system and dripping t...

Page 43

43 instructions for installation and servicing ecotec 839592_12 note the boiler is fitted with a flue gas analysis point (4). A suitable flue gas analyser can be connected to this point to establish the combustion performance of the boiler. • remove the front casing. • start the testing program p.1....

Page 44

44 instructions for installation and servicing ecotec 839592_12 7.1.5 inspection and maintenance work steps no. Activity column 1 inspection must be carried out each year column 2 maintenance must be carried out at regular intervals – but no longer than 5 years 1 check the air flue gas installation ...

Page 45

45 instructions for installation and servicing ecotec 839592_12 7.2 servicing the burner module 7.2.1 removing the burner module the burner module consists of the burner, fan, gas valve und the gas supply (mixer tube). These four components make up the complete assembly, the burner module. Danger! T...

Page 46

46 instructions for installation and servicing ecotec 839592_12 7.2.2 cleaning the integral condensation heat exchanger caution! Protect the electronics box against sprayed water. 3 4 1 2 fig. 7.4 cleaning the integral condensation heat exchanger • dismantle the burner module as described under 7.2....

Page 47

47 instructions for installation and servicing ecotec 839592_12 inspection and maintenance 7 10 9 8 4 5 7 6 fig. 7.7 refitting the burner module • insert the burner module (9) in the integral condensation heat exchanger (10). • tighten the four nuts (4) on the alternate left and right sides until th...

Page 48

48 instructions for installation and servicing ecotec 839592_12 • clean the siphon part section by rinsing it out with water. • fill the lower part with water until about 10 mm below the upper edge. • fasten the lower part again on the condensate siphon. 7.4 checking the expansion vessel 1 fig. 7.11...

Page 49

49 instructions for installation and servicing ecotec 839592_12 8 troubleshooting 8.1 logical fault finding procedure these checks must be carried out before attempting to use the fault finding guide. 1. Carry out electrical safety checks (see section ‘preliminary electrical checks’). 2. Check that ...

Page 50

50 instructions for installation and servicing ecotec 839592_12 in the diagnostic mode, you can change certain parameters or display more information. The diagnostic information is divided into two diagnostic levels. The second diagnostic level can be reached only after entering a password. Caution!...

Page 51

51 instructions for installation and servicing ecotec 839592_12 display meaning display value/adjustable value d.36 hot water flow sensor in l/min d.40 flow temperature actual value in °c d.41 return temperature actual value in °c d.44 digitised ionisation potential display range of 0 to 102, > 80 n...

Page 52

52 instructions for installation and servicing ecotec 839592_12 display meaning display value/adjustable value d.50 offset for minimum speed in rpm/10, adjustment range: 0 to 300 d.51 offset for maximum speed in rpm/10, adjustment range: -99 to 0 d.58 from the third quarter of 2006: activation of so...

Page 53

53 instructions for installation and servicing ecotec 839592_12 code meaning cause f. 0 flow–ntc open circuit ntc broken, ntc cable broken, defective connection at ntc, defective connection at electronics f. 1 return–ntc open circuit ntc broken, ntc cable broken, defective connection at ntc, defecti...

Page 54

54 instructions for installation and servicing ecotec 839592_12 8.2 test programs special functions can be triggered on the appliances by activating various test programs. These programs are given in detail in the table 8.5. • the test programs p.0 to p.6 will be started when “power on” is turned on...

Page 55

55 instructions for installation and servicing ecotec 839592_12 9.2 replacing burner danger! Before replacing the component, comply with the safety instructions in section 9.1. • dismantle the burner module as described in section 7.2.1. 1 fig. 9.1 replacing burner • loosen the 4 screws (1) on burne...

Page 56

56 instructions for installation and servicing ecotec 839592_12 9.4 replacing expansion vessel danger! Before replacing the component, comply with the safety instructions in section 9.1. • disconnect the appliance from the mains as described in section 9.1, and close the service valve in the gas sup...

Page 57

57 instructions for installation and servicing ecotec 839592_12 3 2 1 fig. 9.6 primary heat exchanger holder • disconnect the plug-in connection (2) of the thermal fuse in the primary heat exchanger. • remove the three screws (3) on the primary heat exchanger holder. • turn the holder to the side ar...

Page 58

58 instructions for installation and servicing ecotec 839592_12 10 recycling and disposal both the vaillant ecotec and the associated transport packaging consist primarily of recyclable raw materials. The vaillant ecotec and all accessories and packaging must not be disposed of in the normal househo...

Page 59

Appendix eg declaration of conformity appendix.

Page 60

Installation, commissioning and service record installation, commissioning and service record.

Page 61

Please affix the label from the rear cover of the control box over this area..

Page 62: Service Interval Record

Service interval record it is recommended that your heating system is serviced regularly and that you complete the appropriate service interval record below . Service provider. Before completing the appropriate service interval record below, please ensure you have carried out the service as describe...

Page 64

839592_12 gbie 062010 — subject to alterations.