- DL manuals

- Vaillant

- Boiler

- ecoTEC plus 612

- Instructions For Installation And Servicing

Vaillant ecoTEC plus 612 Instructions For Installation And Servicing

Summary of ecoTEC plus 612

Page 1

For the installer ecotec plus 612 ecotec plus 615 ecotec plus 618 ecotec plus 624 ecotec plus 630 ecotec plus 824 ecotec plus 831 ecotec pro 28 instructions for installation and servicing ecotec wall hung room sealed fan assisted condensing boiler gb.

Page 2

2 contents instructions for installation and servicing ecotec contents 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.1 notes on the documentation . . . . . . . . . . . . . . . 4 1.1.1 applicable documents . . . . . . . . . . . . . . . . . . . . . 4 1.1.2 preservation of docu...

Page 3

3 instructions for installation and servicing ecotec contents 7 inspection and maintenance . . . . . . . . . . . . 38 7.1 initial inspection . . . . . . . . . . . . . . . . . . . . . . . . . . 38 7.1.2 safety instructions. . . . . . . . . . . . . . . . . . . . . . . . 38 7.1.3 maintenance . . . . . ...

Page 4

4 instructions for installation and servicing ecotec 1 introduction 1 introduction 1.1 notes on the documentation the following information is intended to help you throughout the entire documentation. Further documents apply in combination with this instal- lation and maintenance manual. We assume n...

Page 5

5 instructions for installation and servicing ecotec the valliant ecotec are state-of-the-art appliances which have been constructed in accordance with recog- nised safety regulations. Nevertheless, danger to the life and limb of the user or third parties can still occur or the appliance or other ma...

Page 6

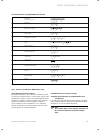

6 instructions for installation and servicing ecotec 2 boiler specifications 2.1 technical data technical data ecotec plus ecotec pro 28 units 824 831 ch heat output range 80 °c flow/60 °c return 60 °c flow/40 °c return 50 °c flow/30 °c return 40 °c flow/30 °c return 6.0 – 18.0 6.1 – 18.6 6.3 – 19.1...

Page 7

7 instructions for installation and servicing ecotec technical data ecotec plus units 612 615 618 624 630 ch heat output range 80 °c flow/60 °c return 60 °c flow/40 °c return 50 °c flow/30 °c return 40 °c flow/30 °c return 4.0 – 12.0 4.1 – 12.3 4.3 – 12.7 4.4 – 12.9 4.0 – 15.0 4.1 – 15.5 4.3 – 15.9 ...

Page 8

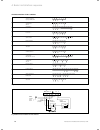

8 instructions for installation and servicing ecotec 2.2 dimensions 241 20 642 720 883 125 100 100 440 35 35 130 180 300 175 190 65 8 6 4 3 2 1 5 7 9 10 1 2 3 4 5 fig. 2.1 dimensions in mm legend: 1 heating return pipe Ø 22 mm 2 cold water connection Ø 15 mm (only 800 series) 3 gas connection Ø 15 m...

Page 9

9 instructions for installation and servicing ecotec 2.4 installation 1 2 3 4 6 5 7 8 9 14 13 12 10 11 fig. 2.2 function elements of 800 series legend: 1 expansion vessel 2 air intake pipe 3 compact thermal module 4 ignition electrode 5 fan 6 diverter valve with by-pass 7 pump 8 aqua-sensor 9 electr...

Page 10

10 instructions for installation and servicing ecotec 2.5 type plate the type plate of the valliant ecotec is attached to the bottom of the appliance at the factory. Fig. 2.4 type plate (example) 3 general requirements 3.1 preliminary remarks this appliance shall only be installed in conjunction wit...

Page 11

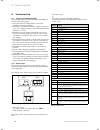

11 instructions for installation and servicing ecotec 1 2 3 4 8 9 7 6 5 fig. 3.1 scope of delivery for ecotec plus 600 series do not remove the boiler from the polystyrene base at this stage. Item quantity description 1 1 hanging bracket 2 1 appliance 3 1 bottom cover 4 4 connecting pipes (gas, heat...

Page 12

12 instructions for installation and servicing ecotec bar i f p 1 2 3 8 7 6 5 4 fig. 3.3 scope of delivery for ecotec pro do not remove the boiler from the polystyrene base at this stage. Item quantity description 1 1 hanging bracket 2 1 appliance 3 2 connecting pipes (hot water, heating safety valv...

Page 13

13 instructions for installation and servicing ecotec bustion air supply is technical free of the above men- tioned substances. 3.5 gas supply the gas supplier should ensure the availability of an adequate supply of gas. A gas meter may only be con- nected to the service pipe by the supplier of gas ...

Page 14

14 instructions for installation and servicing ecotec 3.7 flue termination the following details refer to both flue systems. A. The terminal must be located where the combustible substances can escape freely at all times. B. A plume of water vapour will sometimes be visible from the flue terminal. P...

Page 15

15 instructions for installation and servicing ecotec 3.9 electrical supply a 230 v, ~ 50 hz single phase electricity supply fused to 3 amp. Must be provided in accordance with the latest edition of bs 7671 (iee wiring regulations) and any other local regulations that may apply. In ie reference shou...

Page 16

16 instructions for installation and servicing ecotec 3.11 pump specifications 3.11.1 circulating pump only ecotec plus: the circulating pump is included in the boiler. The resid- ual pump discharge height depending on the by-pass valve is shown in fig. 3.10. The operating mode of the 2-step pump ca...

Page 17

17 instructions for installation and servicing ecotec 4.1.1 select position for boiler refer to section ‘boiler location’ for information regard- ing the appliance location. In general the boiler must be positioned such that: • there is adequate space around the boiler for service and maintenance • ...

Page 18

18 instructions for installation and servicing ecotec 4.2 flue exit • if using rear flue mark the position of the air/flue duct and its circumference. Other flue options flue instructions for other flue systems such as vertical rsf flues, flues run to the side of the boiler and the use of additional...

Page 19

19 instructions for installation and servicing ecotec 4.8 gas connection note with the spacer frame (art. No 308 650), the pipes can be laid in front of the wall upwards behind the appliance. The distance of the appli- ance from the wall thus increases by 65 mm. Danger! The gas installation may only...

Page 20

20 instructions for installation and servicing ecotec ba r 1 2 3 4 5 6 7 fig. 4.7 installing the hot and cold water connection (ecotec pro) note flush all foreign matter from the mains supply before connecting to the boiler. • insert the seal ( 1 ) and screw in the maintenance tap ( 2 ) at the appli...

Page 21

21 instructions for installation and servicing ecotec ecotec pro bar 1 2 3 4 5 fig. 4.9 heating flow and return connection for ecotec pro • insert a seal ( 1 ) and screw in the maintenance taps ( 2 ) at the flow and return connection of the appliance. • insert a union nut ( 4 ) and a pinching ring (...

Page 22

22 instructions for installation and servicing ecotec 4.11 condensate drain pipe 7 d soakaway c 6 5 gulley a internal stackpipe 3 4 3 b internal discharge system 1 2 fig. 4.12 installing the condensate drain pipe (picture shows ecotec 800 plus) the ecotec plus appliances are fitted with a siphonic t...

Page 23

23 instructions for installation and servicing ecotec danger! Mains connection terminals l and n remain live even when the boiler on/off control is switched off. Note do not connect any power voltage to the con- nections 7-8-9. Note ensure that all cords pass through the cable clamps in the rear of ...

Page 24

24 instructions for installation and servicing ecotec 4.13.3 electric board layout fig. 4.15 connection wiring ecotec 4 boiler installation sequence.

Page 25

25 instructions for installation and servicing ecotec x 2 bus + – 24v 7 8 9 230v l n 3 4 5 x 20 x40 x3 1 x12 x41 electronic control box aqua sensor ntc hot water outlet fan unit ignition electrode ntc flow diverter valve gas valve assembly water pressure sensor ntc return x 20/5 red x 20/7 black x 2...

Page 26

26 instructions for installation and servicing ecotec x 2 bus + – 24v 7 8 9 230v l n 3 4 5 x 20 x40 x3 1 x12 x41 electronic control box fan unit ignition electrode ntc flow gas valve assembly hot water contact c1/c2 water pressure sensor ntc return x 20/5 red x 20/7 black x 20/7 black x 20/8 blue x ...

Page 27

27 instructions for installation and servicing ecotec 4.13.4 connection of programmable thermostats l n 2 3 4 l n 3 4 1 acl drayton lyfestyle pt271, pt371 acl drayton digistat 2, 3, 4 acl drayton digistat rf - scr receiver danfoss randall tp4, tp5, tp5e danfoss randall tp5e rf with receiver rx1 danf...

Page 28

28 instructions for installation and servicing ecotec 4.14.4 connection of time switches l n 2 3 4 l n 3 4 1 acl drayton tempus 1, tempus 2 lyfestyle lp111, lp711 acl drayton switchmaster sm300 acl drayton switchmaster 980 danfoss randall 103 series danfoss randall set 1e, ts975 danfoss randall ts71...

Page 29

29 instructions for installation and servicing ecotec 4.14.5 connection details for external time switches and boiler terminal strip fig. 4.19 shows the connection details where a time switch is used without a room thermostat to control the boiler. Note the numbers with arrows indicate connection to...

Page 30

30 instructions for installation and servicing ecotec connection details for control systems utilising 3 port motorised valve via external wiring centre/junction box diagram only applies to the specific controls mentioned l n l n 3 4 5 e n l central heating on hot water on hot water off 3 amp fused ...

Page 31

31 instructions for installation and servicing ecotec connection details for control systems utilising 2 x 2 port motorised valves via external wiring centre/junction box diagram only applies to the specific controls mentioned l n l n 3 4 5 n l central heating on hot water on hot water off 3 amp fus...

Page 32

32 instructions for installation and servicing ecotec 5 commissioning part i 5.1 preliminary electrical checks check the electrical installation by carrying out short circuit, earth continuity and resistance to earth tests and a check for correct polarity. 5.2 gas supply the complete gas installatio...

Page 33

33 instructions for installation and servicing ecotec note both stop valves must be closed while operat- ing the heating system and the filling pipe must be again detached at the double check valve. Fig. 5.3 double check valve detached while heating 5.4.3 filling the heating system in ecotec pro and...

Page 34

34 instructions for installation and servicing ecotec 5.6 filling the condensation water siphon 1 fig. 5.4 filling the condensation water siphon danger! Note that if the boiler is run with an empty condensate trap there is a danger that fumes might escape into the room and cause poison- ing. For thi...

Page 35

35 instructions for installation and servicing ecotec 5.9 checking the gas supply 5.9.1 factory settings caution! Before operating the boiler check the data badge and ensure that the correct gas type appliance has been installed. The boiler is supplied ready adjusted and no further gas adjustments a...

Page 36

36 instructions for installation and servicing ecotec 5.10 refitting the case 1 2 fig. 5.14 refitting the case • hook the top of the front casing over the lip on the top of the boiler chassis and push the bottom of the front casing into place. • ensure the spring retaining clips ( 2 ) engage correct...

Page 37

37 instructions for installation and servicing ecotec fig. 6.1 function check 6.1.2 heating • switch on the appliance. • make sure that there is a heating demand. • press “ i ” to activate the status indicator. As soon as a heat demand is received, the appliance runs through the status indicators “ ...

Page 38

38 instructions for installation and servicing ecotec 6.2 handing over to the user • set the maximum radiator temperature control to the desired setting. • set the maximum hot water temperature control to the desired setting. • instruct the user in the safe and efficient operation of the boiler, in ...

Page 39

39 instructions for installation and servicing ecotec 7.1.3 maintenance before commencing any servicing or maintenance work, carry out an initial inspection of the system as follows: • inspect the flue, pipework and electrical connections for indications of damage or deterioration. • inspect the air...

Page 40

40 instructions for installation and servicing ecotec 7.2 servicing the compact thermal module 7.2.1 removing the compact thermal module the compact thermal module consists of the burner, fan, gas valve und the gas supply (mixer tube). These four components make up the complete assembly, the com- pa...

Page 41

41 instructions for installation and servicing ecotec note you can suspend the compact thermo module on the hook (11) while carrying out maintenance tasks. • after removing the thermal compact module, clean the components as described below. 7.2.2 cleaning the integral condensation heat exchanger ca...

Page 42

42 instructions for installation and servicing ecotec 10 9 8 4 5 6 7 fig. 7.7 refitting the compact thermal module • insert the compact thermo module ( 9 ) in the integral condensation heat exchanger ( 10 ). • tighten the four nuts ( 4 ) on the left/right sides until the burner door fits closely and...

Page 43

43 instructions for installation and servicing ecotec 7.4 checking the expansion vessel 1 fig. 7.10 checking expansion vessel admission pressure note it is not necessary to perform this check every year – a check every three years is sufficient. • ensure the boiler ch service valves are closed. • re...

Page 44

44 instructions for installation and servicing ecotec 8 troubleshooting 8.1 logical fault finding procedure these checks must be carried out before attempting to use the fault finding guide. 1. Carry out electrical safety checks (see section ‘preliminary electrical checks’). 2. Check that the extern...

Page 45

45 instructions for installation and servicing ecotec 8.1.2 diagnosis codes in the diagnosis mode, you can change certain parame- ters or display more information. The diagnosis information is divided into two diagnosis levels. The second diagnosis level can be reached only after entering a password...

Page 46

46 instructions for installation and servicing ecotec display meaning display value/adjustable value d.00 heating part load adjustable heating part load in kw (factory setting: max. Output) d.01 water pump over run time for heating mode 1 - 60 min (factory setting: 5 min) d.02 max. Burner anti cycli...

Page 47

47 instructions for installation and servicing ecotec display meaning display value/adjustable value d.61 number of lock outs number of unsuccessful ignitions in the last attempt d.64 average ignition time in seconds d.65 maximum ignition time in seconds d.68 successful ignitions in the first attemp...

Page 48

48 instructions for installation and servicing ecotec code meaning cause f.00 flow–ntc: ntc broken, ntc cable broken, defective connection at ntc, defective connection at electronics flow–ntc cable defective/broken, ntc faulty f.01 return–ntc: ntc broken, ntc cable broken, defective connection at nt...

Page 49

49 instructions for installation and servicing ecotec 8.4 test programs special functions can be triggered on the appliances by activating various test programs. These programs are given in detail in the table 8.4. • the test programs p.1 to p.6 will be started when “power on” is turned on and the “...

Page 50

50 instructions for installation and servicing ecotec • mount the new burner with a new seal. Ensuring that the notch in the burner aligns with the burner viewing window. • install the compact thermo module as described in section 7.2.4. • after completing the work, check for gas leaks and perform a...

Page 51

51 instructions for installation and servicing ecotec 1 2 3 4 fig. 9.4 replacing expansion vessel • undo the nut ( 4 ) on the water pipe on the lower side of the expansion vessel. • remove both screws ( 1 ) retaining plate ( 2 ) and remove the retaining plate. • pull out the expansion vessel ( 3 ) f...

Page 52

52 instructions for installation and servicing ecotec 3 2 1 fig. 9.6 primary heat exchanger holder • disconnect the plug-in connection ( 2 ) of the thermal fuse in the primary heat exchanger. • remove the three screws ( 3 ) on the primary heat exchanger holder. • turn the holder to the side around t...

Page 53

53 instructions for installation and servicing ecotec 9.7 check co 2 content and if necessary set (air- ratio adjustment) 2 1 fig. 9.7 carrying out measurement of co 2 levels, preparing for air-ratio adjustment note checking/adjustment of this value is required in the following instances: replacemen...

Page 54

54 instructions for installation and servicing ecotec 10 recycling and disposal the design of all vaillant products takes into account the subsequent recycling and/or eventual safe scrapping of each component used. Vaillant’s in–house rules set strict standards in this respect. The selection process...

Page 56

83 9 5 9 2_00 gb 11 2 004.