- DL manuals

- Valentin

- Printer

- Compa II Series

- Operating Manual

Valentin Compa II Series Operating Manual

Summary of Compa II Series

Page 1

Compa ii series operating manual march 2012.

Page 2

Copyright by carl valentin gmbh / 7952005b.0312 information on the scope of delivery, appearance, performance, dimensions and weight reflect our knowledge at the time of printing. We reserve the rights to make modifications. All rights, including those regarding the translation, are reserved. No par...

Page 3

Compa ii series table of contents 03.12 operating manual 3 table of contents table of contents .............................................................................. 3 1 important notes ..................................................................... 5 1.1 intended use ....................

Page 4

Table of contents compa ii series 4 operating manual 03.12 9 maintenance and cleaning .................................................. 77 9.1 general cleaning ................................................................... 78 9.2 cleaning the printer roller .......................................

Page 5

Compa ii series important notes 03.12 operating manual 5 1 important notes the label printer can be used in thermal as well as in thermal transfer applications. The label printer is equipped with 6 vector, 6 bitmap and 6 proportional fonts. It can be printed inverse, in italic format or 90 degrees t...

Page 6

Important notes compa ii series 6 operating manual 03.12 1.2 environmentally-friendly disposal manufacturers of b2b equipment are obliged to take back and dispose of old equipment that was manufactured after 13 august 2005. As a principle, this old equipment may not be delivered to communal collecti...

Page 7

Compa ii series important notes 03.12 operating manual 7 figure 2 0 1 = adjusting screw for transfer ribbon regulating shaft 0 2 = transfer ribbon for regulating shaft 0 3 = printhead lock 0 4 = printhead 0 5 = label material guiding 0 6 = return pulley 0 7 = printer roller 0 8 = label photocell han...

Page 8

Important notes compa ii series 8 operating manual 03.12 figure 3 1 = switch on/off 2 = power supply 3 = plug-in for cf card 4 = usb interface 5 = serial interface rs-232 6 = ethernet 10/100 interface 7 = usb host for usb keyboard and usb memory stick 8 = parallel interface for centronics 9 = extern...

Page 9

Compa ii series safety notes 03.12 operating manual 9 2 safety notes the printer is designed for power supply systems from 110-230 v. Connect the label printer only to electrical outlets with a ground contact. Couple the label printer to devices using extra low voltage only. Before making or undoing...

Page 10

Safety notes compa ii series 10 operating manual 03.12 2.2 operating conditions before initial operation and during operation these operating conditions have to be observed to guarantee save and interference- free service of our printers. Therefore please carefully read these operating conditions. S...

Page 11

Compa ii series safety notes 03.12 operating manual 11 the installation of the power supply to connect our printers has to be effected according to the international rules and regulations, especially the recommendations of one of the three following commissions: • international electronic commission...

Page 12

Safety notes compa ii series 12 operating manual 03.12 immunity to interference according to en 61000-6-2: 2005 industrial sector • stray radiation against discharge of static electricity according to en 61000-4-2: 12-2001 • electromagnetic fields according to en 61000-4-3: 11-2003, env 50204: 03-19...

Page 13

Compa ii series safety notes 03.12 operating manual 13 to avoid inadmissible heating, free air convection has to be ensured. Protection according ip: 20 ambient temperature °c (operation): min. +5 max. +35 ambient temperature °c (storage): min. −20 max. +60 relative air humidity % (operation): max. ...

Page 15

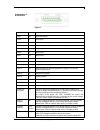

Compa ii series technical data 03.12 operating manual 15 3 technical data compa ii 103/8 t compa ii 104/8 compa ii 106/12 compa ii 106/24 compa ii 108/12 t compa ii 162/12 compa ii 162/12 t print resolution 203 dpi 203 dpi 300 dpi 600 dpi 300 dpi 300 dpi 300 dpi max. Print speed 200 mm/s 200 mm/s 20...

Page 16

Technical data compa ii series 16 operating manual 03.12 operation panel compa ii 103/8 t compa ii 104/8 compa ii 106/12 compa ii 106/24 compa ii 108/12 t compa ii 162/12 compa ii 162/12 t keys test print, function menu, quantity, cf card, feed, enter, 4 x cursor lcd display graphic display 132 x 64...

Page 17

Compa ii series technical data 03.12 operating manual 17 • tear-off edge • real time clock with printout date and time automatic daylight saving time storage of data with shut-down • variables: link field, counter, date/time, currency and shift variable, cf data • integrated unwinder (max. Outer dia...

Page 18

Technical data compa ii series 18 operating manual 03.12 3.1 control inputs and outputs by means of a maximum of 16 control inputs and outputs which, in the following, are also referred to as ports, different functions of the printer system can be triggered and operating states can be displayed. The...

Page 19

Compa ii series technical data 03.12 operating manual 19 figure 5 identification pin description / function port 1 10 print start (input) port 2 1 cut (input) port 3 11 counter reset (input) port 4 2 external synchronisation of label position (input) port 5 12 no function port 6 3 no function port 7...

Page 20

Technical data compa ii series 20 operating manual 03.12 identification pin description / function + 5 vdc ext 25 5 volt dc output for external use. Max. 1 a. This voltage is provided from direct print module and can be used e.G. As control voltage. Never apply any external voltage to this output. +...

Page 21

Compa ii series technical data 03.12 operating manual 21 device connection to a machine with s7-300 sps. Figure 6 device connection to a operating panel. Figure 7 example 1 example 2.

Page 22

Technical data compa ii series 22 operating manual 03.12 device connection version if 'option: 2. Led'. Figure 8 when connecting a reed contact with a control input, the contact must have a switching capacity of min. 1 a in order to prevent the contact from sticking due to the inrush current. As an ...

Page 23

Compa ii series technical data 03.12 operating manual 23 3.2 plug & play plug & play capable printers can be recognised automatically at parallel ports, usb-ieee 1394- or infra-red connections but the last both are not important for our printers. The following table shows the plug & play capability ...

Page 25

Compa ii series installation 03.12 operating manual 25 4 installation ⇒ lift the label printer out of the box. ⇒ check the label printer for transport damages. ⇒ check delivery for completeness. • label printer. • power cable. • empty core, mounted on transfer ribbon rewinder. • tear-off edge (basic...

Page 26

Installation compa ii series 26 operating manual 03.12 4.2 connecting the label printer the label printer is equipped with a versatile power supply unit. The device may be operated with a mains voltage of 110-230 v / 50-60 hz without any adjustments or modifications. Caution! The label printer can b...

Page 27

Compa ii series installation 03.12 operating manual 27 4.4 initiation of the label printer after switching on the label printer the main menu appears which shows the printer type, current date and time. Insert label material and transfer ribbon (see chapter 5. Loading media, page 29). Go to menu lab...

Page 29

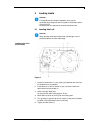

Compa ii series loading media 03.12 operating manual 29 5 loading media notice! For adjustments and simple installation work, use the accompanying hexagonal wrench located in the bottom section of the print unit. No other tools are required for the work described here. 5.1 loading label roll notice!...

Page 30

Loading media compa ii series 30 operating manual 03.12 1. Turn lever (5) counter clockwise to lift up the printhead. 2. Push label guiding on deviating shaft (4) all the way out. 3. Guide label material below the deviating shaft (4) and the label photocell so it leaves the print unit between printh...

Page 31

Compa ii series loading media 03.12 operating manual 31 figure 11 in rewind mode the labels are wound up internally after printing for later use. 1. Guide label strip around the deviating shaft (4) to the internal rewinder (2). 2. Hold rewinder (2) firmly and turn knob (3) clockwise until it stops. ...

Page 32

Loading media compa ii series 32 operating manual 03.12 figure 12 1. Loosen knurled screw (1), turn guiding (2) upwards and move it to the outside as far as possible. 2. Insert label roll on the roll holder so you can see the side from above which can be printed on. 3. Unwind a longer label strip: f...

Page 33

Compa ii series loading media 03.12 operating manual 33 figure 13 in dispensing mode the labels are removed after printing, and only the liner is wound up internally. 1. Lift up pinch roller (4) off the deviating shaft (5). 2. Remove labels from the first 100 mm of the backing paper. 3. Guide liner ...

Page 34

Loading media compa ii series 34 operating manual 03.12 the printhead is pushed on via two plungers (1). The location of the right plunger must be set to the width of the label medium used so as to: • achieve even print quality across the entire label width, • prevent wrinkles in the feed path of th...

Page 35

Compa ii series loading media 03.12 operating manual 35 5.2 removing wound roll figure 15 1. Turn lever (5) anticlockwise to lift up printhead. 2. Cut label strip and wind it fully around the rewinder (2). 3. Hold rewinder (2) firmly and turn knob (3) clockwise. The rewinder spindle relaxes and the ...

Page 36

Loading media compa ii series 36 operating manual 03.12 5.3 loading fanfold labels figure 16 1. Loosen knurled screw (1) and slide guiding (2) outward completely and swivel it downward past the roll retainer (3). 2. If core adapters are mounted on the roll retainer (3), remove core adapters. 3. Posi...

Page 37

Compa ii series loading media 03.12 operating manual 37 5.4 loading transfer ribbon notice! For the thermal transfer printing method it is necessary to load a ribbon, otherwise when using the printer in direct thermal print it is not necessary to load a ribbon. The ribbons used in the printer have t...

Page 38

Loading media compa ii series 38 operating manual 03.12 7. Turn transfer ribbon rewinder (1) counter clockwise to smooth out the feed path of the transfer ribbon. 8. Turn lever (4) clockwise to lock the printhead. Notice! As for the electrostatic unloading the thin coating of the thermal printhead o...

Page 39

Compa ii series loading media 03.12 operating manual 39 5.6 removing and/or installing rewind guide plate removing and/or installing rewind guide plate, dispenser edge or tear-off edge to convert the printer for use in another operating mode, a rewind guide plate, a peel off plate or a tear-off plat...

Page 41

Compa ii series function menu 03.12 operating manual 41 6 function menu 6.1 operation panel 1 the top line of the graphic display shows the printer type. 2 the graphic display shows information about the current status of the printer and the print order, reports errors and shows the printer settings...

Page 42

Function menu compa ii series 42 operating manual 03.12 6.2 menu structure speed contrast ribbon control y offset x offset tear-off offset print settings label length gap length column printing measure label label type material selection photocell scan position label error length synchronisation fli...

Page 43

Compa ii series function menu 03.12 operating manual 43 operating modes double cut cutter control cutter (option) automatic return operating modes photocell level i/o port 1-8 i/o port 9-16 i/o protocol save signal dispenser i/o (option) io profile operating modes application mode support delay on s...

Page 44

Function menu compa ii series 44 operating manual 03.12 status ip address netmask gateway dhcp wlan (option) port interval remote console com1 baud parity data bits stop bit interface start sign stop sign data memory port test protocol printhead resolution drive mapping emulation set date/time summe...

Page 45

Compa ii series function menu 03.12 operating manual 45 label parameters photocell settings photocell/sensors paper counter heater resistance printhead temperature motor ramp print examples input/output online/offline transfer ribbon prior warning zero point adjustment print length +/- service funct...

Page 46

Function menu compa ii series 46 operating manual 03.12 6.3 print settings switch on the label printer and the display shows the main menu. Press key to access the function menu. Press key to select the menu print settings. Indication of print speed in mm/s (see chapter technical data, page 15). The...

Page 47

Compa ii series function menu 03.12 operating manual 47 6.4 label layout switch on the label printer and the display shows the main menu. Press key to access the function menu. Press key as long as you arrive the label layout menu. Press key to select the menu. Indication of label length in mm (see ...

Page 48

Function menu compa ii series 48 operating manual 03.12 press key to arrive the next menu item. In case an error occurs, indication after how many mm a message appears in the display. Value range:1 mm to 999 mm. On: if a label is missed on the liner an error message is displayed. Off: missing labels...

Page 49

Compa ii series function menu 03.12 operating manual 49 6.5 device settings switch on the label printer and the display shows the main menu. Press key to access the function menu. Press key as long as you arrive the device settings menu. Press key to select the menu. Off: the complete print memory i...

Page 50

Function menu compa ii series 50 operating manual 03.12 press key to arrive the next menu item. Selection of region for the desired keyboard layout. The following possibilities are available: germany, england, france, greece, spain, sweden and us. Press key to arrive the next menu item. On: the ques...

Page 51

Compa ii series function menu 03.12 operating manual 51 press key to arrive the next menu item. By a password several functions can be blocked, so the user cannot work with them. There are several applications in which the use of password protection makes sense (see chapter 11.3 password, page 98). ...

Page 52

Function menu compa ii series 52 operating manual 03.12 6.8 interface switch on the label printer and the display shows the main menu. Press key to access the function menu. Press key as long as you arrive the interface menu. Press key to select the menu. Com1: 0 - serial interface off. 1 - serial i...

Page 53

Compa ii series function menu 03.12 operating manual 53 6.9 emulation switch on the label printer and the display shows the main menu. Press key to access the function menu. Press key as long as you arrive the emulation menu. Press key to select the menu. Cvpl: carl valentin programming language zpl...

Page 54

Function menu compa ii series 54 operating manual 03.12 6.10 date & time switch on the label printer and the display shows the main menu. Press key to access the function menu. Press key as long as you arrive the date/time menu. Press key to select the menu. The upper line of display shows the curre...

Page 55

Compa ii series function menu 03.12 operating manual 55 6.11 service functions notice! So that the distributor res. The printer manufacturer in case of service can offer fast support, the printer is equipped with the menu service functions. Necessary information such as selected parameters can be ta...

Page 56

Function menu compa ii series 56 operating manual 03.12 press key to arrive the next menu item. Indication of printhead temperature. The printhead temperature corresponds normally to the room temperature. In case the maximum printhead temperature is exceeded, the current print order is interrupted a...

Page 57

Compa ii series function menu 03.12 operating manual 57 press key to arrive the next menu item. Before the end of transfer ribbon, a signal is send by the control output. Setting of transfer ribbon advance warning diameter. In case you enter a value in mm then a signal appears via control output whe...

Page 59

Compa ii series options 03.12 operating manual 59 7 options 7.1 cutter caution! Risk of injury, particularly during maintenance, the cutter blades are sharp! ⇒ switch off the before attaching the cutter! ⇒ the cutter may only be used when it is mounted on the printer! ⇒ do not try to cut any materia...

Page 60

Options compa ii series 60 operating manual 03.12 select the desired cutter operating mode, then press key to select additional functions. When using this function, after the first cut a feed with the set offset is effected and then cut anew. After the cut a back feed to the printing position is eff...

Page 61

Compa ii series options 03.12 operating manual 61 7.2 dispenser i/o notice! In order to operate the printer in dispensing mode a print order has to be started and the printer has to be in 'waiting' mode. Switch on the label printer and the display shows the main menu. Press key to access the functio...

Page 62

Options compa ii series 62 operating manual 03.12 after selection of desired dispenser i/o operating mode, press key to select additional parameters. Definition of port functions: 2 sign show the current setting for each port. Port 1 2 3 4 5 6 7 8 because of space reasons, the port number cannot be ...

Page 63

Compa ii series options 03.12 operating manual 63 1 print start and cut (input) 2 no function 3 counter reset (input) 4 no function 5 no function 6 no function 7 no function 8 no function 9 error (output) 10 print order active (output) 11 dispenser photocell: label exists at dispenser photocell (out...

Page 64

Options compa ii series 64 operating manual 03.12 7.3 label applicator switch on the label printer and the display shows the main menu. Press key to access the function menu. Press key as long as you arrive the label applicator menu. Press key to select the menu. Press key to change to the next mode...

Page 65

Compa ii series options 03.12 operating manual 65 press key to arrive the next parameter. The supporting air from the blow tube is not immediately switched on at print start but only if the label has covered a distance. This delay helps to prevent a turning or swinging at the front of the label and ...

Page 66

Options compa ii series 66 operating manual 03.12 press key to arrive the next parameter. This parameter is only active if the operating mode 'blow on' is selected. The time period can be adjusted, while the blowing air is switched on for transferring the label onto product. Value range: 0 to 2500 m...

Page 67

Compa ii series options 03.12 operating manual 67 press key to arrive the next parameter. This menu serves for the applicator setup as well as for error tracing. Input signals of the applicator can be monitored and output signals can be set or reset separately. With keys and the corresponding output...

Page 68

Options compa ii series 68 operating manual 03.12 7.4 wlan switch on the label printer and the display shows the main menu. Press key to access the function menu. Press key as long as you arrive the wlan menu. Press key to select the menu. The menu item wlan can only be selected if a wlan card was r...

Page 69

Compa ii series compact flash card / usb memory stick 03.12 operating manual 69 8 compact flash card / usb memory stick 8.1 general information on the back side of the label printer is the slot for the cf card and the usb port for inserting the usb memory stick. The mass storage menu (memory menu) p...

Page 70

Compact flash card / usb memory stick compa ii series 70 operating manual 03.12 8.3 navigation the memory menu is operated with the keys of the foil keyboard of the control unit or with different function keys of an attached usb keyboard. Return to the previous menu. Function load layout: change to ...

Page 71

Compa ii series compact flash card / usb memory stick 03.12 operating manual 71 8.5 filter for certain functions a filter mask or a file name of a file which is to be saved can be entered. This input is indicated in the path line. It is possible with the filter mask to look for certain files. For ex...

Page 72

Compact flash card / usb memory stick compa ii series 72 operating manual 03.12 specifies the standard directory in which the files are stored for further processing. Press key to access to the memory menu. Press key to call the file explorer. Press keys , , , to select the directory. Press key to c...

Page 73

Compa ii series compact flash card / usb memory stick 03.12 operating manual 73 saves the currently loaded layout under the selected name. Press key to access to the memory menu. Press key to call the file explorer. Press key to change to the menu save file. Selct the function savel layout and confi...

Page 74

Compact flash card / usb memory stick compa ii series 74 operating manual 03.12 deletes one or more files and/or directories irrevocably. With the deletion of a directory both the contained files and the subdirectories are deleted. Press key to access to the memory menu. Press key to call the file e...

Page 75

Compa ii series compact flash card / usb memory stick 03.12 operating manual 75 creates a duplicate of the original file and/or the original directory to make changes independently of the original. Press key to access to the memory menu. Press key to call the file explorer. Press keys and to select ...

Page 77

Compa ii series maintenance and cleaning 03.12 operating manual 77 9 maintenance and cleaning danger! Risk of death by electric shock! ⇒ disconnect the label printer from power supply before performing any maintenance work. Notice! When cleaning the label printer, personal protective equipment such ...

Page 78

Maintenance and cleaning compa ii series 78 operating manual 03.12 9.1 general cleaning caution! Abrasive cleaning agents can damage the label printer! ⇒ do not use abrasives or solvents to clean the outer surface of the label printer. ⇒ remove dust and paper fuzz in the printing area with a soft br...

Page 79

Compa ii series maintenance and cleaning 03.12 operating manual 79 9.4 cleaning the label photocell caution! Label photocell can be damaged! ⇒ do not use sharp or hard objects or solvents to clean the label photocell. The label photocell can become dirtied with paper dust and this can adversely affe...

Page 80

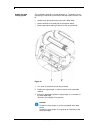

Maintenance and cleaning compa ii series 80 operating manual 03.12 figure 21 1. Turn lever (1) counter clockwise to lift up the printhead. 2. Remove labels and transfer ribbon from the label printer. 3. Remove hexagonal wrench (7) from its retainer and remove the rear cover of printer. 4. Slide the ...

Page 81

Compa ii series maintenance and cleaning 03.12 operating manual 81 9.5 replacing the printhead notice! The printhead (7) is preinstalled on a head plate (1) and precisely aligned at the factory. Do not loosen the screws (4) under any circumstances. Figure 22 1 = head plate 2 = plug connection 3 = pl...

Page 82

Maintenance and cleaning compa ii series 82 operating manual 03.12 figure 23 1. Turn lever (10) counter clockwise to lift up the printhead. 2. Remove labels and transfer ribbon from the label printer. 3. Remove hexagonal wrench (11) from its retainer. 4. Lightly keep printhead mounting bracket (9) o...

Page 83

Compa ii series maintenance and cleaning 03.12 operating manual 83 9.6 replacing the print roller and rewind assist roller figure 24 1. Turn lever (1) counter clockwise to lift up the printhead. 2. Lift the pinch roller (5) off the rewind assist roller. 3. Remove labels and transfer ribbon from the ...

Page 84

Maintenance and cleaning compa ii series 84 operating manual 03.12 figure 25 1. Pull print roller (7) and rewind assist roller (8) from the shafts (9, 10) on the housing. 2. Clean shafts (9, 10) of the rollers (see expanded view at shaft 10). 3. Slide print roller (7) and rewind assist roller (8) on...

Page 85

Compa ii series error correction 03.12 operating manual 85 10 error correction error message cause remedy 1 line too high line rises up completely or partly over the upper edge of label. Move line down (increase y value). Check rotation and font. 2 line too low line rises up completely or partly ove...

Page 86

Error correction compa ii series 86 operating manual 03.12 error message cause remedy 13 com overrun loss of data at serial interface (rs-232). Check baud rate. Check cable (printer and pc). 14 field numer received line number is invalid at rs-232 and centronics. Check sent data. Check connection pc...

Page 87

Compa ii series error correction 03.12 operating manual 87 error message cause remedy 28 cutter error with cut an error occurred. Paper jam. Check label run. Check cutter run. 29 invalid parameter entered data do not correspond to the characters allowed from the application identifier. Check code da...

Page 88

Error correction compa ii series 88 operating manual 03.12 error message cause remedy 40 length command invalid length of the received command statement. Check data sent. Check connection pc - printer. 41 no drive cf card not found / not correctly inserted. Insert cf card correctly. 42 drive error i...

Page 89

Compa ii series error correction 03.12 operating manual 89 error message cause remedy 57 invalid graphic file the selected file does not contain graphic data. Check file name. 58 directory not empty attempt to delete a not empty directory. Delete all files and sub- directories in the desired directo...

Page 90

Error correction compa ii series 90 operating manual 03.12 error message cause remedy 72 page selection a page which is not available is selected. Check the defined pages. 73 page not defined the page is not defined. Check the print definition. 74 format user guiding wrong format for customised entr...

Page 91

Compa ii series error correction 03.12 operating manual 91 error message cause remedy 87 rfid no label rfid unit cannot recognise a label. Displace rfid unit or use an offset. 88 rfid verify error while checking programmed data. Faulty rfid label. Check rfid definitions 89 rfid timeout error at prog...

Page 92

Error correction compa ii series 92 operating manual 03.12 error message cause remedy 99 load software printhead fpga error when programming printhead-fpga. Please contact your responsible distributor. 100 upper position sensor signal up is missing (option apl 100). Check input signals / compressed-...

Page 93

Compa ii series error correction 03.12 operating manual 93 error message cause remedy 113 applicator error error while using applicator. Check applicator. 114 left position left final position switch is not in correct position. Check left final position switch for correct function and position. Chec...

Page 95

Compa ii series additional information 03.12 operating manual 95 11 additional information 11.1 column printing with this printer several columns can be printed, i.E. The information of one column can be printed several times (depending on its width) on a label. Caused by this the use of the complet...

Page 96

Additional information compa ii series 96 operating manual 03.12 11.2 hotstart notice! Because of the fact that no battery-buffered sram is available, the necessary data has to be saved in another way, i.E. The data is saved onto cf card. Therefore the cf card is a condition for the hotstart menu it...

Page 97

Compa ii series additional information 03.12 operating manual 97 in case at switching off the label printer a print order was active, then a print start is released automatically and the required res. Actual number of printed labels is refreshed. In case the print order was stopped at switching off ...

Page 98

Additional information compa ii series 98 operating manual 03.12 11.3 password the supervisor programs a cf card directly with the printer. He stores 10 different labels. As well he adjusts the printer parameters, like contrast, speed, etc. To the corresponding values. The user is only supposed to r...

Page 99

Compa ii series additional information 03.12 operating manual 99 in case no password is defined res. The password protection is not activated, all functions can be used. In the function menu you will find the menu item 'password', where the password can be entered and the password protection activat...

Page 100

Additional information compa ii series 100 operating manual 03.12 11.4 backfeed/delay in continuous dispensing mode (io dynamic continuous, io static continuous, io photocell continuous) no optimised backfeed is possible. Because of the fact when changing the print order, then the current label in t...

Page 101

Compa ii series additional information 03.12 operating manual 101 dispenser: after printing the label it is driven into the dispensing offset and there waited. When releasing a new start signal (io dynamic) then the next label is immediately printed. Because of the fact that the label is already in ...

Page 102

Additional information compa ii series 102 operating manual 03.12 11.5 photocells notice! When using reflection photocells you should observe that the label printer cover is closed and in this way other light (e.G. Working lamp) on the photocell is prevented. For this photocell type the transmitter ...

Page 103

Compa ii series index 03.12 operating manual 103 12 index a assembly drawings ...................................................................... 6, 7, 8 b backfeed/delay ......................................................................... 100, 101 c column printing ............................

Page 104

Index compa ii series 104 operating manual 03.12 inputs/outputs ............................................................................... 18, 20 installation .......................................................................................... 25 intended use ................................

Page 105

Compa ii series index 03.12 operating manual 105 delete file ........................................................................................ 74 display structure ............................................................................. 69 filter ............................................