- DL manuals

- Valeo

- Water Heater

- thermo plus 230

- Workshop Manual

Valeo thermo plus 230 Workshop Manual

Summary of thermo plus 230

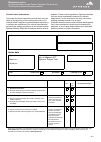

Page 1

Heating systems rev. 07/2017 id.No. 11121156a thermo plus 230 thermo plus 300 thermo plus 350 workshop manual.

Page 2: Thermo Plus 230/300/350

1 thermo plus 230/300/350 content 1 introduction 1.1 content and purpose 101 1.2 effectivity of the workshop manual 101 1.3 meaning of highlighted content 101 1.4 symbols 101 1.5 further documentation to be used 101 1.6 safety information and regulations 101 1.6.1 general safety regulations 101 1.6....

Page 3: Thermo Plus 230/300/350

2 thermo plus 230/300/350 content 5.5.3 error symptom "low voltage" 507 5.5.4 error symptom "extraneous light detected prior to ignition or during purge cycle" 508 5.5.5 error symptom "flameguard defective" 509 5.5.6 error symptoms "temperature sensor / overheating protection defective" and "overhea...

Page 4: Thermo Plus 230/300/350

3 thermo plus 230/300/350 content 10 packing/storage/shipping 10.1 general 1001 appendix periodic heater maintenance a-1.

Page 5: Thermo Plus 230/300/350

101 thermo plus 230/300/350 1 introduction 1 introduction 1.1 content and purpose this workshop manual is used during maintenance and repair of water heaters (further referred to as heaters) thermo plus 230, plus 300 and plus 350. Attention: work on the heater may only be performed by briefed and/or...

Page 6: Thermo Plus 230/300/350

102 thermo plus 230/300/350 1 introduction 1.6.2 other safety information 1.6.2.1 temperature sensors attention: the temperature sensors cable may not be mechani- cally stressed (pull on the cable, carry the heater at the cable etc.). 1.7 suggestions for improvement and change please direct any comp...

Page 7: Thermo Plus 230/300/350

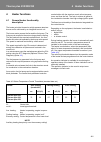

201 thermo plus 230/300/350 2 technical data 2 technical data unless limiting values are defined, the technical data should be understood with tolerances of ±10% common for heaters at an ambient temperature of +20°c, and at nominal voltage. Table 201 technical data 2.1 elektrical components control ...

Page 8: Thermo Plus 230/300/350

202 thermo plus 230/300/350 2 technical data * further information on approved fuels contains the ti (technical information) fuels. It can be found on the spheros homepage under ser- vice/technical updates/heating systems. In case of air temperatures below 0°c a commercial avail- able winter diesel ...

Page 9: Thermo Plus 230/300/350

301 thermo plus 230/300/350 3 assemblies and components 3 description of assemblies and components the heaters spheros thermo plus 230, plus 300 and plus 350 are used in conjunction with the vehicle heating system – to heat the passenger compartment – to defrost the windows – to preheat water-cooled...

Page 10: Thermo Plus 230/300/350

302 thermo plus 230/300/350 3 assemblies and components the heaters of the thermo plus series basically consist of the main components: • burner head • combustion chamber • heat exchanger external in the vehicle a circulation pump is installed or in case of compact device directly on the heater. 3.1...

Page 11: Thermo Plus 230/300/350

303 thermo plus 230/300/350 3 assemblies and components 3.1.2.2 flameguard the flameguard (see fig. 304 ) is integrated in the control device. The flameguard monitors the combustion flame condition during heater operation. The flame guard is a photo transistor that changes its resistance depending o...

Page 12: Thermo Plus 230/300/350

304 thermo plus 230/300/350 3 assemblies and components 3.1.3 fuel pump the fuel pump is responsible for fuel supply. ( fig. 305 ). The pump is driven by the burner motor via a coupling. Fuel is compressed in the fuel pump to approx. 10 bar and atomized by the atomiser nozzle. The solenoid valve ins...

Page 13: Thermo Plus 230/300/350

305 thermo plus 230/300/350 3 assemblies and components the fuel pump can be used in dual-line operation only (fuel supply and return line). If the heater is operated with – a long fuel supply line – check valves in the fuel supply and return line – a fuel filter in the fuel supply line the fuel sup...

Page 14: Thermo Plus 230/300/350

306 thermo plus 230/300/350 3 assemblies and components fig. 307 nozzle block preheater thermostat heating element burner head note: the disc is displayed transparently. Retaining clamp fig. 308 temperature sensors water temperature sensor with integrated overheat protection.

Page 15: Thermo Plus 230/300/350

307 thermo plus 230/300/350 3 assemblies and components 3.2 heat exchanger the heat exchanger ( fig. 309 ) transfers the heat genera- ted by combustion to the coolant circulation system. Depending on the system integration a heat exchanger with or without thread in the coolant inlet socket can be in...

Page 16: Thermo Plus 230/300/350

401 thermo plus 230/300/350 4 heater functions 4 heater functions 4.1 general heater functionality description the heater principle is based on a high-pressure atomizer burner and is monitored by an integrated control unit. The burner motor powers the fan and the fuel pump. The fuel pump is coupled ...

Page 17: Thermo Plus 230/300/350

402 thermo plus 230/300/350 4 heater functions 4.2 operational heater sequence 4.2.1 switching on and start when switched on, the operating display is illuminated, the control unit starts controlled operation and checks the coolant temperature. If the coolant temperature is below the lower temperatu...

Page 18: Thermo Plus 230/300/350

403 thermo plus 230/300/350 4 heater functions the purge cycle ends approx. After 120 seconds. The combustion air fan is switched off. The heater is in a controlled break. The operation indicator is on. Once the temperature falls short of the lower switching threshold, the heater restarts burner ope...

Page 19: Thermo Plus 230/300/350

404 thermo plus 230/300/350 4 heater functions 4.4 fault lock-out and heater lock-out a distinction is made between fault lock-out and heater lock-out. The lock-outs protect the heater and the surrounding vehicle assemblies against sequence errors after a failure or a malfunction of individual heate...

Page 20: Thermo Plus 230/300/350

405 thermo plus 230/300/350 4 heater functions 4.5.4 fault lock-out release and error clearance the fault lock-out is released when the heater is switched off. After that it will be immediately ready for operation. The detected error is stored in the error memory and can be read using stt diagnosis....

Page 21: Thermo Plus 230/300/350

501 thermo plus 230/300/350 5 troubleshooting 5 troubleshooting 5.1 general the safety instructions and regulations of chapter 1 (see 1.6 ) must be observed. This section describes troubleshooting and error correc- tion for thermo plus 230, plus 300 and plus 350 heaters. In case of doubt functional ...

Page 22: Thermo Plus 230/300/350

502 thermo plus 230/300/350 5 troubleshooting error in the water system circulating pump does not operate (aquavent 6000s and aquavent 6000sc only). • error mode activated. In case of malfunctions the motor is switched off via the error mode. Reactivation of the circulating pump motor for this purpo...

Page 23: Thermo Plus 230/300/350

503 thermo plus 230/300/350 5 troubleshooting error in the fuel supply no fuel delivery to the heater. • fuel tank empty. • bent, closed, clogged or leaking lines. • paraffin deposits or frozen water entrapments in fuel lines or lines. • venting opening in tank closed. • fuel lines mixed up. • fuel ...

Page 24: Thermo Plus 230/300/350

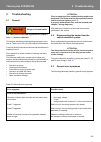

504 thermo plus 230/300/350 5 troubleshooting 5.4 malfunction output via flash code if the heater is equipped with a standard timer, the error message appears on the display. Another way is the a flash code output by means of the operation indicator or a lamp which is connected via the wiring harnes...

Page 25: Thermo Plus 230/300/350

505 thermo plus 230/300/350 5 troubleshooting 5.5 error symptoms during functional tests with malfunction code output or diagnosis 5.5.1 error symptom "no start within safety period" if due to a malfunction the heater unsuccessfully attemp- ted to start eight times in sequence, it will be locked-out...

Page 26: Thermo Plus 230/300/350

506 thermo plus 230/300/350 5 troubleshooting are the combustion air intake opening and line and the exhaust line clean and securely mounted? Clean and securely mount the combustion air intake opening and line and the exhaust line. Is sufficient fresh air intake ensured and are no exhaust fumes draw...

Page 27: Thermo Plus 230/300/350

507 thermo plus 230/300/350 5 troubleshooting 5.5.3 error symptom "low voltage" a value is stored in the control unit as smallest "permis- sible low voltage". It must be noted that the voltage may be lowered during heater start, and that the "low voltage" threshold may be violated. Among others this...

Page 28: Thermo Plus 230/300/350

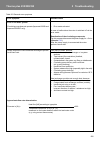

508 thermo plus 230/300/350 5 troubleshooting 5.5.4 error symptom "extraneous light detected prior to ignition or during purge cycle" no yes did overheating occur? Correct overheating cause. Is the burner properly screwed onto the heat exchanger? Properly screw burner onto the heat exchanger. Did th...

Page 29: Thermo Plus 230/300/350

509 thermo plus 230/300/350 5 troubleshooting 5.5.5 error symptom "flameguard defective" the flameguard cannot be replaced. It can only be tested using stt diagnosis. In case of damage or if the target value cannot be reached, the control device must be replaced as needed. 5.5.6 error symptoms "temp...

Page 30: Thermo Plus 230/300/350

510 thermo plus 230/300/350 5 troubleshooting 5.6 individual component tests individual components can basically be tested using visual inspection or manual electrical testing. In addition, the electrical components burner motor, circu- lating pump, electronic ignition unit, solenoid valve, nozzle b...

Page 31: Thermo Plus 230/300/350

511 thermo plus 230/300/350 5 troubleshooting due to increased coolant temperature. Possibly let the heater additionally cool down and have a collec- ting container ready for discharged coolant. Check • inspect temperature sensor, plug and cable for damage and proper fit. • remove temperature sensor...

Page 32: Thermo Plus 230/300/350

512 thermo plus 230/300/350 5 troubleshooting 5.6.5 fan and combustion air intake line visual inspection • inspect a possibly available combustion air intake line for contamination, condition and deposits. • remove hood (see 8.4 ). • inspect fan channels for contamination and deposits. • inspect fan...

Page 33: Thermo Plus 230/300/350

513 thermo plus 230/300/350 5 troubleshooting 5.6.7 electronic ignition unit inspection note: it is possible to manually test the functionality of the elec- tronic ignition unit, and using the component test menu of the stt diagnosis. It can only be verified by visual inspection of the ignition elec...

Page 34: Thermo Plus 230/300/350

514 thermo plus 230/300/350 5 troubleshooting 5.6.8 ignition electrode inspection note: the ignition electrode insulation may not be damaged. Ignition electrodes not functioning properly must be replaced. Attention: do not damage the electronic ignition unit when removing the ignition electrode. Hig...

Page 35: Thermo Plus 230/300/350

515 thermo plus 230/300/350 5 troubleshooting 5.6.10 fuel pump inspection attention: the pump pressure of the fuel pump is adjusted to a defined value in the factory. It is permitted to readjust the pump pressure. According to the manufacturer's specifications the fuel pump and fuel hoses must be re...

Page 36: Thermo Plus 230/300/350

516 thermo plus 230/300/350 5 troubleshooting • install ignition electrode (see 8.6 ). • install burner head (see 8.2 ). 5.6.11 solenoid valve inspection the coil of the solenoid valve can heat up in switched- on condition. The solenoid valve must only be completely replaced. In case of replacement ...

Page 37: Thermo Plus 230/300/350

517 thermo plus 230/300/350 5 troubleshooting manual inspection • remove burner head (see 8.2 ). • disconnect the solenoid valve plug from the control device. • check the electrical functionality by applying direct voltage: – opening voltage: starting at 17.0 volt – power consumption at 24v and 20°c...

Page 38: Thermo Plus 230/300/350

518 thermo plus 230/300/350 5 troubleshooting 5.6.13 circulating pump inspection attention: the circulating pump fuse may never be pulled, while the pump is running. Inspection using the stt diagnosis • check electrical connections as well as the leak-tight- ness of the cooling system. • disconnect ...

Page 39: Thermo Plus 230/300/350

601 thermo plus 230/300/350 6 wiring diagrams 6 wiring diagrams 6.1 general the following figures represent heater connection options to the vehicle electrical system. The minimum cable cross-sections indicated in the table must be applied. * the cable cross-section is to be reduced in front of the ...

Page 40: Thermo Plus 230/300/350

602 thermo plus 230/300/350 6 wiring diagrams fig. 601 system wiring diagram for the heater thermo plus with pre-selection timer up to 85°c ambient temperature, legend see page 604 fig. 602 system wiring diagram for the heater thermo plus with switch up to 85°c ambient temperature, legend see page 6...

Page 41: Thermo Plus 230/300/350

603 thermo plus 230/300/350 6 wiring diagrams fig. 603 system wiring diagram for the heater thermo plus with pre-selection timer up to 100°c ambient temperature, legend see page 604 fig. 604 system wiring diagram for the heater thermo plus with switch up to 100°c ambient temperature, legend see page...

Page 42: Thermo Plus 230/300/350

604 thermo plus 230/300/350 6 wiring diagrams * note for f2: the max. Possible for the design value is shown. The fuse is to be adapt under circumstances acc. To the smaller cable cross section of the connected circulating pump. Position designation ba operation indicator max. 1x5w or 2x2w fa flame ...

Page 43: Thermo Plus 230/300/350

605 thermo plus 230/300/350 6 wiring diagrams fig. 605 wiring harness 11123331a02 for up to 100°c ambient temperature - connector and pin assignment fig. 606 wiring harness 11123507a00 for up to 100°c ambient temperature - connector and pin assignment 1 4 8 5 1 1 7 8 2 1 2 3 5 6 7 8 9 10 4 1 2 wirin...

Page 44: Thermo Plus 230/300/350

606 thermo plus 230/300/350 6 wiring diagrams fig. 607 wiring harness 11123530a00 for up to 100°c ambient temperature - connector and pin assignment 1 2 3 5 6 7 8 9 10 4 1 2 1 2 7 1 2 3 4 5 6 1 2 7 6 5 4 3 wiring harness.

Page 45: Thermo Plus 230/300/350

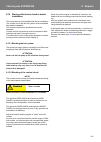

701 thermo plus 230/300/350 7 servicing 7 servicing 7.1 general the safety hints and regulations in chapter 1 (see 1.6 ) must be adhered. 7.1.1 heater servicing for risk of overheating, the battery main current may not be disconnected, while the heater is operating or in purge cycle. Make sure that ...

Page 46: Thermo Plus 230/300/350

801 thermo plus 230/300/350 8 repairs 8 burner head, components and heater removal and installation 8.1 general the safety hints and regulations in chapter 1 (see 1.6 ) must be adhered. Attention: prior to disassembling components the heater must be disconnected from the vehicle electrical system (o...

Page 47: Thermo Plus 230/300/350

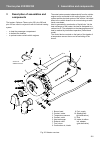

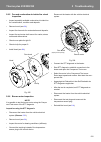

802 thermo plus 230/300/350 8 repairs 8.2 burner head removal and installation burner head removal 1. Disconnect the heater from the vehicle electrical sys- tem ( observe 5.2 ! ). 2. Disconnect the plug for the power supply/control (c). 3. Disconnect the plug for the circulating pump (p). 4. Disconn...

Page 48: Thermo Plus 230/300/350

803 thermo plus 230/300/350 8 repairs 8.3 removal and installation of the temperature sensor with integrated overheating protection risk of scalds if coolant temperature is increased. Removal 1. Disconnect the heater from the vehicle electrical sys- tem ( observe 5.2 ! ). 2. Disconnect the temperatu...

Page 49: Thermo Plus 230/300/350

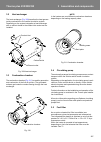

804 thermo plus 230/300/350 8 repairs 8.6 electronic ignition unit and ignition electrode removal and installation removal 1. Remove burner head (see 8.2 ). 2. Lift off ignition electrode from the electronic ignition unit by twisting a screwdriver sideways (see fig. 804 ) and remove it. 3. Remove th...

Page 50: Thermo Plus 230/300/350

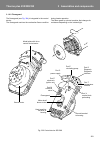

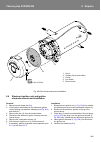

805 thermo plus 230/300/350 8 repairs 8.7 control device removal and installation note: control device and burner motor constitute a unit and cannot be further disassembled! Removal 1. Remove the fuel pump incl. Solenoid valve (see 8.8 ). 2. If necessary remove the coupling (17, fig. 805 ) from the ...

Page 51: Thermo Plus 230/300/350

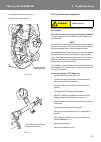

806 thermo plus 230/300/350 8 repairs fig. 805 components removal and installation 1 electronic ignition unit 2 combination screw (2) 3 ignition electrode 4 fuel nozzle 5 disc 6 solenoid valve 7 nozzle block preheater (optional) 8 retaining clamp 9 fuel pump 10 o-rings (2) 11 screen insert 12 screws...

Page 52: Thermo Plus 230/300/350

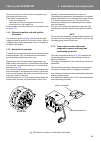

807 thermo plus 230/300/350 8 repairs installation 1. If necessary, install solenoid valve (6, fig. 805 ) onto the fuel pump (9) (siehe 8.9 ). 2. Install new o-rings (10) and a new screen insert (11) into the fuel pump (9). Attention: in order to avoid damage to the o-rings, to not twist fuel pump (...

Page 53: Thermo Plus 230/300/350

808 thermo plus 230/300/350 8 repairs 2. Using a suitable tool, tighten hexagon, wrench size 16 (6, fig. 806 ) of the solenoid valve. 3. Connect the solenoid valve plug (6, fig. 805 ) to the control device (14). 4. Fit the disc (5) onto the nozzle holder of the fuel pump (9) and align it so, the ign...

Page 54: Thermo Plus 230/300/350

809 thermo plus 230/300/350 8 repairs 8.11 fuel nozzle removal and installation removal 1. Remove burner head (see 8.2 ). 2. Lift off ignition electrode (2, fig. 804 ) from the electro- nic ignition unit by twisting a screwdriver sideways and remove it. 3. Remove disc (5, fig. 805 ). Note: we recomm...

Page 55: Thermo Plus 230/300/350

810 thermo plus 230/300/350 8 repairs installation attention: when replacing the combustion chamber, ensure that the new combustion chamber corresponds to the heating capacity class of your heating appliance. 1. Slide combustion chamber (1, fig. 808 ) fully into the heat exchanger (2) against stop. ...

Page 56: Thermo Plus 230/300/350

811 thermo plus 230/300/350 8 repairs 8.15 start-up after burner head or heater installation the fuel system must be bleeded after burner installation. The coolant circuit and the fuel system must be bleeded after heater installation. The vehicle manufacturer specifications must be observed. Coolant...

Page 57: Thermo Plus 230/300/350

901 thermo plus 230/300/350 9 modifications and retrofits 9 modifications and retrofits 9.1 general for further optimization the heaters are continuously improved. Units in the field can usually be upgraded or retrofitted. For this purpose respective modification kits will be available..

Page 58: Thermo Plus 230/300/350

1001 thermo plus 230/300/350 10 packing/storage/shipping 10 packing/storage/shipping 10.1 general the heater or its components, which are sent to spheros for inspection or repair, must be cleaned and packaged to ensure that handling, transport and storage will not damage them. Attention: if a comple...

Page 59

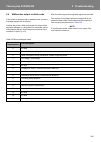

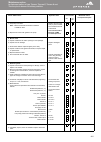

A-1 maintenance plan for spheros heaters of type thermo, thermo e, thermo s and thermo plus in buses und railway vehicles periodic heater maintenance the heater should be inspected in periodic time intervals, latest at the beginning of the heating period (time of in- creased heater usage due to pres...

Page 60

A-2 maintenance plan for spheros heaters of type thermo, thermo e, thermo s and thermo plus in buses und railway vehicles check / maintenance important notes check result measured values, accomplished repairs ok not ok c) fuel pump / fuel lines note: observe technical information if biodiesel or fam...

Page 61

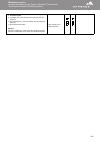

A-3 maintenance plan for spheros heaters of type thermo, thermo e, thermo s and thermo plus in buses und railway vehicles 7. Functional check a) if available, open shut-off valve of the fuel return line and water line. B) check fault memory, clear it as needed using the diagnostic tool (stt). C) che...

Page 62

Memos.

Page 63

Valeo thermal commercial vehicles germany gmbh postfach 1371 - 82198 gilching - germany - tel. +49 (0)8105 7721-0 - fax +49 (0)8105 7721-889 www.Valeo-thermalbus.Com - service-valeobus@valeo.Com.