- DL manuals

- Valor

- Indoor Fireplace

- 1600IN

- Installation & Owner's Manual

Valor 1600IN Installation & Owner's Manual

L1 S

ERIES

DV ZC Two-Sided Gas Fireplace

1600IN (NG) & 1600IP (LPG)

Installation & Owner’s Manual

4003537-09

©2016, Miles Industries Ltd.

This manual contains instructions to install the

ENGINE ONLY. A front or trim kit is REQUIRED

to install the engine. A barrier screen is provided

with the front or trim kit. Refer to the manual

supplied with the front or trim for installation.

— Do not store or use gasoline or other

fl ammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

▪ Do not try to light any appliance.

▪ Do not touch any electrical switch; do

not use any phone in your building.

▪ Leave the building immediately.

▪ Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

▪ If you cannot reach your gas supplier,

call the fi re department.

— Installation and service must be

performed by a qualifi ed installer, service

agency or the gas supplier.

Ce guide est disponible en français sur demande.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certifi ed kit is used.

This appliance is a domestic room-heating

appliance. It must not be used for any other

purposes such as drying clothes, etc.

This appliance is suitable for installation in a

bedroom or bed sitting room.

This appliance may be installed in an

after-market permanently located,

manufactured (mobile) home where not

prohibited by local codes.

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

DANGER

!

A barrier designed to reduce the risk of burns from the hot

viewing glass is provided with this appliance and shall be

installed for the protection of children and other at-risk

individuals.

!

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

INSTALLER

Leave this manual

with the appliance.

CONSUMER

Retain this manual

for future reference.

Please read this manual

BEFORE installing and

operating this appliance.

Summary of 1600IN

Page 1

L1 s eries dv zc two-sided gas fireplace 1600in (ng) & 1600ip (lpg) installation & owner’s manual 4003537-09 ©2016, miles industries ltd. This manual contains instructions to install the engine only. A front or trim kit is required to install the engine. A barrier screen is provided with the front o...

Page 2

2 table of contents safety precautions ................................................. 3 safety and your fireplace ...................................... 4 owner’s information ............................................... 5 operating your fireplace for the first time ............... 5 cleaning y...

Page 3: Safety Precautions

3 safety precautions ! Children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or clothing ignition. Young children should be carefully supervised when they are in the same room as the appliance. Toddlers, young children and others may be ...

Page 4: Safety And Your Fireplace

4 safety and your fireplace please follow these important child safety precautions and recommendations, • parts of your valor fireplace become extremely hot while in operation. • the glass viewing window temperature can exceed 500 f at full capacity. Momentary contact with a hot glass surface can ca...

Page 5: Do Not Put

5 operating your fireplace for the first time when operating your new fi replace for the fi rst time, some vapors may be released due to the burning of curing compounds used in the manufacture of the appliance. They may cause a slight odor and could cause the fl ames to be the full height of the fi ...

Page 6

6 warning do not touch the glass while it is hot! Let the fi replace cool fi rst before cleaning it. ! Spring loaded window levers cleaning your fireplace important - glass cleaning - mineral deposits one of the by-products of the combustion process in a gas appliance is a mineral which can show up ...

Page 7

7 warning choking hazard! Ensure that the fi replace area is clear of fi re glass or vermiculite particles as these could be ingested by small children. Vacuum thoroughly around the fi replace area after cleaning. Valve section views ing agents nor polishes should be used. Dry stains can be removed ...

Page 8

8 the appliance area must always be kept clear and free from combustible materials, gasoline and other fl ammable vapors and liquids. Inspect the vent terminal outdoors regularly to make sure that snow, trees, bushes, leaves, or other objects do not obstruct it. Examine the vent system and terminal ...

Page 9

9 warning do not attempt to touch the data card while the fireplace is still hot! Let the fi replace cool fi rst before touching it. Info card window the info card is located behind the front panel below the window. Thermostatic remote control wall switch wall switch remote control handset owner’s i...

Page 10

10 on: parallel to pipe off: perpendicular to pipe battery holder & wall switch fireplace receiver gas valve the receiver and gas valve are located on the bottom of the fi replace behind the front panel. The battery holder is located next to the wall switch. As well, familiarize yourself with the ga...

Page 11

11 remote control operation note: before using the remote control system for the fi rst time, the receiver and the handset must be synchronized. See the section set-up remote control on page 52 of this manual. Important: before you begin, please note that on this system, the settings of time, temper...

Page 12

12 remote control operation setting the time setting ºc/24-hour or ºf/12-hour clock modes of operation note: manual mode can also be reached by pressing either the (large fl ame) or the (small fl ame) buttons. • press and hold (small fl ame) button to decrease fl ame height or to set the appliance a...

Page 13

13 remote control operation setting the on / off temperatures • briefl y press set button to scroll to temp (sun) mode. Hold the set button until the temp fl ashes. • press (large fl ame) button to increase the daytime set temperature. • press (small fl ame) button to decrease daytime set temperatur...

Page 14

14 remote control operation setting program timers • you can program two periods of time between 12:00 am and 11:50 pm in each 24-hour cycle. • the programs p1 and p2 must be set in the following order during a 24-hour cycle: , , and . • the icon indicates the beginning of the period (on) and the ic...

Page 15

15 remote control operation automatic turn down automatic shut off low battery indication handset / receiver match remote handset: the battery icon will show when the battery needs to be replaced. Replace with one 9 v alkaline battery. Battery holder: frequent ‘beeps’ for 3 seconds when the valve mo...

Page 16

16 required kits* fuel beds (choose one) 1500dgs—decorative glass set 1505dwk—driftwood set kit 1510dgm—decorative glass murano 1514rss—rock & shale set ceramic liners (choose one) 1615fbl—linear fluted black panel set 1625rgl—refl ective glass panel kit trims (choose one) 1550—linear 3-1/2” surroun...

Page 17

17 lighting instructions for your safety, read before lighting warning: if you do not follow these instructions exactly, a fi re or explosion may result causing property damage, personal injury or loss of life. A. This appliance has a pilot which must be lighted by hand, remote control, or wall swit...

Page 18

18 state of massachusetts carbon monoxide detector/vent terminal signage requirements for all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by the commonwealth...

Page 19

19 (d) manufacturer requirements - gas equipment venting system not provided. When the manufacturer of a product approved side wall horizontally vented gas fueled equipment does not provide the parts for venting the fl ue gases, but identifi es “special venting systems”, the following requirements s...

Page 20

20 x valve access side ratings model n p gas natural propane altitude (ft.)* 0-4,500 feet* input maximum (btu/h) 30,000 26,000 input minimum (btu/h) 18,000 18,500 manifold pressure (in w.C.) 4.0” 10.0” minimum supply pressure (in w.C.) 5” 11” maximum supply pressure (in w.C.) 10” 14” main burner inj...

Page 21

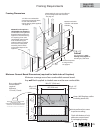

21 overview 1600 heater combustible floor framing—see framing requirements 1/2 inch thick non-combustible cement board – not supplied supplied as horizontal side outlet, fi eld convertible to top vertical outlet. Remote handset wall holder w w w wa ll ll ll f f f i i in i i is h h h a any wall fi ni...

Page 22

22 center line 1-3/8” (35 mm) m in. 44-1/2” (1130 mm) to t op of c ement boar d m in. 43” (1093 mm) to underside of header 1270rbk duct kit inlet (remove plate) gas line access point zero clearance stand-offs zero clearance stand-offs header 6-5/8” dia. Venting field- convertible from side to top ou...

Page 23

23 bottom of unit 0 2” 4” 6” 8” 10” 12” face of 1/2” thick non-combustible cement board do not put furniture or objects within 36” (914 mm) of front of appliance mantel projection (from face of cement board) mantel height (from bottom of unit) fireplace opening fireplace opening ceiling 24” m in. T ...

Page 24

24 39-11/16” fireplace opening wall min. 4” to wall or combustible face of finished wall fireplace combustible sidewall / mantel leg—top view mantel & hearth clearances qualified installer.

Page 25

25 between underside of header and bottom of firebox no hearth required. If using a hearth, see page 23. 1/2” thick non-combustible cement board required above, on each side and below engine opening (not supplied) - see page 36. Note: height of cavity may be affected by vent configuration with clear...

Page 26

26 43” (1093 mm) t o underside of c ombustible ca vit y * 55-1/2” (1410 mm) with 12” v e nt pipe * 45” (1143 mm) 37” (940 mm) required clearance to vertical pipe is within stand-off space 12” pipe section 14-1/2” (369 mm) stand-off 9-3/8” (238 mm) 19-1/4” (489 mm) fireplace * 58” (1473 mm) with 12” ...

Page 27

27 10” (254 mm) 10” (254 mm) align the vent center to the center of the frame venting top or side outlet this unit is supplied with a top vent outlet which can be fi eld-converted to a side vent outlet. See appliance preparation section for more information. Vent material this unit is approved for i...

Page 28

28 horizontal termination 2-piece wall thimble pipe length horizontal termination 2-piece wall thimble pipe length pipe length pipe length pipe length 90˚ elbow ceiling firestop attic firestop attic insulation shield flashing storm collar vertical termination pipe length 90˚ elbow 90˚ elbow co-axial...

Page 29

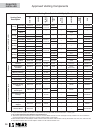

29 2 4 6 8 10 12 14 16 18 20 vertical rise (ft) horizontal run (ft) 40 38 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 0 4 x 90º elbows maximum (or equivalent) position #5 example 1 no installation position #4 position #3 position #2 position #1 allowable co-axial vent confi gurations with rest...

Page 30

30 position #1 position #2 position #3 position #4 position #5 inside fi rebox— roof venting port restrictor the restrictor is located in the roof of the fi rebox hidden above the top liner panel. Adjust the restrictor before installation of the top liner panel. Should subsequent adjustment be requi...

Page 31

31 horizontal vent termination location • the vent terminal must be located on an outside wall or through the roof. • this direct vent appliance is designed to operate when an undisturbed airfl ow hits the outside vent terminal from any direction. • the minimum clearances from this terminal that mus...

Page 32

32 roof pitch minimum "h" (feet) flat to 7/12 1' over 7/12 to 8/12 1.5' over 8/12 to 9/12 2’ over 9/12 to 10/12 2.5’ over 10/12 to 11/12 3.25’ over 11/12 to 12/12 4’ over 12/12 to 14/12 5’ overhang should not extend beyond vent if within 48” of termination cap horizontal overhang vertical wall min. ...

Page 33

33 10-1/2” (267 mm) 7-1/2” (191 mm) 7-1/8” (181 mm) 3” (76 mm) flashing 2 x 3” liners 3” min. Bend radius co-linear adapter 2 x 3” liners co-linear adapter linear engine approved co-linear termination or approved note: appliance needs to be framed as indicated in previous sections. All zero clearanc...

Page 34

34 fold lines other side standoffs outlet side standoffs only qualifi ed licensed or trained personnel should install this appliance. Installation unpack appliance beware of sharp edges! Wear gloves! 1. Remove the cardboard wrapping and the wood pallet from the appliance and discard. 2. Unpack any l...

Page 35

35 non- combustible m aterials onl y read instruc tions m atÉria ux inc ombustibles seulement consul tez le guide d ’inst alla tion fl ush front face of appliance mounting tabs (3) appliance fl ush to framing on both faces valve access side installation remove top outlet (6 screws) install heat shie...

Page 36

36 1/2” (13mm) thick non-combustible cement board gypsum board up to perimeter of cement board min. 9-1/4” (235 mm) min. 44-1/2” (1130 mm) min. 20-1/2” (521 mm) 14-3/4” (375 mm) board flush with bottom of heater; add extra if overlapping framing. 40” (1016 mm) min. 53” (1346 mm) joints preferred at ...

Page 37

37 section views window frame bottom railing valve remove the window on the valve access side only installation remove window the windows are held in place by a spring-loaded lever on each side. Remove the window on the valve access side only. 1. Locate the levers on each side of the window towards ...

Page 38

38 x 2-3/4” (70 mm) gas line access valve access side of the appliance 5-1/2” (140 mm) set-up gas supply the gas supply inlet connec- tion is a 3/8” npt male con- nector located on the left hand side of the fi rebox. The unit is supplied with a stainless steel fl ex line to allow the appliance to be...

Page 39

39 manifold test pressure valve inlet pressure pressure testing installation pressure test points the minimum supply pressure is given in the section specifi cations of this manual—page 20. All piping and connections must be tested for leaks af- ter installation or servicing. All leaks must be corre...

Page 40

40 glass panel anchor bracket top panel rests on anchor brackets top panel installation install liners the liners install in the manner outline below. Unpack them carefully as they are fragile. Ceramic panels 1. Identify the top and bottom (fi re) sides of the top panel, then slide it between the to...

Page 41

41 gap behind burner no gap in front of burner top view—platform installation installed platform pilot shield install driftwood kit 1505dwk material required • black steel platform (supplied with appliance) • small container to distribute vermiculite (non included) • driftwood kit containing: ◊ 5 lo...

Page 42

42 discard this log from the log pack use this log instead, provided with the appliance x x wrong right installation logs and rocks the log and rocks pack contains a center log which is not being used in this installation. Another log is provided with the fi replace in a small separate box and shoul...

Page 43

43 warning choking hazard! Ensure that the fi replace area is clear of vermiculite particles as these could be ingested by small children. Vacuum area after installation. 6. Some vermiculite may be added outside the burner on the platform if desired. 7. Place the rocks on the platform as shown below...

Page 44

44 installation installed glass plate warning choking hazard! Ensure that the fi replace area is clear of fi reglass particles as these could be ingested by small children. Vacuum area after installation. ! 2. Install the glass plate on the platform, the textured side underneath and the smooth side ...

Page 45

45 installation installed tray edge of tray fl ush with edge of fi rebox small round hole at rear left of fi rebox top bottom install decorative glass set 1500dgs material required • middle platform brackets (supplied with set) • small container to distribute fi reglass (not included) • decorative g...

Page 46

46 warning choking hazard! Ensure that the fi replace area is clear of fi reglass particles as these could be ingested by small children. Vacuum area after installation. ! Pilot shield pilot shield fireglass installed—top view 7. Carefully spread the fi reglass in the tray and on the burner. Do not ...

Page 47

47 gap behind burner no gap in front of burner top view—platform installed platform installation install rocks & shale set 1514rss material required • black steel platform (supplied with appliance) • small container to distribute shale (not supplied) • rock & shale set, which contains: ◊ 1/2lb-bag o...

Page 48

48 2. Mix the black and grey shale pieces and spread them in one layer thick on top of the burner around the three rocks. Do not overfi ll! 3. Install the rocks around the shale bed according to the image shown below. Note: some of the rocks may overhang slightly over the burner edge. 4. Add the twi...

Page 49

49 window frame bottom railing section views hot glass warning plate warning failure to install the window correctly can leak carbon monoxide, affect the performance of the fi replace, damage components, cause overheating resulting in dangerous conditions. Damage caused by incorrect window installa-...

Page 50

50 installation caution do not run the switch wire over the top of the fi rebox. Route the wire so it does not contact the fi rebox. Install remote battery and wall switch kit rbwsk (required) the remote battery and wall switch kit is provided with this appliance. It is connected to the receiver in ...

Page 51

51 installation 8. Mount switch plate to junction box with 2 screws provided note: switch position left or right to suit homeowner wishes. 9. Locate and secure magnet plate using 2 ‘long’ screws provided 10. Place and secure cover plate to box using 4 screws provided 11. Feed cable tie through the 2...

Page 52

52 remove front middle platform support accessing air shutter close open injector elbow bracket, burner side injector elbow foam gasket air shutter setting air shutter: loosen screw to adjust and re-tighten afterwards. Battery holder connection reset button velcro appliance’s front panel check opera...

Page 53

53 install trim and barrier screen install the trim chosen by the customer for their fi replace. Install as well the barrier screen which is provided with the trim. Show the customer how to remove the barrier screen to access the controls. Follow the instructions provided with the trim and leave tho...

Page 54

54 wiring diagram wall switch kit gv60 wiring diagram remote battery holder 4 aa batteries 5-pin connector 9-volt connector qualified installer.

Page 55

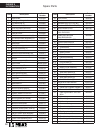

55 approved venting components approved direct vent suppliers for valor models 1100, 1150, 1200 5 , 1400, 1500, 1600 5 and 1700 6 venting parts description venting parts code / availability by manufacturer dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries bdm t...

Page 56

56 approved venting components venting parts description venting parts code / availability by manufacturer dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries bdm pipes 4” x 6 5/8” ( id x od ) 6” long galvanized 46dva-06 4dt-06 tc-4dl6 sv4l6 — — — 94610606 black ...

Page 57: Lor

57 warr an ty pr og ram warr an ty pr og ram va lor co m fo r t va lor co m fo r t va lor co m fo r t warranty 1. Extended warranty coverage for a period of up to ten (10) years, miles industries ltd., (the “company”) or its appointed distributor will at its option pay the initial owner for the repa...

Page 58

58 spare parts code description part number 1 heat shield 4003049 2 45 degrees fl anged elbow 0945m 3 top stand-offs (4) 4002985 3a side stand-offs (4) 4003527 4 liner top panel (all liners) 4003522 5 restrictor plate 4003017 6 take-off cover 4003046 7 lh window latch assembly (2) 4002770 8 rh windo...

Page 59

59 57 70 75 58 59 60 61 62 69 68 67 66 65 64 63 72 73 71 71 89 79 76 77 78 80 81 82 83 84 85 88 87 86 (6) (6) (4) (2) (2) (4) (2) (2) 1514rss 1625rgl 1615fbl 1500dgs 1505dwk (2) 69a 52 51 49 48 50 53 54 55 1500dgm code description part number 69a center log see-thru 4003720 70 decorative glass set 1...

Page 60

60 spare parts 13 1 2 3 4 7 9 9 7 10 11 12 12 8 8 6 5 73 74 14a, 14b 15 17 18 19-23 24-25 26 27a, 27b 28 29 30 31 32 33 34 36a, 36b 35 38 37 41 40 42 39 45 43 44 3a 47 47a 47b 47c 47d 47e 47f 47g 47h 47i owner’s information.

Page 61

61 index automatic shut off . Seeremote control automatic turn down . Seeremote control barrier screen . See alsosafety installation 8 , 53 replacement 3 , 6, 16 batteries . Seeremote control: batteries burner aeration 52 cement board 21 , 23, 25, 36–37 cleaning 6–7 . See alsomaintenance clearances ...

Page 63

Thank you ... For purchasing a valor by miles industries. Your new radiant gas heater is a technical appliance that must be installed by a qualifi ed installer. Please fi ll in the information below. The information provided will be used for customer records only. Online warranty registration at www...

Page 64

Tape shut thank you for choosing a valor product postage needed miles industries ltd. 190 - 2255 dollarton highway north vancouver, bc v7h 3b1 canada fold here online warranty registration at www.Valorfi replaces.Com.