Ultimate inset live fuel effect gas fire model 417 installation and servicing guide the natural gas model is for g20 at a supply pressure of 20mbar the propane gas model is for g31 at a supply pressure of 37mbar these appliances are for use in the united kingdom (gb) and the republic of ireland (ie)...

2 contents page appliance data 3 general installation requirements 3 pack contents 5 preliminary checks 6 • ignition spark check 6 • fireplace check 6 • flue pull check 6 gas supply connection 6 preparing appliance for installation 7 convection box installation 8 • front fixing 8 • cable retention 8...

3 1. Appliance data this product uses fuel effect pieces, burner compartment walls and gaskets containing refractory ceramic fibres (rcf), which are man-made vitreous silicate fibres. Excessive exposure to these materials may cause temporary irritation to eyes, skin and respiratory tract. Consequent...

4 2.2.3 to a fireplace that has a precast concrete or clay flue block system conforming to bs1289. The appliance is suitable for installations conforming to older versions of bs1289 as well as the current edition. The flue blocks must have a minimum width not less than 63mm and a cross-sectional are...

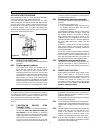

5 fig 2 pack contents 3. Unpacking the pack contains: 1 burner & convection box unit with front surround 1 nut & olive for 8mm inlet pipe 1 ceramic back wall 1 pair of ceramic side walls 1 front base coal- left & right halves 1 rear base coal 1 pack of 7 loose coals 2 small “u” seals for convection ...

6 4. Preliminary checks 4.1check ignition spark before attempting to install, it is worth checking that the piezo electric spark ignition system operates satisfactorily. To initiate the spark, depress the control knob and while keeping it depressed, turn anticlockwise through approximately 60° to th...

7 5.1.4 install the supply pipe to run through the thick line marked “supply pipe entry” and up to the inlet elbow position. Note that the centre of the appliance inlet elbow is 18mm above the fireplace floor. The inlet elbow should be removed from the appliance and fitted to the supply pipe at this...

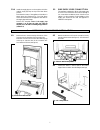

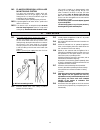

8 6.4 for concealed connection only pierce a hole in the seal at the back of the convection box (see figure 7). The seal must envelop the pipe. If the hole is larger than the pipe, seal it with tape.. Do not pierce the seal unless the supply pipe is to pass through it. 6.5 the appliance is supplied ...

9 7. 2.2 insert a fibre plug into each hole. Use the rawlplugs supplied with this appliance - never use plastic plugs instead of the fibre plugs supplied. Screw the eyebolts into the plugs. Make sure that the bolts are secure. 7. 2.3 place the convection box unit close to the fireplace but allow suf...

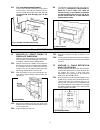

10 7.3 seal the floor front (all installations) using the floor sealing tape supplied, seal the bottom of the convection box to the fireplace and hearth floor. Run the tape over the burner fixing bracket. (see figure 15). 8. Burner, front surround & supply pipe installation 8.1 refit the burner unit...

11 9. Ceramic coals & walls installation 9.1 with its feather edge at the top, place the ceramic rear wall into the channel at the back of the fire box.. Push the wall flat against the rear of the fire box. (see figure 17). 9.2 place the two halves of the front base coal in the burner compartment so...

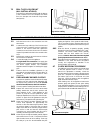

12 9.5 install the 7 loose coals as follows. The smooth surfaces of the coals should be at the bottom and back. 9.5.1 select the two largest coals place them in the central two valleys of the front coal (see figure 21). 9.5.2 place two of the remaining coals in the two outer valleys of the front coa...

13 9.5.3 place the three remaining coals behind and approximately midway between each of the coals in the front row (see figure 23). Fig. 23 middle row of coals.

14 10.Full operating checks 10.1 recheck control settings now that all the ceramic fuel effects are in position, the control operation must be fully rechecked. 10.1.1 make sure that the isolating valve at the inlet elbow is open. 10.1.2 depress the control knob and turn anticlockwise partially towar...

15 10.3 flame supervision & spillage monitoring system this pilot unit incorporates a system which will automatically shut off the gas supply if the pilot flame goes out or if there is insufficient oxygen due to spillage or lack of ventilation. Check that the system operates properly as follows; 10....

16 12. Servicing & parts replacement • always turn off the gas supply before commencing any servicing (the inlet elbow for this appliance incorporates an isolating valve). • this product uses fuel effect pieces, burner compartment walls and gaskets containing refractory ceramic fibres (rcf), which a...

17 12.2 to remove the front surround 12.2.1 remove the bottom front cover casting. 12.2.2 lift the fire front casting up and forward to release the locating screw heads at the back of the casting from the keyholes in the surround sides. Lift the casting clear. 12.2.3 remove the two screws securing t...

18 12.7 to grease the control tap/f.S.D. 12.7.1 detach the tap and remove the piezo generator as section 12.6 making sure that the tap is in the off position. 12.7.2 remove the two screws from the head of the tap. Remove the niting head and spindle complete with collar and spring. 12.7.3 note the po...

19 13. Short list of spares key description no. Off part no. A injector (elbow type) bray cat 82 size 360 for natural gas appliances 1 545959 injector (elbow type) bray cat 92 size 190 for propane appliances 566939 b gas tap & spark generator 1 545969 c spark generator 1 521069 d control knob 1 5459...

20 safety first . Valor fires are ce approved and designed to meet the appropriate british standards and safety marks. Quality and excellence. At the heart of every valor fire. All valor fires are manufactured to the highest standards of quality and excellence and are manufactured under a bs en iso ...