Valor 535 Installation Booklet

- Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

-WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch: do not use

any phone in your building.

Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

If you cannot reach your gas supplier, call the

fire department.

- Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

This appliance is a domestic room heating

appliance. It must not be used for any other

purpose such as drying clothes etc.

This appliance is suitable for installation

in a bedroom or bed sitting room.

•

•

•

•

WARNING: If the information in these

instructions is not followed exactly, a fire or

explosion may result causing property damage,

personal injury or loss of life.

600B469-2

Manufactured by

MILES INDUSTRIES LTD.

British Columbia, Canada

Vous pouvez vous procurer un exemplaire en langue Française

de cette brochure chez votre marchand.

535

GAS FIREPLACE HEATER

INSTALLATION BOOKLET

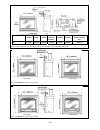

• Safety Information

• Options

• Location

• Supply Gas

• Pack Contents

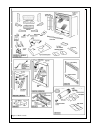

• Appliance

Preparation

• Installations with

different Models

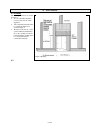

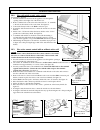

• Installing to Wall

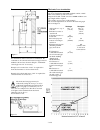

• Installations through

the roof

• Installing to Frame &

Fitting Heating Unit

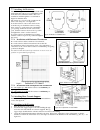

• Fitting Sides and

Switch

• Gas Supply

Installation

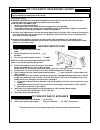

• Aeration Setting

Check

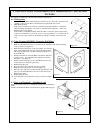

• Ceramic Fuel Bed

Installation

• Window Refitting &

Checking

• Installation

Completion