- DL manuals

- Valor

- Indoor Fireplace

- 719

- Installer's Manual

Valor 719 Installer's Manual

5109946/02

INSTALLER GUIDE

We trust that these instructions give sufficient details to enable this appliance to be

installed and maintained satisfactorily. However, if further information is required, our

Valor Technical Helpline will be pleased to help.

Telephone 08706 061 065 (National call rates apply in the United Kingdom)

In the Republic of Ireland call 0044 08706 061 065

INSTALLER: Please leave this guide with the

owner

© Valor Heating

Model 719

(GC No. 32-032-53)

INSET LIVE FUEL EFFECT GAS FIRE

INCORPORATING THE

VALOR

CONTROL

with

Ultimate

or

Colourway

Firefront

THIS APPLIANCE IS FOR USE WITH NATURAL GAS (G20)

WHEN CONVERTED USING CONVERSION KIT NO. 0595221 THIS

APPLIANCE IS FOR USE WITH PROPANE GAS (G31)

THIS APPLIANCE IS SUITABLE ONLY FOR INSTALLATION IN THE UNITED

KINGDOM (GB) AND THE REPUBLIC OF IRELAND (IE).

Summary of 719

Page 1

5109946/02 installer guide we trust that these instructions give sufficient details to enable this appliance to be installed and maintained satisfactorily. However, if further information is required, our valor technical helpline will be pleased to help. Telephone 08706 061 065 (national call rates ...

Page 2

Safety first. Valor fires are ce approved and designed to meet the appropriate british standards and safety marks. Quality and excellence. At the heart of every valor fire. All valor fires are manufactured to the highest standards of quality and excellence and are manufactured under a bs en iso 9001...

Page 3: Contents

Contents section heading page 1. Safety 4 2. Appliance data 5 3. General installation requirements 6 4. Pack contents 12 5. Fireplace check 14 6. Ignition check 15 7. Gas supply connection 16 8. Preparing appliance for installation 17 9. Convection box installation 19 9.1 method 1- front fixing to f...

Page 4: 1. Safety

1. Safety installer before continuing any further with the installation of this appliance please read the following guide to manual handling ! The lifting weight of this appliance with the surround removed is 8.4 kg. ! One person should be sufficient to lift the fire. If for any reason this weight i...

Page 5: 2. Appliance Data

2. Appliance data this product uses fuel effect pieces and a burner compartment rear wall containing refractory ceramic fibres (rcf), which are man-made vitreous silicate fibres. Excessive exposure to these materials may cause irritation to eyes, skin and respiratory tract. Consequently, it is impor...

Page 6

3. General installation requirements 3.1 the installation must be in accordance with these instructions. For the user’s protection, in the united kingdom it is the law that all gas appliances are installed by competent persons in accordance with the current edition of the gas safety (installation an...

Page 7

Where no specific instructions are given, reference should be made to the relevant british standard code of practice. 3.2 in the united kingdom, as supplied, this appliance can be installed in the following situations: - 3.2.1 a masonry chimney with a minimum diameter of 175mm (7”) free from any obs...

Page 8

Must be not less than the dimension shown in figure 3. The current versions of bs1289 and bs en 1806 recommend that there should be an air space or insulation between the flue blocks and the plaster because heat transfer may cause cracking on directly plastered flues. However, generally this applian...

Page 9

3.3.2 the flue must be clear of any obstruction and its base must be clear of debris. 3.3.3 the flue must be completely sealed so that combustion products do not come into contact with combustible materials outside the chimney. 3.3.4 the flue must serve only one fireplace. 3.4 the flue must conform ...

Page 10

3.11 the minimum height from the top surface of the hearth to the underside of any shelf made from wood or other combustible materials is detailed below. • for a shelf up to 150mm deep: minimum height = 750mm. • for a shelf deeper than 150mm: 150mm + 12.5mm for every 25mm depth over 150mm. (see grap...

Page 11

3.16 propane gas appliances must not be installed in a room, which is built entirely below ground level (see bs 5871 pt2). 3.17 if the appliance is to be fitted against a wall with combustible cladding, the cladding must be removed from the area covered by the outer surround. The cladding must also ...

Page 12: 4. Pack Contents

3.19 proprietary terminals must comply with bs 715 or bs 1289. Any terminal or termination must be positioned in accordance with bs 5440 part 1 to ensure that the products of combustion can be safely dispersed into the outside atmosphere. Where the appliance is connected to an unlined brick chimney ...

Page 13

1 length of self-adhesive foam seal 1 battery 1 slider knob extension bracket for colourway 4 screws for knob extension bracket for colourway 1 “t” connector including pressure test point 1 literature pack section 2 - fire front casting contains 1 firefront casting 1 front cover casting. Remove all ...

Page 14: 5. Fireplace Check

5. Fireplace check 5.1 fireplace check 5.1.1 fireplace size the fireplace must comply with the requirements described in section 3.2. This may entail removing the fireback and infill material behind the fireback. 5.1.2 fireplace general condition the fireplace floor should be reasonably flat to ensu...

Page 15: 6. Ignition Check

Possible, upstairs rooms and loft spaces for signs of escaping smoke indicating a defective flue. If there is not a definite flow warm the flue for a few minutes and repeat the smoke pellet test. If there is still no definite flow the flue may need remedial work – do not fit the appliance until ther...

Page 16: 7. Gas Supply Connection

7. Gas supply connection a nut and olive are provided for an 8mm pipe inlet connection to the ‘t’ connector at the bottom front of the appliance. The ‘t’ connector can be rotated to allow a connection from any direction. The ‘t’ connector includes a valve for isolating the gas supply and a pressure ...

Page 17

8. Preparing appliance for installation 8.1 appliance preparation 1. Remove any transit tape and packing and inspect for any evidence of mishandling which might affect the performance. Each unit is flame tested before it leaves the factory and as a result there may be slight discolouration around th...

Page 18

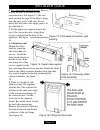

Page 18 installer guide 6. For concealed connection only: pierce a hole in the seal at the back of the convection box. See figure 13. The seal must envelop the pipe. If the hole is larger than the pipe, seal it with tape. Do not pierce the seal unless the supply pipe is to pass through it. 7. Fit th...

Page 19

8.2 the flue restrictor this appliance is supplied with a flue restrictor for use where the flue draught is excessive. The restrictor must not be fitted where a precast flue or a 125mm flue liner is used. For flue liners greater than 125mm and all other installations the restrictor should be fitted....

Page 20

9.2 method 2 - cable retention 1. Make sure that the relevant areas at the fireplace back are sound enough to take the eyebolts. If these areas have deteriorated due to prolonged use they should be made sound with a suitable cement. 2. Drill four holes in the rear wall of the fireplace for the eyebo...

Page 21

Page 21 bottom front sides of the convection box. See figure 21. 7. Place the convection box fully back into the fireplace opening so that it is sealed against the fireplace front surround. 8. Fit a cable retainer over the bottom end of each cable. 9. Pull each cable taut. Push the cable retainers h...

Page 22: Important

9.3 floor sealing (all installations) using the floor sealing tape supplied, seal the bottom of the convector box to the fireplace and hearth floor. Run the tape over the centre bracket (see figure 24). 10. Burner & supply pipe installation important before continuing with the installation of this g...

Page 23

You should feel some resistance when the slide button reaches the maximum burner flame position. Sliding further upwards until the knob comes to a stop should then turn the burner and pilot off. When the above checks have been completed close the isolating valve on the inlet ‘t’ connector. If the ab...

Page 24

12. Ceramic coals installation 1. Place the rear base coal in the firebox. It should rest on the ledges at the rear sides of the burner unit. When located gently move the rear base coal so that it is as far forward as possible. The amount of movement will be negligible (see figure 28). 2. Place the ...

Page 25

4. Place a type “b” coal between the front and rear base coals as shown in figure 31. The letter “b” should be upright. 5. Place a type “a” coal between the front and rear base coals with the letter “a” upright. The top of the coal should rest against the centre coal of the rear base coal as shown i...

Page 26: 13. Firefront Casting

13. Firefront casting 8 installation 1. Locate the two screw heads through the keyhole slots at the inner sides of the surround. If the screw heads do not project enough or project too far, the screws can be adjusted. Lower the casting so that it rests on the hearth. See figure 35. 3. Fit the front ...

Page 27

Investigate the pilot unit. 14.1.2 operating the burner. 1. Gradually slide the button up to increase the burner setting. The burner should be at its maximum setting at the high heat position shown in figure 36. You should feel a check to the button movement at this position. 2. Slide the control bu...

Page 28

The fireplace surround. If the sealing is satisfactory but the appliance is installed with the flue restrictor (see section 8.2) remove the restrictor, reseal the appliance and retest. If smoke is still not drawn into the appliance disconnect the appliance and seek expert advice. 5. If the above tes...

Page 29: 16. Final Review

16. Final review 1. Visually inspect the appliance. Clean off any marks incurred during installation. 2. Advise the customer how to operate the fire. 3. Explain to the customer that the appliance has a flame failure and spillage monitoring system. Point out the explanation of this system shown in th...

Page 30: Setting Is Correct (See

Page 30 17. Servicing & parts replacement always turn off the gas supply before commencing any servicing (the appliance inlet “t” connector incorporates an isolating valve). It is recommended that, at least once a year, the appliance is disconnected and the fireplace opening checked and cleared of a...

Page 31

17.2 to remove the ignition microswitch see figures 39 & 40 the ignition microswitch is stamped v4nt9c4yc 1. Remove the bottom front cover and the front cover casting. 2. Detach the microswitch cover by removing one screw and pulling clear of the location lug. See figure 39. 3. Disconnect the leads ...

Page 32

5. Replace in the reverse order. When refitting the leads to the interrupter block, make sure that they are secured firmly to give a good electrical contact. 17.4 to remove the fire front surround 1. Remove the bottom front cover and the fire front casting. 2. Detach the control-linking bar from the...

Page 33

–see figure 45. 5. Replace in the reverse order. 17.7 to remove the electronic ignition generator 1. Remove the burner unit - see section 17.6 2. Remove the battery. 3. Remove the spark lead and microswitch leadsremembering to make note of their positions. 5. Unscrew the two fixing screws that attac...

Page 34

Interrupter block to give a good electrical contact. 17.9 to remove the pilot unit 1. Remove the burner unit - see section 17.6. 2. Detach the pilot pipe from the pilot unit. 3. Detach the thermocouple from the interrupter block by unscrewing the thermocouple nut. 4. Detach the electrode lead from t...

Page 35

7. Loosen the hexagonal locknut securing the elbow to the tap. Remove the elbow by rotating it. 8. If fitting a new tap, remove the hexagonal nut at the mounting bracket end of the old tap and fit to the replacement tap. Prior to refitting the elbow to the shut-off tap, apply an approved sealant to ...

Page 36

The microswitch. 7. Remove the hexagonal bolt securing the control pivot bracket to the controller at the rear. 8. Detach the control pivot bracket. 9. Remove the hexagonal nut securing the controller to the front mounting bracket and remove the flow rate controller. 10. Refit in the reverse order. ...

Page 37

Page 37 installer guide.

Page 38: 18. Short List of Spares

18. Short list of spares page 38 installer guide.

Page 39

Page 39 installer guide key no. Description no. Off maker’s part no. A shut-off tap 1 0540899 b gas flow rate controller 1 0540919 c thermocouple interrupter block 1 5108851 d ignition microswitch 1 0540959 e gas shut-off microswitch 1 0540969 f pilot unit - for natural gas appliances 1 3002988 pilo...