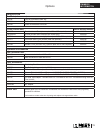

Valor PORTRAIT 530INI Installation & Owner's Manual

4005323-01

P

ORTRAIT

Installation & Owner’s Manual

Direct Vent Gas Insert Fireplace

530INI (NG) & 530IPI (LPG)

This manual contains instructions to install the EN-

GINE ONLY. A front trim kit is REQUIRED to install

the engine as it affects the framing cavity and posi-

tion of the engine. A barrier screen is provided with

the front or trim kit. Refer to the manual supplied

with the front for framing and fi nishing.

— Do not store or use gasoline or other

fl ammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

▪ Do not try to light any appliance.

▪ Do not touch any electrical switch; do

not use any phone in your building.

▪ Leave the building immediately.

▪ Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

▪ If you cannot reach your gas supplier,

call the fi re department.

— Installation and service must be

performed by a qualifi ed installer, service

agency or the gas supplier.

Ce guide est disponible en français sur demande.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certifi ed kit is used.

This appliance is a domestic room-heating

appliance. It must not be used for any other

purposes such as drying clothes, etc.

This appliance is suitable for installation in a

bedroom or bed sitting room.

This appliance may be installed in an

after-market permanently located,

manufactured (mobile) home where not

prohibited by local codes.

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

DANGER

!

A barrier designed to reduce the risk of burns from the hot

viewing glass is provided with this appliance and shall be

installed for the protection of children and other at-risk

individuals.

!

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

INSTALLER

Leave this manual

with the appliance.

CONSUMER

Retain this manual

for future reference.

Please read this manual

BEFORE installing and

operating this appliance.

©2016, Miles Industries Ltd. All rights reserved.