- DL manuals

- Varimixer

- Mixer

- ERGO100

- Operation Manual

Varimixer ERGO100 Operation Manual

Summary of ERGO100

Page 1

Spare part and operation manual food mixer model ergo60 ergo100 ergo150 012016.

Page 2

2 caution -read before operating- caution varimixer recommends that mixer operators be at least 18 years of age and be thoroughly trained on the use, cleaning and lubrication of the mixer. This manual should be seen as an integral part of the mixer and should be kept by the machine throughout its wo...

Page 3

3 limited warranty varimixer warrants its commercial mixers to the original purchaser against defects in material or manufacture for a period of one year from the date of original purchase, subject to the following exclusions and limitations. The warranties provided by varimixer do not apply in the ...

Page 4: The Mixer Must Be Bolted

4 g eneral : in case of complaints, please contact your dealer. The guarantee does not cover faults resulting from faulty operation, overloading and lacking observance of directions of maintenance. It should be checked that all loose parts are delivered with the mixer such as bowl, tools, and rubber...

Page 5

5 c onstruction of the mixer : bowl clamping system with inductive sensor: at the back of the right- hand bowl arm is an in- ductive sensor which is activated when the bowl is correctly positioned in the bowl clamping system (at the very back of the bowl arms). This sensor must be activated in order...

Page 6

6 capacities per mix ergo60 ergp100 ergo150 dough, bread 65%ar 90 lbs. 155 lbs. 190 lbs. Dough, bread 50%ar 75 lbs. 135 lbs. 175 lbs. Dough, donut - yeast 70 lbs. 150 lbs. 170 lbs. Dough, donut - cake 60 lbs. 140 lbs. 225 lbs. Pie dough 58 lbs. 95 lbs. 135 lbs. Cookie, dough 50 lbs. 105 lbs. 160 lbs...

Page 7

7 c ontrol p anel vl4: bowl up to raise the bowl, press the + + fields simultaneously and con- stantly until the bowl reaches the top. Start/stop bowl down lowers the bowl once the mixer has stopped. If this field is activated while the mixer is running, the bowl will be lowered auto- matically when...

Page 8

8 1 2 3 4 remix remix remix remix vl4 control panel - survey of various operating situations : the following pictures show various operating situations and corresponding explanation: if the field is activated while the mixer is running, the chosen operation time is reset and the speed is set to mini...

Page 9

9 remix remix remix remix remix remix 5 6 7 8 9 10 remix remix remix remix remix remix the bowl screen has been opened while the mixer was running. The bowl can be lowered. When the bowl screen is closed and the operator presses twice, the mixer starts at its lowest speed. As figure 6, but automatic...

Page 10

10 o peration of the mixer : before starting the mixer: mount the required tool in the bayonet shaft. Place the bowl in the bowl arms and close the bowl screen. To raise the bowl, activate the fields , and simultaneously, the activation to be continued until the bowl has reached its top position. Wh...

Page 11

11 o verload : do not overload the mixer. Sticky and heavy doughs can overload the mixer. Overloading is further exac- erbated if the speed of the mixing tool is increased beyond the recommended values or if a wrong mixing tool is used. Large lumps of fat or cooled ingredients must be cut into small...

Page 12

12 m echanical component error : the bowl is too tight or too loose in the bowl arms. Solution: “adjustment of bowl clamping and centering”, page 14 the tool hits the sides of the bowl. Solution: “adjustment of bowl clamping and centering”, page 14 abnormal noise from the lifting actuator: solution:...

Page 13

13 c all up an error log of the last 10 disconnections : the last 10 disconnections due to errors resulting in code can be read on the mixer display: • press the emergency stop • press and to browse the log • the diodes on the speed indicator light up. The age of the error is indicated by the diode ...

Page 14

14 the bearing (a) has two diameters. As standard the mixer is delivered with the bearings mounted so that the largest dia meter points away from the bowl arms, which means the tightest bowl clamping. A djustment of bowl centering ergo60 and ergo100: first find the present bowl centering: mount the ...

Page 15

15 a djusting of bowl clamping and centering ergo150: in the rear part of the bowl arms (j) a shaft with an eccentric stud (k) has been mounted, on which the ball bearing is mounted. By turning the eccentric stud, the bowl arms can be opened and closed so that the clamping and the centering of the b...

Page 16

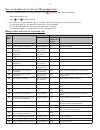

16 ¡ ¢ ¢ ¢ ¢ £ ¢ ¢ £ ¤ ¤ ¢ ¢ ¢ ¢ ¤ £ ¤ ¤ ¤ ¢ ¢ ¢ ¢ ¢ £ ¢ ¢ ¢ £ ¤ ¢ ¢ ¢ £ ¢ ¢ £ ¢ ¢ ¢ ¤ ¢ ¢ ¢ ¢ £ ¢ ¢ ¥ ¦ ¤ ¦ ¢ ¢ ¢ ¤ ¦ § § § ¤ ¦ ¤ ¢ ¦ ¤ ¢ ¥ ¥ ¤ ¦ ¤ ¦ ¤ ¥ ¦ ¤ ¦ ¤ ¥ ¦ ¦ ¢ ¢ ¥ ¦ ¤ ¢ ¥ ¢ ¥ ¢ ¥ ¥ ¢ ¥ ¤ ¢ ¥ ¦ ¦ ¤ ¦ ¢ ¥ ¦ ¤ ¢ ¤ ¢ ¢ ¢ § § ¢ ¥ ¥ ¥ ¥ ¢ ¢ ¢ ¤ § § ¥ ¤ ¥ ¢ ¢¥ ¥ ¥ ¢¥ ¤...

Page 17

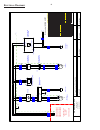

17 ¡ s afety circuit :.

Page 18

18 be beige bk black bn brown bnbu brownblue bngn browngreen bnrd brownred bu blue bubk blueblack bugn bluegreen gn green gnbk greenblack gy grey gybk greyblack gybn gra ybrown gybu greyblue gygn greygreen gyrd greyred gyvt greyviolet og orange ogbu orangeblue oggn orangegreen oggy orangegrey ogbn o...

Page 19

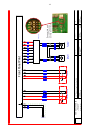

19 deep-switche must be in off-position, as they are not in use 0 1 2 3 4 5 6 7 8 9 a/s wodschow & co kirkebjerg søpark 6 dk-2605 broenby www .Bearvarimixer .Dk page previous page next page number of pages: last printed: last corrected: page rev .: project rev .: rev . 8 / appr . (init/date): / cons...

Page 20

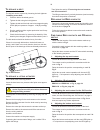

20 cc f dl fig. 2. Belt tension. T o replace a lifting actuator : lift the bowl arms to the top position. Lower the bowl arms to a pressure relief point set at approx. Midway. It is very important that the bowl arms are low- ered to a pressure relief point before disassem- bling the lifting actuator...

Page 21

21 a/s wodschow & co. Industrisvinget 6 dk-2605 broendby www.Bearvarimixer.Dk date: design: format: dimension: matr: 26-05-2010 mh a3 stroke 616mm rev: scale: surface: a b c x/y x/y ergo60: a = 1 3/8” b = 9 1/16” c = 20 15/32” ergo100: a = 2 33/64” b = 9 27/32” c = 24 51/64” ergo150: a = 19/32” b = ...

Page 22

22 a b c d fig. 6a l ubrication overview : part location oil/grease explanation frequency bushings in the bowl arms item a, fig.6 organic oil or grease, e.G texaco startplex ep remove the back cover. Lubricate the bowl arm axle with grease. Per 5,000 batches or min. Once yearly or in case of unusual...

Page 23

23.

Page 24

24.