Summary of V20

Page 1

1 spare part and operation manual food mixer model v20 012016.

Page 2

2 caution -read before operating- caution varimixer recommends that mixer operators be at least 18 years of age and be thoroughly trained on the use, cleaning and lubrication of the mixer. This manual should be seen as an integral part of the mixer and should be kept by the machine throughout its wo...

Page 3

3 varimixer warrants its commercial mixers to the original purchaser against defects in material or manufacture for a period of one year from the date of original purchase, subject to the following exclusions and limitations. The warranties provided by varimixer do not apply in the following instanc...

Page 4

4 t able o f c ontents i nstallation and fixing : the ambient temperature around the machine must not exceed 113 o f. If the mixer is placed on a table, it must always be bolted into the table top. The bolts fixing the mixer on the pallet can be used for this, no nuts are needed as there are threads...

Page 5: V20

5 t echnical data : gross weight ......................................233 lbs. Net weight ..........................................196 lbs level capacity, large bowl ..................21 qt. Level capacity, small bowl .................13 qt. Agitator speed, min. ...........................100 r.P....

Page 6

6 s afety : the machine is designed for the manufacture of products that do not trigger any reactions or release substances that may be harmful to the user when in use. User safety is assured as follows: • tools can only rotate when the bowl screen is closed and the bowl is lifted. • no access to ro...

Page 7

7 varimixer bear 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 hold varimixer bear 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 hold varimixer bear 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 hold 6 5 4 7 8 2 3 1 varimixer i 0 bear place the tool in the bowl. Place the bowl in the bowl arms. Ensure that the bowl is plac...

Page 8

8 o verloading : the mixer must not be overloaded. Possible overload situations: • working with excessively tough and heavy dough • mixer tool exceeding the recommended speed • wrong mixer tool being used. Big lumps of grease or cooled ingredients must be divided into fine particles before being pla...

Page 9

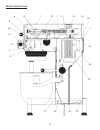

9 s ervice i nstructions 5 55 3 21 4 40 41 9 7 22 1 10 6 8 42 43 2 16 17 18 20 19 44.

Page 10

10 s ervice i nstructions (1) remove the top cover of the mixer (1) and the plastic cover (43) by removing the 2 screws (3) the attachment engagement hub is taken out by removing the plastic cover (4) and the 4 bolts (5). (6) the control box is taken off by removing the 2 screws (55). (7) the specia...

Page 11

11 the planetary head is removed in the following way: a) the top cover of the mixer (1), the attachment engagement hub (3), the special v-belt (7), and the control box (6) are removed. B) the plastic ring (26) can be removed by knocking it gently on the front edge, then pressing a screwdriver betwe...

Page 12

12 mounting of the planetary head should be done in reverse order. When the lower fork (15) and the spring (34) are mounted, the speed selector lever (8) is turned counter clockwise, so that it points hori- zontally backward, at the same time as the lower fork is pressed down gently. When the speed ...

Page 13

13 (45) the bowl arms are to be replaced in the following way: a) disconnect the mixer on the main switch or disconnect the connecting cable. B) lower the bowl arms. C) place the mixer on its back and remove the legs of the mixer (17) by removing the screws (18). D) the bottom plate (19) is removed ...

Page 14

14 m achine c olumn 20 18 19 11 13 10 17 9 12 6 15 3 7 14 5 16 2 1 4 8 06020-0407 10a.

Page 15

15 m achine c olumn fig. No. Description part number 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 10a 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. Top lid .............................................................................................................. 20d-21 screw............................................

Page 16

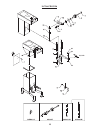

16 l ifting s ystem 56rn20-15 20n-62z 20n-65.1m 20n-68.5m 22 23 24 21, 21a.

Page 17

17 l ifting s ystem fig. No. Description part number 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 14. 15. 16. 17. 18. 19. 20. 21. 21a. 22. 23. 24. Key ......................................................................................................................Sta 2019 snap ring .....................

Page 18

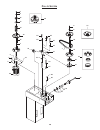

18 p ulley s ystem 8 9 16 13 14 12 7 10 3 4 35 2 6 18 12 20 21 1 28 26 23 32 30 27 25 27 31 24 29 27 37 36 38 34 40 33 39 5 22 19.

Page 19

19 p ulley s ystem fig. No. Description part number 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 12. 13. 14. 16. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. Belt ...........................................................................................................

Page 20

20 p lanetary h ead 31 33 34 35 27 28 29 30 25 26 14 15 16 17 18 19 12 20 21 22 23 10 9 4 6 7 8 1 2 3 20n-2.1z 20n-3 20n-2 20n-2.1m 20n-30 20-33 20-36 20n-101 5 11 24 32 13.

Page 21

21 p lanetary h ead fig. No. Description part number 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. Snap ring .............................................................................................................

Page 22

22 a ttachment h ub rn20-10.6m9 #12 hub 17 11 16 3 15 12 14 13 7 1 6 4 5 2 8 9 10 2î i.D. ȍu,' 1 ½” i.D. 18.

Page 23

23 a ttachment h ub fig. No. Description part number 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. Snap ring ............................................................................................................ Sta 3410 wormwheel .................................................

Page 24

24 e lectrical c omponents 1 19 4 5 13 12 11 3 2 6 7 10 9 8 16 17 18 15 14 15 20

Page 25

25 e lectrical c omponents fig. No. Description part number 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. Start switch assembly ...................................................................................... Ar31-174.2 stop switch assembly ...............................

Page 26

26 b owl s creen 1 5 10 2 3 9 7 8 4 6 11 20 19 12 13 14 15 18 16 17 56sn20-15.

Page 27

27 b owl s creen fig. No. Description part number 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. Bowl screen kit ................................................................................................. 14020-0001 bushing..................................................

Page 28

28 t ools and a ttachments 1, 2 10 10 10 10 3, 4 5 6 11 7, 8 9 12, 13 14, 15 16, 17 10 19 20 18 21.

Page 29

29 t ools and a ttachments fig. No. Description part number 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. S/s bowl 20qt ......................................................................................................203/20n s/s bowl 12qt. .............................

Page 30

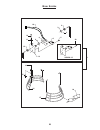

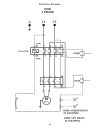

30 e lectrical d iagram.

Page 31

31.

Page 32

32 14240 south lakes drive charlotte, nc 28273 (800) 222-1138 www.Varimixer.Com.