- DL manuals

- Varimixer

- Mixer

- W80

- Operation Manual

Varimixer W80 Operation Manual

Summary of W80

Page 1

Spare part and operation manual food mixer model w80, w100n, w150pl 1993 to present form 109 (08/10).

Page 2

Caution -read before operating- caution varimixer recommends that mixer operators be at least 18 years of age and be thoroughly trained on the use of the mixer. Varimixer recommends that the following precautions be adopted to help make the mixer operation safer and more efficient. ........ - all op...

Page 3

Varimixer warrants its commercial mixers to the original purchaser against defects in material or manufacture for a period of one year from the date of original purchase, subject to the following exclusions and limitations. The warranties provided by varimixer do not apply in the following instances...

Page 4

Table of contents installation instructions...................................................................................................4 operating instructions.....................................................................................................5 cleaning-maintenance..............

Page 5

Read this page entirely before beginning installation . Varimixer installation instructions the mixer must be mounted with the rubber feet, which neutralize both shaking and rusting. Spacers can be inserted under the mixer’s feet if the floor is uneven. The mixer can be bolted to the floor if d esir...

Page 6

Operation of the mixer: a) open the bowl screen and place the bowl in the bowl arms. Note: the bowl arms must be in lowest position and the bowl must be pushed all the way into the bowl arms. (fig.3). B) place the mixing tool in the bayonet shaft. The pin on the tool must be turned into the bayonet ...

Page 7

Maintenance and lubrication: the variable speed pulleys must be lubricated regularly, i.E. A lubrication interval of approx. 60 hours of operation or once a week. Lubrication of variable speed pulleys: -start the mixer and increase the speed to approx. 50%. Stop the mixer and open the lid on the top...

Page 8

A rattling sound from the closed part of the mixer. Adjustment of special v-belt the mixer starts “striking” when kneading dough adjustment of special v-belt which normally causes no problems. The mixer changes its speed by itself. Adjustment of special v-belt the minimum and the maximum speeds are ...

Page 9

8 adjustment of bowl centering: first find the present bowl centering: mount the beater and the bowl, then raise the bowl arms up to normal working position. With your hand turn the beater, and then measure the distance between beater and bowl edge. By removing the rear covering, the bowl arm guide ...

Page 10

% ar=weight of liquids weight of flour water weights 1 gallon =8.33 lbs. 1 quart =2.08 lbs 1 pint (16 oz.) =1.04 lbs. 1 cup = .52 lbs. Batch size and/or speed reduction may be necessary due to one of the following conditions: 1.High gluten flour-reduce batch size by 10% 2.Ar % under 40%-reduce batch...

Page 11

Notes: 10

Page 12

11.

Page 13

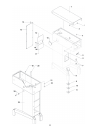

Machine column w80-w100 description w80 100-21 sta 5017 sta 6580 sta 5232 15-214 sta 6519 sta 2526 80-212 80n-213 80n-214.3 80n-214.6 sta 5080 100n-22.7 81-270 sta 5834 sta 6027 81-271 15-71 nla 81-148 sta 6056 sta 5625 n/a sta 2515 81-22 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18...

Page 14

13.

Page 15

Bowl lift microswitches w80-w100 description w80 81-612 81-173 sta 5270 81-174 1. 2. 3. 4. Fig. No. Microswitch bracket (manual lift) microswitch screw microswitch bracket assembly (power bowl lift) w100 n/a n/a n/a 81-174 14.

Page 16

15.

Page 17

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 24a. 25. 26. 27. 28. 29. . Manual bowl lift (w80 only) description w80 15-65 60-63 81-68 81-83 60-110 sta 2020 sta 3408 sta 3462 sta 5088 sta 5827 sta 6205 sta 6370 31-128 100-62m sta 3308 81-71.10 81-71.5m 81-600...

Page 18

17.

Page 19

Power bowl lift w80-w100 description w80 81-86.40 81-68 60-110 sta 3408 sta 3462 sta 5088 100-67 100n-66 sta 6205 sta 6370 31-128 81-71 100n-86.02 81-86.1 81-86.2 81-86.15 140-87 140-430 140-430.1 81-71.10 81-71.5m 81-23 81-24 sta 5819 sta 2526 sta 5550 31-127 sta 5322 1. 2. 3. 4. 5. 6. 7. 8. 9. 10....

Page 20

19.

Page 21

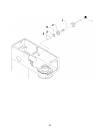

Planetary head w80-w100 description w80 100-90.1 order qty 3 sta 3419 sta 6048 sta 3419 100-129a 100-99 sta 3532 sta 5346 sta 6057 100-3 100-141 100-1 sta 5044 100-22.9p 100-37 sta 3530 sta 3478 100-36 100-100 sta 3530 100-96 100-235 sta 2030 100-31 100n-30 100n-32n 100-101race sta 6460 100-2 sta 60...

Page 22

21.

Page 23

Transmission w80-w100 description w80 sta 3220 sta 6018 27-227 sta 5612 15-17 15-103 60-15.1m sta 2505 60-91 15-156 60-285 60-13.1m sta 5602 sta 2011 sta 2007 sta 5018 60-61 n/a sta 5345 sta 6010 sta 5433 sta 6026 sta 5815 sta 6040 20-19 sta 5810 sta 5446 sta 5810 sta 5895 40p-275 20-26 30n-305 sta ...

Page 24

23.

Page 25

1. 1a. 2. 3. 4. 5. 6. Speed lever system w80-w100 description w80-w100 80n-47m 100n-47m 30n-47.10 30n-47.20 sta 3306 sta 3414 sta 5247 fig. No. Speed lever w80 speed lever w100 disc w/ arrow white clamp black knob snap ring screw 24.

Page 26

25.

Page 27

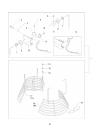

Attachment drive (w80 only) description w80 sta 3220 60-61 sta 5018 sta 6054 15-11 20-104 sta 3410 sta 2007 20-52 sta 2011 20-49 15-10 sta 5433 sta 6020 sta 5908 nla nla sta 5433 sta 6056 15-105 20-9 20-107 sta 5908 sta 5018 15-5 sta 2032 15-50 30-50 15-8 30-8 sta 6056 sta 6316 sta 5322 sta 5561 4r-...

Page 28

27.

Page 29

Bowl screen w80-w100 description w80-w100 225/80n 225/100n sta 5250 sta 5819 56sn30-22 sta 5665 sta 5665 56sn30-21 56sn30-24 56sn30-23 sta 5251 56sn20-30 56sn30-13 56p30-15 sta 5810 sta 6056 56g30-26 225/80nr 225/100nr 225/80nf 225/100nf 227 1. 1a. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16....

Page 30

29.

Page 31

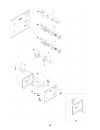

Electrical control panel w80-w100 1998-present description w80-w100 60-86.1 31-174.2 31-174.3 30-188.15 30-190 sta 5987 sta 6483 sta 3017 sta 3038 sta 3010 20-88.24 20-88.21 20-88.47 sta 5097 sta 6483 100-88.5 20-88.91 sta 5232 31-457 31-152 31-149 1. 2. 3. 4. 5. 6. 7. 8. 10. 11. 12. 12a. 13. 14. 15...

Page 32

31.

Page 33

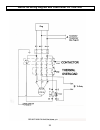

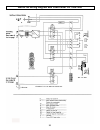

Electrical power supply w80-w100 1998-present description w80-w100 20e-418 20e-416 100-88.5 20-88.91 20-88.47 20-88.24 20-88.21 140e-420 140e-421 100n-86.01 60e-430.1 150e-425 1. 2. 3. 3a. 4. 5 5a. 6. 7. 8. 9. 10. Fig. No. Fuse fuse holder contactor 220v contactor 480v auxiliary switch thermal overl...

Page 34

33.

Page 35

Accessories w80-w100 description w80 203/80n na 203/40bn 213/80d 213/40bn 205/80n na 205/40bn 204/80n 207/80n 221/80n na 207/40bn 209/80n na na 224/80n na 224/40bn sta 5652 42rn100-101m 42ar80-202 na 42ar41-202 42ar80-204 42r40-204 215/80n na 215/40bn 100-206a 100-206 22r100-40 22r20-40 sta 5608 22r...

Page 36

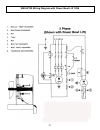

W80-w100 wiring diagram with power bowl lift 1988-1996 35.

Page 37

W80-w100 wiring diagram with power bowl lift 1988-1996 36.

Page 38

W80-w100 wiring diagram with power bowl lift 1996 37.

Page 39

This page intentionally left blank. 38.

Page 40

W80-w100 front panel wiring diagram with power bowl lift 2005-present 39.

Page 41

W80-w100 power supply wiring diagram with power bowl lift 2005-present 40

Page 42

5489 campus drive shreveport la 71129 (800) 222-1138 (318) 635-3131 fax www.Varimixer.Com.