- DL manuals

- Vector2

- Gate Opener

- V400

- Installation Instructions Manual

Vector2 V400 Installation Instructions Manual - Strength Of The Pillar

Page 15

Site Considerations

Site Considerations

Page 14

In order to ensure a reliable and durable installation thought should be given to:

Strength of the pillar

For reliable operation it is important to ensure that the way the operator is secured to the wall takes into

account the strength of the pillar, the size of the gate, and how frequently the gate would be used:

PILLAR

PILLAR

PILLAR

This mounting works well for

heavy gates shorter than

about 2m in single house-

hold domestic applications.

Alternatively it should be

considered for use on pillars

of low or unknown strength.

This mounting means is

typically used on light to

medium weight domestic

gates that are about 1.5m

long, and that is mounted on

pillars of average strength.

This mounting is highly

recommended for all light

industrial gates, or for heavy

gates of any length.

Alternatively it should be

considered for use on pillars

of low or unknown strength.

Strength of the gate and gate bracket

The gate adaptor kit both strengthens the connection to the gate, and also allows for more flexibility when

mounting the bracket to the gate:

The Mechano kit

This kit is useful when fitting VECTORS to existing installations, and also makes adjustments easier when

doing new installations.

Applications:

• Light industrial

• Heavy gates

• Frequent use

Applications:

• Domestic

• Medium gates

• Frequent use

Applications:

• Domestic

• Light gates

• Infrequent use

Standard bracket

High security kit

High security kit

together with a

Wall adaptor kit

BEST

WORKS WELL

GOOD

As important as the bracket is how the bracket is secured to the pillar:

Applications:

• Prefabricated

walling

• For heavy gates

operating

frequently

PILLAR

PILLAR

STEEL

PILLAR

PILLAR

PILLAR

Applications:

• Masonry pillars

• Frequent use

Applications:

• Lighter gates

• Domestic

Applications:

• Light gates

• Domestic

Applications:

• Very light

• Very domestic

Through wall

Chemical

anchors

Welding

Sleeve

anchors

RAWL Bolts

BEST

WORKS WELL

WORKS WELL

OK

NOT

RECOMMENDED

Welding

Gate adaptor kit

Through bolts

Gate adaptor kit

Welding

Through bolts

(High tensile)

FAIR

GOOD

VERY GOOD

BEST

Tex screws and mild steel bolts are not recommended

Summary of V400

Page 1

Otech group pty t: 07 3205 1123 f: 07 3205 1124 e: info@rotech.Com.Au.

Page 2

Centurion systems has been manufacturing automatic gate systems since 1987, and is committed to providing reliable, cost effective solutions in the field of access automation. Centurion strives to give service and backup second to none. Our engineers are available to give sales support, installation...

Page 3: Warnings For The Installer

Important safety instructions important safety instructions page 4 to ensure the safety of people, it is important that you read all the following instructions. Incorrect installation or incorrect use of the product could cause serious harm to people. The installer, being either professional or diy,...

Page 4: Warnings For The Installer

Important safety instructions important safety instructions page 4 to ensure the safety of people, it is important that you read all the following instructions. Incorrect installation or incorrect use of the product could cause serious harm to people. The installer, being either professional or diy,...

Page 5: Operator V400/v500

Power configurations: extention/retraction (no load): max. Output force: max. Operations (day): standby operations: standby period: ½ day 1 day 2 days typical gate opening/ closing time: operating temp. Range: housing protection: mass of operator: operator stroke: dc current draw (max): nominal inpu...

Page 6: Operator V400/v500

Power configurations: extention/retraction (no load): max. Output force: max. Operations (day): standby operations: standby period: ½ day 1 day 2 days typical gate opening/ closing time: operating temp. Range: housing protection: mass of operator: operator stroke: dc current draw (max): nominal inpu...

Page 7: Allowable Gate Mass

Page 8 allowable gate mass maximum allowable gate mass for v400 operator: gate swing angle up to up to up to up to up to up to 1.5m 2m 2.5m 3m(#1) 3.5m(#1) 4m(#1) 90° 500kg 500kg 500kg 360kg 260kg 200kg 100° 500kg 500kg 388kg 160kg 190kg 150kg 110° 500kg 306kg 198kg 130kg 120° 180kg 100kg 65kg (#1 -...

Page 8: Allowable Gate Mass

Page 8 allowable gate mass maximum allowable gate mass for v400 operator: gate swing angle up to up to up to up to up to up to 1.5m 2m 2.5m 3m(#1) 3.5m(#1) 4m(#1) 90° 500kg 500kg 500kg 360kg 260kg 200kg 100° 500kg 500kg 388kg 160kg 190kg 150kg 110° 500kg 306kg 198kg 130kg 120° 180kg 100kg 65kg (#1 -...

Page 9

Page 10 item description qty. Part no. 1 wall bracket (high security) 1 1050m30000 2 padlock 2 m-pltri263 4 vector high security kit packing leaflet 1 doc1050d05 high security kit (optional) vechsk00v1 page 11 control box including charger & controller (domestic) veccad00v2 / (light industrial) vecc...

Page 10

Page 10 item description qty. Part no. 1 wall bracket (high security) 1 1050m30000 2 padlock 2 m-pltri263 4 vector high security kit packing leaflet 1 doc1050d05 high security kit (optional) vechsk00v1 page 11 control box including charger & controller (domestic) veccad00v2 / (light industrial) vecc...

Page 11

Page 12 required tools & equipment required tools & equipment figure 4 required tools and equipment spanner 17mm, 15mm preferably socket set screw drivers 6mm philips 3.5 flat crimping tool and pin lugs pliers side cutters hammer 2 x g-clamps electric drilling machine measuring tape hacksaw angle gr...

Page 12

Page 12 required tools & equipment required tools & equipment figure 4 required tools and equipment spanner 17mm, 15mm preferably socket set screw drivers 6mm philips 3.5 flat crimping tool and pin lugs pliers side cutters hammer 2 x g-clamps electric drilling machine measuring tape hacksaw angle gr...

Page 13: Strength Of The Pillar

Page 15 site considerations site considerations page 14 in order to ensure a reliable and durable installation thought should be given to: strength of the pillar for reliable operation it is important to ensure that the way the operator is secured to the wall takes into account the strength of the p...

Page 14: Strength Of The Pillar

Page 15 site considerations site considerations page 14 in order to ensure a reliable and durable installation thought should be given to: strength of the pillar for reliable operation it is important to ensure that the way the operator is secured to the wall takes into account the strength of the p...

Page 15

Cabling requirements cabling requirements figure 6 cabling requirements figure 5 minimum installation requirements page 17 1. 220v ac mains cable via mains isolator or switch (3 core lne 0,5mm²)* 2 optional keypad ( 3 core 0,5mm multi- or stranded). Low voltage 16v ac battery charger 6. Optional inf...

Page 16

Cabling requirements cabling requirements figure 6 cabling requirements figure 5 minimum installation requirements page 17 1. 220v ac mains cable via mains isolator or switch (3 core lne 0,5mm²)* 2 optional keypad ( 3 core 0,5mm multi- or stranded). Low voltage 16v ac battery charger 6. Optional inf...

Page 17

4. Secure the bracket to the wall with the most appropriate means. It is critical that the wall bracket is securely mounted. See page 14 for site considerations. 5. Fit the gate bracket to the operator. 1 or 2 turns 6. Fit the motor end of the operator to the wall bracket. 7. Open the gate fully and...

Page 18

4. Secure the bracket to the wall with the most appropriate means. It is critical that the wall bracket is securely mounted. See page 14 for site considerations. 5. Fit the gate bracket to the operator. 1 or 2 turns 6. Fit the motor end of the operator to the wall bracket. 7. Open the gate fully and...

Page 19: Adjust Origin Clamp

Or 13.Unlock the operator and open the gate fully. 14. Slide the origin clamp along the actuator tube, right up to the operator. Secure in place with an allen key tighten properly. 15. Attach warning decals to the gate as shown. 2 1 adjust origin clamp (nb - not required for outward swinging gates) ...

Page 20: Adjust Origin Clamp

Or 13.Unlock the operator and open the gate fully. 14. Slide the origin clamp along the actuator tube, right up to the operator. Secure in place with an allen key tighten properly. 15. Attach warning decals to the gate as shown. 2 1 adjust origin clamp (nb - not required for outward swinging gates) ...

Page 21: For V400 (400Mm Operator)

Alternative positions a and b ‘min value’ gate swing a+b should up to up to up to up to up to up to angle not exceed 1.5m 2m 2.5m 3m 3.5m 4m 60° - 90° or less 460mm 100° 400mm 110° 340mm 120° 285mm recommended positions (only for a 2.5m gate or shorter) a value b value 90° or less 205 250 100° 165 2...

Page 22: For V400 (400Mm Operator)

Alternative positions a and b ‘min value’ gate swing a+b should up to up to up to up to up to up to angle not exceed 1.5m 2m 2.5m 3m 3.5m 4m 60° - 90° or less 460mm 100° 400mm 110° 340mm 120° 285mm recommended positions (only for a 2.5m gate or shorter) a value b value 90° or less 205 250 100° 165 2...

Page 23: For V400 (400Mm Operator)

Page 25 alternative positions a and b ‘min value’ gate swing a+b should up to up to up to up to up to up to angle not exceed 1.5m 2m 2.5m 3m 3.5m 4m 60° - 90° or less 455mm 100° 390mm 110° 330mm 120° 275mm recommended positions (only for a 2.5m gate or shorter) a value b value 90° or less 222 246 10...

Page 24: For V400 (400Mm Operator)

Page 25 alternative positions a and b ‘min value’ gate swing a+b should up to up to up to up to up to up to angle not exceed 1.5m 2m 2.5m 3m 3.5m 4m 60° - 90° or less 455mm 100° 390mm 110° 330mm 120° 275mm recommended positions (only for a 2.5m gate or shorter) a value b value 90° or less 222 246 10...

Page 25: Secure Control Box to Wall

Electrical set-up electrical set-up warning 1. Always check that the isolator in the mains supply to the gate is in the off position, before doing any work. 2. Ensure that all low voltage systems (less than 42.4v) are suitably protected from damage, by disconnecting all sources of power such as char...

Page 26: Secure Control Box to Wall

Electrical set-up electrical set-up warning 1. Always check that the isolator in the mains supply to the gate is in the off position, before doing any work. 2. Ensure that all low voltage systems (less than 42.4v) are suitably protected from damage, by disconnecting all sources of power such as char...

Page 27

Figure 10 provides the full menu of features that can be set up on the system. Explanation of each feature is provided in the section “controller features”. When setting up the vector system via the lcd display, all the steps that have to be followed are clearly provided via the display. It is only ...

Page 28

Figure 10 provides the full menu of features that can be set up on the system. Explanation of each feature is provided in the section “controller features”. When setting up the vector system via the lcd display, all the steps that have to be followed are clearly provided via the display. It is only ...

Page 29

Page 30 figure 10 part b of “menu navigation map” page 31 pedestrian open position: 7.1 pedestrian autoclose time: 7.2 pedestrian pre-open delay: 7.3 pedestrian pre-close delay: 7.4 lock enabled status: 8.1 lock type: 8.2 release time: 8.3 pre-release time: 8.4 lock location: 8.5 lock drive (ac/dc):...

Page 30

Page 30 figure 10 part b of “menu navigation map” page 31 pedestrian open position: 7.1 pedestrian autoclose time: 7.2 pedestrian pre-open delay: 7.3 pedestrian pre-close delay: 7.4 lock enabled status: 8.1 lock type: 8.2 release time: 8.3 pre-release time: 8.4 lock location: 8.5 lock drive (ac/dc):...

Page 31

Closed position and via the pcm, push the two gates into the fully closed position, but not past. Short stop value the short stop distance can be set between 1mm and 40mm of piston stroke. Pcm push force the amount of force applied by the actuator when in pcm can be set as a value from 1 to 15. Leaf...

Page 32

Closed position and via the pcm, push the two gates into the fully closed position, but not past. Short stop value the short stop distance can be set between 1mm and 40mm of piston stroke. Pcm push force the amount of force applied by the actuator when in pcm can be set as a value from 1 to 15. Leaf...

Page 33

Page 34 page 35 ramp down distance sets the ramp-down distance in millimeters of travel of the piston when stopping. This setting applies to both motors. Crawl distance sets the final crawl distance in millimeters of travel of the piston when reaching an endpoint. This setting applies to both motors...

Page 34

Page 34 page 35 ramp down distance sets the ramp-down distance in millimeters of travel of the piston when stopping. This setting applies to both motors. Crawl distance sets the final crawl distance in millimeters of travel of the piston when reaching an endpoint. This setting applies to both motors...

Page 35

Page 36 page 37 pedestrian opening – menu 7 this feature is associated with the ped input on the controller. When activating this input, the system will open one of the gates (selectable in a double swing gate installation) to the pedestrian open position, and then automatically close after the pede...

Page 36

Page 36 page 37 pedestrian opening – menu 7 this feature is associated with the ped input on the controller. When activating this input, the system will open one of the gates (selectable in a double swing gate installation) to the pedestrian open position, and then automatically close after the pede...

Page 37

Page 38 diagnostic screen status allow a diagnostic screen to be displayed. Can be useful when troubleshooting, but requires some technical knowledge. Test button disabled allows the round test button on the controller to be disabled, in cases where higher security is required. Remote controls – men...

Page 38

Page 38 diagnostic screen status allow a diagnostic screen to be displayed. Can be useful when troubleshooting, but requires some technical knowledge. Test button disabled allows the round test button on the controller to be disabled, in cases where higher security is required. Remote controls – men...

Page 39

Page 41 page 40 description of terminal functions description of terminal functions s sens1 motor s (mtr s) operator . Connects to the thin purple wire of the motor s operator. S sens2 motor s (mtr s)operator. Connects to the thin blue or orange wire of the motor s operator. M sens1 motor m (mtr m)o...

Page 40

Page 41 page 40 description of terminal functions description of terminal functions s sens1 motor s (mtr s) operator . Connects to the thin purple wire of the motor s operator. S sens2 motor s (mtr s)operator. Connects to the thin blue or orange wire of the motor s operator. M sens1 motor m (mtr m)o...

Page 41: During Normal Operation

Page 42 led external gate status indicator. (a low current output signal.) an output terminal which provides a low current, drive (approx. 4,5v dc, 20ma) to a led which can be used to indicate the gate status remotely. If more than 3 led's are required it is necessary to fit the cp78 multi led drive...

Page 42: During Normal Operation

Page 42 led external gate status indicator. (a low current output signal.) an output terminal which provides a low current, drive (approx. 4,5v dc, 20ma) to a led which can be used to indicate the gate status remotely. If more than 3 led's are required it is necessary to fit the cp78 multi led drive...

Page 43

Charger and pillar light connections charger and pillar light connections page 44 use this procedure to accurately determine the gate opening angle: the following protection fuses are provided on the system: determine gate swing angle determine gate swing angle use gate swing angle of 90 degrees 100...

Page 44

Charger and pillar light connections charger and pillar light connections page 44 use this procedure to accurately determine the gate opening angle: the following protection fuses are provided on the system: determine gate swing angle determine gate swing angle use gate swing angle of 90 degrees 100...

Page 45

Figure 13 wiring diagram for motor m figure 14 wiring diagram for motor s 15 15 15 15 s sens1 s sens2 m sens1 m sense2 sens+ sens- saf clo saf ope com lck/stp trg ped com frx lit led com aux 12v com saf sol light light batt + bat - mtr m+ mtr — mtr s+ mtr s- master slave black black red red blue blu...

Page 46

Figure 13 wiring diagram for motor m figure 14 wiring diagram for motor s 15 15 15 15 s sens1 s sens2 m sens1 m sense2 sens+ sens- saf clo saf ope com lck/stp trg ped com frx lit led com aux 12v com saf sol light light batt + bat - mtr m+ mtr — mtr s+ mtr s- master slave black black red red blue blu...

Page 47

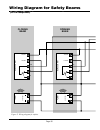

Page 49 com nc no opening beam +12v/24v com nc no irb receiver - 12v/24v 12v or 24v irb tx closing beam +12v/24v irb receiver - 12v/24v 12v or 24v irb tx s sens1 s sens2 m sens1 m sens2 light light batt + batt - mtr m+ mtr m - mtr s+ mtr s - sens+ sens- safe cls safe opn com lck/stp trg ped com frx ...

Page 48

Page 49 com nc no opening beam +12v/24v com nc no irb receiver - 12v/24v 12v or 24v irb tx closing beam +12v/24v irb receiver - 12v/24v 12v or 24v irb tx s sens1 s sens2 m sens1 m sens2 light light batt + batt - mtr m+ mtr m - mtr s+ mtr s - sens+ sens- safe cls safe opn com lck/stp trg ped com frx ...

Page 49

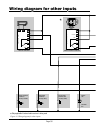

Page 51 wiring diagram for other inputs wiring diagram for other inputs neg +12v/24v com nc no r adio receiver remote control circuitry neg +12v com nc no loop loop detector free exit circuitry holiday lockout keyswitch (normally closed) pillar light pushbutton (normally open) pedestrian keyswitch (...

Page 50

Page 51 wiring diagram for other inputs wiring diagram for other inputs neg +12v/24v com nc no r adio receiver remote control circuitry neg +12v com nc no loop loop detector free exit circuitry holiday lockout keyswitch (normally closed) pillar light pushbutton (normally open) pedestrian keyswitch (...

Page 51

Page 52 wind speeds for which operator will still operate the gate (for v400 or v500 operators) for a 25% covered gate: (palisades, etc.) x 1.8m high value of gate lengths: a or b dimension up to up to up to up to up to up to once installed. #1 1.5m 2m 2.5m 3m(#2) 3.5m(#2) 4m(#2) 100mm 94km/h 66km/h...

Page 52

Page 52 wind speeds for which operator will still operate the gate (for v400 or v500 operators) for a 25% covered gate: (palisades, etc.) x 1.8m high value of gate lengths: a or b dimension up to up to up to up to up to up to once installed. #1 1.5m 2m 2.5m 3m(#2) 3.5m(#2) 4m(#2) 100mm 94km/h 66km/h...