- DL manuals

- Vega

- Transmitter

- VEGABAR 17

- Operating Instructions Manual

Vega VEGABAR 17 Operating Instructions Manual

Summary of VEGABAR 17

Page 1

Operating instructions process pressure transmitter with metallic measuring cell vegabar 17 document id: 27636.

Page 2: Contents

2 contents vegabar 17 • 27636-en-150224 contents 1 about this document 1.1 function ........................................................................................................................... 4 1.2 target group ............................................................................

Page 3

3 contents vegabar 17 • 27636-en-150224 safety instructions for ex areas takenoteoftheexspecificsafetyinstructionsforexapplications. These instructions are attached as documents to each instrument with ex approval and are part of the operating instructions manual. Editing status: 2015-02-10

Page 4: 1 About This Document

4 1 about this document vegabar 17 • 27636-en-150224 1 about this document 1.1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instruc- tionsformaintenanceandfaultrectification.Pleasereadthisinforma- tion befor...

Page 5: 2 For Your Safety

5 2 for your safety vegabar 17 • 27636-en-150224 2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the required person...

Page 6

6 2 for your safety vegabar 17 • 27636-en-150224 2.5 safety label on the instrument the safety approval markings and safety tips on the device must be observed. 2.6 ce conformity thedevicefulfillsthelegalrequirementsoftheapplicableecguide- lines.Byaffixingthecemarking,weconfirmsuccessfultestingofthe...

Page 7: 3 Product Description

7 3 product description vegabar 17 • 27636-en-150224 3 product description 3.1 configuration the scope of delivery encompasses: • vegabar 17 process pressure transmitter • depending on the version, with plug connector, connection cable or terminal housing • documentation – this operating instruction...

Page 8

8 3 product description vegabar 17 • 27636-en-150224 the process pressure acts on the sensor element via the stainless steel diaphragm. The process pressure causes a resistance change which is converted into a corresponding output signal and outputted as measured value. 1) 4 … 20 ma two-wire electro...

Page 9: 4 Mounting

9 4 mounting vegabar 17 • 27636-en-150224 4 mounting 4.1 general instructions make sure that all parts of the instrument coming in direct contact with the process, especially the sensor element, process seal and processfitting,aresuitablefortheexistingprocessconditions,such as process pressure, proc...

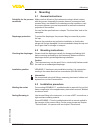

Page 10

10 4 mounting vegabar 17 • 27636-en-150224 fig. 2: mounting of vegabar 17.

Page 11

11 5 connecting to power supply vegabar 17 • 27636-en-150224 5 connecting to power supply 5.1 preparing the connection always keep in mind the following safety instructions: • connect only in the complete absence of line voltage • if overvoltage surges are expected, overvoltage arresters should be i...

Page 12

12 5 connecting to power supply vegabar 17 • 27636-en-150224 this can lead to unacceptably high currents in the cable screen if it is grounded at both ends. Information: themetallicpartsoftheinstrument(processfitting,housing,etc.)are conductively connected to the ground terminal. Take note of the co...

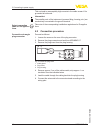

Page 13

13 5 connecting to power supply vegabar 17 • 27636-en-150224 2 3 1 4 fig. 4: connection to the screw terminals 1 cable gland 2 plug housing 3 plug insert 4 plug seal 7. Snap the plug insert into the plug housing and insert the sensor seal 8. Plug the plug insert with seal to vegabar 17 and tighten t...

Page 14

14 5 connecting to power supply vegabar 17 • 27636-en-150224 1 5 2 3 4 fig. 6: connection to the screw terminals 1 cable gland 2 cover 3 plug housing 4 plug insert 5 plug seal 8. Snap the plug insert into the plug housing and insert the sensor seal information: note the correct arrangement, see illu...

Page 15

15 5 connecting to power supply vegabar 17 • 27636-en-150224 5.3 wiring plan 1 2 3 + - 1 fig. 7: wiring plan, angle plug connector according to iso 4400, top view to vegabar 17 1 voltage supply and signal output 3 + - 1 3 2 4 1 fig. 8: wiring plan, round plug connector m12 x 1, top view to vegabar 1...

Page 16

16 5 connecting to power supply vegabar 17 • 27636-en-150224 3 2 1 – + – + 4 5 1 2 fig. 10: wiring plan, terminal housing 1 to power supply or processing system 2 control instrument (4 … 20 ma measurement) terminal housing.

Page 17: 6 Setup

17 6 setup vegabar 17 • 27636-en-150224 6 setup 6.1 setup steps after mounting and electrical connection, vegabar 17 is ready for operation. Vegabar 17 delivers a current of 4 … 20 ma corresponding to the actual process pressure. Further settings are not necessary. 6.2 recalibration withbothinstrume...

Page 18

18 6 setup vegabar 17 • 27636-en-150224 1 2 3 4 5 6 fig. 11: open the instrument 1 plug connector 2 plug seal 3 screwed ring 4 instrument plug 5 plug seal 6 housing 3. Setzeroinunpressurizedstatus,check4masignalinthecircuit 4. Set span with exact reference pressure 5. Checkzero 2 1 fig. 12: adjustme...

Page 19

19 6 setup vegabar 17 • 27636-en-150224 1 2 fig. 13: adjustment of zero and span 1 zero (z) 2 span (s) 2. Setzeroinunpressurizedstatus,check4masignalinthecircuit 3. Setaspanwithasufficientlyprecisereferencepressure 4. Checkzero 5. Screw the housing lid back on.

Page 20

20 7maintenanceandfaultrectification vegabar 17 • 27636-en-150224 7 maintenanceandfaultrectification 7.1 maintenance if the instrument is used properly, no special maintenance is required in normal operation. 7.2 rectify faults the operator of the system is responsible for taking suitable meas- ures...

Page 21

21 7maintenanceandfaultrectification vegabar 17 • 27636-en-150224 by doing this you help us carry out the repair quickly and without hav- ing to call back for needed information. If a repair is necessary, please proceed as follows: • printandfilloutoneformperinstrument • clean the instrument and pac...

Page 22: 8 Dismount

22 8 dismount vegabar 17 • 27636-en-150224 8 dismount 8.1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel or pipeline, high temperatures, cor- rosive or toxic products etc. Take note of chapters "mounting" and "connecting to...

Page 23: 9 Supplement

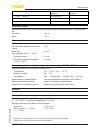

23 9 supplement vegabar 17 • 27636-en-150224 9 supplement 9.1 technical data general data parameter, pressure gauge pressure, absolute pressure, vacuum measuring principle piezoresistive/thinfilmdms communication interface none materials and weights materials, wetted parts Ʋ processfitting 316ti Ʋ d...

Page 24

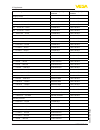

24 9 supplement vegabar 17 • 27636-en-150224 nominal range overload capacity, max. Pressure overload capacity, min. Pressure gauge pressure -0.1 … 0 bar/-10 … 0 kpa 1 bar/100 kpa -1 bar/-100 kpa -0.16 … 0 bar/-16 … 0 kpa 1.5 bar/150 kpa -1 bar/-100 kpa -0.25 … 0 bar/-25 … 0 kpa 2 bar/200 kpa -1 bar/...

Page 25

25 9 supplement vegabar 17 • 27636-en-150224 nominal range overload capacity, max. Pressure overload capacity, min. Pressure 0 … 6 bar/0 … 600 kpa 35 bar/3500 kpa 0 … 10 bar/0 … 1000 kpa 35 bar/3500 kpa 0 … 16 bar/0 … 1600 kpa 80 bar/8 mpa adjustment ranges specificationsrefertothenominalmeasuringra...

Page 26

26 9 supplement vegabar 17 • 27636-en-150224 averagetemperaturecoefficientofthe span thefollowingspecificationsarevalidforvaluesnotwithinthecompensatedtemperaturerange. Averagetemperaturecoefficientofthezerosignal Ʋ standard typ. Ʋ meas. Ranges 0 … 0.1 and 0 … 0.16 bar typ. Averagetemperaturecoeffic...

Page 27

27 9 supplement vegabar 17 • 27636-en-150224 Ʋ additional -30 … +125 °c (-22 … +257 °f) Ʋ with cooling element -20 … +150 °c (-4 … +302 °f) Ʋ measuring ranges from 400 bar, front- flushprocessfitting -30 … +70 °c (-22 … +158 °f) shock resistance Ʋ version with terminal housing 600 g according to iec...

Page 28

28 9 supplement vegabar 17 • 27636-en-150224 Ʋ with round plug connection ip 65 Ʋ with cable outlet ip 67, ip 68 (0.5 bar) Ʋ with terminal housing ip 67 voltage resistance of the insulation 500 v ac reverse voltage protection available approvals instrumentswithapprovalscanhavedifferenttechnicalspeci...

Page 29

29 9 supplement vegabar 17 • 27636-en-150224 9.2 dimensions vegabar 17 - standard housing g1/4 ~116 mm (4.57 ") 2 mm (0.08") 13 mm (0.51") 2 mm ø 5 mm (0.20") ø 9,5 mm (0.37") sw27 g1/2 ~123 mm (4.84 ") ø 27 mm (1.06") 3 mm (0.12") 3 mm 20 mm (0.79") ø 6 mm (0.24") ø 17,5 mm (0.69") g1/2 14 mm (0.55...

Page 30

30 9 supplement vegabar 17 • 27636-en-150224 vegabar 17 - standard housing (ex version) sw27 g1/4 g1/2 1/4npt 1/2npt g1 10 mm (0.39") ~136 mm (5.35 ") ~136 mm (5.35" ) ~143 mm (5.63 ") ø 27 mm (1.06") sw41 g1 28 mm (1.10") ~155 mm (6.10" ) ø 30 mm (1.18") 13 mm (0.51") 2 mm (0.08") 3 mm (0.12") 3 mm...

Page 31

31 9 supplement vegabar 17 • 27636-en-150224 vegabar 17 - terminal housing sw27 g1/4 g1/2 1/4npt 1/2npt g1 20,5 mm (0.81") 10 mm (0.39") ~128 mm (5.04 ") ~128 mm (5.04" ) ~135 mm (5.31 ") ø 27 mm (1.06") sw41 g1 28 mm (1.10") ~147 mm (5.79" ) ø 30 mm (1.18") 13 mm (0.51") 2 mm (0.08") 3 mm (0.12") 3...

Page 32

32 9 supplement vegabar 17 • 27636-en-150224 vegabar 17 - cooling elements, plug, cable outlet g1/2 g1 ~48 mm (1.89") ~ 17,5 mm (0.69") 27,5 mm (1.08") ~ 17,5 mm (0.69") 13,5 mm (0.53") 12 mm (0.47") 1 2 3 4 5 fig. 18: vegabar 17 - cooling elements, plug, cable outlet 1 cooling element g½ b 2 coolin...

Page 33

33 notes vegabar 17 • 27636-en-150224.

Page 34

34 notes vegabar 17 • 27636-en-150224.

Page 35

35 notes vegabar 17 • 27636-en-150224.

Page 36

Printing date: vega grieshaber kg am hohenstein 113 77761 schiltach germany 27636-en-150224 all statements concerning scope of delivery, application, practical use and operat- ing conditions of the sensors and processing systems correspond to the information available at the time of printing. Subjec...