- DL manuals

- Vega

- Transmitter

- VEGABAR 17

- Operating Instructions Manual

Vega VEGABAR 17 Operating Instructions Manual

Summary of VEGABAR 17

Page 1

Operating instructions vegabar 17 d ocument id: 27636 p rocess pressure.

Page 2: Contents

Contents 1 about this document 1.1 f unction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 t arget group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 s ymbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 a uthor...

Page 3

Supplementary documentation information: s upplementary documents appropriate to the ordered version come with the delivery. You can find them listed in chapter "product description". E diting status: 2012-05-29 vegabar 17 3 c ontents 27636 - en -120531.

Page 4: About This Document

1 about this document 1 .1 function t his operating instructions manual provides all the information you need for mounting, connection and setup as well as important instructions for maintenance and fault rectification. Please read this information before putting the instrument into operation and kee...

Page 5: For Your Safety

2 for your safety 2 .1 authorised personnel a ll operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. D uring work on and with the device the required personal protective equipment must always be worn. 2...

Page 6

2 .5 safety label on the instrument t he safety approval markings and safety tips on the device must be observed. 2 .6 ce conformity t he device fulfills the legal requirements of the applicable ec guidelines. By affixing the ce marking, we confirm successful testing of the product. Y ou can find the con...

Page 7: Product Description

3 product description 3 .1 structure t he scope of delivery encompasses: l vegabar 17 process pressure transmitter l d epending on the version, with plug connector, connection cable or terminal housing l d ocumentation - this operating instructions manual - e x-specific "safety instructions" (with ex...

Page 8

3 .2 principle of operation vegabar 17 is a pressure transmitter for measurement of gauge pressure, absolute pressure or vacuum. Measured products are gases, vapours and liquids. The front flush versions are also suitable for use in viscous or contaminated products. T he process pressure acts on the ...

Page 9

L d ry and dust free l n ot exposed to corrosive media l p rotected against solar radiation l a voiding mechanical shock and vibration l s torage and transport temperature see chapter "supplement - technical data - ambient conditions" l r elative humidity 20 … 85 % storage and transport temperature ...

Page 10: Mounting

4 mounting 4 .1 general instructions m ake sure that all parts of the instrument exposed to the process, in particular the sensor element, process seal and process fitting, are suitable for the existing process conditions. These include above all the process pressure, process temperature as well as t...

Page 11

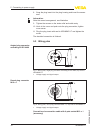

Fig. 2: mounting of vegabar 17 vegabar 17 11 4 m ounting 27636 - en -120531.

Page 12

5 connecting to power supply 5 .1 preparing the connection a lways keep in mind the following safety instructions: l c onnect only in the complete absence of line voltage l i f overvoltage surges are expected, overvoltage arresters should be installed tip: w e recommend vega overvoltage arrester Üsb...

Page 13

C onnect the cable screen on both ends to ground potential. I f potential equalisation currents are expected, the connection on the processing side must be made via a ceramic capacitor (e. G. 1 nf, 1500 v). T he low frequency potential equalisation currents are thus suppressed, but the protective eff...

Page 14

1 2 3 fig. 3: loosen the plug insert 1 cable gland 2 plug insert 3 plug housing 4 r emove approx. 5 cm of the cable mantle, strip approx. 1 cm insulation from the individual wires 5 l ead the cable through the cable gland into the plug housing 6 c onnect the wire ends to the screw terminals accordin...

Page 15

1 l oosen the screw in the cover of the plug connector 2 o pen the cover and remove it 3 p ress the plug insert downwards 4 l oosen the screws of the strain relief and cable entry 4 3 2 1 3 2 1 fig. 5: loosen the plug insert 1 plug insert 2 strain relief 3 cable gland 4 plug housing 5 r emove approx...

Page 16

8 s nap the plug insert into the plug housing and insert the sensor seal information: n ote the correct arrangement, see illustration 9 t ighten the screws on the strain relief and cable entry 10 h ook in the cover and push onto the plug connection, tighten cover screw 11 p lug the plug insert with ...

Page 17

Wire colour socket b rown 1 w hite 2 b lue 3 b lack 4 1 2 3 fig. 9: wiring plan cable outlet 1 brown (+) power supply and signal output 2 green (-) power supply and signal output 3 blue = cable screen 3 2 1 – + – + 4 5 1 2 fig. 10: wiring plan, terminal housing 1 to power supply or the processing sy...

Page 18: Setup

6 setup 6 .1 setup steps a fter mounting and electrical connection, vegabar 17 is ready for operation. Vegabar 17 delivers a current of 4 … 20 ma corresponding to the actual process pressure. F urther settings are not necessary. 6 .2 recalibration w ith both instruments with thread ring or field hous...

Page 19

1 2 3 4 5 6 fig. 11: open the instrument 1 plug connector 2 plug seal 3 screwed ring 4 instrument plug 5 plug seal 6 housing 3 s et zero in unpressurized status, check 4 ma signal in the circuit 4 s et span with exact reference pressure 5 c heck zero 2 1 fig. 12: adjustment of zero and span 1 zero (...

Page 20

P roceed as follows: 1 s crew on the housing cover in connected status 4 5 fig. 13: adjustment of zero and span 1 zero (z) 2 span (s) 2 s et zero in unpressurized status, check 4 ma signal in the circuit 3 s et a span with a sufficiently precise reference pressure 4 c heck zero 5 s crew the housing co...

Page 21

7 maintenance and fault rectification 7 .1 maintenance i f the instrument is used properly, no special maintenance is required in normal operation. 7 .2 remove interferences t he operator of the system is responsible for taking suitable measures to rectify faults. Vegabar 17 offers maximum reliability...

Page 22

D epending on the reason for the fault and the measures taken, the steps described in chapter "set up" may have to be carried out again. 7 .3 instrument repair i f a repair is necessary, please proceed as follows: y ou can download a return form (23 kb) from our internet homepage www.Vega.Com under:...

Page 23: Dismounting

8 dismounting 8 .1 dismounting steps warning: b efore dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. T ake note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in re...

Page 24: Supplement

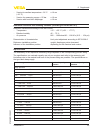

9 supplement 9 .1 technical data general data p arameter, pressure g auge pressure, absolute pressure, vacuum m easuring principle p iezoresistive/thin film dms c ommunication interface n one materials and weights m aterials, wetted parts - p rocess fitting 316t i - d iaphragm 316t i - d iaphragm with...

Page 25

- v ersion for medium temperature (-22 °f) ≤ 10 ms - v ersion for measuring ranges > 25 bar ≤ 10 ms - v ersion with front-flush diaphragm ≤ 10 ms reference conditions and actuating variables (according to din en 60770-1) r eference conditions according to din en 61298-1 - t emperature + 15 … +25 °c (...

Page 26

Nominal range overload capacity, max. Pressure overload capacity, min. Pressure 0 … 25 bar/0 … 2500 kpa 50 bar/5000 kpa -1 bar/-100 kpa 0 … 40 bar/0 … 4000 kpa 80 bar/8000 kpa -1 bar/-100 kpa 0 … 60 bar/0 … 6000 kpa 120 bar/12 mpa -1 bar/-100 kpa 0 … 100 bar/0 … 10 mpa 200 bar/20 mpa -1 bar/-100 kpa...

Page 27

A verage temperature coefficient of the span typ. Long-term stability (according to din 16086, dinv 19259-1 and iec 60770-1) l ong-term drift of the zero signal 6) 0.2 %/ year ambient conditions a mbient temperature (note temperature derating!) - c able outlet -20 … +80 °c (-4 … +176 °f) - r ound plug...

Page 28

- v ersion with plug connector or cable outlet 1000 g according to iec 60068-2-27 (mechanical shock) - v ersion with cooling element 400 g according to iec 60068-2-27 (mechanical shock) v ibration resistance - v ersion with terminal housing or cooling element 10 g according to iec 60068-2-6 (resonan...

Page 29

I nterference resistance - hf 10 v/ m - b urst 2 kv o ther protective measures - i nterpolation protection a vailable - o vervoltage protection up to 36 v dc approvals i nstruments with approvals can have different technical data depending on the version. T hat's why the associated approval documents...

Page 30

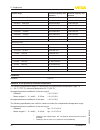

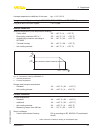

9 .2 dimensions vegabar 17 - standard housing g1/4 ~116 mm (4.57 ") 2 mm (0.08") 13 mm (0.51") 2 mm ø 5 mm (0.20") ø 9,5 mm (0.37") sw27 g1/2 ~123 mm (4.84 ") ø 27 mm (1.06") 3 mm (0.12") 3 mm 20 mm (0.79") ø 6 mm (0.24") ø 17,5 mm (0.69") g1/2 14 mm (0.55") 10 mm (0.39") ~119,5 mm (4.70") g1/2 g¼ ~...

Page 31

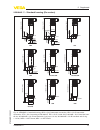

Vegabar 17 - standard housing (ex version) sw27 g1/4 g1/2 1/4npt 1/2npt g1 10 mm (0.39") ~136 mm (5.35 ") ~136 mm (5.35") ~143 mm (5.63 ") ø 27 mm (1.06") sw41 g1 28 mm (1.10") ~155 mm (6.10") ø 30 mm (1.18") 13 mm (0.51") 2 mm (0.08") 3 mm (0.12") 3 mm 20 mm (0.79") 13 mm (0.51") 2 mm ø 5 mm (0.20"...

Page 32

Vegabar 17 - terminal housing sw27 g1/4 g1/2 1/4npt 1/2npt g1 20,5 mm (0.81") 10 mm (0.39") ~128 mm (5.04 ") ~128 mm (5.04") ~135 mm (5.31 ") ø 27 mm (1.06") sw41 g1 28 mm (1.10") ~147 mm (5.79") ø 30 mm (1.18") 13 mm (0.51") 2 mm (0.08") 3 mm (0.12") 3 mm 20 mm (0.79") ~135 mm (5.31") 13 mm (0.51")...

Page 33

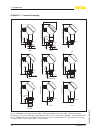

Vegabar 17 - cooling elements, plug, cable outlet g1/2 g1 ~48 mm (1.89") ~ 17,5 mm (0.69") 27,5 mm (1.08") ~ 17,5 mm (0.69") 13,5 mm (0.53") 12 mm (0.47") 1 2 3 4 5 fig. 18: vegabar 17 - cooling elements, plug, cable outlet 1 cooling element g½ b 2 cooling element g1 b 3 plug according to iso 4400 4...

Page 34

34 vegabar 17 9 s upplement 27636 -en -120531.

Page 35

Vegabar 17 35 9 s upplement 27636 - en -120531.

Page 36

Iso 9001 a ll statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the information avail- able at the time of printing. © vega g rieshaber kg, schiltach/germany 2012 s ubject to change without prior notice 27...