- DL manuals

- Vega

- Measuring Instruments

- VEGACAL 66

- Operating Instructions Manual

Vega VEGACAL 66 Operating Instructions Manual

Summary of VEGACAL 66

Page 1

Operating instructions vegacal 66 4 … 20 ma/hart.

Page 2: Contents

Contents 1 about this document 1.1 function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 symbolism used . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 authorised personnel . . . . . . . ....

Page 3

7 setup with pactware™ and other adjustment programs 7.1 connecting the pc . . . . . . . . . . . . . . . . . . . . . 34 7.2 parameter adjustment with pactware™. . . . . . 35 7.3 parameter adjustment with ams™ and pdm . . 36 7.4 saving the parameter adjustment data . . . . . . . 36 8 maintenance and ...

Page 4: 1 About This Document

1 about this document 1.1 function this operating instructions manual has all the information you need for quick setup and safe operation. Please read this manual before you start setup. 1.2 target group this operating instructions manual is directed to trained, qualified personnel. The contents of t...

Page 5: 2 For Your Safety

2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the operator. For safety and warranty reasons, any internal work on the instruments must be carried out only by personnel a...

Page 6

L sensor software for dtm-vegacal 66 hart, pa or ff l dtm vegacal 66 for adjustment software pactware™ l adjustment module plicscom for sensor software the parameter adjustment of the basic sensor functions is independent of the software version. The range of available functions depends on the respe...

Page 7

L operate you instrument in the range of the specified electrical limit values. Permissible supply voltage: see "technical data" l mount and operate the instrument in such a way that no ignition danger is expected by electrostatic charges. The process fitting, the plastic-coated/covered probe part or ...

Page 8: 3 Product Description

3 product description 3.1 configuration the scope of delivery encompasses: l vegacal 66 level sensor l documentation - this operating instructions manual - ex-specific safety instructions (with ex versions), if necessary further certificates. Vegacal 66 consists of the following components: l process fi...

Page 9

3.2 principle of operation vegacal 66 is a level sensor with fully insulated probe for continuous level measurement. The electronics functions acc. To the admittance principle (phase-selective admittance processing). It is designed for industrial use in all areas of process technology and can be app...

Page 10

The supply voltage range can differ depending on the instrument version. The exact range is stated in the "technical data" in the "supplement". 3.3 adjustment vegacal 66 can be adjusted with four different adjustment media: l the indicating and adjustment module plicscom l the suitable vega dtm in con...

Page 11: 4 Mounting

4 mounting 4.1 general instructions select an installation position you can easily reach for mounting and connecting as well as later retrofitting of an indicating and adjustment module. The housing can be rotated by 330° without the use of any tools. You can also install the indicating and adjustmen...

Page 12

Insulating measures, such as e.G. Covering the thread with teflon tape, can interrupt the necessary electrical connection with metal vessels. For this reason, ground the probe on the vessel or use a conductive seal material. Metal vessel make sure that the mechanical connection of the probe to the ve...

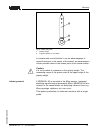

Page 13

1 3 2 fig. 4: fasten the probe 1 gravity weight 2 lug m12 (article no. 2.27423) in vessels with conical bottom it can be advantageous to mount the sensor in the center of the vessel, as measurement is then possible down to the lowest point of the vessel bottom. Caution: it is not possible to measure...

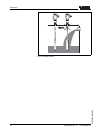

Page 14

Fig. 5: inflowing material 14 vegacal 66 - 4 … 20 ma/hart mounting 30036 -en -060306.

Page 15

5 connecting to power supply 5.1 preparing the connection always observe the following safety instructions: l connect only in the complete absence of line voltage l if overvoltages are expected, overvoltage arresters should be installed tip: we recommend using vega overvoltage arresters Üs-f-lb-i an...

Page 16

Caution: no grease should be used when screwing the npt cable gland or steel tube into the threaded insert. Standard grease can contain additives affecting the connection between threaded insert and housing. This will influence the stability of the connection and the tightness of the housing. If scree...

Page 17

Fig. 6: connection steps 6 and 7 8 press the opening lever of the terminals downward, you will hear the terminal spring closing 9 check the hold of the wires in the terminals by lightly pulling on them 10 connect the screen to the internal ground terminal and the external ground terminal to potentia...

Page 18

1 4 4 4 2 3 fig. 7: material versions, single chamber housing 1 plastic 2 aluminium 3 stainless steel 4 filter element for pressure compensation or blind stopper with version ip 66/ ip 68, 1 bar i2c display 1 2 5 6 7 8 3 4 1 2 fig. 8: electronics and connection compartment, single chamber housing 1 ...

Page 19

I2c display 1 1 2 5 6 7 8 fig. 9: wiring plan, single chamber housing 1 power supply/signal output 5.4 wiring plans, double chamber housing the following illustration apply to non-ex as well as ex ia versions. The exd version is described in the next subchapter. 1 2 3 4 5 fig. 10: double chamber hou...

Page 20

1 3 2 display 1 2 5 6 7 8 i2c fig. 11: electronics compartment, double chamber housing 1 plug connector for vegaconnect (i²c interface) 2 internal connection cable to the connection compartment 3 terminals for vegadis 61 3 1 2 display 1 2 i2c fig. 12: connection compartment, double chamber housing 1...

Page 21

I2c 1 1 2 fig. 13: wiring plans, double chamber housing 1 power supply/signal output 5.5 wiring plans, double chamber housing exd 1 2 3 4 5 fig. 14: double chamber housing 1 housing cover, connection compartment 2 blind stopper or plug m12x1 for vegadis 61 (option) 3 housing cover, electronics compa...

Page 22

1 3 2 display 1 2 5 6 7 8 i2c fig. 15: electronics compartment, double chamber housing 1 plug connector for vegaconnect (i²c interface) 2 internal connection cable to the connection compartment 3 terminals for vegadis 61 1 2 1 2 fig. 16: connection compartment, double chamber housing exd 1 spring-lo...

Page 23

1 1 2 fig. 17: wiring plan, double chamber housing exd 1 power supply/signal output 5.6 wiring plans, version ip 66/ip 68 (1 bar) + - 1 2 fig. 18: wire assignment, connection cable 1 br (+) and bl (-) for power supply or to the processing system 2 screen wiring plan wire assignment, connection cable...

Page 24: Adjustment Module Plicscom

6 setup with the indicating and adjustment module plicscom 6.1 short description the indicating and adjustment module plicscom is used for measured value display, adjustment and diagnosis. It can be mounted in the following housing versions and instruments: l all sensors of the plics ® instrument fa...

Page 25

Fig. 19: installation of plicscom note: if you intend to retrofit vegacal 66 with a plicscom for continuous measured value indication, a higher cover with an inspection glass is required. Vegacal 66 - 4 … 20 ma/hart 25 setup with the indicating and adjustment module plicscom 30036 -en -060306.

Page 26

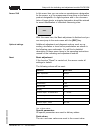

6.3 adjustment system 1.1 2 3 1 fig. 20: indicating and adjustment elements 1 lc display 2 indication of the menu item number 3 adjustment keys l [ok] key: - move to the menu overview - confirm selected menu - edit parameter - save value l [->] key to select: - menu change - list entry - editing posi...

Page 27

6.4 setup procedure after vegacal 66 is connected to voltage supply or after voltage recurrence, the instrument carries out a self-test for approx. 30 seconds. The following steps are carried out: l internal check of the electronics l indication of the instrument type, the firmware version as well as...

Page 28

Tip: if the indicating and adjustment module plicscom remains on the probe as a display, we recommend saving the sensor data in plicscom. Use the function "copy sensor data". Start your parameter adjustment with the following menu items of the basic adjustment: to be on the safe side, note the adjus...

Page 29

Min. Adjustment 0.00 % = 0.0 pf 54.5 pf 3 prepare the adjustment value for editing with [ok]. Move to the selection window with [ok]. Min. Adjustment accept current meas- ured value? Accept? Edit? 4 accept the current measured value or move to the editing window with "edit". To edit, set the cursor ...

Page 30

2 accept the current measured value or move to the editing window with "edit". To edit, set the cursor to the requested position with [->]. Set the requested % value with [+] and save with [ok]. The cursor jumps to the capacitance value. 3 enter the current capacitance value in pf (displayed below) ...

Page 31

In this menu item you can enter an unambiguous designation for the sensor, e.G. The measurement loop name or the tank or product designation. In digital systems and in the documen- tation of larger plants, a singular designation should be entered for exact identification of individual measuring sites...

Page 32

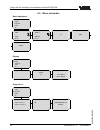

6.5 menu schematic basic adjustment 1 ▶ basic adjustment display diagnostics service info 1.1 min. Adjustment 0.00 % = 0.0 pf 82.5 pf 1.2 max. Adjustment 100.00 % = 1000.0 pf 327.4 pf 1.3 damping 0 s 1.4 linearization curve linear 1.5 sensor-tag sensor display 2 basic adjustment ▶ display diagnostic...

Page 33

Service 4 basic adjustment display diagnostics ▶ service info 4.1 current output output mode: 4-20 ma fail.Mode: min. Current: 4 ma 4.2 simulation start simulation? 4.3 reset reset? 4.4 language deutsch 4.5 hart mode standard address 0 4.6 copy sensor data copy from sensor copy to sensor 4.7 pin ena...

Page 34: Adjustment Programs

7 setup with pactware™ and other adjustment programs 7.1 connecting the pc ~ = power supply vegaconnect 3 pactware / tm >pa 2 3 1 fig. 21: pc connected directly to the sensor 1 rs232 connection 2 vegacal 66 3 i²c adapter cable for vegaconnect 3 necessary components: l vegacal 66 l pc with pactware™ ...

Page 35

2 3 1 4 ~ = power supply vegaconnect 3 pactware / tm fig. 22: connecting the pc to the signal cable 1 rs232 connection 2 vegacal 66 3 hart adapter cable for vegaconnect 3 4 hart resistance 250 ohm necessary components: l vegacal 66 l pc with pactware™ and suitable vega-dtm l vegaconnect 3 with hart ...

Page 36

Detailed description is available in the online help of pactware™ and the vega-dtms. Note: keep in mind that for setup of vegacal 66, dtm-collection 04/2005 or a newer version must be used. All currently available vega-dtms are provided in the dtm collection on cd and can be obtained from the respon...

Page 37

8 maintenance and fault rectification 8.1 maintenance when used as directed in normal operation, vegacal 66 is completely maintenance-free. 8.2 fault rectification vegacal 66 offers maximum reliability. Nevertheless faults can occur during operation. These may be caused by the following, e.G.: l sensor...

Page 38

L no power supply à check cables for line break, repair, if necessary l supply voltage too low or load resistance too high à check and adapt, if necessary ? Current signal greater than 22 ma or less than 3.6 ma l electronics module defective à exchange instrument or return it for repair in ex applic...

Page 39

1 2 3 fig. 23: check the resistance in the probe 1 screen 2 probe 3 ground potential à there should be no contact between any of the connections (high resistance) à however, if there is somehow contact, exchange instrument or return it for repair ? E017 l adjustment span too small à carry out a fres...

Page 40

In ex applications, only an instrument and an electronics module with appropriate ex approval may be used. If there is no electronics module available on site, one can be ordered from the vega agency serving you. The order data of the sensor must be downloaded into the new electronics module. This c...

Page 41

L attach the completed form and possibly also a safety data sheet to the instrument l please contact your respective agency for the address of the return shipment! Maintenance and fault rectification vegacal 66 - 4 … 20 ma/hart 41 30036 -en -060306.

Page 42: 9 Dismounting

9 dismounting 9.1 dismounting procedure warning: before dismounting, be aware of dangerous process con- ditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in...

Page 43: 10 Supplement

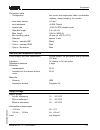

10 supplement 10.1 technical data general data material 316l corresponds to 1.4404 or 1.4435 materials, wetted parts - process fitting - thread 316l - process fitting - flange 316l - process seal klingersil c-4400 - insulation (fully insulated) ptfe materials, non-wetted parts - probe (cable ptfe full...

Page 44

Output variable output signal 4 … 20 ma/hart resolution 1.6 µa fault signal current output unchanged; 20.5 ma; 22 ma; current limitation 22 ma load see load diagram in power supply integration time (63 % of the input variable) 0 … 999 s, adjustable rise time 500 ms (ti: 0 s, 0 … 100 %) fulfilled namu...

Page 45

Process conditions process pressure -1 … 40 bar/-100 … 4000 kpa (-14.5 … 580 psi) process temperature vegacal 66 of 316l -50 … +150°c (-58 … +302°f) 1 2 3 -50˚c (-58˚f) 50˚c (122˚f) 40˚c (104˚f) -40˚c (-40˚f) 80˚c (176˚f) 0˚c (32˚f) 100˚c (212˚f) 150˚c (302˚f) 200˚c (392˚f) fig. 24: ambient temperat...

Page 46

Electromechanical data - version ip 66/ip 67 and ip 66/ip 68; 0.2 bar cable entry/plug 4) - single chamber housing l 1x cable entry m20x1.5 (cable-ø 5 … 9 mm), 1x blind stopper m20x1.5 or: l 1x closing cap ½ npt, 1x blind plug ½ npt or: l 1x plug (depending on the version), 1x blind plug m20x1.5 - d...

Page 47

Connection cable - configuration four cores, one suspension cable, one breather capillary, screen braiding, foil, mantle - wire cross section 0.5 mm² - wire resistance - tensile load >1200 n (270 pounds force) - standard length 5 m (16.4 ft) - max. Length 1000 m (3280 ft) - min. Bending radius 25 mm ...

Page 48

1000 750 500 250 12 18 16 14 20 22 24 26 28 30 32 34 36 Ω v 4 1 2 3 fig. 25: voltage diagram 1 hart load 2 voltage limit eex ia instrument 3 voltage limit non-ex/exd instrument 4 supply voltage electrical protective measures protection - plastic housing ip 66/ip 67 - alu and stainless steel standard...

Page 49

10.2 dimensions housing versions in protection ip 66/ip67 and ip 66/ip 68; 0.2 bar 112mm (4 13 / 32 ") 117mm (4 39 / 64 ") 116mm (4 9 / 16 ") 120mm (4 23 / 32 ") ~ 69mm (2 23 / 32 ") ø 77mm (3 1 / 32 ") ~ 69mm (2 23 / 32 ") ~ 116mm (4 9 / 16 ") ~ 87mm (3 27 / 64 ") ø 77mm (3 1 / 32 ") ø 84mm (3 5 / ...

Page 50

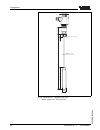

ø30 (1 3 / 16 ") ø8mm ( 5 / 16 ") 177mm (2 1 / 4 ") 56 mm (2 1 / 4 ") l 22mm (2 1 / 4 ") g 1 a, g 1 1 / 2 a fig. 28: vegacal 66 - threaded version g1 l = sensor length, see "technical data" supplement 50 vegacal 66 - 4 … 20 ma/hart 30036 -en -060306.

Page 51

10.3 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com. Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte....

Page 52

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info@de.Vega.Com www.Vega.Com iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the...