- DL manuals

- Vega

- Switch

- VEGACAP 66

- Operating Instructions Manual

Vega VEGACAP 66 Operating Instructions Manual

Summary of VEGACAP 66

Page 1

Operating instructions vegacap 66 with relay output.

Page 2: Contents

Contents 1 about this document 1.1 function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 symbolism used . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 authorised personnel. . . . . . . . ...

Page 3

9 supplement 9.1 technical data. . . . . . . . . . . . . . . . . . . . . . . . . 27 9.2 dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 9.3 certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 9.4 industrial property rights. . . . . . . . . . . . . . . . . . 34 ve...

Page 4: 1 About This Document

1 about this document 1.1 function this operating instructions manual has all the information you need for quick setup and safe operation of vegacap 66. Please read this manual before you start setup. 1.2 target group this operating instructions manual is directed to trained personnel. The contents ...

Page 5: 2 For Your Safety

2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained, specialised personnel authorised by the operator. For safety and warranty reasons, any internal work on the instruments must be carried out only by personnel...

Page 6

2.6 safety information for ex areas please note the ex-specific safety information for installation and operation in ex areas. These safety instructions are part of the operating instructions manual and come with the ex- approved instruments. 2.7 environmental instructions protection of the environme...

Page 7: 3 Product Description

3 product description 3.1 configuration the scope of delivery encompasses: l vegacap 66 level sensor l documentation - this operating instructions manual - ex-specific safety instructions (with ex versions) and, if necessary, further certificates vegacap 66 consists of the following components: l housi...

Page 8

3.2 principle of operation vegacap 66 is a level sensor with fully insulated capacitive electrode for level detection. Vegacap 66 is very rugged and maintenance-free and can be used in all areas of industrial process technology. Fully insulated probes such as vegacap 66 are used in solids as well as...

Page 9

Vegacap 66 is a compact instrument, i.E. It can be operated without external evaluation system. The integrated electronics evaluates the level signal and outputs a switching signal. With this switching signal, a connected device can be operated directly (e.G. A warning system, a plc, a pump etc.). T...

Page 10: 4 Mounting

4 mounting 4.1 general instructions in general,vegacap 66 can be mounted in any position. The instrument must be mounted in such a way that the probe is at the height of the requested switching point. With screwed versions, the housing must not be used for screwing in! Tightening can cause damages o...

Page 11

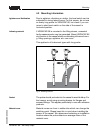

4.2 mounting information due to agitators, vibrations or similar, the level switch can be subjected to strong lateral forces. For this reason, do not use an overly long probe for vegacap 66, but check if you can mount a short level switch on the side of the vessel in horizontal position. If vegacap ...

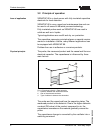

Page 12

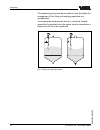

The measuring probe must be mounted in a way that takes the arrangement of the filling and emptying apertures into consideration. To compensate measurement errors in cylindrical vessels caused by the material cone, the sensor must be mounted at a distance of d/6 from the vessel wall. D d d 6 d 6 fig....

Page 13

D d 6 1 2 3 fig. 6: filling in the center, emptying laterally 1 vegacap 66 2 emptying opening 3 filling opening make sure that the max. Permissible tensile load of the suspension cable is not exceeded. This danger exists particularly with very heavy solids and large meas. Lengths. The max. Permissib...

Page 14

5 connecting to power supply 5.1 preparing the connection always observe the following safety instructions: l connect only in the complete absence of line voltage connect the power supply acc. To the following diagrams. Oscillator cp60r is designed in protection class 1. To maintain this protection ...

Page 15

7 press down the opening levers of the terminals, you will hear the terminal spring closing 8 check the hold of the wires in the terminals by lightly pulling on them 9 tighten the compression nut of the cable entry, the seal ring must completely encircle the cable 10 screw the housing cover back on ...

Page 16

4 5 6 2 1 3 fig. 9: electronics and connection compartment 1 potentiometer for switching point adaptation 2 dil switch for measuring range selection 3 dil switch for mode adjustment 4 ground terminal 5 terminals 6 control lamp we recommend connecting vegacap 66 in such a way that the switching circu...

Page 17

3 2 1 fig. 10: wiring plan 1 relay output 2 relay output 3 supply voltage vegacap 66 - with relay output 17 connecting to power supply 30020 -en -050920

Page 18: 6 Set Up

6 set up 6.1 general the numbers in brackets refer to the following illustrations. On the electronics module you will find the following indicating and adjustment elements: l potentiometer for switching point adaptation l dil switch for measuring range selection l dil switch for mode adjustment - min...

Page 19

The switching status of the electronics can be checked with closed housing (only plastic housing), see "function chart“. Note: screw the housing cover tightly to the point where the inspection glass is above the control lamp (led). To adjust vegacap 66, first of all remove the housing cover. You can ...

Page 20

The adjustment of the switching point is only possible in installed condition the numbers in brackets refer to the following illustrations. Vertically mounted probes 1 set mode switch (3) to mode max. 2 set meas. Range selection switch (2) to range 1. 3 fill the vessel up to the requested level. 4 t...

Page 21

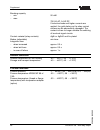

Level switching sta- tus control lamp max. Mode overfill protection 5 3 4 (8) (6) (7) relay deener- gized red min. Mode dry run protection 5 3 4 (8) (6) (7) relay energized green min. Mode dry run protection 5 3 4 (8) (6) (7) relay deener- gized red failure of the supply voltage (min./max. Mode) any ...

Page 22

7 maintenance and fault rectification 7.1 maintenance when used as directed in normal operation, vegacap 66 is completely maintenance-free. 7.2 fault rectification vegacap 66 offers maximum reliability. Nevertheless faults can occur during operation. These may be caused by the following, e.G.: l sensor...

Page 23

à push the mode switch. If the instrument then does not change the mode, the oscillator may be defective. Exchange the oscillator. à check if there is buildup on the probe, and if so, remove it. L unfavourable installation location à mount the instrument at a location where no dead zones or mounds c...

Page 24

2 1 fig. 12: loosen the screws 1 electronics module 2 screws (2 pcs.) 6 remove the old oscillator 7 compare the new oscillator with the old one. The type label of the oscillator must correspond to that of the old oscillator. This applies particularly to instruments used in hazardous areas. 8 compare...

Page 25

The electronics exchange is finished. 7.4 instrument repair if it is necessary to repair vegacap 66 please proceed as follows: you can download a return form (23 kb) from our homepage www.Vega.Com under: "services – downloads – forms and certificates – repair form". By doing this you help us carry out...

Page 26: 8 Dismounting

8 dismounting 8.1 dismounting procedure warning: before dismounting, be aware of dangerous process con- ditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in...

Page 27: 9 Supplement

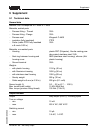

9 supplement 9.1 technical data general data material 316l corresponds to 1.4404 or 1.4435 materials, wetted parts - process fitting – thread 316l - process fitting - flange 316l - process seal klingersil c-4400 - insulation (fully insulated) ptfe - probe (cable ptfe fully insulated ø 8 mm/ø 0.32 in) ...

Page 28

Breaking capacity - min. 50 mw - max. 750 va ac, 54 w dc if inductive loads and higher currents are applied, the gold plating on the relay contact surface can be permanently damaged. The contact is then no longer suitable for switching of low-level signal circuits. Contact material (relay contacts) ...

Page 29

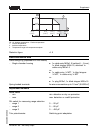

1 2 3 -50˚c (-58˚f) 50˚c (122˚f) 40˚c (104˚f) -40˚c (-40˚f) 80˚c (176˚f) 0˚c (32˚f) 100˚c (212˚f) 150˚c (302˚f) 200˚c (392˚f) fig. 13: ambient temperature – product temperature 1 product temperature 2 ambient temperature 3 temperature range with temperature adapter dielectric figure >1.5 electromecha...

Page 30

Supply voltage supply voltage 20 … 253 v ac, 50/60 hz, 20 … 72 v dc (at u >60 v dc the ambient temperature must be max. 50°c/122°f) power consumption 1 … 8 va (ac); approx. 1 w (dc) electrical protective measures protection ip 66/ip 67 overvoltage category iii protection class i approvals 1) overfill...

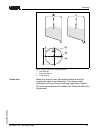

Page 31

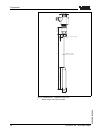

9.2 dimensions vegacap 66 2) ø77mm (3 1 / 32 ") 112mm (4 13 / 32 ") 69mm (2 23 / 32 ") ø77mm (3 1 / 32 ") 69mm (2 23 / 32 ") 117mm (4 39 / 64 ") 116mm (4 9 / 16 ") ø84mm (3 5 / 16 ") 116mm (4 9 / 16 ") m20x1,5 m20x1,5/ ½ npt m20x1,5/ ½ npt m20x1,5/ ½ npt 1 2 3 fig. 14: housing versions 1 plastic hou...

Page 32

ø30 (1 3 / 16 ") ø8mm ( 5 / 16 ") 177mm (2 1 / 4 ") 56 mm (2 1 / 4 ") l 22mm (2 1 / 4 ") g 1 a, g 1 1 / 2 a fig. 15: vegacap 66 - threaded version g1a l = sensor length, see technical data 32 vegacap 66 - with relay output supplement 30020 -en -050920

Page 33

9.3 certificates ce declaration of conformity fig. 16: ce declaration of conformity vegacap 66 - with relay output 33 supplement 30020 -en -050920

Page 34

9.4 industrial property rights 34 vegacap 66 - with relay output supplement 30020 -en -050920

Page 35

Vegacap 66 - with relay output 35 supplement 30020 -en -050920

Page 36

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info@de.Vega.Com www.Vega.Com iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the...