- DL manuals

- Vega

- Measuring Instruments

- VEGAFLEX 86

- Operating Instructions Manual

Vega VEGAFLEX 86 Operating Instructions Manual

Summary of VEGAFLEX 86

Page 1

Operating instructions tdr sensor for continuous level and interface measurement of liquids vegaflex 86 profibus pa rod and cable probe -196 … +280 °c -196 … +450 °c document id: 44232.

Page 2: Contents

2 contents vegaflex 86 • profibus pa 44232-en-160518 contents 1 about this document 1.1 function ........................................................................................................................... 4 1.2 target group ...............................................................

Page 3

3 contents vegaflex 86 • profibus pa 44232-en-160518 9.2 diagnosis memory ......................................................................................................... 60 9.3 status messages ....................................................................................................

Page 4: 1 About This Document

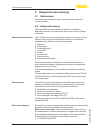

4 1 about this document vegaflex 86 • profibus pa 44232-en-160518 1 about this document 1.1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instruc- tions for maintenance and fault rectification. Please read th...

Page 5: 2 For Your Safety

5 2 for your safety vegaflex 86 • profibus pa 44232-en-160518 2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the re...

Page 6

6 2 for your safety vegaflex 86 • profibus pa 44232-en-160518 you can find the ce certificate of conformity in the download section of our homepage. Electromagnetic compatibility instruments in four-wire or ex-d-ia version are designed for use in an industrial environment. Nevertheless, electromagne...

Page 7: 3 Product Description

7 3 product description vegaflex 86 • profibus pa 44232-en-160518 3 product description 3.1 configuration the type label contains the most important data for identification and use of the instrument: 2 1 13 14 15 16 12 11 5 3 6 4 7 8 9 10 fig. 1: layout of the type label (example) 1 instrument type ...

Page 8

8 3 product description vegaflex 86 • profibus pa 44232-en-160518 • scan the data matrix code on the type label of the instrument or • enter the serial number manually in the app this operating instructions manual applies to the following instrument versions: • hardware from 1.0.0 • software from 1....

Page 9

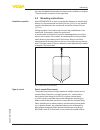

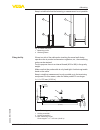

9 3 product description vegaflex 86 • profibus pa 44232-en-160518 d h 1 fig. 2: level measurement 1 sensorreferenceplane(sealsurfaceoftheprocessfitting) d distance to the level h height - level probe end tracking to increase sensitivity, the probe is equipped with probe end tracking. In products wit...

Page 10

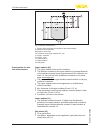

10 3 product description vegaflex 86 • profibus pa 44232-en-160518 ts d1 h1 h2 d2 1 l2 l1 l3 fig. 3: interface measurement 1 sensorreferenceplane(sealsurfaceoftheprocessfitting) d1 distance to the interface d2 distance to the level tsthicknessoftheuppermedium(d1-d2) h1 height - interface h2 height -...

Page 11

11 3 product description vegaflex 86 • profibus pa 44232-en-160518 the instrument is always preset to the application "level measure- ment". For the interface measurement, you can select the requested output signal with the setup. 3.3 packaging, transport and storage your instrument was protected by...

Page 12

12 3 product description vegaflex 86 • profibus pa 44232-en-160518 the vegadis 81 is an external display and adjustment unit for vega plics ® sensors. For sensors with double chamber housing the interface adapter "disadapt" is also required for vegadis 81. You can find further information in the ope...

Page 13

13 3 product description vegaflex 86 • profibus pa 44232-en-160518 you can find additional information in the operating instructions manual "externalhousing" (document-id 46802). If you are using an instrument with rod version, you can extend the rod probe individually with curved segments and rod a...

Page 14: 4 Mounting

14 4 mounting vegaflex 86 • profibus pa 44232-en-160518 4 mounting 4.1 general instructions on instruments with threaded process fitting, the hexagon must be tightened with a suitable wrench. For the proper wrench size see chapter "dimensions". Warning: the housing must not be used to screw the inst...

Page 15

15 4 mounting vegaflex 86 • profibus pa 44232-en-160518 you can find detailed information on the process conditions in chapter "technicaldata" as well as on the type label. 4.2 mounting instructions mount vegaflex 86 in such a way that the distance to vessel instal- lations or to the vessel wall is ...

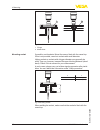

Page 16

16 4 mounting vegaflex 86 • profibus pa 44232-en-160518 1 2 fig. 5: installation in non-metallic vessel 1 flange 2 metal sheet if possible, avoid sockets. Mount the sensor flush with the vessel top. If this is not possible, use short sockets with small diameter. Higher sockets or sockets with a bigg...

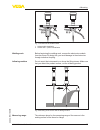

Page 17

17 4 mounting vegaflex 86 • profibus pa 44232-en-160518 1 2 fig.7:socketmustbeinstalledflush 1 unfavourable installation 2 socketflush-optimuminstallation before beginning the welding work, remove the electronics module from the sensor. By doing this, you avoid damage to the electronics through indu...

Page 18

18 4 mounting vegaflex 86 • profibus pa 44232-en-160518 keep in mind that a min. Distance must be maintained below the refer- ence plane and possibly also at the end of the probe - measurement in these areas is not possible (dead band). The length of the cable can be used all the way to the end only...

Page 19

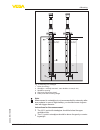

19 4 mounting vegaflex 86 • profibus pa 44232-en-160518 1 2 h fig. 9: position of the spacer or centering weight 1 rod probe with spacer (steel) 2 cableprobewithcenteringweight h measurable tube section note: measurement in a standpipe is not recommended for extremely adhe- sive products. In case of...

Page 20

20 4 mounting vegaflex 86 • profibus pa 44232-en-160518 standpipe. When designing the standpipe, keep the upper blocking distance of the probe in mind and plan the length above the upper lateral filling opening accordingly. Microwaves can penetrate many plastics. This is why plastic tubes are proble...

Page 21

21 4 mounting vegaflex 86 • profibus pa 44232-en-160518 1 2 a b 3 ≥ 10 mm (0.39") ≥ 10 mm (0.39") ø 150 - 200 mm (5.91 - 7.87") ø 150 - 200 mm (5.91 - 7.87") h fig. 10: mounting in a standpipe 1 holes (for mixing) 2 standpipe - vertically mounted - max. Deviation 10 mm (0.4 in) 3 ventilation opening...

Page 22

22 4 mounting vegaflex 86 • profibus pa 44232-en-160518 • a false signal suppression with installed sensor is generally rec- ommended to achieve the best possible accuracy. Instruments for a temperature range up to +280 °c (536 °f) or up to +450 °c (842 °f) have a distance piece between process fitt...

Page 23

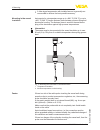

23 4 mounting vegaflex 86 • profibus pa 44232-en-160518 keep in mind that below the fastening, a measurement is not possible. 1 2 1 2 fig. 12: fasten the probe 1 measuring probe 2 retaining sleeve if there is a risk of the cable probe touching the vessel wall during operation due to product movement...

Page 24

24 4 mounting vegaflex 86 • profibus pa 44232-en-160518 in case of difficult installation conditions, the probe can also be mounted laterally. For this, adapt the rod with rod extensions or angled segments. To compensate for the resulting changes in signal runtime, let the instrument determine the p...

Page 25

25 5 connecting to power supply vegaflex 86 • profibus pa 44232-en-160518 5 connecting to power supply 5.1 preparing the connection always keep in mind the following safety instructions: warning: connect only in the complete absence of line voltage. • the electrical connection must only be carried o...

Page 26

26 5 connecting to power supply vegaflex 86 • profibus pa 44232-en-160518 make sure that the cable screen and grounding are carried out ac- cording to fieldbus specification. We recommend to connect the cable screen to ground potential on both ends. In systems with potential equalisation, connect th...

Page 27

27 5 connecting to power supply vegaflex 86 • profibus pa 44232-en-160518 fig.15:connectionsteps5and6-doublechamberhousing 6. Insert the wire ends into the terminals according to the wiring plan information: solid cores as well as flexible cores with wire end sleeves are insert- ed directly into the...

Page 28

28 5 connecting to power supply vegaflex 86 • profibus pa 44232-en-160518 5 0 0 5 1 6 2 7 3 8 4 9 0 5 1 6 2 7 3 8 4 9 1 0 1 6 7 8 bus 2 3 4 5 1 2 + ( ) (-) 1 fig.16:electronicsandterminalcompartment,singlechamberhousing 1 voltage supply, signal output 2 for display and adjustment module or interface...

Page 29

29 5 connecting to power supply vegaflex 86 • profibus pa 44232-en-160518 bus 5 1 2 + ( ) (-) 6 7 8 2 3 4 1 fig.18:terminalcompartment,doublechamberhousing 1 voltage supply, signal output 2 for display and adjustment module or interface adapter 3 for external display and adjustment unit 4 groundterm...

Page 30

30 5 connecting to power supply vegaflex 86 • profibus pa 44232-en-160518 5.5 double chamber housing with disadapt 3 1 2 fig.20:viewtotheelectronicscompartmentwithdisadaptforconnectionof the external display and adjustment unit 1 disadapt 2 internal plug connection 3 plug connector m12 x 1 3 4 1 2 f...

Page 31

31 5 connecting to power supply vegaflex 86 • profibus pa 44232-en-160518 5.6 wiring plan - version ip 66/ip 68, 1 bar 1 2 fig. 22: wire assignment in permanently connected connection cable 1 brown (+) and blue (-) to power supply or to the processing system 2 shielding 5.7 supplementary electronics...

Page 32

32 5 connecting to power supply vegaflex 86 • profibus pa 44232-en-160518 the hardware addressing is effective if an address the address selection switches on the instrument. Software address- ing is then no longer effective, the set hardware address applies. 5 0 0 5 1 6 2 7 3 8 4 9 0 5 1 6 2 7 3 8 ...

Page 33: Module

33 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 6 set up with the display and adjustment module 6.1 insert display and adjustment module the display and adjustment module can be inserted into the sensor and removed again at any time. You can choose any on...

Page 34

34 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 1 2 fig. 26: installing the display and adjustment module in the double chamber housing 1 in the electronics compartment 2 in the terminal compartment note: if you intend to retrofit the instrument with a di...

Page 35

35 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 – move to the menu overview – confirm selected menu – edit parameter – save value • [->] key: – change measured value presentation – select list entry – select editing position • [+] key: – change value of t...

Page 36

36 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 6.3 parameter adjustment - quick setup to quickly and easily adapt the sensor to the application, select the menu item "quick setup" in the start graphic on the display and adjustment module. The following s...

Page 37

37 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 info: instrument name, hardware and software version, date of manu- facture, instrument features note: for optimum adjustment of the measuring point, the individual sub- menu items in the main menu item "set...

Page 38

38 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 • numbers from 0 … 9 • special characters + - / _ blanks in this menu item you select the distance unit and the temperature unit. For the distance units you can choose between m, mm and ft and for the temper...

Page 39

39 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 you have the option of choosing the demonstration mode. This mode is only suitable for test and demonstration purposes. In this mode, the sensor ignores the parameters of the application and reacts immedi- a...

Page 40

40 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 in this menu item you can enter the max. Adjustment for the level. With interface measurement this is the maximum total level. Adjust the requested percentage value with [+] and store with [ok]. Enter the ap...

Page 41

41 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 you can accept the settings of the level measurement also for the interface measurement. If you select "yes", the current setting will be displayed. If you have selected "no", you can enter the adjustment fo...

Page 42

42 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 proceed as follows: enter the actual distance from the sensor to the product surface. All interfering signals in this section are detected by the sensor and stored. Note: check the distance to the product su...

Page 43

43 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 warning: if a linearisation curve is selected, the measuring signal is no longer necessarily linear to the filling height. This must be considered by the user especially when adjusting the switching point on...

Page 44

44 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 in menu item"channel" you determine which measured value the output refers to. In menu item "scaling unit" you define the scaling variable and the scaling unit for the level value on the display, e.G. Volume...

Page 45

45 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 with active pin, only the following adjustment functions are possible without entering a pin: • select menu items and show data • read data from the sensor into the display and adjustment mod- ule. Caution: ...

Page 46

46 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 the default setting for the displayed value 2 is the electronics tem- perature. The integrated background lighting can be switched off via the adjustment menu. The function depends on the strength of the sup...

Page 47

47 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 in another window you can carry out a reset of the two peak values separately. The respective min. And max. Measured values are saved in the sensor. The values are displayed in the menu item "peak values ad-...

Page 48

48 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 select the requested simulation variable and set the requested value. Caution: during simulation, the simulated value is outputted as 4 … 20 ma cur- rent value and digital hart signal. Push the [esc] key to ...

Page 49

49 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 with a reset, certain parameter adjustments carried out by the user are reset. The following reset functions are available: delivery status: restoring the parameter settings at the time of ship- ment from th...

Page 50

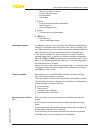

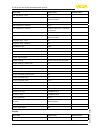

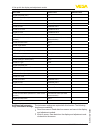

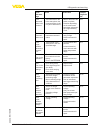

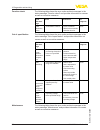

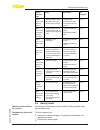

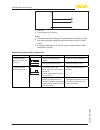

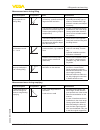

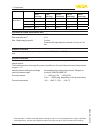

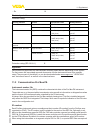

50 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 menu item default value modifiedvalue min. Adjustment - level 0 % min. Adjustment - level distance: probe length - take dead band into account accept adjustment of the level measurement? No max. Adjustment -...

Page 51

51 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 menu item default value modifiedvalue displayed value 1 filling height level displayed value 2 electronics temperature backlight switched on diagnostics menu item default value modifiedvalue status signals -...

Page 52

52 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 menu item default value modifiedvalue ai fb2 out scale (min.) 0 % ai fb2 out scale (max.) 100 % ai fb2 pv ftime 0 s ai fb2 hi hi limit 3.402823e+38 % ai fb2 hi limit 3.402823e+38 % ai fb2 lo lo limit -3.4028...

Page 53

53 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 the following data or settings for adjustment of the display and ad- justment module are saved: • all data of the menu "setup" and "display" • in the menu "additional adjustments" the items "reset,date/time"...

Page 54

54 6 set up with the display and adjustment module vegaflex 86 • profibus pa 44232-en-160518 in this menu item, the date of factory calibration of the sensor as well as the date of the last change of sensor parameters are displayed via the display and adjustment module or via the pc. In this menu it...

Page 55: 7 Setup With Pactware

55 7 setup with pactware vegaflex 86 • profibus pa 44232-en-160518 7 setup with pactware 7.1 connect the pc 3 1 2 fig.29:connectionofthepcdirectlytothesensorviatheinterfaceadapter 1 usbcabletothepc 2 interfaceadaptervegaconnect 3 sensor 7.2 parameter adjustment with pactware for parameter adjustment...

Page 56

56 7 setup with pactware vegaflex 86 • profibus pa 44232-en-160518 fig.30:exampleofadtmview all device dtms are available as a free-of-charge standard version and as a full version that must be purchased. In the standard version, all functions for complete setup are already included. An assistant fo...

Page 57

57 7 setup with pactware vegaflex 86 • profibus pa 44232-en-160518 fig. 31: select quick setup 1 quick setup 2 extendedadjustment 3 maintenance quick setup with quick setup you can carry out the parameter adjustment of vegaflex 86 for your application in just a few simple steps. The assistant-driven...

Page 58

58 7 setup with pactware vegaflex 86 • profibus pa 44232-en-160518 7.4 saving the parameter adjustment data we recommend documenting or saving the parameter adjustment data via pactware. That way the data are available for multiple use or service purposes..

Page 59

59 8 set up with other systems vegaflex 86 • profibus pa 44232-en-160518 8 set up with other systems 8.1 dd adjustment programs device descriptions as enhanced device description (edd) are available for dd adjustment programs such as, for example, ams™ and pdm. The files can be downloaded at www.Veg...

Page 60

60 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 9 diagnostics and servicing 9.1 maintenance if the instrument is used correctly, no maintenance is required in normal operation. 9.2 diagnosis memory the instrument has several memories which are available for diagnostic purpos...

Page 61

61 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 • control system with edd • display and adjustment module further echo curves: up to 10 echo curves can be stored in a ring buffer in this memory section. Further echo curves are stored via: • pc with pactware/dtm • control sys...

Page 62

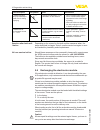

62 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 still valid. Plan in maintenance for the instrument because a failure is expected in the near future (e.G. Due to buildup). This status message is inactive by default. It can be activated by the user via pactware/dtm or edd. Th...

Page 63

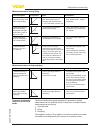

63 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 code text mes- sage cause rectification devspec diagnosis bits f105 measured value is de- termined – the instrument is still in the start phase, the measured value could not yet be determined – wait for the end of the switch-on...

Page 64

64 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 the following table shows the error codes and text messages in the status message "function check" and provides information on causes as well as corrective measures. Code text mes- sage cause rectification tb diagnose c700 simu...

Page 65

65 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 code text mes- sage cause rectification tb diagnose m500 error in the delivery status – with the reset to deliv- ery status, the data could not be restored – repeat reset – load xml file with sensor data into the sensor bit 15 ...

Page 66

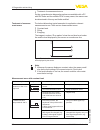

66 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 • treatment of measurement errors further comprehensive diagnostics options are available with a pc with pactware and the suitable dtm. In many cases, the reasons can be determined in this way and faults rectified. The below ta...

Page 67

67 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 measurementerrorduringfilling fault description error pattern cause rectification 3. Measured value re- mains in the area of the bottom during filling level time 0 – echo from the probe end larger than the product echo, for exa...

Page 68

68 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 1 2 level time 0 1 real level 2 level displayed by the sensor notes: • whenever the sensor displays a constant value, the reason could also be that the fault setting of the current output is set to "hold value" • if the level i...

Page 69

69 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 measurementerrorduringfilling fault description error pattern cause rectification 3. Measured value jumps towards 0 % during filling level time 0 – amplitude of a multiple echo (vessel top - product surface) is larger than the ...

Page 70

70 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 fault description error pattern cause rectification 7. Measured value jumps sporadically to- wards 100 % during emptying level time 0 – varying condensation or con- tamination on the antenna – carry out false signal suppres- si...

Page 71

71 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 if you have stored the data of the parameter adjustment during the first setup of the sensor, you can transfer these to the replacement electronics module. A new setup is no more necessary. 9.6 exchange or shorten cable/rod the...

Page 72

72 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 information: please maintain the specified torque so that the max. Tensile strength of the connection remains. 6. Enter new probe length and if necessary the new probe type and then carry out a fresh adjustment (see "setupproce...

Page 73

73 9 diagnostics and servicing vegaflex 86 • profibus pa 44232-en-160518 9.7 software update the following components are required to update the instrument software: • instrument • voltage supply • interface adapter vegaconnect • pc with pactware • current instrument software as file you can find th...

Page 74: 10 Dismount

74 10 dismount vegaflex 86 • profibus pa 44232-en-160518 10 dismount 10.1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel or pipeline, high temperatures, cor- rosive or toxic products etc. Take note of chapters "mounting" an...

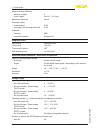

Page 75: 11 Supplement

75 11 supplement vegaflex 86 • profibus pa 44232-en-160518 11 supplement 11.1 technical data general data 316l corresponds to 1.4404 or 1.4435 materials, wetted parts Ʋ process fitting - rod version 316l, alloy c22 (2.4602) and aluminium oxide-ceramic 99.7 % (al 2 o 3 ) or alloy c22 (2.4602) and alu...

Page 76

76 11 supplement vegaflex 86 • profibus pa 44232-en-160518 Ʋ contacts alloy c22 Ʋ helium leak rate -6 mbar l/s Ʋ pressure resistance see process pressure of the sensor ohmic contact between ground terminal, process fitting and probe process fittings Ʋ pipe thread, cylindrical (iso 228 t1) g1½ accord...

Page 77

77 11 supplement vegaflex 86 • profibus pa 44232-en-160518 Ʋ cable: ø 4 mm (0.157 in) 20 nm (14.75 lbf ft) Ʋ rod: ø 16 mm (0.63 in) 20 nm (14.75 lbf ft) torque for npt cable glands and conduit tubes Ʋ plastic housing max. 10 nm (7.376 lbf ft) Ʋ aluminium/stainless steel housing max. 50 nm (36.88 lbf...

Page 78

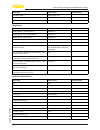

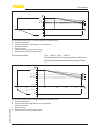

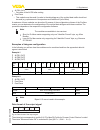

78 11 supplement vegaflex 86 • profibus pa 44232-en-160518 2 4 3 5 1 2 4 5 3 1 fig.53:measuringranges-vegaflex86 1 reference plane 2 probe length l 3 measuring range (default setting refers to the measuring range in water) 4 upper dead band (see following diagrams - grey section) 5 lower dead band (...

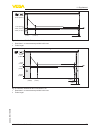

Page 79

79 11 supplement vegaflex 86 • profibus pa 44232-en-160518 l 0 -2mm (-0.079") 2mm (0.079") 15mm (0.591") -5mm (-0.197") 0,3 m (11.811") 0,08 m (3.15") 1 0,015 m (0.591") fig.54:deviationvegaflex86inrodversioninwater 1 dead band - no measurement possible in this area l probe length l 2mm (0.079") -2m...

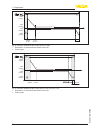

Page 80

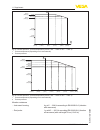

80 11 supplement vegaflex 86 • profibus pa 44232-en-160518 0 2mm (0.079 ") -2mm (-0.079 ") 15mm (0.591 ") 10mm (0.394 ") 0,08 m (3.15 ") 0,3 m (11.811 ") 0,1m (3.94 ") l 1 fig.56:deviationvegaflex86incableversioninwater 1 dead band - no measurement possible in this area l probe length l 0 -15mm (-0....

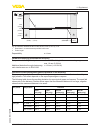

Page 81

81 11 supplement vegaflex 86 • profibus pa 44232-en-160518 l 0 -15mm (-0.591") 2mm (0.079") -2mm (-0.079") 25mm (0.984") 0,2 m (7.874") 0,15 m (5.906") 0,15 m (5.906") 0,1 m (3.937") 1 1 fig.58:deviationvegaflex86incableversion4mm(0.157in),inoil 1 dead band - no measurement possible in this area l p...

Page 82

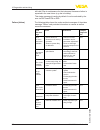

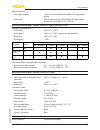

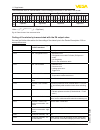

82 11 supplement vegaflex 86 • profibus pa 44232-en-160518 gas phase temperature pressure 10 bar (145 psig) 50 bar (725 psig) 100 bar (1450 psig) 200 bar (2900 psig) 400 bar (5800 psig) steam (satu- rated steam) 100 °c/212 °f - - - - - 180 °c/356 °f 2.1 % - - - - 264 °c/507 °f 1.44 % 9.2 % - - - 366...

Page 83

83 11 supplement vegaflex 86 • profibus pa 44232-en-160518 1 2 3 4 a b 0°c / 32°f -40°c / -40°f 80°c / 176°f 45°c / 113°f 50°c / 122°f 40°c / 104°f 60°c / 140°f 150°c 302°f 200°c 392°f 250°c 482°f 280°c 536°f 100°c 212°f 50°c 122°f 80°c 176°f -50°c -58°f -100°c -148°f -80°c -112°f -150°c -238°f -196...

Page 84

84 11 supplement vegaflex 86 • profibus pa 44232-en-160518 2 1 -100°c (-148°f) -196°c (-321°f) 100 bar (1450 psig) 200 bar (2900 psig) 400 bar (5800 psig) 380 bar (5510 psig) 356 bar (5160 psig) 0°c (32°f) 200°c (392°f) 100°c (212°f) 280°c (536°f) fig.61:processpressure-processtemperature(version-19...

Page 85

85 11 supplement vegaflex 86 • profibus pa 44232-en-160518 shock resistance Ʋ instrument housing 100 g, 6 ms according to en 60068-2-27 (mechanical shock) Ʋ rod probe 25 g, 6 ms according to en 60068-2-27 (mechanical shock) with rod length 50 cm (19.69 in) electromechanical data - version ip 66/ip 6...

Page 86

86 11 supplement vegaflex 86 • profibus pa 44232-en-160518 measured value indication Ʋ number of digits 5 Ʋ size of digits w x h = 7 x 13 mm adjustment elements 4 keys protection rating Ʋ unassembled ip 20 Ʋ mounted in the housing without lid ip 40 materials Ʋ housing abs Ʋ inspection window polyest...

Page 87

87 11 supplement vegaflex 86 • profibus pa 44232-en-160518 Ʋ ex 10 electrical protective measures protection rating housing material version ip-protection class nema protection plastic single chamber ip 66/ip 67 type 4x double chamber ip 66/ip 67 type 4x aluminium single chamber ip 66/ip 68 (0.2 bar...

Page 88

88 11 supplement vegaflex 86 • profibus pa 44232-en-160518 ve010bf5 the following table shows the instrument id and the gsd names for the vegaflex sensor series. Device name instrument id gsdfilename vega instrument class in profile3.02 vega profile-specific vegaflex 80 se- ries 0xbf5 0x9702 ve010bf...

Page 89

89 11 supplement vegaflex 86 • profibus pa 44232-en-160518 • ai fb3 (out) – out value of the ai fb3 after scaling • free place – this module must be used if a value in the data telegram of the cyclical data traffic should not be used (e.G. Replacement of temperature and additional cyclic value) a ma...

Page 90

90 11 supplement vegaflex 86 • profibus pa 44232-en-160518 the measured value is transferred as a 32 bit floating point number in the ieee-754 format. Byte n byte n+1 bit 7 vz exponent bit 6 2 bit 5 2 bit 4 2 bit 3 2 bit 2 2 bit 1 2 bit 0 2 bit 7 2 bit 6 2 bit 5 2 bit 4 2 bit 3 2 bit 2 2 bit 1 2 bit...

Page 91

91 11 supplement vegaflex 86 • profibus pa 44232-en-160518 status code description according to profibusstandard possible cause 0 x 89 good (non-cascade) - ac- tive advisory alarm - low limited lo-alarm 0 x 8a good (non-cascade) - ac- tive advisory alarm - high limited hi-alarm 0 x 8d good (non-casc...

Page 92

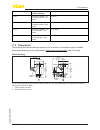

92 11 supplement vegaflex 86 • profibus pa 44232-en-160518 aluminium housing 2 1 ø 86 mm (3.39") ~ 116 mm (4.57") 116 mm (4.57") m20x1,5 m20x1,5/ ½ npt ~ 87 mm (3.43") m16x1,5 ø 86 mm (3.39") 120 mm (4.72") m20x1,5/ ½ npt fig.67:housingversionswithprotectionratingip66/ip68(0.2bar)-withintegrateddisp...

Page 93

93 11 supplement vegaflex 86 • profibus pa 44232-en-160518 stainless steel housing ~ 69 mm (2.72") ø 79 mm (3.11") 117 mm (4.61") m20x1,5/ ½ npt ~ 59 mm (2.32") ø 80 mm (3.15") 112 mm (4.41") m20x1,5/ ½ npt ~ 87 mm (3.43") ø 86 mm (3.39") 120 mm (4.72") m20x1,5/ ½ npt m16x1,5 3 2 1 fig.69:housingver...

Page 94

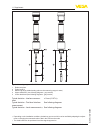

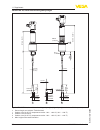

94 11 supplement vegaflex 86 • profibus pa 44232-en-160518 vegaflex 86, cable version with gravity weight 4 1 2 3 sw 60 (2.36") g1½ / 1½ npt l 35mm (1.38") 312 mm (12.28" ) 237 mm (9.33") ø 4 mm (0.16") ø 4 mm (0.16") ø 20 mm (0.79") 100 mm (3.94") ø 20 mm (0.79") 100 mm (3.94") l 50 mm (1.97") ø 2 ...

Page 95

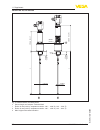

95 11 supplement vegaflex 86 • profibus pa 44232-en-160518 vegaflex 86, cable version with centering weight g1½ / 1½ npt l 35mm (1.38") 312 mm (12.28" ) x ø 4 mm (0.16") 30 mm (1.18") ø 2 mm / (0.08") sw 60 (2.36") 45 mm (1.77") 237 mm (9.33") x ø 4 mm (0.16") 30 mm (1.18") ø 2 mm / (0.08") l 1 2 3 ...

Page 96

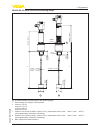

96 11 supplement vegaflex 86 • profibus pa 44232-en-160518 vegaflex 86, rod version sw 60 (2.36") g1½ / 1½ npt ø 16mm (0.63") l 35mm (1.38") 312 mm (12.28" ) 45 mm (1.77") 237 mm (9.33") ø 16 mm (0.63") l 1 2 3 fig.73:vegaflex86,threadedversion l sensorlength,seechapter"technicaldata" 1 rodø16mm(0.6...

Page 97

97 11 supplement vegaflex 86 • profibus pa 44232-en-160518 11.4 industrial property rights vega product lines are global protected by industrial property rights. Further information see www.Vega.Com. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte. Nähere informationen un...

Page 98: Index

98 index vegaflex 86 • profibus pa 44232-en-160518 index a adjustment – max. Adjustment 40 – min. Adjustment 40, 41 adjustment system 35 ai fb1 function block 43 application 38, 39 application area 8 b backlight 46 c channel 44 connection 26 copy sensor settings 52 curve indication – echo curve 47 c...

Page 99

99 index vegaflex 86 • profibus pa 44232-en-160518 sensor characteristics 54 sensor status 46 service hotline 70 simulation 47 software addressing 32, 37 special parameters 53 status bytes pa output value 90 t telegram configuration 89 type label 7 type of medium 38 u units 38 v vessel insulation 22.

Page 100

Printing date: vega grieshaber kg am hohenstein 113 77761 schiltach germany 44232-en-160518 all statements concerning scope of delivery, application, practical use and operat- ing conditions of the sensors and processing systems correspond to the information available at the time of printing. Subjec...