- DL manuals

- Vega

- Switch

- VEGAKON 66

- Operating Instructions Manual

Vega VEGAKON 66 Operating Instructions Manual

Summary of VEGAKON 66

Page 1

Level and pressure operating instructions vegakon 66.

Page 2: Safety Information

2 vegakon 66 safety information safety information please read this manual carefully, and also take note of country-specific installation standards (e.G. The vde regulations in germany) as well as all prevailing safety regulations and accident pre- vention rules. For safety and warranty reasons, any...

Page 3: Contents

Vegakon 66 3 contents safety information ........................................................................ 2 1 product description 1.1 function and configuration .................................................. 4 1.2 types and version ...........................................................

Page 4: 1 Product Description

4 vegakon 66 product description 1 product description 1.1 function and configuration vegakon 66 conductive compact level switches detect levels of conductive liquids. Depending on the sensor electronics (mod- ule), a relay energises or deenergises or the transistor output is conductive or blocks (m...

Page 5: 1.4 Technical Data

Vegakon 66 5 product description 1.4 technical data mechanical configuration housing housing material plastic pbtp (polyester) aluminium (plastic coated) protection - plastic housing ip 66 - aluminium housing ip 66/ip 67 cable entry - with relay module (r) 2 x pg 13.5 - with transistor module (t) 1 ...

Page 6

6 vegakon 66 product description relay module supply voltage 20 … 250 v ac, 50/60 hz 20 … 72 v dc power consumption approx. 1 … 9 va, max. 1.5 w relay data - output relay output (dpdt), 2 floating spdts - contact material agcdo and au plated - potential separation min. 500 v dc - turn-on voltage min...

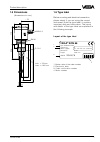

Page 7: 1.5 Dimensions

Vegakon 66 7 1.5 dimensions (dimensions in mm) product description ~ 75 85 112 92,5 24 m20x1,5 sw 60 g 1½ a l2 l3 l1 lmin. = 120 mm lmax. = 4.000 mm ø 4 1.6 type label before mounting and electrical connection, please check if you are using the correct instrument. Note the type label, it contains im...

Page 8: 2 Mounting

8 vegakon 66 mounting 2 mounting 2.1 general instructions - seal vegakon on the thread in case of gauge or low pressure. Cover the thread with teflon tape, hemp or similar or use the sup- plied seal ring. - in case of strong vibrations and shocks, e.G. By stirrers or turbulences in the vessel etc., ...

Page 9: 3 Electrical Connection

Vegakon 66 9 electrical connection relay output power supply 3 electrical connection 3.1 connection instructions danger switch off the power supply before starting any connection work. The electrical connection must be carried out according to the type of electronics in the sensor. Connect mains vol...

Page 10

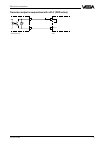

10 vegakon 66 npn action pnp action npn action pnp action npn action pnp action 3.3 connection, transistor module floating transistor output power supply: - 10 … 55 v dc (for further information see the following con- nection examples as well as "1.4 technical data") the transistor switches a second...

Page 11

Vegakon 66 11 + – – + electrical connection transistor output in conjunction with a plc (pnp action) vegakon 66 plc e1.0

Page 12: 4 Setup

12 vegakon 66 8 7 6 5 4 3 1 2 max. 250v ac 5a 750va max. 250v dc 1a 54w 20...72v dc 20...250v ac l n + - r kon e66r max min k test 0.1 test 300 100 30 0.3 1 3 10 a 2s 6s 12s b off off off 1 2 3 4 5 6 7 setup 4 setup 4.1 indicating and adjustment ele- ments it is possible to check led (2) when the ho...

Page 13

Vegakon 66 13 setup determination of the response height for horizontally mounted instruments, the in- stallation height determines the response height. For vertically mounted instruments, the re- sponse height is determined by the length of the electrode rods. Modifying the response height by chang...

Page 14

14 vegakon 66 pump control, mode a • fill the vessel until the shortest electrode is immersed approx. 1 cm. • switch on the power supply. • set the a/b switch to mode a. • set the rotary switch to position "test min". • turn the rotary switch slowly clockwise until the red led lights. • the instrume...

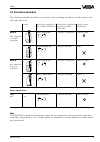

Page 15: 4.3 Functions Schedule

Vegakon 66 15 4.3 functions schedule the following schedule provides an overview of the switching conditions as they relate to the set mode and level. Level switching condition re- switching conditioning control lamp lay module kon e66 r transistor module vegakon kon e66 t mode a relay energised tra...

Page 16: 5 Diagnostics

16 vegakon 66 diagnostics 5 diagnostics 5.1 replacement of electronics replacing the electronics modules is no problem, since they are subject to narrow limits of variation and require no adaptation to other sensor (mechanical or electrical) com- ponents. Before removing the electronics module, the ...

Page 17

Vegakon 66 17 notes.

Page 18

18 vegakon 66 notes.

Page 19

Vegakon 66 19 notes.

Page 20

Iso 9001 the statements on types, application, use and operating conditions of the sensors and processing systems correspond to the latest informa- tion at the time of printing. Technical data subject to alteration 2.24 378 / jan. '00 vega grieshaber kg am hohenstein 113 d-77761 schiltach phone (0 7...