- DL manuals

- Vega

- Radar

- VEGAPULS SR 68

- Operating Instructions Manual

Vega VEGAPULS SR 68 Operating Instructions Manual

Summary of VEGAPULS SR 68

Page 1

O perating i nstructions vegapuls sr 68 4 … 20 m a / hart two - wire d ocument id : 38294 r adar.

Page 2: Ontents

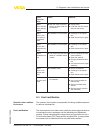

C ontents 1 a bout this document 1 . 1 f unction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1 . 2 t arget group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1 . 3 s ymbolism used . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 f or your safety ...

Page 3

8 s et up with other systems 8 . 1 dd adjustment programs . . . . . . . . . . . . . . . . . . . . . 50 8 . 2 c ommunicator 375 , 475 . . . . . . . . . . . . . . . . . . . . . . 50 9 d iagnosis , fault recti fi cation and service 9 . 1 m aintenance . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4: Bout This Document

1 a bout this document 1 . 1 f unction t his operating instructions manual provides all the information you need for mounting , connection and setup as well as important instructions for maintenance and fault recti fi cation . P lease read this information before putting the instrument into operation...

Page 5: Or Your Safety

2 f or your safety 2 . 1 a uthorised personnel a ll operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator . D uring work on and with the device the required personal protective equipment must always be wor...

Page 6

D epending on the instrument version , the emitting frequencies are in the c or k band range . T he low emitting frequencies are far below the internationally approved limit values . W hen used correctly , there is no danger to health . 2 . 5 ce conformity t he device ful fi lls the legal requirement...

Page 7: Roduct Description

3 p roduct description 3 . 1 s tructure t he type label contains the most important data for identi fi cation and use of the instrument : 2 1 12 11 5 3 6 4 7 8 9 10 f ig . 1 : s tructure of the type label ( example ) 1 i nstrument type 2 p roduct code 3 a pprovals 4 e lectronics 5 p rotection rating ...

Page 8

- s afety m anual ( sil ) ( optional ) - t est certi fi cate measuring accuracy ( optional ) - o perating instructions manual " i ndicating and adjustment module " ( optional ) - s upplementary instructions " gsm / gprs radio module " ( op - tional ) - s upplementary instructions manual " h eating fo...

Page 9

T he delivery must be checked for completeness and possible transit damage immediately at receipt . A scertained transit damage or concealed defects must be appropriately dealt with . U p to the time of installation , the packages must be left closed and stored according to the orientation and stora...

Page 10

Y ou can fi nd further information in the operating instructions " vegadis 62 " ( d ocument - id 36469 ). T he plicsmobile t 61 is an external gsm / gprs radio unit for transmission of measured values and for remote parameter adjust - ment of plics ® sensors . T he adjustment is carried out via pact ...

Page 11: Ounting

4 m ounting 4 . 1 g eneral instructions w ith instruments with threaded process fi tting , suitable tools must be applied for tightening the hexagon . W arning : t he housing must not be used to screw the instrument in ! A pplying tightening force can damage internal parts of the housing . U se the r...

Page 12

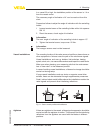

N ote : t he radar sensor with rinsing air connection or antenna extension is provided with a notch on the antenna socket . T his notch must correspond to the marking on the hexagon of the process fi tting ( the marking speci fi es the position of the polarisation level of the radar signal ). 3 4 1 2 ...

Page 13

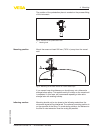

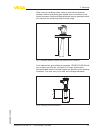

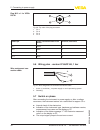

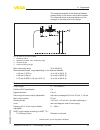

T he position of the polarisation plane is marked on the process fi tting of the instrument . 1 1 f ig . 3 : p osition of the polarisation level 1 m arking hole m ount the sensor at least 200 mm ( 7 . 874 in ) away from the vessel wall . 1 > 200 mm (7.87") f ig . 4 : m ounting of the radar sensor on ...

Page 14

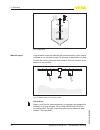

F ig . 5 : m ounting of the radar sensor with in fl owing medium t he socket piece should be dimensioned in such a way that the antenna end protrudes slightly out of the socket . Ca. 10 mm f ig . 6 : r ecommended socket mounting with horn antenna s ocket 14 vegapuls sr 68 • 4 … 20 m a / hart two - wi...

Page 15

W hen using a swivelling holder , keep in mind that the distance between antenna and socket gets smaller as the inclination of the sensor increases . A dditional false re fl ections may be generated which can in fl uence the measuring result at close range . F ig . 7 : d istance between antenna and so...

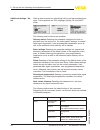

Page 16

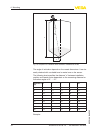

S ocket diameter d s ocket length h 40 mm 100 mm 50 mm 150 mm 80 mm 250 mm 100 mm 500 mm 150 mm 800 mm s ocket diameter d s ocket length h 1 ½" 3 . 9 in 2 " 5 . 9 in 3 " 9 . 8 in 4 " 19 . 7 in 6 " 31 . 5 in t ip : t he instrument is also optionally available with an antenna extension . T he antenna ...

Page 17

F ig . 9 : o rientation i f mounting in the center of the silo is not possible , the sensor can be directed to the vessel center by means of an optional swivelling holder . T he following description gives an overview on the determination of the necessary angle of inclination . Vegapuls sr 68 • 4 … ...

Page 18

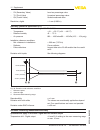

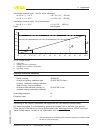

D a α f ig . 10 : p roposal for installation after orientation vegapuls sr 68 t he angle of inclination depends on the vessel dimensions . I t can be easily checked with a suitable level or water leve on the sensor . T he following chart speci fi es the distance " a " between installation position an...

Page 19

I n a vessel 20 m high , the installation position of the sensor is 1 . 4 m from the vessel centre . T he necessary angle of inclination of 4 ° can be read out from this chart . P roceed as follows to adjust the angle of inclination with the swivelling holder : 1 l oosen terminal screw of the swivel...

Page 20

F ig . 12 : a gitators l arge material heaps are detected with several sensors , which can be mounted on e . G . Traverse cranes . F or this type of application , it is best to orient the sensor toward the solid surface . A mutual infuence of the sensors is not possible . F ig . 13 : r adar sensors ...

Page 21

I nstruments for a temperature range up to 250 ° c or up to 450 ° c have a distance piece between process fi tting and electronics housing . T hs distance piece is used for thermal decoupling of the electronics against high process temperatures . I nformation : t he distance piece must only be incorp...

Page 22

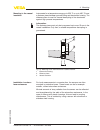

1 2 f ig . 15 : m ounting of the instrument in an subsurface enclosure 1 s ubsurface enclosure 2 c oncrete bottom t he silo walls of multiple chamber silos are often made of pro fi le walls , such as e . G . Pro fi le sheeting , to ensure the required stability . I f the radar sensor is mounted very c...

Page 23

F ig . 17 : o rientation of vegapuls sr 68 for emptying in the silo center t o avoid strong buildup and dust in the antenna system , the sensor should not be mounted directly at the dust extraction of the vessel . I n case of extreme dust deposits in the antenna system , vegapuls sr 68 is available ...

Page 24: Onnecting To Power Supply

5 c onnecting to power supply 5 . 1 p reparing the connection a lways keep in mind the following safety instructions : l c onnect only in the complete absence of line voltage l i f overvoltages are expected , install overvoltage arresters p ower supply and current signal are carried on the same two ...

Page 25

I f screened cable is necessary , connect the cable screen on both ends to ground potential . I n the sensor , the screen must be connected directly to the internal ground terminal . T he ground terminal on the outside of the housing must be connected to the potential equalisation ( low impedance )....

Page 26

5 i nsert the cable into the sensor through the cable entry f ig . 19 : c onnection steps 5 and 6 6 i nsert the wire ends into the terminals according to the wiring plan i nformation : s olid cores as well as fl exible cores with cable end sleeves are inserted directly into the terminal openings . I ...

Page 27

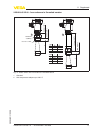

5 1 2 + ( ) (-) 6 7 8 4...20ma 2 3 4 1 f ig . 20 : e lectronics and connection compartment , single chamber housing 1 v oltage supply / s ignal output 2 f or indicating and adjustment module or interface adapter 3 f or external indicating and adjustment unit 4 g round terminal for connection of the ...

Page 28

4...20ma 2 3 1 2 + ( ) (-) 1 f ig . 22 : c onnection compartment , double chamber housing 1 v oltage supply / s ignal output 2 f or indicating and adjustment module or interface adapter 3 g round terminal for connection of the cable screen 1 bus usb status test sim-card 1 2 + ( ) (-) f ig . 23 : cc ...

Page 29

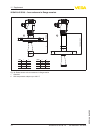

5 . 5 w iring plan with double chamber housing e x d 5 6 7 8 1 2 + ( ) (-) 3 1 2 4...20ma f ig . 24 : e lectronics compartment , double chamber housing 1 i nternal connection to the connection compartment 2 f or indicating and adjustment module or interface adapter 3 i nternal connection to the plug...

Page 30

3 4 1 2 f ig . 26 : t op view of the plug connector 1 p in 1 2 p in 2 3 p in 3 4 p in 4 c ontact pin c olour connection cable in the sensor t erminal , electronics p in 1 b rown 5 p in 2 w hite 6 p in 3 b lue 7 p in 4 b lack 8 5 . 6 w iring plan - version ip 66 / ip 68 , 1 bar + - 1 2 f ig . 27 : w ...

Page 31

A s soon as a plausible measured value is found , the corresponding current is outputted to the signal cable . T he value corresponds to the actual level as well as the settings already carried out , e . G . Factory setting . Vegapuls sr 68 • 4 … 20 m a / hart two - wire 31 5 c onnecting to power su...

Page 32: Module

6 s et up with the indicating and adjustment module 6 . 1 i nsert indicating and adjustment module t he indicating and adjustment module can be inserted into the sensor and removed again at any time . I t is not necessary to interrupt the power supply . P roceed as follows : 1 u nscrew the housing c...

Page 33

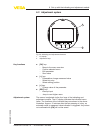

6 . 2 a djustment system 1 2 f ig . 29 : i ndicating and adjustment elements 1 lc display 2 a djustment keys l [ ok ] key : - m ove to the menu overview - c on fi rm selected menu - e dit parameter - s ave value l [- > ] key : - p resentation change measured value - s elect list entry - s elect editi...

Page 34

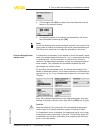

6 . 3 p arameter adjustment t hrough the parameter adjustment the instrument is adapted to the application conditions . T he parameter adjustment is carried out via an adjustment menu . I nformation : i n this operating instructions manual , the instrument - speci fi c param - eters are described . F...

Page 35

T hrough this selection , the sensor is adapted perfectly to the product and measurement reliability , particularly in products with poor re fl ective properties , is considerably increased . E nter the requested parameters via the appropriate keys , save your settings with [ ok ] and jump to the nex...

Page 36

L s etup : large - volumed , upright cylindrical , spherical l p roduct speed : slow fi lling and emptying l p rocess / measurement conditions - c ondensation - s mooth product surface - m ax . Requirement to the measurement accuracy s torage tanke with product circulation : l s etup : large - volume...

Page 37

- f oam generation s tandpipe : l p roduct speed : very fast fi lling and emptying l v essel - v ent hole - j oins like fl anges , weld joints - s hifting of the running time in the tube l p rocess / measurement conditions - c ondensation - b uildup b ypass : l p roduct speed : - f ast up to slow fi ll...

Page 38

- d istance sensor to water surface to big - e xtreme damping of output signal due to wave generation - i ce and condensation on the antenna possible - s piders and insect nestle in the antennas - f loating material and animals sporadically on the water surface o pen fl ume ( fl ow measurement ): l g ...

Page 39

S ilo ( slim and high ): l v essel of metal : weld joints l p rocess / measurement conditions : - f illing too close to the sensor - s ystem noise with completely empty silo increased - a utomatic false signal suppression with partly fi lled vessel b unker ( large - volumed ): l v essel of concrete o...

Page 40

T hrough this selection , the sensor is adapted optimally to the application or the location and measurement reliability under the various basic conditions is increased considerably . E nter the requested parameters via the appropriate keys , save your settings with [ ok ] and jump to the next menu ...

Page 41

T he real product level during this adjustment is not important , because the min ./ max . Adjustment is always carried out without changing the product level . T hese settings can be made ahead of time without the instrument having to be installed . P roceed as follows : 1 s elect the menu item " s...

Page 42

3 s et the requested percentage value with [ + ] and save with [ ok ] . T he cursor jumps now to the distance value . 4 e nter the appropriate distance value in m ( corresponding to the percentage value ) for the full vessel . K eep in mind that the max . Level must lie below the min . Distance to t...

Page 43

4 c on fi rm again with [ ok ] and enter the actual distance from the sensor to the product surface . 5 a ll interfering signals in this section are detected by the sensor and stored after con fi rming with [ ok ] . N ote : c heck the distance to the product surface , because if an incorrect ( too lar...

Page 44

W hen a reset is carried out , all settings ( with only a few exceptions ) are reset . T he exceptions are : pin , language , lighting , sil and hart mode . T he following reset functions are available : d elivery status : r estoring the parameter settings at the time of shipment from the factory in...

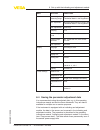

Page 45

M enu m enu item d efault value v esell height / m easuring range r ecommended measuring range , see " t echnical data " in the supplement m in . Adjustment r ecommended measuring range , see " t echnical data " in the supplement m ax . Adjustment 0 , 000 m ( d ) d amping 0 . 0 s c urrent output mod...

Page 46

T he following data or settings for adjustment of the indicating and adjustment module are saved : l a ll data of the menu " s etup " and " d isplay " l i n the menu " a dditional settings " the items " d istance unit , temperature unit and linearization " l t he values of the user programmable line...

Page 47: Etup With

7 s etup with pact ware 7 . 1 c onnecting the pc 3 1 2 f ig . 30 : c onnection of the pc directly to the sensor via the interface adapter 1 usb cable to the pc 2 i nterface adapter vegaconnect 4 3 s ensor i nformation : t he interface adapter vegaconnect 3 or additional previous versions are not sui...

Page 48

N ote : w ith power supply units with integrated hart resistance ( internal resistance approx . 250 Ω), an additional external resistance is not necessary . T his applies , e . G . To the vega instruments vegatrenn 149 a , vegamet 381 , vegamet 391 . C ommon e x separators are also usually equipped ...

Page 49

F ig . 32 : e xample of a dtm view a ll device dtm s are available as a free - of - charge standard version and as a full version that must be purchased . I n the standard version , all functions for complete setup are already included . A n assistant for simple project con fi guration simpli fi es th...

Page 50: Et Up With Other Systems

8 s et up with other systems 8 . 1 dd adjustment programs d evice descriptions as e nhanced d evice d escription ( edd ) are available for dd adjustment programs such as , for example , ams ™ and pdm . A free - of - charge download of these fi les is available via i nternet . M ove via www . Vega . C...

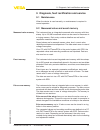

Page 51: Iagnosis

9 d iagnosis , fault recti fi cation and service 9 . 1 m aintenance w hen the device is used correctly , no maintenance is required in normal operation . 9 . 2 m easured value and event memory t he instrument has an integrated measured value memory with time stamp . U p to 100 , 000 measured values c...

Page 52

9 . 3 e rror messages according to ne 107 t he instrument has self - monitoring and diagnosis according to ne 107 and vdi / vde 2650 . S tatus messages are outputted on the device status . D etailed messages are visible under diagnosis via dtm , indicating and adjustment module and edd . T he messag...

Page 53

C ode t ext mes - sage c ause r emoval f 025 e rror in the li - nearization table l i ndex markers are not continuously rising , for examle unlogical value pairs l c heck linearization table l d elete table / c reate new f 036 n o operable software l f ailed or interrupted soft - ware update l r epe...

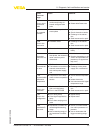

Page 54

C ode t ext mes - sage c ause r emoval f 265 m easurement function dis - turbed l s ensor does no longer carry out a measurement l o perating voltage too low l c heck operating voltage l c arry out a reset l s eparate operating voltage brie fl y t he following table shows the error codes and text mes...

Page 55

C ode t ext mes - sage c ause r emoval m 500 e rror with the reset delivery status l w ith the reset to delivery status , the data could not be restored l r epeat reset l l oad xml fi le with sensor data into the sensor m 501 e rror in the non - active li - nearization table l h ardware error eeprom ...

Page 56

C onnect a handmultimeter in the suitable measuring range according to the wiring plan . T he following table describes possible errors in the current signal and helps to remove them : e rror c ause r emoval 4 … 20 m a signal not stable l evel fl uctuations s et damping according to the instru - ment...

Page 57

T he new electronics module must be loaded with the default settings of the sensor . T hese are the options : l i n the factory l o r on site by the user i n both cases , the serial number of the sensor is needed . T he serial numbers are stated on the type label of the instrument , inside the housi...

Page 58

9 . 7 h ow to proceed in case of repair i f a repair is necessary , please proceed as follows : y ou can download a return form ( 23 kb ) from our i nternet homepage www . Vega . Com under : " d ownloads - f orms and certi fi cates - r epair form " . B y doing this you help us carry out the repair qu...

Page 59: Ismounting

10 d ismounting 10 . 1 d ismounting steps w arning : b efore dismounting , be aware of dangerous process conditions such as e . G . Pressure in the vessel , high temperatures , corrosive or toxic products etc . T ake note of chapters " m ounting " and " c onnecting to power supply " and carry out th...

Page 60: Upplement

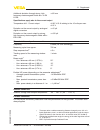

11 s upplement 11 . 1 t echnical data g eneral data 316 l corresponds to 1 . 4404 or 1 . 4435 m aterials , wetted parts - p rocess fi tting 316 l - p rocess seal o n site ( instruments with thread : k lingersil c - 4400 is attached ) - a ntenna 316 l , 316 l electropolished , 316 l s afecoat - coated...

Page 61

T he measured quantity is the distance between process fi tting of the sensor and product surface . T he reference plane is the seal surface on the hexagon or the lower side of the fl ange . 3 4 2 1 f ig . 33 : d ata of the input variable 1 r eference plane 2 m easured variable , max . Measuring range...

Page 62

- sv ( s econdary v alue ) l evel as percentage value - tv ( t hird v alue ) l inearised percentage value - qv ( f ourth v alue ) s caled measured value r esolution , digital 1 mm ( 0 . 039 in ) a ccuracy ( similar to din en 60770 - 1 ) p rocess reference conditions according to din en 61298 - 1 - t...

Page 63

A dditional deviation through strong , high frequency electromagnetic fi elds acc . To en 61326 50 mm s peci fi cations apply also to the current output t emperature drift - c urrent output ± 0 . 03 % / 10 k relating to the 16 m a span max . ± 0 . 3 % d eviation on the current output by analogue / dig...

Page 64

S eal a ntenna impedance co - ne p rocess temperature ( measured on the process fi tting ) fkm ( v iton ) ptfe - 40 … + 130 ° c (- 40 … + 266 ° f ) ffkm ( k alrez 6375 ) pffe - 20 … + 130 ° c (- 4 … + 266 ° f ) peek - 20 … + 250 ° c (- 4 … + 482 ° f ) ffkm ( k alrez 2035 ) pffe - 15 … + 130 ° c ( 5 …...

Page 65

- opening pressure 0 . 5 bar ( 7 . 25 psig ) - n ominal pressure stage pn 250 e lectromechanical data - version ip 66 / ip 67 and ip 66 / ip 68 ; 0 . 2 bar c able entry / plug 6 ) - s ingle chamber housing l 1 x cable gland m 20 x 1 . 5 ( cable : ø 5 … 9 mm ), 1 x blind stopper m 20 x 1 . 5 or : l 1...

Page 66

- w ire resistance 0 . 036 Ω/ m - t ensile strength 1200 n ( 270 lbf ) - s tandard length 5 m ( 16 . 4 ft ) - m ax . Length 1000 m ( 3280 ft ) - m in . Bending radius 25 mm ( 0 . 984 in ) with 25 ° c ( 77 ° f ) - d iameter approx . 8 mm ( 0 . 315 in ) - c olour - standard pe b lack - c olour - stand...

Page 67

P ermissible residual ripple - n on - e x , e x - ia instrument - for 9 . 6 v u n 14 v ≤ 0 . 7 v e ff ( 16 … 400 h z ) - for 18 v u n 36 v ≤ 1 . 0 v e ff ( 16 … 400 h z ) p ermissible residual ripple - e x - d - ia instrument - for 18 v u n 36 v ≤ 1 v e ff ( 16 … 400 h z ) l oad see diagram 1200 927 50...

Page 68

11 . 2 d imensions t he following dimensional drawings represent only an extract of the possible versions . D etailed dimensional drawings can be downloaded on www . Vega . Com under " d ownloads " and " d rawings " . P lastic housing ~ 69 mm (2.72") ø 79 mm (3.03") 112 mm (4.41") m20x1,5/ ½ npt ~ 8...

Page 69

A luminium housing in protection rating ip 66 / ip 68 ( 1 bar ) 120 mm (4.72") ~ 105 mm (4.13") 116 mm (4.57") ~ 150 mm (5.91") ø 84 mm (3.31") ø 84 mm (3.31") m20x1,5/ ½ npt m16x1,5 2 m20x1,5 m20x1,5 1 1 s ingle chamber version 2 d ouble chamber version s tainless steel housing ~ 69 mm (2.72") ø 79...

Page 70

S tainless steel housing in protection rating ip 66 / ip 68 , 1 bar 117 mm (4.61") ~ 103 mm (4.06") ø 77 mm (3.03") 120 mm (4.72") ~ 105 mm (4.13") ø 84 mm (3.31") ~ 93 mm (3.66") ø 80 mm (3.15") 112 mm (4.41") m20x1,5/ ½ npt m20x1,5 3 m20x1,5/ ½ npt m16x1,5 2 1 1 s ingle chamber version , electropo...

Page 71

Vegapuls sr 68 - horn antenna in threaded version mm inch 38 mm (1.50") 22 mm (0.87") 22 mm (0.87") sw 46 mm (1.81") 8.50" 16.93" 3.94" ø1.58" ø1.89" ø2.95" ø3.74" 4.72" x y 100 ø40 120 ø48 216 ø75 430 ø95 1½" 2" 3" 4" x y 1½" 2" 3" 4" x y g1½a / 1½ npt x y 2 1 144 mm (5.67") f ig . 41 : r adar sens...

Page 72

Vegapuls sr 68 - horn antenna in fl ange version x y 2 1 165 mm (6.5") 60 mm (2.36") mm inch 8.50" 16.93" 3.94" ø1.58" ø1.89" ø2.95" ø3.74" 4.72" x y 100 ø40 120 ø48 216 ø75 430 ø95 1½" 2" 3" 4" x y 1½" 2" 3" 4" f ig . 42 : r adar sensor with horn antenna in fl ange version 1 s tandard 2 w ith tempera...

Page 73

Vegapuls sr 68 - horn antenna and swivelling holder mm inch 20 mm (0.79") 20 mm (0.79") 3.94" ø 1.58" ø 1.89" ø 2.95" ø 3.74" 4.72" 8.50" 16.93" x y x y 1 x y 100 ø 40 120 ø 48 216 ø 75 430 ø 95 1½" 2" 3" 4" x y 1½" 2" 3" 4" 40 mm (1.58") 146 mm (5.75") 2 max. 15° (0.59") f ig . 43 : r adar sensor w...

Page 74

11 . 3 i ndustrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com . Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit gesch ü tzt durch gewerbliche schutzr...

Page 75: Index

Index a a ccessory - external indicating and adjustment unit 9 - external radio unit 10 - flanges 10 - indicating and adjustment module 9 - interface adapter 9 - protective cover 10 a djustment 40 - max. Adjustment 41 - min. Adjustment 41 a djustment system 33 a gitator 19 a pplication - bulk solid ...

Page 76

V v essel form 40 v essel height 40 v essel installations 19 v essel insulation 21 v oltage supply 24 76 vegapuls sr 68 • 4 … 20 m a / hart two - wire i ndex 38294 - en - 110209.

Page 77

Vegapuls sr 68 • 4 … 20 m a / hart two - wire 77 i ndex 38294 - en - 110209.

Page 78

78 vegapuls sr 68 • 4 … 20 m a / hart two - wire i ndex 38294 - en - 110209.

Page 79

Vegapuls sr 68 • 4 … 20 m a / hart two - wire 79 i ndex 38294 - en - 110209.

Page 80

Vega g rieshaber kg a m h ohenstein 113 77761 s chiltach g ermany p hone + 49 7836 50 - 0 f ax + 49 7836 50 - 201 e - mail : info @ de . Vega . Com www . Vega . Com p rinting date : iso 9001 a ll statements concerning scope of delivery , application , practical use and operating conditions of the se...