- DL manuals

- Vega

- Radar

- VEGAPULS 67

- Operating Instructions Manual

Vega VEGAPULS 67 Operating Instructions Manual

Summary of VEGAPULS 67

Page 1

Operating instructions vegapuls 67 4 … 20 ma/hart - two-wire document id: 36531 radar.

Page 2: Contents

Contents 1 about this document 1.1 function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 symbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 authorised...

Page 3

8 set up with other systems 8.1 dd adjustment programs . . . . . . . . . . . . . . . . . . . . . 54 8.2 communicator 375, 475 . . . . . . . . . . . . . . . . . . . . . . 54 9 diagnosis, asset management and service 9.1 maintaining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 9.2 ...

Page 4: About This Document

1 about this document 1 .1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instructions for maintenance and fault rectification. Please read this information before putting the instrument into operation and keep...

Page 5: For Your Safety

2 for your safety 2 .1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the required personal protective equipment must always be worn. 2 ....

Page 6

Depending on the instrument version, the emitting frequencies are in the c or k band range. The low emitting frequencies are far below the internationally approved limit values. When used correctly, there is no danger to health. 2 .5 ce conformity the device fulfills the legal requirements of the app...

Page 7

L the device must be non-sensitive to interfering immissions, including those that may cause undesirable operating conditions. Modifications not expressly approved by the manufacturer will lead to expiry of the operating licence according to fcc/ic. The instrument is in conformity with rss-210 of the...

Page 8: Product Description

3 product description 3 .1 structure the type label contains the most important data for identification and use of the instrument: 2 1 13 14 15 16 12 11 5 3 6 4 7 8 9 10 fig. 1: structure of the type label (example) 1 instrument type 2 product code 3 approvals 4 power supply and signal output, electr...

Page 9

This operating instructions manual applies to the following instrument versions: l hardware from 2.1.1 l software from 4.4.0 the scope of delivery encompasses: l radar sensor l documentation - this operating instructions manual - test certificate measuring accuracy (optional) - operating instructions...

Page 10

The delivery must be checked for completeness and possible transit damage immediately at receipt. Ascertained transit damage or concealed defects must be appropriately dealt with. Up to the time of installation, the packages must be left closed and stored according to the orientation and storage mar...

Page 11

You can find further information in the operating instructions "vegadis 62" (document-id 36469). The plicsmobile t61 is an external gsm/gprs radio unit for transmission of measured values and for remote parameter adjust- ment of plics ® sensors. The adjustment is carried out via pactware/ dtm by usin...

Page 12: Mounting

4 mounting 4 .1 general instructions with instruments with threaded process fitting, suitable tools must be applied for tightening the hexagon. Warning: the housing must not be used to screw the instrument in! Applying tightening force can damage internal parts of the housing. Use the recommended cab...

Page 13

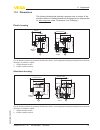

Fig. 2: flange mounting of the radar sensor 4 .3 mounting strap the mounting strap enables simple mounting on the vessel wall or silo top. It is suitable for wall, ceiling or boom mounting. Especially in open vessels this is a very easy and effective way to align the sensor to the bulk solid surface....

Page 14

The strap is supplied unassembled and must be screwed to the sensor before setup with three hexagon screws m5 x 10 and spring washers. Max. Torque, see chapter "technical data". Required tools: allen wrench size 4. There are two ways to screw the strap onto the sensor. Depending on the selected vers...

Page 15

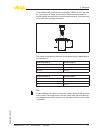

3 tighten all screws with the torque stated in the technical data the emitted radar pulses of vegapuls 67 are electromagnetic waves. They thus have electrical and magnetical components that are perpendicular to each other. The polariation plane is defined by the direction of the electrical component....

Page 16

Fig. 7: mounting of the radar sensor with inflowing medium a corresponding collar flange for dn 80 (asme 3" or jis 80) as well as a suitable adapter flange are available for mounting vegapuls 67. With the housing versions plastic, aluminium single chamber and stainless steel, the collar flange can be pl...

Page 17

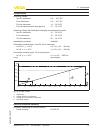

If the medium has good reflective properties, vegapuls 67 can also be mounted on a longer socket piece. Recommended values for socket heights are specified in the following illustration. You must carry out a false echo storage afterwards. D h the below charts specify the max. Socket piece length h dep...

Page 18

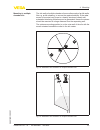

Fig. 10: alignment in silos to detect nearly the complete vessel volume the sensor should be directed in such a way that the measuring beam reaches the lowest level in the vessel, i.E. The outlet. Fig. 11: mounting in open vessel orientation 18 vegapuls 67 • 4 … 20 ma/hart - two-wire 4 mounting 3653...

Page 19

Fig. 12: mounting on the vessel ceiling caution: when mounting on the vessel ceiling mark sure that the sensor does not overfill. Depending on the measured product, this can cause a mechanical damage. In a cylindrical silo with conical outlet, it is the easiest way to carry out the mounting on a sock...

Page 20

Fig. 13: orientation large material heaps are best measured with several instruments, which can be mounted on e.G. Traverse cranes. For this type of application it is advantageous to orient the sensor perpendicular to the bulk solid surface. The sensors do not influence each other. Information: keep ...

Page 21

Fig. 14: radar sensors on traverse crane the mounting location of the radar sensor should be a place where no other equipment or fixtures cross the path of the microwave signals. Vessel installations, such as e.G. Ladders, limit switches, heating spirals, struts, etc., can cause false echoes and impa...

Page 22

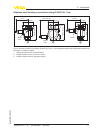

Fig. 16: agitators for level measurements in concrete silos, the sensors are often mounted in protective boxes. These boxes can be for example metallic, closed subsurface enclosures. Minimal amounts of stray radiation from the sensor can be reflected and strengthened by the walls of the subsurface en...

Page 23

The silo walls of multiple chamber silos are often made of profile walls, like e.G. Profile sheeting, to ensure the required stability. If the radar sensor is mounted very close to a heavily structured vessel wall, substantial interfering reflections can be generated. Hence the sensor should be mounted...

Page 24

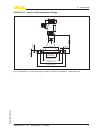

Air rinsing is useful for avoiding buildup, particularly when there is strong condensation. Since vegapuls 67 has no direct rinsing air connection, a separate rinsing air connection must be provided in the mounting socket. By inclining this connection towards the top, a particularly effective cleanin...

Page 25

5 connecting to power supply 5 .1 preparing the connection always keep in mind the following safety instructions: l connect only in the complete absence of line voltage l if voltage surges are expected, install overvoltage arresters power supply and current signal are carried on the same two-wire ca...

Page 26

If screened cable is necessary, connect the cable screen on both ends to ground potential. In the sensor, the screen must be connected directly to the internal ground terminal. The ground terminal on the outside of the housing must be connected to the potential equalisation (low impedance). If poten...

Page 27

The connection to the indicating and adjustment module or to the interface adapter is carried out via contact pins in the housing. Proceed as follows: 1 unscrew the housing cover 2 if an indicating and adjustment module is installed, remove it by turning it slightly to the left. 3 loosen compression...

Page 28

Information: the terminal block is pluggable and can be removed from the electronics. To do this, lift the terminal block with a small screwdriver and pull it out. When inserting the terminal block again, you should hear it snap in. 5 .3 wiring plan, single chamber housing the following illustration...

Page 29

5 6 7 8 4...20ma 2 1 2 + ( ) (-) 1 1 fig. 23: electronics compartment, double chamber housing 1 internal connection to the connection compartment 2 for indicating and adjustment module or interface adapter information: the connection of an external indicating and adjustment unit is not possible with...

Page 30

1 bus usb status test sim-card 1 2 + ( ) (-) fig. 25: cconnection of the voltage supply of the radio module 1 voltage supply you can find detailed information for connection in the supplementary instructions "plicsmobile gsm/gprs radio module". 5 .5 wiring plan with double chamber housing ex d 5 6 7 ...

Page 31

4...20ma 2 1 2 + ( ) (-) 1 fig. 27: connection compartment, ex-d double chamber housing 1 voltage supply, signal output 2 ground terminal for connection of the cable screen 3 4 1 2 fig. 28: top view of the plug connector 1 pin 1 2 pin 2 3 pin 3 4 pin 4 contact pin colour connection cable in the sens...

Page 32

5 .6 wiring plan - version ip 66/ip 68, 1 bar 1 2 fig. 29: wire assignment fix-connected connection cable 1 brown (+) and blue (-) to power supply or to the processing system 2 shielding 5 .7 switch-on phase after connecting the instrument to power supply or after a voltage recurrence, the instrument...

Page 33: Module

6 set up with the indicating and adjustment module 6 .1 insert indicating and adjustment module the indicating and adjustment module can be inserted into the sensor and removed any time. Four positions displaced by 90° can be selected. It is not necessary to interrupt the power supply. Proceed as fo...

Page 34

1 2 fig. 31: insertion of the indicating and adjustment module with double chamber housing 1 in the electronics compartment 2 in the connection compartment (with ex d version not possible) note: if you intend to retrofit the instrument with an indicating and adjustment module for continuous measured ...

Page 35

6 .2 adjustment system 1 2 fig. 32: indicating and adjustment elements 1 lc display 2 adjustment keys l [ok] key: - move to the menu overview - confirm selected menu - edit parameter - save value l [->] key: - presentation change measured value - select list entry - select editing position l [+] key:...

Page 36

6 .3 parameter adjustment through the parameter adjustment the instrument is adapted to the application conditions. The parameter adjustment is carried out via an adjustment menu. The main menu is divided into five sections with the following functions: setup: settings, e.G., for measurement loop nam...

Page 37

Through this selection, the sensor is adapted perfectly to the product and measurement reliability, particularly in products with poor reflective properties, is considerably increased. Enter the requested parameters via the appropriate keys, save your settings with [ok] and jump to the next menu item...

Page 38

L product speed: slow filling and emptying l process/measurement conditions: - condensation - smooth product surface - max. Requirement to the measurement accuracy storage tanke with product circulation: l setup: large-volumed, upright cylindrical, spherical l product speed: slow filling and emptying ...

Page 39

Standpipe: l product speed: very fast filling and emptying l vessel: - vent hole - joins like flanges, weld joints - shifting of the running time in the tube l process/measurement conditions: - condensation - buildup bypass: l product speed: - fast up to slow filling with short up to long bypass tube p...

Page 40

- ice and condensation on the antenna possible - spiders and insect nestle in the antennas - floating material and animals sporadically on the water surface open flume (flow measurement): l gauge rate of change: slow gauge change l process/measurement conditions: - ice and condensation on the antenna ...

Page 41

L vessel of metal: weld joints l process/measurement conditions: - filling too close to the sensor - system noise with completely empty silo increased - automatic false signal suppression with partly filled vessel bunker (large-volumed): l vessel of concrete or metal: - structured vessel walls - inst...

Page 42

Through this selection, the sensor is adapted optimally to the application or the location and measurement reliability under the various basic conditions is increased considerably. Enter the requested parameters via the appropriate keys, save your settings with [ok] and jump to the next menu item wi...

Page 43

The real product level during this adjustment is not important, because the min./max. Adjustment is always carried out without changing the product level. These settings can be made ahead of time without the instrument having to be installed. Proceed as follows: 1 select the menu item "setup" with [...

Page 44

3 set the requested percentage value with [+] and save with [ok]. The cursor jumps now to the distance value. 4 enter the appropriate distance value in m (corresponding to the percentage value) for the full vessel. Keep in mind that the max. Level must lie below the min. Distance to the antenna edge...

Page 45

A comparison of echo curve and false signal suppression allows a more accurate conclusion on measurement reliability. The selected curve is continuously updated. With the [ok] key, a submenu with zoom functions is opened: l " x-zoom": zoom function for the meas. Distance l " y-zoom": 1, 2, 5 and 10x...

Page 46

1 select the menu item "additional settins" with [->] and confirm with [ok] . With [->] you have to select the menu item "false signal suppression" and confirm with [ok]. 2 confirm again with [ok]. 3 confirm again with [ok]. 4 confirm again with [ok] and enter the actual distance from the sensor to the p...

Page 47

The menu item "extend" is used to extend an already created false signal suppression. This is useful if a false signal suppression was carried out with a too high level and not all false signals could be detected. When selecting "extend", the distance to the product surface of the created false sign...

Page 48

Delivery status: restoring the parameter settings at the time of shipment from the factory incl. The order-specific settings. A created false signal suppression, user-programmable linearization curve as well as the measured value memory will be deleted. Basic settings: resetting the parameter setting...

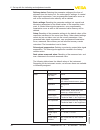

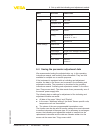

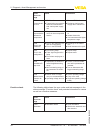

Page 49

Menu menu item default value lock operation released display language like order displayed value distance display unit m scaling size volume l scaling 0.00 lin %, 0 l 100.00 lin %, 100 l lighting switched off further settings distance unit m temperature unit ° c probe length length of the standpipe e...

Page 50

50 vegapuls 67 • 4 … 20 ma/hart - two-wire 6 set up with the indicating and adjustment module 36531 -en -120301.

Page 51: Setup With Pactware

7 setup with pactware 7 .1 connect the pc 3 1 2 fig. 33: connection of the pc directly to the sensor via the interface adapter 1 usb cable to the pc 2 interface adapter vegaconnect 4 3 sensor information: the interface adapter vegaconnect 3 or additional previous versions are not suitable for connec...

Page 52

Note: with power supply units with integrated hart resistance (internal resistance approx. 250 Ω), an additional external resistance is not necessary. This applies, e.G. To the vega instruments vegatrenn 149a, vegamet 381, vegamet 391. Common ex separators are also usually equipped with a sufficient c...

Page 53

All device dtms are available as a free-of-charge standard version and as a full version that must be purchased. In the standard version, all functions for complete setup are already included. An assistant for simple project configuration simplifies the adjustment considerably. Saving/printing the pro...

Page 54

8 set up with other systems 8 .1 dd adjustment programs device descriptions as enhanced device description (edd) are available for dd adjustment programs such as, for example, ams™ and pdm. A free-of-charge download of these files is available via internet. Move via www.Vega.Com and "downloads" to "s...

Page 55

9 diagnosis, asset management and service 9 .1 maintaining if the device is used correctly, no maintenance is required in normal operation. In some applications, buildup on the antenna system can influence the measuring result. Depending on the sensor and application, make arrangements to avoid stron...

Page 56

The echo curve of setup is stored via: l pc with pactware/dtm l control system with edd l indicating and adjustment module further echo curves: up to 10 echo curves can be stored in a ring buffer in this memory section. Additional echo curves are stored via: l pc with pactware/dtm l control system wi...

Page 57

Out of specification: the measured value is unstable because the instrument specification is exceeded (e.G. Electronics temperature). This status message is inactive by default. It can be activated by the user via pactware/dtm or edd. Maintenance: due to external influences, the instrument function is ...

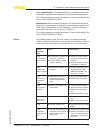

Page 58

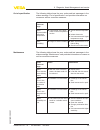

Code text mes- sage cause rectification f 113 communicati- on error l emc interferences l transmission error with the external communication with 4-wire power supply unit l remove emc influences l exchange 4-wire power supply unit or electronics f 125 unpermissible electronics temperature l temperatur...

Page 59

The following table shows the error codes and text messages in the status message "out of specification" and provides information on causes as well as corrective measures. Code text mes- sage cause rectification s 600 unpermissible electronics temperature l temperature of the elect- ronics in the non-...

Page 60

Code text mes- sage cause rectification m 504 error on an device inter- face l hardware defect l check connections l exchange of the electro- nics l send instrument for repair m 505 no echo avai- lable l level echo can no longer be detected l clean the antenna l use a more suitable an- tenna/sensor l...

Page 61

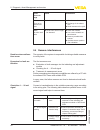

Error cause rectification l operating vol- tage too low or load resis- tance too high l check, adapt if necessary current signal greater than 22 ma or less than 3.6 ma l electronics module in the sensor defecti- ve l exchange the instrument or send it in for repair the below tables show typical examp...

Page 62

Fault description error pattern cause rectification 2. Measured value jumps towards 100 % level time 0 l due to the process, the amplitude of the product echo sinks l a false signal sup- pression was not carried out l carry out false signal suppression l amplitude or posi- tion of a false echo has ch...

Page 63

Fault description error pattern cause rectification 5th measured value jumps sporadically to 100 % during filling leve l time 0 l varying condensation or con- tamination on the antenna l carry out a false signal sup- pression or increase false sig- nal suppression with condensation/contamination in th...

Page 64

The hotline is also available outside the normal working hours on seven days a week around the clock. Since we offer this service worldwide, the support is in the english language. The service itself is free of charge, the only costs involved are the normal call charges. 9 .5 exchanging the electroni...

Page 65

L store the extracted files, for example on the desktop l connecting the sensor to voltage supply and via the interface adapter to the pc l start pactware and go via the menu "project" to the vega project assistant l select "usb", "create new project" and "set instrument online" l activate the projec...

Page 66: Dismounting

10 dismounting 10 .1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in re...

Page 67: Supplement

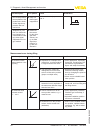

11 supplement 11 .1 technical data general data 316l corresponds to 1.4404 or 1.4435 materials, wetted parts - adapter flange pp - seal, adapter flange fkm (cog vi500), epdm (cog ap310) - antenna pbt-gf 30 - focussing lense pp materials, non-wetted parts - compression flange pp - mounting strap 316l - ...

Page 68

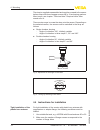

The measured variable is the distance between the process fitting of the sensor and the product surface. The reference plane is the seal surface of the flange. 3 4 2 1 fig. 46: data of the input variable 1 reference plane 2 measured variable, max. Measuring range 3 antenna length 4 useful measuring ra...

Page 69

- sv (secondary value) level as percentage value - tv (third value) linearised percentage value - qv (fourth value) scaled measured value resolution, digital 1 mm (0.039 in) accuracy (according to din en 60770-1) process reference conditions according to din en 61298-1 - temperature + 18 … +30 °c (+...

Page 70

± 3 mm/10 k relating to the max. Measuring range or max. 10 mm additional deviation through strong, high frequency electromagnetic fields acc. To en 61326 50 mm specifications apply also to the current output temperature drift - current output ± 0.03 %/10 k relating to the 16 ma span max. ± 0.3 % devi...

Page 71

Vibration resistance 5) - plastic horn antenna with compression or adapter flange mechanical vibrations up to 2 g in the frequency range 5 … 200 hz - plastic horn antenna with mounting strap mechanical vibrations up to 1 g in the frequency range 5 … 200 hz electromechanical data - version ip 66/ip 67...

Page 72

- double chamber housing 1 x ip 68 cable gland m20 x 1.5; 1 x blind stopper m 20 x 1.5; 1 x blind stopper m16 x 1.5 connection cable - wire cross-section 0.5 mm² (awg 20) - wire resistance 0.036 Ω/m - tensile strength 1200 n (270 lbf) - standard length 5 m (16.4 ft) - max. Length 180 m (590.6 ft) - ...

Page 73

Voltage supply operating voltage - non-ex instrument 9.6 … 36 v dc - ex-ia instrument 9.6 … 30 v dc - ex-d-ia instrument 14 … 36 v dc - ex-d-ia instrument with ship approval 15 … 36 v dc operating voltage with illuminated indicating and adjustment module - non-ex instrument 16 … 36 v dc - ex-ia inst...

Page 74

- aluminium housing, stainless steel housing - investment casting, stainless steel housing - electro-polished ip 66/ip 68 (0.2 bar) 10) - aluminium and stainless housing, in- vestment casting (optionally available) ip 66/ip 68 (1 bar) overvoltage category iii protection class ii approvals instrument...

Page 75

11 .2 dimensions the following dimensional drawings represent only an extract of the possible versions. Detailed dimensional drawings can be downloaded on www.Vega.Com under "d ownloads" and "drawings". Plastic housing ~ 69 mm (2.72") ø 79 mm (3.03") 1 1 2 mm (4 .4 1 ") m20x1,5/ ½ npt ~ 84 mm (3.31"...

Page 76

Aluminium housing in protection rating ip 66/ip 68 (1 bar) 1 2 0 mm (4 .7 2 ") ~ 105 mm (4.13") 1 16 m m (4.57 ") ~ 150 mm (5.91") ø 84 mm (3.31") ø 84 mm (3.31") m20x1,5/ ½ npt m16x1,5 2 m20x1,5 m20x1,5 1 fig. 51: housing versions in protection ip 66/ip 68 (1 bar) - with integrated indicating and a...

Page 77

Stainless steel housing in protection rating ip 66/ip 68, 1 bar 1 17 m m (4.61 ") ~ 103 mm (4.06") ø 77 mm (3.03") 1 20 m m (4. 7 2 ") ~ 105 mm (4.13") ø 84 mm (3.31") ~ 93 mm (3.66") ø 80 mm (3.15") 1 12 m m (4.41 ") m20x1,5/ ½ npt m20x1,5 3 m20x1,5/ ½ npt m16x1,5 2 1 fig. 53: housing versions in p...

Page 78

Vegapuls 67 , version with mounting strap 125 mm (4.92") 2,5 mm (0.10") 75 mm (2.95") 107 mm (4.21") 115 mm (4.53") 300 mm (11.81 ") 19 mm (0.75 ") 98 mm (3.86 ") 15 mm (0.59 ") 8,5 mm (0 .34 ") 9 mm (0.35") 85 mm (3.35") 12 mm (0.47") 9 mm (0.35") 12 mm (0.47") 170 mm (6.69") fig. 54: vegapuls 67, ...

Page 79

Vegapuls 67 , version with compression flange 1 2 6 mm (4 .9 6 ") 1 0 ,5 mm (0 .4 1 ") 1 9 m m (0 .7 5 ") ø 75 mm (2.95") ø 115 mm (4.53") ø 156 mm (6.14") ø 200 mm (7.87") ø 21 mm (0.83") ø 107 mm (4.21") fig. 55: vegapuls 67, compression flange suitable for dn 80 pn 16/asme 3" 150lbs/jis80 10k vegap...

Page 80

Vegapuls 67 , version with adapter flange 2 1 1 3 8 mm (5 .4 3 ") 3 1 mm (1 .2 2 ") 2 0 mm (0 .7 9 ") 8 mm (0 .3 2 ") ø 75 mm (2.95") ø 98 mm (3.86") fig. 56: vegapuls 67, adapter flange 1 adapter flange 2 seal 80 vegapuls 67 • 4 … 20 ma/hart - two-wire 11 supplement 36531 -en -120301.

Page 81

11 .3 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com . Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrecht...

Page 82: Index

Index a accessory - external indicating and adjustment unit 10 - external radio unit 11 - indicating and adjustment module 10 - interface adapter 10 - protective cap 11 adjustment 42 - max. Adjustment 43 - min. Adjustment 43 adjustment system 35 agitator 21 application - bulk solid 40 - liquid 37 - ...

Page 83

Storage 10 subsurface enclosure 22 t type label 8 v vessel form 42 vessel height 42 vessel installations 21 voltage supply 25 vegapuls 67 • 4 … 20 ma/hart - two-wire 83 index 36531 -en -120301.

Page 84

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info.De@vega.Com www.Vega.Com printing date: iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems co...