- DL manuals

- Vega

- Switch

- VEGASWING 51

- Operating Instructions Manual

Vega VEGASWING 51 Operating Instructions Manual

Summary of VEGASWING 51

Page 1

Operating instructions vegaswing 51 - transistor (pnp) document id: 30213 vibration.

Page 2: Contents

Contents 1 about this document 1.1 function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 symbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 authorised...

Page 3

Editing status: 2012-01-10 vegaswing 51 • - transistor (pnp) 3 contents 30213 - en -120124.

Page 4: About This Document

1 about this document 1 .1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instructions for maintenance and fault rectification. Please read this information before putting the instrument into operation and keep...

Page 5: For Your Safety

2 for your safety 2 .1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the required personal protective equipment must always be worn. 2 ....

Page 6

2 .5 safety label on the instrument the safety approval markings and safety tips on the device must be observed. 2 .6 ce conformity this device fulfills the legal requirements of the applicable ec guidelines. By attaching the ce mark, vega provides a confirmation of successful testing. You can find the...

Page 7: Product Description

3 product description 3 .1 structure the scope of delivery encompasses: l vegaswing 51 point level switch l test magnet l documentation - this operating instructions manual - if necessary, certificates the vegaswing 51 consists of the components: l housing with electronics l process fitting with tunin...

Page 8

3 .2 principle of operation vegaswing 51 is a point level sensor with tuning fork for level detection. It is designed for industrial use in all areas of process technology and can be used in liquids. Typical applications are overfill and dry run protection. With a tuning fork of only 40 mm length, ve...

Page 9

3 .4 storage and transport your instrument was protected by packaging during transport. Its capacity to handle normal loads during transport is assured by a test according to din en 24180. The packaging of standard instruments consists of environment- friendly, recyclable cardboard. For special vers...

Page 10: Mounting

4 mounting 4 .1 general instructions make sure that all parts of the instrument exposed to the process, in particular the sensor element, process seal and process fitting, are suitable for the existing process conditions. These include above all the process pressure, process temperature as well as th...

Page 11

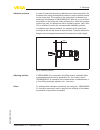

1 2 fig. 3: horizontal installation 1 switching point 2 switching point (recommended mounting position, particularly for adhesive products) use the recommended cables (see chapter "connecting to power supply") and tighten the cable gland. You can give your vegaswing 51 additional protection against ...

Page 12

The process fitting must be sealed if there is gauge or low pressure in the vessel. Before use, check if the seal material is resistant against the measured product and the process temperature. The max. Permissible pressure is specified in chapter "technical data" or on the type label of the sensor. T...

Page 13

In case of horizontal mounting in adhesive and viscous products, the surfaces of the tuning fork should be vertical in order to reduce buildup on the tuning fork. The position of the tuning fork is indicated by a marking on the hexagon of vegaswing 51. With this, you can check the position of the tu...

Page 14

5 connecting to power supply 5 .1 preparing the connection always keep in mind the following safety instructions: l connect only in the complete absence of line voltage the instrument is connected with standard two-wire cable without screen. If electromagnetic interference is expected which is above...

Page 15

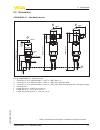

5 .2 wiring plan 1 2 3 fig. 7: overview of the connection versions 1 m12 x 1 plug connection 2 valve plug iso 4400 3 valve plug iso 4400 with idc method of termination m12 x 1 plug connection this plug connection requires a prefabricated cable with plug. Depending on the version, protection ip 66/ip...

Page 16

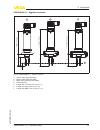

1 4 5 6 7 8 9 10 2 3 fig. 8: connection, valve plug iso 4400 1 pressure screw 2 pressure disc 3 seal ring 4 fixing screw 5 seal washer 6 plug housing 7 plug insert 8 profile seal 9 control lamp 10 vegaswing 51 valve plug iso 4400 with idc method of termination for this plug version you can use standa...

Page 17

1 2 3 4 5 fig. 9: connection, valve plug iso 4400 with idc crimping technology 1 compression nut 2 cable 3 seal ring 4 terminal insert 5 plug housing for connection to binary inputs of a plc with an input resistance 100 kΩ. Note: for inputs with an input resistor > 100 kΩ, the instrument signals fai...

Page 18

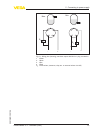

Max. Min. 3 2 1 3 2 1 - + r l r l - + pa pa fig. 10: wiring plan, transistor output with valve plug iso 4400 pa potential equalisation r l load resistor (contactor, relay etc. Or external resistor 100 kΩ) 18 vegaswing 51 • - transistor (pnp) 5 connecting to power supply 30213 -en -120124.

Page 19

R l r l 1 4 2 3 1 4 2 3 - max. Min. - + + fig. 11: wiring plan (housing), transistor output with m12 x 1 plug connection 1 brown 2 white 3 blue 4 black r l load resistor (contactor, relay etc. Or external resistor 100 kΩ) vegaswing 51 • - transistor (pnp) 19 5 connecting to power supply 30213 - en -...

Page 20: Set Up

6 set up 6 .1 indication of the switching status the switching status of the electronics can be checked via the signal lamp integrated in the upper part of the housing. 6 .2 simulation the vegaswing 51 has an integrated function for simulation of the output signal which can be activated magnetically...

Page 21

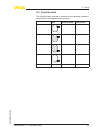

6 .3 function chart the following chart provides an overview of the switching conditions depending on the adjusted mode and level. Level switching status control lamp mode max. Closed green mode max. Open red mode min. Closed green mode min. Open red malfunction any open flashes red vegaswing 51 • - ...

Page 22

7 maintenance and fault rectification 7 .1 maintenance if the instrument is used properly, no special maintenance is required in normal operation. 7 .2 remove interferences the operator of the system is responsible for taking suitable measures to rectify faults. Vegaswing 51 offers maximum reliability...

Page 23

Error cause rectification the signal lamp flashes alternately red and green shortcircuit or overload check the electrical connection depending on the reason for the fault and the measures taken, the steps described in chapter "set up" may have to be carried out again. 7 .3 exchange of the electronics ...

Page 24

13 tighten the screw (1) with a wrench (fasten m12 x 1 plug connection by screwing the compression nut) vegaswing 51 is again ready for operation. 4 1 2 3 5 6 7 8 fig. 17: exchange of the electronics 1 fixing screw 2 valve plug iso 4400 3 profile seal 4 electronics module 5 rotary switch (16-steps) 6...

Page 25

7 .4 instrument repair if a repair is necessary, please proceed as follows: you can download a return form (23 kb) from our homepage at www. Vega.Com under: "downloads - forms and certificates - repair form". By doing this you help us carry out the repair quickly and without having to call back for n...

Page 26: Dismounting

8 dismounting 8 .1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in reve...

Page 27: Supplement

9 supplement 9 .1 technical data general data material 316l corresponds to 1.4404 or 1.4435 materials, wetted parts - tuning fork 316l - process seal klingersil c-4400 - process fittings 316l materials, non-wetted parts - housing 316l and plastic pei weight approx. 250 g (9 oz) process fittings - pipe...

Page 28

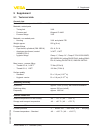

1 2 0 °c (32 °f) -20 °c (-4 °f) 40 °c (104 °f) 20 °c (68 °f) 80 °c (176 °f) 60 °c (140 °f) -40 °c (-40 °f) 0 °c (32 °f) 70 °c (158 °f) 50 °c (122 °f) -40 °c (-40 °f) 100 °c (212 °f) fig. 18: dependendency ambient temperature to process temperature 1 ambient temperature in °c (°f) 2 process temperatu...

Page 29

Operation plug connections specification see "connecting to power supply" signal lamp (led) - green output closed - red output open - red (flashing) failure, output open output variable output transistor output pnp load current max. 250 ma (output, permanently short-circuit proof) voltage loss 3 v tur...

Page 30

Overvoltage category iii protection class ii approvals instruments with approvals can have different technical data depending on the version. That's why the associated approval documents have to be noted with these instruments. They are part of the delivery or can be downloaded under www.Vega.Com via...

Page 31

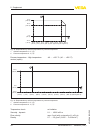

9 .2 dimensions vegaswing 51 - standard version 158mm (6 7 / 32 ") 165mm (6 1 / 2 ") 35mm (1 3 / 8 ") 42mm (1 21 / 32 ") 27mm (1 1 / 16 ") 36mm (1 27 / 64 ") 28mm (1 7 / 64 ") l 40mm (1 37 / 64 ") 10mm ( 25 / 64 ") 13mm ( 33 / 64 ") ø21,3mm ( 27 / 32 ") ø31,7mm (1 1 / 4 ") g 3 / 4 a, 3 / 4 "npt g1a,...

Page 32

Vegaswing 51 - high temperature version 162,5mm (6 25 / 64 ") 188mm (7 13 / 32 ") 182mm (7 11 / 64 ") 35mm (1 3 / 8 ") 27mm (1 1 / 16 ") 36mm (1 27 / 64 ") l 40mm (1 37 / 64 ") 13mm ( 33 / 64 ") ø21,3mm ( 27 / 32 ") ø31,7mm (1 1 / 4 ") g 3 / 4 a, 3 / 4 "npt g1a, 1"npt 32 1 4 2 3 42mm (1 21 / 32 ") 2...

Page 33

Vegaswing 51 - hygienic versions ~101 mm (3 31 / 32 ") 4 l 2 1 3 ~115 mm (7 13 / 32 ") l 40 mm (1 37 / 64 ") ~105 mm (4 9 / 64 ") l 13 mm ( 33 / 64 ") fig. 22: vegaswing 51 - hygienic versions 1 clamp (valve plug iso 4400) 2 bolting (valve plug iso 4400) 3 sms 1145 (valve plug iso 4400) 4 switching ...

Page 34

9 .3 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com . Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte...

Page 35

Vegaswing 51 • - transistor (pnp) 35 9 supplement 30213 - en -120124.

Page 36

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info.De@vega.Com www.Vega.Com printing date: iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems co...