- DL manuals

- Vega

- Switch

- VEGASWING 66

- Operating Instructions Manual

Vega VEGASWING 66 Operating Instructions Manual

Summary of VEGASWING 66

Page 1

Operating instructions vibrating level switch for liquids under extreme process temperatures and pressures vegaswing 66 relay document id: 43756.

Page 2: Contents

2 contents vegaswing 66 • relay 43756-en-170126 contents 1 about this document 1.1 function ........................................................................................................................... 4 1.2 target group ....................................................................

Page 3

3 contents vegaswing 66 • relay 43756-en-170126 safety instructions for ex areas takenoteoftheexspecificsafetyinstructionsforexapplications. These instructions are attached as documents to each instrument with ex approval and are part of the operating instructions manual. Editing status: 2017-01-16.

Page 4: 1 About This Document

4 1 about this document vegaswing 66 • relay 43756-en-170126 1 about this document 1.1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instruc- tionsformaintenanceandfaultrectification.Pleasereadthisinforma- ti...

Page 5: 2 For Your Safety

5 2 for your safety vegaswing 66 • relay 43756-en-170126 2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the require...

Page 6

6 2 for your safety vegaswing 66 • relay 43756-en-170126 2.5 safety label on the instrument the safety approval markings and safety tips on the device must be observed. 2.6 eu conformity thedevicefulfilsthelegalrequirementsoftheapplicableeuguide- lines.Byaffixingthecemarking,weconfirmsuccessfultesti...

Page 7: 3 Product Description

7 3 product description vegaswing 66 • relay 43756-en-170126 3 product description 3.1 configuration the scope of delivery encompasses: • vegaswing 66 point level switch • documentation – this operating instructions manual – safety manual "functional safety (sil)" (optional) – supplementary instruct...

Page 8

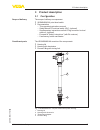

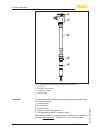

8 3 product description vegaswing 66 • relay 43756-en-170126 1 2 3 4 5 fig. 2: vegaswing 66 with plastic housing and tube extension 1 housing lid 2 housing with electronics 3 temperature adapter 4 processfitting 5 tube extension thetypelabelcontainsthemostimportantdataforidentificationand use of the...

Page 9

9 3 product description vegaswing 66 • relay 43756-en-170126 youcanfindtheserialnumberontheinsideoftheinstrumentaswell as on the type label on the outside. 3.2 principle of operation vegaswing 66 is a point level sensor with tuning fork for point level detection. It is designed for industrial use in...

Page 10

10 3 product description vegaswing 66 • relay 43756-en-170126 • mode switch for selecting the switching behaviour (min./max.) 3.4 storage and transport your instrument was protected by packaging during transport. Its capacity to handle normal loads during transport is assured by a test based on iso ...

Page 11

11 3 product description vegaswing 66 • relay 43756-en-170126 youcanfindinformationintheoperatinginstructionsmanualofthe electronics module. For connecting the sensors with a separator to voltage supply or sig- nal processing, the sensors are also available with plug connectors. The following plug c...

Page 12: 4 Mounting

12 4 mounting vegaswing 66 • relay 43756-en-170126 4 mounting 4.1 general instructions make sure that all parts of the instrument coming in direct contact with the process, especially the sensor element, process seal and processfitting,aresuitablefortheexistingprocessconditions,such as process press...

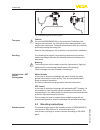

Page 13

13 4 mounting vegaswing 66 • relay 43756-en-170126 1 2 fig. 4: horizontal mounting 1 switching point 2 markingontopwiththreadedversions,markingalignedtoflangeholeswith flangeversions 1 2 fig. 5: horizontal installation (recommended mounting position, particularly for adhesive products) 1 switching p...

Page 14

14 4 mounting vegaswing 66 • relay 43756-en-170126 fig. 7: measures against moisture ingress caution: do not hold vegaswing 66 on the tuning fork. Particularly with flangeortubeversions,thetuningforkcanbedamagedjustbythe weight of the instrument. Transport coated instruments very carefully and avoid...

Page 15

15 4 mounting vegaswing 66 • relay 43756-en-170126 make sure that with instruments with 1" npt thread, the screw-in opening on the vessel has an inside diameter of at least 29.5 mm (1.16 in). To mount the sensor, proceed as follows: 1. Screw the vegaswing 66 into the mounting boss up to the stop. Yo...

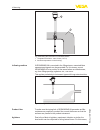

Page 16

16 4 mounting vegaswing 66 • relay 43756-en-170126 1 2 fig. 8: mounting the instrument on insulated vessels. 1 temperature isolation - max. 50 mm (1.97 in) 2 ambient temperature on the housing ifvegaswing66ismountedinthefillingstream,unwantedfalse measurement signals can be generated. For this reaso...

Page 17

17 4 mounting vegaswing 66 • relay 43756-en-170126 do not use an overly long extension tube (optional) for vegaswing 66, instead check if it is possible to mount a short level switch vegaswing66onthesideofthevesselinhorizontalposition. Extreme vibration caused by the process or the equipment, e.G. A...

Page 18

18 5 connecting to power supply vegaswing 66 • relay 43756-en-170126 5 connecting to power supply 5.1 preparing the connection always keep in mind the following safety instructions: warning: connect only in the complete absence of line voltage. • the electrical connection must only be carried out by...

Page 19

19 5 connecting to power supply vegaswing 66 • relay 43756-en-170126 5.2 connection procedure with ex instruments, the housing cover may only be opened if there is no explosive atmosphere present. Proceed as follows: 1. Unscrew the housing lid 2. Loosen compression nut of the cable gland and remove ...

Page 20

20 5 connecting to power supply vegaswing 66 • relay 43756-en-170126 7 4 6 1 5 3 2 on g / cm3 0,7 min max 0,47 r fig. 12: electronics and terminal compartment, single chamber housing 1 control lamp - fault indication (red) 2 control lamp - switching status (yellow) 3 control lamp - operating status ...

Page 21: 6 Setup

21 6 setup vegaswing 66 • relay 43756-en-170126 6 setup 6.1 general information thefiguresinbracketsrefertothefollowingillustrations. Inthebasicsetting,productswithadensity≥0.7g/cm³(0.025lbs/in³) can be detected. For products with lower density, you have to set the switchto≥0.47g/cm³(0.017lbs/in³). ...

Page 22

22 6 setup vegaswing 66 • relay 43756-en-170126 the instrument monitors the vibrating frequency, electronics tempera- ture and internal instrument functions. • red led lights = fault • relaydeenergizes the signal lamp for indication of the switching condition of the relay. With the mode setting (4),...

Page 23

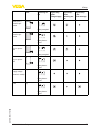

23 6 setup vegaswing 66 • relay 43756-en-170126 level switching sta- tus signal lamp - green voltage supply signal lamp - yellow switching sta- tus signal lamp - red fault message mode (max.) overflowpro- tection 5 3 4 (8) (6) (7) relayenergized mode max. Overflowpro- tection 5 3 4 (8) (6) (7) relay...

Page 24

24 7maintenanceandfaultrectification vegaswing 66 • relay 43756-en-170126 7 maintenanceandfaultrectification 7.1 maintenance if the instrument is used properly, no special maintenance is required in normal operation. 7.2 rectify faults the operator of the system is responsible for taking suitable me...

Page 25

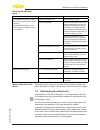

25 7maintenanceandfaultrectification vegaswing 66 • relay 43756-en-170126 error reason removal vegaswing 66 signals "covered" withoutbeingsubmerged(overflow protection) vegaswing 66 signals "uncov- ered" when being submerged (dry run protection) operating voltage too low check operating voltage elec...

Page 26

26 7maintenanceandfaultrectification vegaswing 66 • relay 43756-en-170126 7.4 how to proceed if a repair is necessary youcanfindaninstrumentreturnformaswellasdetailedinforma- tion about the procedure in the download area of our homepage: www.Vega.Com. By doing this you help us carry out the repair q...

Page 27: 8 Dismount

27 8 dismount vegaswing 66 • relay 43756-en-170126 8 dismount 8.1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power...

Page 28: 9 Supplement

28 9 supplement vegaswing 66 • relay 43756-en-170126 9 supplement 9.1 technical data note for approved instruments the technical data in the respective safety instructions are valid for approved instruments (e.G. With exapproval).Thesedatacandifferfromthedatalistedherein,forexampleregardingtheproces...

Page 29

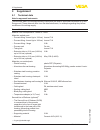

29 9 supplement vegaswing 66 • relay 43756-en-170126 Ʋ contacts kovar (gold-plated) Ʋ helium leak rate -8 mbar l/s Ʋ pressure resistance pn 160 sensor length - compact version Ʋ alloy c22 (2.4602) 74 mm (2.91 in) Ʋ inconel 718 74 mm (2.91 in) sensor length (l) - tube version Ʋ 316l, alloy c22 (2.460...

Page 30

30 9 supplement vegaswing 66 • relay 43756-en-170126 contact material (relay contacts) agni (au plated) or agsno (au plated) modes (switchable) Ʋ max. Max.Detectionoroverflow/overfillprotection Ʋ min. Min. Detection or dry run protection accuracy (according to din en 60770-1) reference conditions an...

Page 31

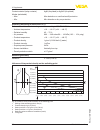

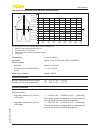

31 9 supplement vegaswing 66 • relay 43756-en-170126 influenceoftheprocesspressuretotheswitchingpoint 1 2 3 4 20 (290) 60 (870) 40 (580) 80 (1160) 100 (1450) 10 (0.39") 8 (0.31") 6 (0.24") 4 (0.16") 2 (0.08") -2 (-0.08") -4 (-0.16") -6 (-0.24") -8 (-0.31") -10 (-0.39") mm 0 120 (1740) 140 (2030) 160...

Page 32

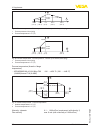

32 9 supplement vegaswing 66 • relay 43756-en-170126 200 °c (392 °f) 450 °c (842 °f) -196 °c (-321 °f) 0 °c (32 °f) -110 °c (-166 °f) 40 bar 64 bar 100 bar 1 2 fig. 45: process temperature - process pressure - version up to 100 bar (1450 psig) 1 process pressure in bar (psig) 2 process temperature i...

Page 33

33 9 supplement vegaswing 66 • relay 43756-en-170126 density 0.7…2.5g/cm³(0.025…0.09lbs/in³);0.47…2.5g/ cm³(0.017…0.09lbs/in³)byswitchingover optionallyalso≥0.42g/cm³(0.015lbs/in³) 3) vibration resistance Ʋ instrument housing 1gat5…200hzaccordingtoen60068-2-6(vibration with resonance) Ʋ sensor 1gwit...

Page 34

34 9 supplement vegaswing 66 • relay 43756-en-170126 for that reason the associated approval documents of these instruments have to be carefully noted. They are part of the delivery or can be downloaded under www.Vega.Com, "vega tools" and "instrument search" as well as in the general download area....

Page 35

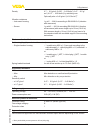

35 9 supplement vegaswing 66 • relay 43756-en-170126 vegaswing 66, compact version 41 ø 28,5 mm (1.12") ø 28,5 mm (1.12") ø 33,7 mm (1.33") g 1, 1 npt 40 mm (1.57") 74 mm (2.91") 320 mm (12.60") 40 mm (1.57") 74 mm (2.91") 323 mm (12.72") 1 dn50 pn40 fig. 49: vegaswing 66, compact version 1 sealing ...

Page 36

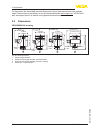

36 9 supplement vegaswing 66 • relay 43756-en-170126 vegaswing 66, tube version 41 ø 33,7 mm (1.33") ø 21,3 mm (0.84") ø 28,5 mm (1.12") g 1, 1 npt 40 mm (1.57") 85 mm (3.35") ø 28,5 mm (1.12") 40 mm (1.57") 85 mm (3.35") 320 mm (12.60") l l 1 ø 33,7 mm (1.33") 323 mm (12.72") dn50 pn40 fig. 50: veg...

Page 37

37 9 supplement vegaswing 66 • relay 43756-en-170126 9.3 industrial property rights vega product lines are global protected by industrial property rights. Further information see www.Vega.Com. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte. Nähere informationen unter www...

Page 38

38 notes vegaswing 66 • relay 43756-en-170126.

Page 39

39 notes vegaswing 66 • relay 43756-en-170126.

Page 40

Printing date: vega grieshaber kg am hohenstein 113 77761 schiltach germany 43756-en-170126 all statements concerning scope of delivery, application, practical use and operat- ing conditions of the sensors and processing systems correspond to the information available at the time of printing. Subjec...