- DL manuals

- Venmar

- Ventilation Hood

- HEPA 3.2

- Installation Instructions And User Manual

Venmar HEPA 3.2 Installation Instructions And User Manual

INSTALLATION INSTRUCTIONS

AND USER MANUAL

RESIDENTIAL USE ONLY

INSTALLER: LEAVE THIS MANUAL WITH CONSUMER.

HOMEOWNER: USE AND CARE INFORMATION

ON PAGES 22, 25, 28, 29 and 30.

READ AND SAVE THESE INSTRUCTIONS

05438 rev E

.

M O D E L S

H E P A 3 . 2 * a n d T H H 1 . 0 *

VB0049

VB0058

*Patents pending

NOTE: HEPA 3.2 model available in Canada only.

For United States, use Venmar HEPA 1000 model.

Summary of HEPA 3.2

Page 1

Installation instructions and user manual residential use only installer: leave this manual with consumer. Homeowner: use and care information on pages 22, 25, 28, 29 and 30. Read and save these instructions 05438 rev e . M o d e l s h e p a 3 . 2 * a n d t h h 1 . 0 * vb0049 vb0058 *patents pending...

Page 2: About This Manual

About this manual first, we want to congratulate you on your purchase of this excellent unit which will allow you and your family to enjoy clean and healthy air throughout your home for years to come! The illustrations in this publication are typical ones. Some details of your unit may be slightly d...

Page 3

1. T echnical d ata . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 1.1 performance charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 1.2 specifications . ...

Page 4: 1. Technical Data

E xt. Static net supply gross air flow pressure air flow supply exhaust 1. Technical data hepa 3.2 f iltration a irflow thh 1.0 v entilation p erformance 1.00 0.80 0.60 0.40 0.20 0.00 vg0064 100 125 150 175 200 225 250 275 300 325 1.20 high speed (boost mode) low speed (normal mode) airflow (cubic f...

Page 5: 1. Technical Data

- 5 - 1. Technical data (cont’d) 1.3 d imensions hepa 3.2 thh 1.0 front view top view front view top view 17.8'' (452 mm) 29'' (737 mm) 22.9'' (581 mm) vk0047 17.8'' (452 mm) 30.2'' (767 mm) 22.9'' (581 mm) vk0049 1.4 m ounting and s ervicing c onsiderations • the two following pictures are showing ...

Page 6: Hep

2. Hep a 3.2 unit inst alla tion vh0038 i nst alla tion type sho wn :c entral d ra w point s ee s ection 2.8.2 s t and a lone i nst alla tion s ee s ection 2.8.1 r eturn - return i nst alla tion s ee s ection 2.8.3 h o w t o hang the u nit s ee s ection 2.5 s ection 4: c ontr ol d uct s ize , i nst ...

Page 7

2.1 i nspect the c ontent of the b ox • inspect the exterior of the unit for shipping damage. Ensure there is no damage to the door, door latches, main switch, etc. • inspect the interior of the unit for damage. Ensure the blower assembly, insulation, prefilter, hepa filter, etc. Are all intact. • i...

Page 8

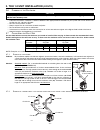

2. Hepa 3.2 unit installation (cont’d) 2.5 h ow to h ang the u nit ( cont ’ d ) • turn the switch knob to off position in order to unlock the door. Unlatch the door and open it. Note: if preferred, the door can be removed. First, remove the stopper ( a ) located on the right side of the door hinge, ...

Page 9

2. Hepa 3.2 unit installation (cont’d) 2.6 p lanning of the d uctwork • follow the instructions in section 2.7 below to determine the appropriate duct diameters for your system. Do not use branch lines smaller than 6”ø (152 mm) diameter. • do not use wall cavities as ducts. • keep it simple. Plan fo...

Page 10

2.8 i nstalling d uctwork and r egisters 2.8.1 s tand a lone s ystem stale air exhaust ductwork • install the stale air exhaust registers in the areas where the contaminants are produced: kitchen, living room, etc. Position the register as far from the stairway as possible and in such a way that the...

Page 11

2. Hepa 3.2 unit installation (cont’d) 2.8 i nstalling d uctwork and r egisters 2.8.2 c entral d raw p oint filtered air distribution ductwork (return side connection) • locate the opening for the filtered air ductwork on the furnace / air handler return duct at a minimum linear distance of 2’ (0.61...

Page 12: Thh 1.0 Unit Inst

3. Thh 1.0 unit inst alla tion vh0040 i nst alla tion type sho wn :c entral d ra w point s ee s ection 3.8.2 s t and a lone i nst alla tion s ee s ection 3.8.1 r eturn - return i nst alla tion s ee s ection 3.8.3 h o w t o hang the u nit s ee s ection 3.5 c onnecting the d rain s ee s ection 3.11 s ...

Page 13

3.1 i nspect the c ontent of the b ox • inspect the exterior of the unit for shipping damage. Ensure there is no damage to the door, door latches, main switch, etc. • inspect the interior of the unit for damage. Ensure the blower assembly, insulation, prefilter, hepa filter,heat recovery core, etc. ...

Page 14

3. Thh 1.0 unit installation (cont’d) 3.5 h ow to h ang the u nit ( cont ’ d ) • turn the switch knob to off position in order to unlock the door. Unlatch the door and open it. Note: if preferred, the door can be removed. First, remove the stopper ( a ) located on the right side of the door hinge, t...

Page 15

3.6 p lanning of the d uctwork • follow the instructions in section 3.7 below to determine the appropriate duct diameters for your system. Do not use branch lines smaller than 4”ø (102 mm) diameter. • do not use wall cavities as ducts. • keep it simple. Plan for a minimum of bends and joints. • do n...

Page 16

3.8 i nstalling d uctwork and r egisters 3.8.1 s tand a lone s ystem stale air exhaust ductwork • install the stale air exhaust registers in the areas where the contaminants are produced: kitchen, living room, etc. Position the register as far from the stairway as possible and in such a way that the...

Page 17

3. Thh 1.0 unit installation (cont’d) 3.8 i nstalling d uctwork and r egisters ( cont ’ d ) 3.8.2 c entral d raw p oint note: for this type of installation, it is not essential that the furnace blower runs when the unit is in operation, but we recommend it. Fresh / filtered air distribution ductwork...

Page 18

3.9 i nstalling i nsulated f lexible d ucts use the following procedure for connecting the insulated flexible ducts to the tandem® transition* ( exhaust air to outside and fresh air from outside ). • the joist opening needed to install the tandem®* transition must be 9 3/4” (248 mm) minimum. Also, t...

Page 19

3.9 i nstalling i nsulated f lexible d ucts ( cont ’ d ) 3.9.2 c onnection to the 5’’ to 6’’ oval ports of the unit use the following procedure for connecting the insulated flexible ducts to the 5’’ to 6’’ oval ports of the unit ( exhaust air to outside and fresh air from outside ). 1. Pull back the...

Page 20

3. Installation of the thh 1.0 unit (cont’d) 3.10 i nstalling d ual e xterior h ood * 3.10.1 a ssembling d ual e xterior h ood exterior dual hood comes in separate parts. Using 2 #8 x 3/4” screws, assemble the top metal screen and the plastic grille to the dual exterior hood. Then, slide the bottom ...

Page 21

3. Installation of the thh 1.0 unit (cont’d) 3.11 c onnecting the d rain vo0025 1 vo0046 1 2 3 1 . Remove the door by turning the switch knob to the off position (to unlock the door). Then, unlatch the door and open it. Slide out the core assembly to access the 2 drain fitting hole locations ( 1 ). ...

Page 22: 4. Controls

4.1 m ain s witch these unist are equipped with a 3-position main switch, located on the front panel. 4.2 o ptional w all c ontrols the optional wall control part number for the hepa 3.2 unit is 04862 (for venmar unit) or 05439 (for vänee unit). The optional wall control part number for the thh 1.0 ...

Page 23: 4. Controls

4.4 i nstallation of the o ptional w all c ontrol ( cont ’ d ) 4. Splice back this end of the cable to access to the 4 wires. Remove the insulated sleeve of each wire ends. Make a loop with each bare end wire to hook them to their corresponding screw. Connect yellow wire to “y” screw, red wire to “r...

Page 24: 4. Controls

4.4 i nstallation of the o ptional w all c ontrol ( cont ’ d ) 8. Remove the front panel of the unit by unscrewing its retaining screws. 9. Using a small rod, pierce a hole through the unit at the end of the wire channel. (see picture beside.) splice back the end of the cable to access the 4 wires. ...

Page 25: 4. Controls

4. Controls (cont’d) 4.6 o perating #04391 or #05536 c ontrol 4.6.1 #04391 or #05536 c ontrol description 4.6.2 u sing #04391 or #05536 c ontrol • off : to stop the unit, slide the button on this position. • n ormal : for a day-to-day usage, slide the button on this position. The unit then will oper...

Page 26: 5. Wiring Diagrams

- 26 - electronic assembly electronic assembly fan motor transformer j3 nc 3 2 1 j4 j5 9.6v, 60hz, ul class 2 60v 120v neutral soldered wires l 2 s1 a1 t1 1 3 nc a b c see note 1 j6 4 3 2 1 field wiring remote control (see note 3) 120v, 60hz w1 120v, 60hz neutral 120v, 60hz line f1 motor capacitor k...

Page 27

- 27 - 6. Balancing procedure (thh 1.0 only) 6.1 w hat y ou n eed to b alance the u nit • a magnehelic gauge capable of measuring 0 to 0.5 inches water gauge (0 to 125 pa) and 2 plastic tubes. • two flow collars (the size will vary depending of duct diameter). Vp0005 flow collar 6.2 p reliminary s t...

Page 28: 7. Maintenance

7. Maintenance 7.1 s emi - annual m aintenance ( essential ) if your unit is equipped with an optionnal wall control (04862 / 05439 or 04391 / 05536) you should perform this maintenance when the filter maintenance light is flashing . Otherwise, this maintenance must be performed every 6 months to en...

Page 29: 7. Maintenance

7.1 s emi - annual m aintenance ( essential ) ( cont ’ d ) for thh unit only wash the 2 core filters under hot water with mild soap. Soak the core in a solution of warm water and mild soap. Rinse the core filters and the core thoroughly and let dry before reinstalling them in the unit. 1) core filte...

Page 30

Warranty venmar ventilation inc. And vänee canada warrant to the original consumer purchaser of their products, that such products will be free from defects for a period of two (2) years, from date of original purchase. There are no other warranties, express or implied, including, but not limited to...