- DL manuals

- Ventrac

- Tractor

- 4100 Series

- Operator's Manual

Ventrac 4100 Series Operator's Manual

Summary of 4100 Series

Page 1

Operator’s manual ventrac 4100 serial # 1502- revised 06/11/14 09.10050 rev. 02.

Page 2

2 a a b b to the owner contact information and product identifi cation if you need to contact an authorized ventrac dealer for information on servicing your product, always provide the product model and serial numbers. Please fi ll in the following information for future reference. See the picture(s...

Page 3

3 v enture products inc. Is pleased to provide you with your new ventrac! We hope that ventrac equipment will provide you with a one tractor solution. Listed below are just some of the items that can provide you versatility as you use your 4100. Please visit our web site, or contact your authorized ...

Page 4: Table of Contents

Table of contents 4 introduction page 7 product description ................................................................................................................................7 why do i need an operator’s manual? .............................................................................

Page 5: Table of Contents

Table of contents 5 general operation page 23 daily inspection ....................................................................................................................................23 starting the engine .....................................................................................

Page 6: Table of Contents

Table of contents 6 maintenance chart page 39 ventrac 4100 maintenance schedule ..................................................................................................39 ventrac 4100 maintenance checklist .......................................................................................

Page 7: Introduction

Introduction - 7 introduction product description • the 4100 is a unique all-wheel-drive power unit that distributes its weight to four equal sized fl otation tires for excellent control, traction, stability, maneuvering, and braking. • performance is enhanced by a sturdy, articulated chassis which ...

Page 8: Introduction

Introduction introduction - 8 using your manual throughout this manual, you will encounter special messages and symbols that identify potential safety concerns to help you as well as others avoid personal injury or damage to the equipment. Attention this symbol identifi es potential health and safet...

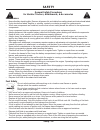

Page 9: Safety

Safety safety - 9 safety d d c c h h g g safety decals the following safety decals must be maintained on your ventrac 4100 power unit. Keep all safety decals legible. Remove all grease, dirt, and debris from safety decals and instructional labels. If any decals are faded, illegible, or missing, cont...

Page 10: Safety

Safety safety - 10 decal description part number quantity a danger, explosion hazard 00.0121 1 b warning - battery gases 00.0124 1 c upper dash - general safety 00.0175 1 d lower dash - high/low shift safety 00.0176 1 e warning - moving parts 00.0216 1 f warning - read owners manual 00.0217 1 g warn...

Page 11: Safety

Safety safety - 11 general safety procedures for ventrac power units, attachments, & accessories training required • the owner of this machine is solely responsible for properly training the operators. • the owner/operator is solely responsible for the operation of this machine and prevention of acc...

Page 12: Safety

Safety safety - 12 safety general safety procedures for ventrac tractors, attachments, & accessories • if equipped with a high/low range feature, never shift between high and low range while on a slope. Always move the machine to level ground and place the selector lever in park before shifting rang...

Page 13: Safety

Safety safety - 13 general safety procedures for ventrac tractors, attachments, & accessories operating on slopes • slopes can cause loss-of-control and tip-over accidents, which can result in severe injury or death. Be familiar with the emergency parking brake, along with the power unit controls an...

Page 14: Safety

Safety safety - 14 general safety procedures for ventrac tractors, attachments, & accessories maintenance • keep all safety decals legible. Remove all grease dirt, and debris from safety decals and instructional labels. • if any decals are faded, illegible, or missing, contact your dealer promptly f...

Page 15: Safety

Safety safety - 15 hydraulic safety • make sure all hydraulic connections are tight and all hydraulic hoses and tubes are in good condition. Repair any leaks and replace any damaged or deteriorated hoses or tubes before starting the machine. • hydraulic leaks can occur under high pressure. Hydraulic...

Page 16: Safety

Safety safety - 16 kt4100 safety procedures • weight transfer springs may contain stored energy. Always disengage the weight transfer system before performing maintenance or repairs on the weight transfer system, the front hitch, or the lift hydraulics. • power unit hydraulic system may contain stor...

Page 17: Safety

Safety safety - 17 operator interlock systems the operator interlock systems: • prevent the engine from starting unless the selector lever is in the park position. • prevent the pto clutch from engaging unless the operator is present on the seat and activates the pto. • deactivates the pto if the op...

Page 18: Operational Controls

Operational controls operation - 18 operational controls cc cc bb bb aa aa v v t t w w u u s s under seat under seat q q p p r r a a b b d d e e f f g g h h i i j j c c k k l l r r o o n n m m x x y y z z.

Page 19: Operational Controls

Operational controls operation - 19 o perational c ontrol l ocations the images on the previous page match with ref- erence letters as shown below to help identify the locations of operational controls for this power unit. A - pto switch b - ignition key switch c - throttle d - volt gauge e - tachom...

Page 20: Operational Controls

Operational controls operation - 20 l ight s witch (h) depressing the top of the switch will turn on the headlights, the taillights, and the backlighting on the dash gauge(s). Depressing the bottom part of the switch will turn the lights off. Lights only work when the key is in the run or start posi...

Page 21: Operational Controls

Operational controls operation - 21 improves traction & hillside stability, aids in lifting, reduces steering effort, and lessens the attachment resistance when in contact with the ground. Note: the weight transfer system is only active while the primary s.D.L.A. Is in the fl oat position. The weigh...

Page 22: Operational Controls

Operational controls operation - 22 s eat l atch (dd) a a b b the seat latch (a) secures the standard seat during transport. To release, pull the latch away from the seat plate while lifting up on the seat. S eat p rop (ee) the seat prop (b) secures the seat in the tipped forward position while serv...

Page 23: General Operation

General operation operation - 23 d aily i nspection 1. Always set the parking brake, shut off the power unit engine, remove the ignition key, and ensure all moving parts have stopped before checking mower deck or blade condition, or attempting any repair or adjustment. Park the power unit on a level...

Page 24: General Operation

General operation operation - 24 s topping the p ower u nit to slow or stop the power unit, move the s.D.L.A. Control lever in the opposite direction that you are traveling. Return the s.D.L.A. Control lever to the neutral position to make a complete stop. A foot pedal brake is not required because ...

Page 25: General Operation

General operation operation - 25 f ront a uxiliary c ouplers equipment damage! Dirt and other debris in hydraulic system can cause damage to the system. Wipe clean the mating parts of the couplers before coupling. Use protective rubber plugs over hydraulic couplers when not in use. If attachment req...

Page 26: General Operation

General operation operation - 26 t urning r adius your power unit has three mounting positions for the steering cylinder that determine the power unit’s turning radius. 1 1 2 2 3 3 position # 1: standard position. This position is the stan- dard position, and enables the tightest turning radius. Pos...

Page 27: General Operation

General operation operation - 27 avoid engine damage! Vanguard gasoline engines are rated for a maximum angle of operation of 25° for continuous use (all directions) and 30° for intermittent use. Exceeding the engine’s rated angle of operation may result in damage to the engine. Maintain suffi cient...

Page 28: Attention

Service - 28 c leaning & g eneral m aintenance for best results, and to maintain the fi nish of the power unit, clean or wash the power unit to remove accumu- lated clippings, leaves, dirt, gravel, and salt deposits. Attention to maintain the fi nish of the power unit, thoroughly wash the equipment ...

Page 29: Service

Service - 29 l ubrication l ocations lubrication is required at the following locations. For service intervals, see maintenance schedule. When greasing pivot points and bearings, use only one pump of grease. Grease spray lube service front hitch center pivot 3 point hitch pivot & cylinder seat rails...

Page 30: Service

Service - 30 c hecking h ydraulic o il l evel check hydraulic oil level before operating unit when the hydraulic system is cold. If the hydraulic sys- tem is warm, allow 1 hour for the hydraulic system to cool before checking. If the hydraulic system is warm when the oil level is checked, it will pr...

Page 31: Service

Service - 31 c hecking e ngine rpm check engine rpm’s when engine is warmed up and not under load. Observe tachometer: • slow idle (no load) - 1500 +/-50 • fast idle (no load) - 3600 +/-50 if engine rpm is incorrect, contact your local ven- trac dealer. C hecking e ngine o il l evel attention: avoid...

Page 32: Service

Service - 32 8. Remove oil fi lter (b) located in front of the left side of the engine. Turn fi lter counterclockwise to remove. 9. B b wipe the fi lter mounting surface with a clean cloth. 10. Apply a thin fi lm of clean engine oil to gasket of oil fi lter. 11. Install new fi lter. Note: turn fi lt...

Page 33: Danger

Service - 33 10. Install the new fi lter element(s). 11. Reinstall the air canister cap. 12. Close engine hood. F illing the f uel t ank 1. Danger fuel is fl ammable and/or explosive. Follow all safety instructions in the fuel safety section of this manual and in the engine operator’s manual. Cautio...

Page 34: Service

Service - 34 c leaning e ngine c ompartment & o il c ooler clean engine compartment daily or prior to each use, to reduce the risk of engine overheating and ignition of accumulated debris. 1. Park power unit on a level surface. 2. Engage parking brake and shut off engine. 3. Remove ignition key from...

Page 35: Service

Service - 35 a a b b 7. Loosen fastener (c) and remove battery clamp. 8. C c slide battery out of battery compartment. Installing: 1. Slide battery into battery compartment. 2. Install battery clamp over battery fl ange and fasten. Do not over tighten. 3. Connect positive battery cable to the positi...

Page 36: Service

Service - 36 c hanging the h eadlight b ulb avoid personal injury! The headlight bulb contains gases under pres- sure. The bulb may shatter if the glass is scratched or dropped. Wear eye protection and handle bulb with care. 1. Park power unit on a level surface. 2. Engage parking brake and shut off...

Page 37: Service

Service - 37 i nspection of pto b elt periodically checking the pto belt (a) of this power unit can prevent sudden failure by fi nding problems before they cause the belt to break. It is recom- mended to inspect the pto belt every 50 hours of operation, or if a problem is suspected. There may be a p...

Page 38: Service

Service - 38 p arking b rake a djustment if the parking brake is not holding suffi ciently, the brake linkage will need to be adjusted. 1. Park power unit on a level surface and block tires to prevent movement. 2. Move the selector lever out of the park brake position to relieve pressure on the brak...

Page 39: Maintenance Chart

Service - 39 maintenance chart v entrac 4100 m aintenance s chedule this sheet is a guide for recommended service and maintenance for the 4100..

Page 40: Maintenance Chart

Service - 40 maintenance chart v entrac 4100 m aintenance c hecklist this sheet is a checklist for tracking service and maintenance for the 4100..

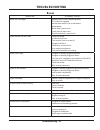

Page 41: Troubleshooting

Troubleshooting - 41 s ymptom : p ossible c ause : starter will not engage. Selector lever is not in the park position. Pto switch is engaged. Neutral start switch is out of adjustment. Dead battery. Blown fuse in start circuit. Faulty relay in start circuit. Electrical problem in start circuit. Eng...

Page 42: Troubleshooting

Troubleshooting troubleshooting - 42 s ymptom : p ossible c ause : battery does not charge. Loose or corroded connections. Broken or loose wire in charge system. Defective battery. Defective alternator. Defective voltage regulator. Lights do not activate. Blown fuse. Blown light bulb. Broken wire/co...

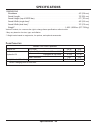

Page 43: Specifications

Specifications specifi cations - 43 engine manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vanguard model number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 543477 type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gasoline cylinder...

Page 44: Specifications

Specifications specifi cations - 44 dimensions wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43” (109 cm) overall length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79” (201 cm) overall height (top of rops bar) . . . . . . . . . . . . . . . . . . . . . . 67”...

Page 45: Warranty

Warranty warranty - 45 limited warranty - ventrac turf equipment venture products, inc. (shall be referred to as v.P.I.) warrants on the terms and conditions herein, that it will repair, replace, or adjust any part manufactured by venture products inc. And found by venture products inc. To be defect...

Page 46: Warranty

Warranty warranty - 46 limited warranty - ventrac turf equipment equipment or other than as recommended in the operator’s manual or other operational instructions provided by v.P.I.; (h) repairs or replacements resulting from parts or accessories which have adversely affected the operation, performa...