- DL manuals

- Ventrac

- Tractor

- 4100 Series

- Owner's/operator's Manual

Ventrac 4100 Series Owner's/operator's Manual

Summary of 4100 Series

Page 1

Revised 04-18-07 2nd edition 09.10026 tractor 4100 serial # 1001-1501 owner/operator’s manual venture products inc. Orrville, oh.

Page 2: To The Owner

Ii to the owner congratulations on the purchase of a new ventrac 4100! The purpose of this manual is to assist you in its safe and effective operation and maintenance. With proper usage and care, the tractor will provide many years of service. Please read and understand this manual entirely before u...

Page 3: Table Of Contents

Table of contents iii introduction section a description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1 specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2 safety section b safety symbols . . . . . . . . . . . . . . . . . . . . . . ...

Page 4: Table Of Contents

Table of contents iv maintenance & service (cont.) section d neutral adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7 platform cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8 pto belt change . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5: Introduction

A-1 introduction product description ventrac 4100 • the ventrac series 4100 is a unique all wheel drive tractor that spreads its weight to four equal-sized flotation tires for excellent power, stability, traction, braking and maneuvering. • performance is enhanced by a sturdy articulated chassis fra...

Page 6: Introduction

A-2 introduction ventrac 4100 specifications engines: engine displacement kawasaki: gasoline, model fh721d, 25 hp, 2 cylinder, air-cooled . . . . 675 (cc) briggs & stratton: gasoline, model 54 31 hp, 2 cylinder, air-cooled. . . . 895 (cc) electrical: . . . . . . . . . . . . . . . Kawasaki, 450 cca b...

Page 7: Safety

Safety b-1 attention : this symbol identifies potential health and safety hazards. It marks safety precautions. Your safety and the safety of others is involved. Signal word definitions indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury and/or p...

Page 8: Safety

Safety b-2 general safety procedures for ventrac tractors, attachments, & accessories read and understand the operator’s manual before operating this equipment. Observe and follow all safety decals. Do not let children or any untrained person operate the tractor or attachment. Make sure that all ope...

Page 9: Safety

Safety b-3 ventrac 4100 safety procedures before operating • check engine fluid levels before starting. • check brake action before operating and adjust or service as needed. • inspect machine before operating. Be sure shields and guards are in good condition and securely in place. Be sure hardware ...

Page 10: Safety

Safety b-4 slopes • use low range when on hills and slopes. • whenever possible, drive up and down a hill….Dual wheels are recommended for mowing across slopes. Be careful when you change direction on a slope. Drive slowly. • make allowances in speed selection for hills, slopes, and rough terrain. I...

Page 11: Operation

Operation c-1 the ventrac 4100 is an innovative all-wheel drive, compact articulated tractor (cat) (figure 1). Its innovative design offers many advantages and some variables from conventional compact utility tractors. The differences make it very important for the operator to read and understand th...

Page 12: Operation

Figure 4 figure 5 note: • low range is recommended for most pulling, pushing, and slow travel. • high range is for transport and light duty tasks. C-2 operation the dash shows important operational and safety instructions. A manual choke pull is located in the right lower corner for gasoline engine ...

Page 13: Operation

Figure 6 & 7 c-3 operation rear controls s.D.L.A. System—speed, direction, lift, auxiliary the primary lever with the large round knob (see figure 6) is the directional control (sometimes called the forward/reverse lever, f/r). It has two distinct functions: i.) operator must be seated to release th...

Page 14: Operation

Figure 8 figure 9 figure 10 c-4 operation fenders the right fender serves as a storage box. The cover opens outward. Operator should always close the cover before operating the tractor. Tractors with the 3-point hitch option have a modified cover and use the front part of the storage box for the hyd...

Page 15: Operation

Figure 11 figure 13 figure 14 c-5 operation seat the ventrac 4100 has an adjustable seat — forward and back. Each operator should adjust the seat for the greatest control and comfort in relation to the steering wheel as well as the directional control lever (figure 11). The seat can also be tilted u...

Page 16: Operation

Figure 15 figure 16 figure 17 c-6 operation battery the battery is located under the seat. Tilting the seat forward gives access to the top of the battery. Before using jumper cables or connecting a battery charger, always check polarity (figure 15). The red cover means positive. The black cover mea...

Page 17: Operation

Figure 18 figure 19 c-7 operation right side controls at the right side of the operator and below the dash, is the pto belt tension lever, the front hitch lock, and one weight transfer adjustment chain. Pto belt tension lever the lever located on the side of the center column is the pto belt tension...

Page 18: Operation

Figure 20 figure 21 c-8 operation front hitch & pto the two rail, minute mount front hitch, (figure 20) is the secret of stable, secure and safe mounting of attachments to the all-wheel-drive ventrac 4100! Just align the two rails to the two corresponding hitch arms on the attachment. Raise or lower...

Page 19: Operation

Figure 22 figure 23 c-9 operation lights (figure 22) headlights and taillights improve safety and operational visibility. Their use is highly recommended especially at dawn or dusk and at night. The headlights can be adjusted to the operator’s preference by loosening the mounting bolt directly under...

Page 20: Operation

Figure 24 figure 25 c-10 operation starting procedure 1. Check engine oil and fuel levels. 2. Read “caution” and instructions on dash. 3. Operator should be sitting on the seat. 4. Fasten seat belt. 5. Make sure the tractor is in park. (figure 24) 6. Throttle should be at or near idle. (choke as nee...

Page 21: Operation

Figure 26 figure 27 figure 28 c-11 operation attaching attachments most front mounted ventrac attachments can be positioned so that it is convenient to drive into the hitch arms with nearly correct alignment (figure 26 & 27). Slight adjustment may be required to complete the hitch engagement. When c...

Page 22: Operation

C-12 operation figure 31a figure 32a initial mounting instructions note: prior to serial number ---1095, begin with step 1. Starting with serial number ---1095, the 7/16 x 2-1/2” bolts are standard on the tractor, skip to step 2. 1. Raise up the tractor and remove the existing wheel. Drive out the f...

Page 23: Operation

C-13 operation dual mounting instructions (cont.) to install wheel assembly: raise tractor up approximately 2” by driving on planks or using a jack. Insert threaded end of dual assembly into the inner wheel mount, turn wheel clockwise until the wheel is hand tight. Using a 1” socket, torque draw bol...

Page 24: Operation

C-14 operation 20 degrees max. Without dual wheels 30 degrees max. With dual wheels 30 de gre es ma x . 30 degrees max. Operating on slopes operation on slopes decreases tractor stability and increases the possibility for unexpected difficulties. Only experienced ventrac 4100 operators should operat...

Page 25: Service & Maintenance

D-1 service & maintenance the operator’s manual and decals should be read and understood before operating the tractor, attachments, or implements. This manual should be reviewed periodically or when in doubt about any function, procedure, or safety factor on this equipment. Daily check the oil level...

Page 26: Service & Maintenance

Figure 34a figure 35 d-2 service & maintenance each day’s operation of the tractor should begin with an oil and fuel check. See engine manual for oil specifications. Engine oil each engine is equipped with a dipstick to check the crankcase oil level. Check the engine manual for specific instruction ...

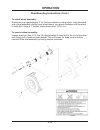

Page 27: Service & Maintenance

Figure 36a figure 37 d-3 service & maintenance air intake filter kawasaki engine air intake filters are located above the engine and have a prefilter band over a paper element. (figure 36a) the paper element should be changed if its appearance is dirty or light is no longer visible through the eleme...

Page 28: Service & Maintenance

Figure 38 d-4 service & maintenance rear transaxle the rear transaxle oil is captive and remains constant unless there is a leak. For convenience, the same oil is recommended that is used in the front transaxle. Oil can be added through the plug from the rear (figure 38). It is located above the rea...

Page 29: Service & Maintenance

Figure 42a d-5 service & maintenance inline fuel filter fuel line filter (s) in-line fuel filter ventrac 4100’s have an in-line fuel filter located near the engine on the right side (figure 42a - kawasaki) or inside the foot platform cover (figure 42b - briggs & stratton). Always use clean, fresh fu...

Page 30: Service & Maintenance

Tire pressure figure 46 figure 48 d-6 service & maintenance brake adjustment a 6” diameter brake band is activated by the 3-position control selector. The brake holds only when the lever is in the down position. If brake is not holding sufficiently, tighten the 1/4” nut on the brake linkage, located...

Page 31: Service & Maintenance

Figure 49 d-7 service & maintenance neutral adjustment the tractor should always come to a complete stop when the control selector is in the “park brake” position (down) or the “neutral detent & spring assist” position (level) when the directional control lever is in neutral. If the tractor consiste...

Page 32: Service & Maintenance

D-8 service & maintenance platform cover (figure 51) to remove: 1. Remove bolt at the front of the cover. 2. Pull the cover forward enough to disengage the 2 tabs at the lower rear end of the cover. 3. Lift rear part of cover to free the top 2 tabs from the chassis. 4. Continue to raise the rear par...

Page 33

9 - 2 limited warranty – ventrac turf equipment venture products, inc. (shall be referred to as v.P.I.) warrants on the terms and conditions herein, that it will repair, replace, or adjust any part manufactured by venture products inc. And found by venture products inc to be defective in material an...

Page 34

9 - 3 limited warranty – ventrac turf equipment operation of, or use of the turf equipment which is not in accordance with operating instructions as specified in the operator’s manual or other operational instructions provided by v.P.I.; (f) repair or replacement arising as a result of any operation...