- DL manuals

- W & H

- Steriliser

- Lisa MB 17

- User Manual

W & H Lisa MB 17 User Manual

Summary of Lisa MB 17

Page 1

Water steam sterilizer lisa mb17/22 201 10 aen rev. 9 user manual.

Page 3

1 user manual summary 1. Unpacking 1.1. Unpacking the sterilizer 1.2. Unpacking the accessories 2. Set-up 2.1. Installation 2.2. Electricity supply 2.3. Printer connection (optional) 3. Description 3.1. Front view of the sterilizer 3.2. Rear view of the sterilizer 4. Use 4.1. Main menu 4.2. Descript...

Page 4

User manual 2 recommendations – safety the purpose of this user manual is to provide you with all the information you need in order to ensure: ព a proper installation and set-up. ព optimal use. ព a safe and reliable operation. ព a regular and correct servicing requirements. Declaration of conformity...

Page 5

3 user manual general recommendations – safety the user is responsible for operating and servicing the sterilizer in accordance with the instructions listed in this manual. The sterilizer has not been designed for the sterilisation of liquids. The sterilizer has not been designed to operate in the p...

Page 6

User manual 4 1. Unpacking the sterilizer, the accessories, the user manual and the warranty card are supplied in a sturdy box. Check the condition of the packaging on receipt. Contact the carrier immediately and inform your supplier if the outer packaging is damaged. 1.1. Unpacking the sterilizer 4...

Page 7

5 user manual 1.2. Unpacking the accessories open the door and remove the accessories from the sterilization chamber. Check the contents: 5 anodised aluminium trays reversible rack for 3/5 trays tray holder drain tube mains cable funnel user manual and warranty card declaration of conformity insert ...

Page 8

User manual 6 2. Set-up 2.1. Installation the sterilizer has been calibrated and tested in the factory. It does not require calibration during installation. Working temperature range: 10°c to 40°c / humidity : 0 to 90%. Storage temperature range : -20°c to 60°c / humidity : 0 to 90% (water tanks emp...

Page 9

7 user manual 2.2. Electricity supply the electrical installation must comply with the current standards in the country. ព the electricity supply must be single phase 230 volts ±10%, 50/60hz, 10a. ព installation category / mains overload category = ii ព an earth connection is essential. The maximum ...

Page 10

User manual 8 2.3. Printer connection (optional) connect the printer cable to the 25 pin parallel port socket at the back of the sterilizer. Cable length should not exceed 2 metres. Plug in the printer mains cable. Switch on the printer. Switch on the sterilizer. Select the printer type (§ 4.5.4.). ...

Page 11

9 user manual 3. Description 3.1. Front view of the sterilizer door touch screen service door main switch / circuit breaker * switch on/off of the sterilizer. Use this switch to interrupt a cycle only in the case of a noted defect. * replaces the fuses. Main water tank drain connection bacteriologic...

Page 12

User manual 10 3.2. Rear view of the sterilizer 25 pin printer port mains plug socket condenser ventilation connection for external used water drainage compliance plate.

Page 13

11 user manual 4. Use 4.1. Main menu activate the mains switch, the selection screen appears. If the sterilizer is not used for a certain period of time, it will automatically go into stand-by mode. Stand-by mode time is programmable (§ 4.5.6.). Cycle selection (§ 4.6.2.) access to sub menus (§ 4.5....

Page 14

User manual 12 4.2. Description of the water tank the sterilizer is equipped with 2 independent water tanks of equal volume - 3.5 litres (mb17) or 4,5 litres (mb22). The left tank also called the "main tank" contains the distilled or demineralized water required for each cycle. It is fitted with 2 l...

Page 15

13 user manual 4.3. Filling of the main water tank remove the main water tank cap located on the top of the sterilizer … …fill the tank with approx. 3 litres on mb17 (or 4 litres on mb22) of water... …once the tank is almost full, an audible tone will be heard. When you hear the tone proceed careful...

Page 16

User manual 14 4.4. Draining of the used water tank when the used water tank is full, it is impossible to run another cycle. The following message appears: ♦ open the service door. ♦ insert the drain tube into the quick coupling drain connection of the used water tank (right) as shown in the diagram...

Page 17

15 user manual 4.5. Programming press the "m" key on the selection screen… …the program menu is displayed… … place the cursor ">" in front of the desired sub-menu using the "up" and "down" keys. Confirm the selection by pressing the sub-menu access key. Refer to the relevant chapter for the sub-menu...

Page 18

User manual 16 4.5.1. Selecting the language 4.5.2. Programming the name of the doctor / surgery cursor up cursor down selection confirmation to exit the sub-menu alphabet scrolling + letter selection cursor to the right letter selection cursor to the left alphabet scrolling - confirmation, exit of ...

Page 19

17 user manual 4.5.3. Programming the date and time it is essential to adjust the date and time especially if the sterilizer is connected to a printer. These parameters are systematically printed at the beginning and at the end of the cycle report. Place the selection cursors under the data that is ...

Page 20

User manual 18 4.5.5. Programming the brightness of the touch screen 4.5.6. Programming the stand-by mode darker lighter confirmation, exit from the sub-menu cursor up cursor down confirmation of the selection exit from the sub-menu.

Page 21

19 user manual 4.5.7. Maintenance program this screen shows the number of cycles remaining before replacement of the bacteriological filter (400), the door seal (1000) as well as when general servicing (4000) is required. The three counters are decreased in value after each cycle. When one of the co...

Page 22

User manual 20 4.6. Cycle selection 4.6.1. Cycle table sterilization cycles test cycles b cycle b cycle b cycle type of cycle b-standard 134 b-prion 134 b-standard 121 b&d/ helix test vacuum test temperature 135.5°c 135.5°c 122.5°c 135.5°c -- pressure 2.16 bar 2.16 bar 1.16 bar 2.16 bar -0.85 bar du...

Page 23

21 user manual 4.6.2. Selection – start of the cycle exit, if necessary, from the stand-by mode… …enter cycle select menu… position the cursor in front of the required cycle. Confirm your selection by pressing the "ok" key. Start the selected cycle. Cursor down confirmation of the selection cursor u...

Page 24

User manual 22 c y c l e p r i n t o u t c o p i e s o f l a s t increase the quantity (1-9) decrease the quantity (1-9) back to previous screen without printing printing 4.6.3. Cycle procedure the following information is displayed during the cycle: 4.6.4. Copies of cycle printouts it is possible t...

Page 25

23 user manual 4.7. Manual stop if needed, the cycle can be interrupted at any moment by pressing the "stop" key for 2 seconds. An audible tone will confirm the request… …this is followed by a phase of approximately 2 minutes, required to reinitialise the system and return the chamber to atmospheric...

Page 26

User manual 24 4.8. Cycle data information you can access the technical data at any time during the cycle by pressing the " i nfo" icon. ..The following data will be displayed… exit and return to the current cycle screen. Date time chamber pressure t° calculated/pressure t° of the steam t° chamber h...

Page 27

25 user manual 4.9. Cycle data summary (end of cycle) at the end of the cycle, before opening the door, the " i nfo" icon gives access to the technical data summary of the completed cycle. The first screen lists the pressure and duration of each phase until the process... ( pv- vacuum pulse / pp- pr...

Page 28

User manual 26 5. Messages a certain number of messages can appear at the beginning or at the end of the cycle. This is merely information and not an alarm. The user can continue to operate the sterilizer with complete confidence. During a cycle, the micro-processor continuously analyses all the par...

Page 29

27 user manual 6. Alarms the micro-processor continuously analyses all the cycle parameters. If there is any doubt regarding sterilization efficiency, the cycle is immediately interrupted and an alarm displayed. This is followed by a phase of approximately 2 minutes required to reinitialise the ster...

Page 30

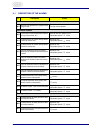

User manual 28 6.1. Description of the alarms n° description action mains a01 mains failure or significant fall in voltage occurred during the cycle. The load cannot be considered sterile. The cycle must be repeated. Sterilization chamber a10 the time spent to reach the sterilization plateau is too ...

Page 31

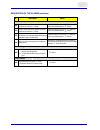

29 user manual description of the alarms (continue) n° description action vacuum pump a31 during a vacuum phase, the maximum achieved vacuum is not lower than – 0.20 bar. Clean and check the door seal (§ 7.2.), repeat the cycle. If the problem persists ℡ service. A32 during a vacuum phase, the maxim...

Page 32

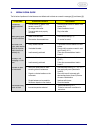

User manual 30 7. User maintenance a distinction must be made between two levels of maintenance, that performed regularly by the user and preventive maintenance carried out by an approved technician (§ 8). 7.1. Maintenance program frequency / n° of cycles operation spare number description weekly 50...

Page 33

31 user manual 7.2. Cleaning the door seal clean the door seal and the porthole with a lint free cloth saturated with alcohol. The porthole can also be cleaned with a non-abrasive detergent. 7.3. Cleaning the chamber, trays and tray holder remove the trays from the chamber. Disconnect and remove the...

Page 34

User manual 32 7.6. Cleaning the water tanks completely drain both water tanks (main and used water tank). Open the service door. Insert the drain tube into the quick coupling drain connection of the used water tank (right). Allow the entire contents of the tank to empty and discard the used water. ...

Page 35

33 user manual 7.7. Replacing the door seal fully open the door of the sterilizer. Remove the door seal by hand. Carefully clean the seal seat with a cotton bud moistened with alcohol. Moisten the new seal. Insert the seal in the sequence illustrated in the following diagrams: insert the seal starti...

Page 36

User manual 34 8. Servicing conducted by the approved technician service is essential to continued effective sterilization. We recommend servicing by an approved technician every 3 years or 4000 cycles. Check list: replacement of the 5 solenoid valves. Replacement of the vacuum pump membrane kit. Re...

Page 37

35 user manual 9. Break-down guide the list below of problems is limited because most defects and incidents are covered in messages (§5) and alarms (§6). Problems potential causes solutions the sterilizer remains switched off. The main switch or network circuit breaker is open (off). No voltage at t...

Page 38

User manual 36 annex 1 technical characteristics electricity supply single phase 230 vac ±10% – 50/60hz – 10a sterilizer: working temperature / humidity storage temperature / humidity min. Atmospheric pressure nominal voltage : max. Absorbed power : max. Current : dimensions overall : max. Space req...

Page 39

37 user manual annex 2. Preparation of the load 1. Cleaning of the instrument the instruments to be sterilized must be clean and free from all types of residue such as fragments, dentine and blood, etc. These substances can damage the objects placed in the trays and even the sterilizer itself. ♦ cle...

Page 40

User manual 38 annex 3 maintenance of dynamic instrumentation 1. External disinfecting this procedure prevents the risk of infection during cleaning and maintenance. ♦ wear gloves. ♦ dampen the instrument with a non-corrosive disinfectant (ph from 2.5 to 9) or with 70-80% ethyl alcohol. ♦ comply wit...

Page 41

39 user manual annex 4: bowie & dick test the bowie & dick test, also called the brown test, is representative of the small porous type load. It comprises several sheets of paper and foam wrapped in a small packet in the middle of which there is a chemical heat-sensitive indicator strip (physic-chem...

Page 42

User manual 40 annex 5 helix test the helix test is the most complex representation of a hollow instrument load ( type a ). Characteristics: length: 150 cm strip test internal diameter: 2 mm material : ptfe this test is used to validate the equipment performance in terms of hollow instruments steril...

Page 43

41 user manual annex 6 vacuum test this test is used to validate the performance of the sterilizer in terms of leakage: the efficiency of the vacuum pump. The tightness of the pneumatic circuit. The profile of the cycle, specific for this test includes: a vacuum phase up to p1 = - 0.85 bar. A stabil...

Page 44

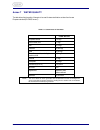

User manual 42 annex 7 water quality the table below lists the quality of the water to be used for steam sterilization as taken from the new european standard (en 13060, annex c) table c.1: contaminants of feed water feed water evaporate residue ≤ 10 mg/l silicium oxide, sio 2 ≤ 1 mg/l iron ≤ 0,2 mg...

Page 45

43 user manual annex 8 accessories description spare number printer: custom dp40h/cable a70010xx anodised perforated aluminium trays 18,5mm x 28,5mm t523200x (mb17) t523202x (mb22) reversible rack f523002x (mb17) f523006x (mb17) cassette holder f523000x tray holder f523001x drain tubing with quick c...

Page 48

Importer : manufacturer : w&h sterilization s.R.L italy, i-24060 brusaporto (bg) via bolgara, 2 t +39/035/66 63 000 f +39/035/50 96 988 wh.Com.