- DL manuals

- Wacker Neuson

- Power Tool

- BS 50-4s

- Operator's Manual

Wacker Neuson BS 50-4s Operator's Manual

Summary of BS 50-4s

Page 1

Www.Wackergroup.Com rammer bs 50-4 bs 50-4s operator’s manual 0158431en 006 1106 0 1 5 8 4 3 1 e n.

Page 3: Bs 50-4

Bs 50-4 table of contents wc_bo0158431en_006toc.Fm 1 1. Foreword 3 2. Emission control system information 4 3. Safety information 11 3.1 operating safety ................................................................................ 12 3.2 operator safety while using internal combustion engines .....

Page 4: Table of Contents

Table of contents bs 50-4 wc_bo0158431en_006toc.Fm 2 6. Maintenance 29 6.1 periodic maintenance schedule ..........................................................29 6.2 servicing air cleaner ...........................................................................30 6.3 engine oil ..................

Page 5

Wc_tx000001gb.Fm 3 california proposition 65 warning: engine exhaust, some of its constituents, and certain vehicle components, contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. 1. Foreword this manual provides information and pr...

Page 6: Wm 90

Emission control system information wm 90 wc_tx000369gb.Fm 4 2. Emission control system information source of emissions the combustion process produces carbon monoxide, oxides of nitrogen, and hydrocarbons. Control of hydrocarbons and oxides of nitrogen is very important because, under certain condi...

Page 7: Wm 90

Wm 90 emission control system information wc_tx000369gb.Fm 5 replacement parts the emission control systems on your wacker engine were designed, built, and certified to conform with epa and california emissions regulations. We recommend the use of genuine wacker parts whenever you have maintenance d...

Page 8: Wm 90

Emission control system information wm 90 wc_tx000369gb.Fm 6 methanol - (methyl or wood alcohol) 5% by volume. You may use gasoline containing up to 5% methanol by volume, as long as it contains cosolvents and corrosion inhibitors to protect the fuel system. Gasoline containing more than 5% methanol...

Page 9: Wm 90

Wm 90 emission control system information wc_tx000369gb.Fm 7 emissions component defect warranty coverage this emission warranty is applicable in all states. Wacker corporation, n92 w15000 anthony avenue, menomonee falls, wi 53051-1504, (herein "wacker") warrant(“s”) to the initial retail purchaser ...

Page 10: Wm 90

Emission control system information wm 90 wc_tx000369gb.Fm 8 parts covered listed below are the parts covered by the emission components defect warranty. Some of the parts listed below may require scheduled maintenance and are warranted up to the first scheduled replacement point for that part. (1) ...

Page 11: Wm 90

Wm 90 emission control system information wc_tx000369gb.Fm 9 obtaining warranty service to obtain warranty service, take your engine to the nearest authorized wacker service dealer. Bring your sales receipts indicating date of purchase for this engine. The service dealer authorized by wacker will pe...

Page 12: Wm 90

Emission control system information wm 90 wc_tx000369gb.Fm 10 things you should know about the emission control system warranty: maintenance and repairs you are responsible for the proper maintenance of the engine. You should keep all receipts and maintenance records covering the performance of regu...

Page 13: Bs 50-4

Bs 50-4 safety information wc_si000117gb.Fm 11 3. Safety information this manual contains danger, warning, caution, and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is used to aler...

Page 14: Safety Information

Safety information bs 50-4 wc_si000117gb.Fm 12 3.1 operating safety familiarity and proper training are required for the safe operation of equipment. Equipment operated improperly or by untrained personnel can be dangerous. Read the operating instructions contained in both this manual and the engine...

Page 15: Bs 50-4

Bs 50-4 safety information wc_si000117gb.Fm 13 3.1.18 always guide the rammer in such a way that the operator is not squeezed between the rammer and solid objects. Special care is required when working on uneven ground or when compacting coarse material. Make sure to stand firmly when operating the ...

Page 16: Safety Information

Safety information bs 50-4 wc_si000117gb.Fm 14 3.2 operator safety while using internal combustion engines internal combustion engines present special hazards during operation and fueling. Read and follow the warning instructions in the engine owner’s manual and the safety guidelines below. Failure ...

Page 17: Bs 50-4

Bs 50-4 safety information wc_si000117gb.Fm 15 3.3 service safety poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 3.3.1 do not attempt to clean or ...

Page 18: Safety Information

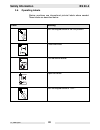

Safety information bs 50-4 wc_si000117gb.Fm 16 3.4 label locations.

Page 19: Bs 50-4

Bs 50-4 safety information wc_si000117gb.Fm 17 3.5 safety labels wacker machines use international pictorial labels where needed. These labels are described below: label meaning this molded-in label contains important safety and operating information. If it becomes illegible, the cover must be repla...

Page 20: Safety Information

Safety information bs 50-4 wc_si000117gb.Fm 18 caution! Use only clean, filtered gasoline fuel. Warning! Hot surface! Warning! Serious injury if struck by compressed spring or cover. If the spring system cover is removed improperly, the springs can eject. For optimal control, performance, and minima...

Page 21: Bs 50-4

Bs 50-4 safety information wc_si000117gb.Fm 19 a nameplate listing the model number, item number, revision number, and serial number is attached to each unit. Please record the information found on this plate so it will be available should the nameplate become lost or damaged. When ordering parts or...

Page 22: Safety Information

Safety information bs 50-4 wc_si000117gb.Fm 20 3.6 operating labels wacker machines use international pictorial labels where needed. These labels are described below: label meaning turn the engine switch to the on position. Close the choke. Pull the rewind starter. Open the choke. Turn the engine sw...

Page 23: Bs 50-4

Bs 50-4 safety information wc_si000117gb.Fm 21 throttle control lever: turtle = idle or slow rabbit = full or fast fuel valve: closed open engine stop button: press to stop engine. Choke: 0 = open l = closed this rammer is equipped with a low oil shutoff switch, it will not allow the engine to opera...

Page 24: Technical Data

Technical data bs 50-4 wc_td000117gb.Fm 22 4. Technical data 4.1 rammer item number: bs 50-4 0009386, 0620077 0620108 bs 50-4s 0620071, 0620078 rammer engine model type wm90 engine speed - full rpm 4300 ± 100 engine speed - idle rpm 2000 ± 100 clutch engagement rpm 2500 ± 100 spark plug type ngk bm4...

Page 25: Bs 50-4

Bs 50-4 technical data wc_td000117gb.Fm 23 4.2 sound measurements products are tested for sound pressure level in accordance with en iso 11204. Sound power level is tested in accordance with european directive 2000/14/ec - noise emission in the environment by equipment for use outdoors. • the sound ...

Page 26: Operation

Operation bs 50-4 wc_tx000308gb.Fm 24 5. Operation 5.1 application rammers are designed to compact loose soils and gravel to prevent settling and to provide a firm, solid base for the placement of footings, concrete slabs, foundations, and other structures. 5.2 recommended fuel this engine is certif...

Page 27: Bs 50-4

Bs 50-4 operation wc_tx000308gb.Fm 25 note: first time use, engines recently serviced, run out of fuel or not used for long periods of time may need the rope to be pulled more times to move fuel to the carburetor. 5.4.6 open choke (b2) on the carburetor as the engine warms up. Note: a cold engine sh...

Page 28: Operation

Operation bs 50-4 wc_tx000308gb.Fm 26 5.6 low oil shutoff switch (if equipped) the low oil shutoff switch is designed to prevent engine damage caused by an insufficient amount of oil. When starting the machine: • if the warning light flashes quickly once, this indicates the engine oil level is accep...

Page 29: Bs 50-4

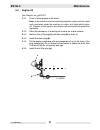

Bs 50-4 operation wc_tx000308gb.Fm 27 5.7 proper operation see graphic: wc_gr002612, wc_gr001455 keep vibratory rammer clean and dry. Avoid no-load strokes. Never allow the rammer to run full throttle when forcing away material or when lifting the equipment. For optimal control, performance, and min...

Page 30: Operation

Operation bs 50-4 wc_tx000308gb.Fm 28 5.8 proper compaction see graphic: wc_gr000045 5.8.1 run rammer at the full throttle position (a4) for maximum performance. 5.8.2 guide rammer with its handle. Allow machine to pull itself forward. Do not try to over-power the machine. 5.8.3 for best compaction,...

Page 31: Bs 50-4

Bs 50-4 maintenance wc_tx000309gb.Fm 29 6. Maintenance 6.1 periodic maintenance schedule maintenance, replacement, or repair of the emission control devices and systems may be performed by any non-road engine repair establishment or individual. Daily before starting after first 5 hours every week or...

Page 32: Maintenance

Maintenance bs 50-4 wc_tx000309gb.Fm 30 6.2 servicing air cleaner see graphic: wc_gr001306 never use gasoline or other types of low flash point solvents for cleaning the air filter. A fire or explosion could result. Caution: never run engine without main paper air cleaner (b). Severe engine damage w...

Page 33: Bs 50-4

Bs 50-4 maintenance wc_tx000309gb.Fm 31 6.3 engine oil see graphic: wc_gr002431 6.3.1 drain oil while engine is still warm. Note: in the interests of environmental protection, place a plastic sheet and a container under the machine to collect any liquid which drains off. Dispose of this liquid in ac...

Page 34: Maintenance

Maintenance bs 50-4 wc_tx000309gb.Fm 32 6.4 lubrication see graphic: wc_gr001456 ramming system check oil level: 6.4.1 place the rammer so it is resting on its shoe on a level surface. 6.4.2 check the oil level through oil sightglass (d). Proper ramming system lubrication is indicated when approxima...

Page 35: Bs 50-4

Bs 50-4 maintenance wc_tx000309gb.Fm 33 6.5 shoe hardware see graphic: wc_gr000048 on new machines, or after replacing shoe, check and tighten shoe hardware (a) after the first 5 hours of operation. Inspect hardware every week thereafter. Torque hardware as specified. 6.6 long-term storage 6.6.1 dra...

Page 36: Maintenance

Maintenance bs 50-4 wc_tx000309gb.Fm 34 6.7 transportation see graphic: wc_gr001457 6.7.1 always shut off engine and close fuel valve when transporting machine. 6.7.2 make sure lifting device has enough capacity to hold machine (see identification plate on machine for weight). 6.7.3 use central lift...

Page 37: Bs 50-4

Bs 50-4 maintenance wc_tx000309gb.Fm 35 6.8 troubleshooting problem / symptom reason / remedy engine does not start, or stalls. • no fuel in tank. • check engine oil level. • spark plug fouled. • fuel valve closed. • engine switch is in the “off” position. Engine does not accelerate, is hard to star...

Page 38: Maintenance

Maintenance bs 50-4 wc_tx000309gb.Fm 36 on machines equipped with the low oil shutoff switch, the engine starts and continues to run but the low oil warning light stays on continuously. • check the switch for proper wire connections. • switch is not functioning properly. Replace the switch. On machi...

Page 39

2006-ce-bs50-4-bs60-4-q.Fm william lahner greg orzal vice president of engineering manager, product engineering wacker corporation date / datum / fecha / date ec declaration of conformity ce-konformitÄtserklÄrung declaraciÓn de conformidad de la ce dÉclaration de conformitÉ c.E. Wacker corporation, ...

Page 40

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific operations...