- DL manuals

- Wacker Neuson

- Trowels

- CT 36

- Operator's Manual

Wacker Neuson CT 36 Operator's Manual

Summary of CT 36

Page 1

Trowel ct 36 ct 48 operator’s manual 0159226en 005 0408 0 1 5 9 2 2 6 e n.

Page 3: Ct 36 / Ct 48

Ct 36 / ct 48 table of contents 3 1. Foreword 5 2. Safety information 6 2.1 laws pertaining to spark arrestors ...................................................... 6 2.2 operating safety .................................................................................. 7 2.3 operator safety while ...

Page 4: Table of Contents

Table of contents ct 36 / ct 48 wc_bo0159226en_005toc.Fm 4 4. Maintenance 30 4.1 periodic maintenance schedule - honda ............................................30 4.2 periodic maintenance schedule - wacker ..........................................31 4.3 engine oil - honda ..........................

Page 5: Foreword

Foreword wc_tx000001gb.Fm 5 california proposition 65 warning: engine exhaust, some of its constituents, and certain vehicle components, contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. 1 foreword this manual provides informatio...

Page 6: Safety Information

Safety information ct 36 / ct 48 wc_si000139gb.Fm 6 2. Safety information this manual contains danger, warning, caution, notice and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is ...

Page 7: Ct 36 / Ct 48

Ct 36 / ct 48 safety information wc_si000139gb.Fm 7 2.2 operating safety familiarity and proper training are required for the safe operation of the machine. Machines operated improperly or by untrained personnel can be dangerous. Read the operating instructions contained in both this manual and the ...

Page 8: Safety Information

Safety information ct 36 / ct 48 wc_si000139gb.Fm 8 2.2.15 always operate machine with all safety devices and guards in place and in working order. Do not modify or defeat safety devices. Do not operate machine if any safety devices or guards are missing or inoperative. 2.2.16 always be sure operato...

Page 9: Ct 36 / Ct 48

Ct 36 / ct 48 safety information wc_si000139gb.Fm 9 2.4 service safety a poorly maintained machine can become a safety hazard! In order for the machine to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 2.4.1 do not attempt to clean ...

Page 10: Safety Information

Safety information ct 36 / ct 48 wc_si000139gb.Fm 10 2.5 label locations.

Page 11: Ct 36 / Ct 48

Ct 36 / ct 48 safety information wc_si000139gb.Fm 11 2.6 safety and information labels wacker machines use international pictorial labels where needed. These labels are described below: label meaning danger! Engines emit carbon monoxide; operate only in well-ventilated area. Read the operator’s manu...

Page 12: Safety Information

Safety information ct 36 / ct 48 wc_si000139gb.Fm 12 warning! Remove pan from trowel before lifting machine overhead. Pans can fall and cause death or serious injury if a person is hit. (located on top side of float pan.) variable speed throttle caution! Read and understand the supplied operator’s m...

Page 13: Ct 36 / Ct 48

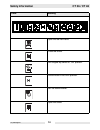

Ct 36 / ct 48 safety information wc_si000139gb.Fm 13 a nameplate listing the model number, item number, revision number, and serial number is attached to each unit. Please record the infor- mation found on this plate so it will be available should the nameplate become lost or dam- aged. When orderin...

Page 14: Safety Information

Safety information ct 36 / ct 48 wc_si000139gb.Fm 14 label meaning open the fuel flow valve. Close the choke. Turn engine key switch to “on” position. Place throttle in the idle position. Pull the rewind starter. Open the choke..

Page 15: Ct 36 / Ct 48

Ct 36 / ct 48 safety information wc_si000139gb.Fm 15 press the stop button. Turn engine key switch to “off” position. Close the fuel flow valve. Label meaning.

Page 16: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 16 3. Operation 3.1 application this trowel is a modern, high production machine intended for floating and finishing freshly poured concrete slabs. The machine's good balance, adjustable handle, and easily reached controls add to operator comfort and producti...

Page 17: Ct 36 / Ct 48

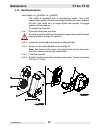

Ct 36 / ct 48 operation wc_tx000373gb.Fm 17 3.4 installing blades see graphic: wc_gr003238 there are four types of blades available for the trowels. Float pans are large "pizza pan" style blades, which hook on over finish or combination blades and are available for the 36" machines only. Float blade...

Page 18: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 18 3.5 installing and adjusting handles see graphic: wc_gr001758, wc_gr003219 on new machines the pipe handle comes assembled with the pitch control (twist or pro-shift®) (c), stop button (b), throttle (a), screws (g), and nut (m). To install the pipe handle ...

Page 19: Ct 36 / Ct 48

Ct 36 / ct 48 operation wc_tx000373gb.Fm 19 wc_gr001758 f g h j k m.

Page 20: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 20 3.6 controls see graphic: wc_gr003219 ref. Description ref. Description a throttle lever d handle height adjustment (if equipped) b stop button e foldable handle adjustment (if equipped) c twist pitch control or pro-shift® pitch control.

Page 21: Ct 36 / Ct 48

Ct 36 / ct 48 operation wc_tx000373gb.Fm 21 3.7 stop button see graphic: wc_gr003219 when the stop button (b) is pressed, the engine will shut off. To prevent uncontrolled spinning of the trowel, the engine control module is designed to shutoff the engine under certain conditions. For example, if th...

Page 22: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 22 3.9 to start - honda see graphic: wc_gr003219, wc_gr001098 3.9.1 open fuel valve by moving lever to the right (g1). Note: if engine is cold, move choke lever to closed position (i1). If engine is hot, set choke to open position (i2). 3.9.2 turn engine swit...

Page 23: Ct 36 / Ct 48

Ct 36 / ct 48 operation wc_tx000373gb.Fm 23 3.10 to stop - honda see graphic: wc_gr003219, wc_gr001098 3.10.1 reduce engine rpm to idle by moving the throttle lever to idle position (a1). 3.10.2 push the stop button (b). 3.10.3 turn engine switch to “off” (h2). 3.10.4 close fuel valve by moving leve...

Page 24: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 24 3.11 to start - wacker see graphic: wc_gr003219, wc_gr002747 3.11.1 open fuel valve by moving lever down (g1). Note: if engine is cold, move choke lever to close position (i2). If engine is hot, set choke to open position (i1). 3.11.2 turn engine switch to...

Page 25: Ct 36 / Ct 48

Ct 36 / ct 48 operation wc_tx000373gb.Fm 25 3.12 to stop - wacker see graphic:wc_gr003219, wc_gr002747 3.12.1 reduce engine rpm to idle by moving the throttle lever to idle position (a1). 3.12.2 push the stop button (b). 3.12.3 turn engine switch to “off” (h1). 3.12.4 close fuel valve (g2). G1 g2 h2...

Page 26: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 26 3.13 engine control module to prevent uncontrolled spinning of the trowel, the engine control module is designed to shutoff the engine under certain conditions. For example, if the operator loses his/her grip on the trowel, the engine control module will s...

Page 27: Ct 36 / Ct 48

Ct 36 / ct 48 operation wc_tx000373gb.Fm 27 3.14.6 to move to the right press down slightly on the handle (d). 3.14.7 clean trowel after each use to remove concrete splatter. Allow the muffler to cool before cleaning or servicing the machine. A hot muffler could ignite the fuel and start a fire. It ...

Page 28: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 28 3.15 braking system the braking system of the trowel is spring loaded. The brake is engaged anytime the input shaft of the gearbox is not rotating and/or there is no resistance placed against the blades of the trowel. The brake is released when the input s...

Page 29: Ct 36 / Ct 48

Ct 36 / ct 48 operation wc_tx000373gb.Fm 29 3.16 pitch adjustment see graphic: wc_gr003220 to adjust blade pitch (angle): a = twist pitch: turn the pitch adjusting knob (a) clockwise to increase pitch and counterclockwise to decrease pitch. B = pro-shift®: pull the handle (b) towards the operator to...

Page 30: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 30 4. Maintenance 4.1 periodic maintenance schedule - honda the chart below lists basic machine and engine maintenance. Refer to your engine operator’s manual for additional information on engine maintenance. Daily after first 20 hrs. Every 50 hrs. Every 10...

Page 31: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 31 4.2 periodic maintenance schedule - wacker the chart below lists basic machine and engine maintenance. Refer to your engine operator’s manual for additional information on engine maintenance. * perform initially after first 25 hours of operation. Mainten...

Page 32: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 32 4.3 engine oil - honda see graphic: wc_gr002381 4.3.1 drain oil while the engine is still warm. 4.3.2 remove the oil fill plug (a) and drain cap (b) to drain oil. Note: in the interests of environmental protection, place a plastic sheet and a container u...

Page 33: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 33 4.4 engine oil - wacker see graphic: wc_gr003201 4.4.1 drain oil while engine is still warm. Note: in the interests of environmental protection, place a plastic sheet and a container under the machine to collect any liquid which drains off. Dispose of th...

Page 34: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 34 4.5 air cleaner - honda see graphic: wc_gr000025 the engine is equipped with a dual element air cleaner. Service air cleaner frequently to prevent carburetor malfunction. Notice: never run engine without air cleaner. Severe engine damage will occur. Neve...

Page 35: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 35 4.6 air cleaner - wacker see graphic: wc_gr000656 never use gasoline or other types of low-flash point solvents for cleaning the air cleaner. A fire or explosion could result. Notice: never run the engine without the air cleaner. Severe engine damage wil...

Page 36: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 36 4.7 spark plug see graphic: wc_gr000028 clean or replace the spark plug as needed to ensure proper operation. Refer to your engine operator’s manual. The muffler becomes very hot during operation and remains hot for a while after stopping the engine. Do ...

Page 37: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 37 4.8 cleaning sediment cup - honda see graphic: wc_gr000029 4.8.1 turn the fuel valve off. 4.8.2 remove the sediment cup (a) and the o-ring (b). 4.8.3 wash both thoroughly in a nonflammable solvent. Dry and reinstall them. 4.8.4 turn the fuel valve on and...

Page 38: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 38 4.10 adjusting idle speed - honda see graphic: wc_gr001122 remove the drive belt before making any adjustment to the carburetor. See belt replacement. The blades will engage unless the belt is removed from the machine. Adjust engine to the no load or idl...

Page 39: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 39 4.11 carburetor adjustment - honda see graphic: wc_gr0001061 remove the drive belt before making any adjustment to the carburetor. See belt replacement. The blades will engage unless the belt is removed from the machine. The pilot screw (a) is fitted wit...

Page 40: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 40 4.12 belt replacement see graphic: wc_gr002380, wc_gr003221 the trowel is equipped with a self-adjusting clutch. This clutch automatically tightens the belt and compensates for belt wear. Replace the belt if the clutch can no longer tighten belt enough t...

Page 41: Ct 36 / Ct 48

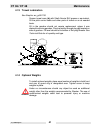

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 41 4.13 trowel lubrication see graphic: wc_gr001755 grease trowel arms (b) with shell alvania rl2 grease or equivalent. Oil the pitch control cable and other parts of trowel on an as needed basis. Oil in the gearbox should not require replacement unless it ...

Page 42: Maintenance

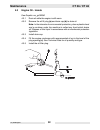

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 42 4.15 lifting see graphic: wc_gr001762 never lift the machine solely by the handle. The component may fail, causing the machine to fall, possibly injuring bystanders. See technical data for the weight of the machine. To lift the machine manually: 4.15.1 s...

Page 43: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 43.

Page 44: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 44 4.16 storage if trowel is being stored for more than 30 days: • change engine oil. • drain fuel from engine. • remove spark plug and pour 15 ml (½ ounce) of sae 30 engine oil into the cylinder. Replace spark plug and crank engine to distribute oil. Refer...

Page 45: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 45 4.17 troubleshooting problem / symptom reason / remedy trowel does not develop full speed. • remove deposits built up in engine cylinder and engine head. • engine speed too low. Adjust speed. • clean or replace air filter. • clean debris from moving part...

Page 46: Technical Data

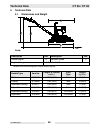

Technical data ct 36 / ct 48 wc_td000141gb.Fm 46 5. Technical data 5.1 dimensions and weight guide *models without letter designation feature wacker engines. Description ref. Description ref. Honda engine* a variable speed v engine horsepower 4, 5, 6, 8, 9, 11, 13 handle type item no. Length of hand...

Page 47: Ct 36 / Ct 48

Ct 36 / ct 48 technical data wc_td000141gb.Fm 47 without handle with handle model item no. L 1 x w x h 1 mm (in.) l 2 x w x h 2 mm (in.) without weight kit kg (lbs.) with weight kit kg (lbs.) ct 36-5a 0009438 0620106 915x915x607 (36x36x24) 2005x915x1040 (79x36x41) 85 (183) 91 (201) ct 36-6 0009443 9...

Page 48: Technical Data

Technical data ct 36 / ct 48 wc_td000141gb.Fm 48 5.2 engine 5.2.1 engine power rating net power rating per sae j1349. Actual power output may vary due to conditions of specific use. Item no. Ct 36-5a 0009438, 0620106 ct 36-6 0009443 engine engine make honda wacker engine model gx 160 k1 qx2 wm170 ra...

Page 49: Ct 36 / Ct 48

Ct 36 / ct 48 technical data wc_td000141gb.Fm 49 item no. Ct 36-8a 0009439 ct 36-8a-v 0009442 ct36-9 0009444 ct 36-9-v 0009447 engine engine make honda wacker engine model gx 240 k1 qa wm270 rated power kw (hp) 6.2 (8.3) @ 3800 rpm 6.5 (8.7) @ 3800 rpm spark plug ngk bpr 6es ngk br6hs champion rl86c...

Page 50: Technical Data

Technical data ct 36 / ct 48 wc_td000141gb.Fm 50 item no. Ct 48a-8a 0009449 ct 48-9 0009453 engine engine make honda wacker engine model gx 240 k1 qa wm270 rated power kw (hp) 6.2 (8.3) @ 3800 rpm 6.5 (8.7) @ 3800 rpm spark plug ngk bpr 6es ngk br6hs champion rl86c electrode gap mm (in.) 0.7 – 0.8 (...

Page 51: Ct 36 / Ct 48

Ct 36 / ct 48 technical data wc_td000141gb.Fm 51 item no. Ct 48-11a 0009450 ct 48-13a-v 0009452 engine engine make honda engine model gx 340 k1 qa gx 390 u1 qa rated power kw (hp) 8.7 (11.6) @ 3800 rpm 10 (13.4) @ 3800 rpm spark plug ngk bpr 6es electrode gap mm (in.) 0.7 – 0.8 (0.028 – 0.031) engin...

Page 52: Technical Data

Technical data ct 36 / ct 48 wc_td000141gb.Fm 52 5.3 trowel *trowel blades must not be interchanged, i.E., do not put larger diameter blades on a smaller diameter trowel. Model item no. Trowel diameter* mm (in.) number of blades gear box lubrication type/ml (oz.) speed range rpm pitch range degrees ...

Page 53: Ct 36 / Ct 48

Ct 36 / ct 48 technical data wc_td000141gb.Fm 53 5.4 sound and vibration data the required sound specification, paragraph 1.7.4.F of 89/392/eec machinery directive, is: • the sound pressure level at operator’s location (l pa ) : "a" db(a) • the guaranteed sound power level (l wa ) = "b" db(a) these ...

Page 55

Aem_concretepowertrowel.Qxd 7/23/03 6:31 am page 1.

Page 56: Word of Explanation

Safety alert symbol this safety alert symbol means attention is required! The safety alert symbol identifies important safety messages on machines, safety signs, in manuals or elsewhere. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in the...

Page 57: Table of Contents

3 table of contents page word of explanation ................................................................2 foreword ........................................................................................4 a word to the user ....................................................................5 f...

Page 58: A Word to The User

Remember that you are the key to safety. Good safety practices not only protect you but also protect the people around you. It is your responsibility to study this manual and the manufacturer’s manual(s) for your specific machine before operating your machine. Make them a working part of your safety...

Page 59: Prepare For Safe Operation

Learn to be safe • read the operator’s manual. If one has not been provided, get one and study it before operating the equipment. • learn the location and understand the functions of all controls before attempting to operate the equipment. • know the meaning of all identification symbols on the cont...

Page 60: Prepare For Safe Operation

Fire prevention always stop the engine and allow it to cool before refueling. Never refuel – • when engine is running • near open flame or sparks • while smoking • in poorly ventilated areas never overfill fuel tanks or fluid reservoirs. In the event of a fuel spill, do not attempt to start the engi...

Page 61: Start Safely

Start correctly – start safely before starting, check for proper functioning of all operation and shutdown controls. Check all controls to be sure they are in the correct startup position. Know the proper starting procedure for your trowel. Follow the manufacturer’s operational instructions. Walk-be...

Page 62: Work Safely

Safe working procedures danger – carbon monoxide exhaust from the engine contains poisonous carbon monoxide gas that is not easily detected as it is colorless and odorless. Exposure to carbon monoxide can cause loss of consciousness and may lead to death! Do not operate your trowel indoors or in an ...

Page 63: Shut Down Safely

Shut down procedures never disable or disconnect the safety devices! Always close fuel valves when the machine is not being used. Refer to the manufacturer’s manuals for specific shut down procedures. 15 shut down safely trowel.Qxd 11/24/04 10:18 am page 15 precautions • power trowels are heavy and ...

Page 64: Perform Maintenance Safely

Service and maintenance safety poorly maintained equipment can become a safety hazard! In order for your trowel to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. Do not attempt to clean, service, or perform adjustments on the trowel...

Page 65: Perform Maintenance Safely

Fire prevention avoid fire hazards. Always stop the engine and allow it to cool before you refuel the trowel. Do not refuel while smoking or near open flame or sparks. Never overfill fuel tanks or fluid reservoirs. Remove all trash or debris. Make sure oily rags or other flammable materials are not ...

Page 66: Perform Maintenance Safely

Trowel blades and pans • do not attempt to clean, service or perform adjustments on the trowel while it is running. • do not remove while the trowel is hanging overhead. Always support the trowel securely on a flat, level surface before changing blades or pans. • always handle blades and pans carefu...

Page 67: A Final Word to The User

Remember that you are the key to safety. Good safety practices not only protect you but protect the people around you. You have read this safety manual and the manufacturer’s manual(s) for your specific trowel. Make them a working part of your safety program. Keep in mind that this safety manual is ...

Page 68

Aem_concretepowertrowel.Qxd 7/23/03 6:31 am page 1.

Page 69

2006-ce-ct36_48-q.Fm william lahner robert motl vice president of engineering manager, product engineering wacker corporation date / datum / fecha / date ec declaration of conformity ce-konformitÄtserklÄrung declaraciÓn de conformidad de la ce dÉclaration de conformitÉ c.E. Wacker corporation, n92 w...

Page 70

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific operations...