- DL manuals

- Wacker Neuson

- Trowels

- CT 36

- Repair Manual

Wacker Neuson CT 36 Repair Manual

Summary of CT 36

Page 1

Www.Wackergroup.Com walk-behind trowels ct 36 ct 48 repair manual 0163091en 003 1007 0 1 6 3 0 9 1 e n.

Page 3: Ct Repair

Ct repair foreword wc_tx000550gb.Fm 3 operating / parts information you must be familiar with the operation of this machine before you attempt to troubleshoot or make any repairs to it. Basic operating and maintenance procedures are described in the operator’s / parts manual supplied with the machin...

Page 4: Ct Repair

Ct repair foreword wc_tx000550gb.Fm 4 this manual provides information and procedures to safely operate and maintain this wacker model. For your own safety and protection from injury, carefully read, understand and observe the safety instructions described in this manual. Keep this manual or a copy ...

Page 5: Ct Repair

Ct repair table of contents 5 1. Safety information 8 1.1 laws pertaining to spark arrestors ...................................................... 8 1.2 operating safety .................................................................................. 9 1.3 operator safety while using internal com...

Page 6: Table of Contents

Table of contents ct repair wc_br0163091en_003toc.Fm 6 4. Maintenance 40 4.1 periodic maintenance schedule - honda ............................................40 4.2 periodic maintenance schedule - wacker ..........................................41 4.3 engine oil - honda ..............................

Page 7: Ct Repair

Ct repair table of contents 7 7. Spider 78 7.1 spider assembly—exploded view ..................................................... 78 7.2 spider assembly—components ........................................................ 79 7.3 replacing the blades .....................................................

Page 8: Safety Information

Safety information ct 36 / ct 48 wc_si000139gb.Fm 8 1. Safety information this manual contains danger, warning, caution, noticeand note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is u...

Page 9: Ct 36 / Ct 48

Ct 36 / ct 48 safety information wc_si000139gb.Fm 9 1.2 operating safety familiarity and proper training are required for the safe operation of machine. Machines operated improperly or by untrained personnel can be dangerous. Read the operating instructions contained in both this manual and the engi...

Page 10: Safety Information

Safety information ct 36 / ct 48 wc_si000139gb.Fm 10 1.2.15 always operate machine with all safety devices and guards in place and in working order. Do not modify or defeat safety devices. Do not operate machine if any safety devices or guards are missing or inoperative. 1.2.16 always be sure operat...

Page 11: Ct 36 / Ct 48

Ct 36 / ct 48 safety information wc_si000139gb.Fm 11 1.4 service safety poorly maintained machines can become a safety hazard! In order for the machine to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 1.4.1 do not attempt to clean ...

Page 12: Safety Information

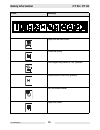

Safety information ct 36 / ct 48 wc_si000139gb.Fm 12 1.5 label locations.

Page 13: Ct 36 / Ct 48

Ct 36 / ct 48 safety information wc_si000139gb.Fm 13 1.6 safety and information labels wacker machines use international pictorial labels where needed. These labels are described below: label meaning danger! Engines emit carbon monoxide; operate only in well-ventilated area. Read the operator’s manu...

Page 14: Safety Information

Safety information ct 36 / ct 48 wc_si000139gb.Fm 14 warning! Remove pan from trowel before lifting machine overhead. Pans can fall and cause death or serious injury if a person is hit. (located on top side of float pan.) variable speed throttle caution! Read and understand the supplied operator’s m...

Page 15: Ct 36 / Ct 48

Ct 36 / ct 48 safety information wc_si000139gb.Fm 15 a nameplate listing the model number, item number, revision number, and serial number is attached to each unit. Please record the infor- mation found on this plate so it will be available should the nameplate become lost or dam- aged. When orderin...

Page 16: Safety Information

Safety information ct 36 / ct 48 wc_si000139gb.Fm 16 label meaning open the fuel flow valve. Close the choke. Turn engine key switch to “on” position. Place throttle in the idle position. Pull the rewind starter. Open the choke..

Page 17: Ct 36 / Ct 48

Ct 36 / ct 48 safety information wc_si000139gb.Fm 17 press the stop button. Turn engine key switch to “off” position. Close the fuel flow valve. Label meaning.

Page 18: Technical Data

Technical data ct 36 / ct 48 wc_td000141gb.Fm 18 2. Technical data 2.1 dimensions and weight guide *standard models feature wacker engine. Description ref. Description ref. Honda engine* a variable speed v engine horse power 4, 5, 6, 8, 9, 11, 13 handle type item no. L mm(in.) pitch type weight kg (...

Page 19: Ct 36 / Ct 48

Ct 36 / ct 48 technical data wc_td000141gb.Fm 19 without handle with handle model item no. Lxwxh mm (in.) lxwxh mm (in.) without weight kit kg (lbs.) with weight kit kg (lbs.) ct 36-5a 0009438 0620106 915x915x607 (36x36x24) 2005x915x1040 (79x36x41) 85 (183) 91 (201) ct 36-6 0009443 915x915x607 (36x3...

Page 20: Technical Data

Technical data ct 36 / ct 48 wc_td000141gb.Fm 20 2.2 engine item no. Ct 36-5a 0009438, 0620106 ct 36-6 0009443 engine engine make honda wacker engine model gx 160 k1 qx2 wm170 rated power kw (hp) 4.3 (5.7) @ 3800rpm 4.2 (5.6) @ 3800 rpm spark plug ngk bpr 6es ngk br6hs champion rl86c electrode gap m...

Page 21: Ct 36 / Ct 48

Ct 36 / ct 48 technical data wc_td000141gb.Fm 21 item no. Ct 36-8a 0009439 ct 36-8a-v 0009442 ct36-9 0009444 ct 36-9-v 0009447 engine engine make honda wacker engine model gx 240 k1 qa wm270 rated power kw (hp) 6.2 (8.3) @ 3800 rpm 6.5 (8.7) @ 3800 rpm spark plug ngk bpr 6es ngk br6hs champion rl86c...

Page 22: Technical Data

Technical data ct 36 / ct 48 wc_td000141gb.Fm 22 item no. Ct 48a-8a 0009449 ct 48-9 0009453 engine engine make honda wacker engine model gx 240 k1 qa wm270 rated power kw (hp) 6.2 (8.3) @ 3800 rpm 6.5 (8.7) @ 3800 rpm spark plug ngk bpr 6es ngk br6hs champion rl86c electrode gap mm (in.) 0.7 – 0.8 (...

Page 23: Ct 36 / Ct 48

Ct 36 / ct 48 technical data wc_td000141gb.Fm 23 item no. Ct 48-11a 0009450 ct 48-13a-v 0009452 engine engine make honda engine model gx 340 k1 qa gx 390 u1 qa rated power kw (hp) 8.7 (11.6) @ 3800 rpm 10 (13.4) @ 3800 rpm spark plug ngk bpr 6es electrode gap mm (in.) 0.7 – 0.8 (0.028 – 0.031) engin...

Page 24: Technical Data

Technical data ct 36 / ct 48 wc_td000141gb.Fm 24 2.3 trowel *trowel blades must not be interchanged, i.E., do not put larger diameter blades on a smaller diameter trowel. Model item no. Trowel diameter* mm (in.) number of blades gear box lubrication type/ml (oz.) speed range rpm pitch range degrees ...

Page 25: Ct 36 / Ct 48

Ct 36 / ct 48 technical data wc_td000141gb.Fm 25 2.4 sound and vibration data the required sound specification, paragraph 1.7.4.F of 89/392/eec machinery directive, is: • the sound pressure level at operator’s location (l pa ) : “a” db(a) • the guaranteed sound power level (l wa ) = “b” db(a) these ...

Page 26: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 26 3. Operation 3.1 application this trowel is a modern, high production machine intended for floating and finishing freshly poured concrete slabs. The machine's good balance, adjustable handle, and easily reached controls add to operator comfort and producti...

Page 27: Ct 36 / Ct 48

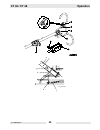

Ct 36 / ct 48 operation wc_tx000373gb.Fm 27 3.4 installing blades see graphic: wc_gr003238 there are four types of blades available for the trowels. Float pans are large "pizza pan" style blades, which hook on over finish or combination blades and are available for the 36" machines only. Float blade...

Page 28: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 28 3.5 installing and adjusting handles see graphic: wc_gr001758, wc_gr003219 on new machines the pipe handle comes assembled with the pitch control (twist or pro-shift®) (c), stop button (b), throttle (a), screws (g), and nut (m). To install the pipe handle ...

Page 29: Ct 36 / Ct 48

Ct 36 / ct 48 operation wc_tx000373gb.Fm 29 wc_gr001758 e f g h j k.

Page 30: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 30 3.6 controls see graphic: wc_gr003219 ref. Description ref. Description a throttle lever d handle height adjustment (if equipped) b stop button e foldable handle adjustment (if equipped) c twist pitch control or pro-shift® pitch control.

Page 31: Ct 36 / Ct 48

Ct 36 / ct 48 operation wc_tx000373gb.Fm 31 3.7 stop button see graphic: wc_gr003219 when the stop button (b) is pressed, the engine will shut off. To prevent uncontrolled spinning of the trowel, the engine control module is designed to shutoff the engine under certain conditions. For example, if th...

Page 32: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 32 3.9 to start - honda see graphic: wc_gr003219, wc_gr001098 3.9.1 open fuel valve by moving lever to the right (g1). Note: if engine is cold, move choke lever to closed position (i1). If engine is hot, set choke to open position (i2). 3.9.2 turn engine swit...

Page 33: Ct 36 / Ct 48

Ct 36 / ct 48 operation wc_tx000373gb.Fm 33 3.10 to stop - honda see graphic: wc_gr003219, wc_gr001098 3.10.1 reduce engine rpm to idle by moving the throttle lever to idle position (a1). 3.10.2 push the stop button (b). 3.10.3 turn engine switch to “off” (h2). 3.10.4 close fuel valve by moving leve...

Page 34: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 34 3.11 to start - wacker see graphic: wc_gr003219, wc_gr002747 3.11.1 open fuel valve by moving lever down (g1). Note: if engine is cold, move choke lever to close position (i2). If engine is hot, set choke to open position (i1). 3.11.2 turn engine switch to...

Page 35: Ct 36 / Ct 48

Ct 36 / ct 48 operation wc_tx000373gb.Fm 35 3.12 to stop - wacker see graphic:wc_gr003219, wc_gr002747 3.12.1 reduce engine rpm to idle by moving the throttle lever to idle position (a1). 3.12.2 push the stop button (b). 3.12.3 turn engine switch to “off” (h1). 3.12.4 close fuel valve (g2). G1 g2 h2...

Page 36: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 36 3.13 engine control module to prevent uncontrolled spinning of the trowel, the engine control module is designed to shutoff the engine under certain conditions. For example, if the operator loses his/her grip on the trowel, the engine control module will s...

Page 37: Ct 36 / Ct 48

Ct 36 / ct 48 operation wc_tx000373gb.Fm 37 3.14.6 to move to the right press down slightly on the handle (d). 3.14.7 clean trowel after each use to remove concrete splatter. Allow the muffler to cool before cleaning or servicing the machine. A hot muffler could ignite the fuel and start a fire. It ...

Page 38: Operation

Operation ct 36 / ct 48 wc_tx000373gb.Fm 38 3.15 braking system the braking system of the trowel is spring loaded. The brake is engaged anytime the input shaft of the gearbox is not rotating and/or there is no resistance placed against the blades of the trowel. The brake is released when the input s...

Page 39: Ct 36 / Ct 48

Ct 36 / ct 48 operation wc_tx000373gb.Fm 39 3.16 pitch adjustment see graphic: wc_gr003220 to adjust blade pitch (angle): a = twist pitch: turn the pitch adjusting knob (a) clockwise to increase pitch and counterclockwise to decrease pitch. B = pro-shift®: pull the handle (b) towards the operator to...

Page 40: Maintenance

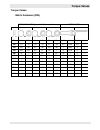

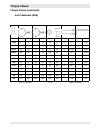

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 40 4. Maintenance 4.1 periodic maintenance schedule - honda the chart below lists basic machine and engine maintenance. Refer to the engine manufacturer’s operator’s manual for additional information on engine maintenance. Daily after first 20 hrs. Every 50...

Page 41: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 41 4.2 periodic maintenance schedule - wacker the chart below lists basic machine and engine maintenance. Refer to the engine manufacturer’s operator’s manual for additional information on engine maintenance. * perform initially after first 20 hours of oper...

Page 42: Maintenance

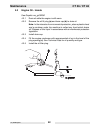

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 42 4.3 engine oil - honda see graphic: wc_gr002381 4.3.1 drain oil while the engine is still warm. 4.3.2 remove the oil fill plug (a) and drain cap (b) to drain oil. Note: in the interests of environmental protection, place a plastic sheet and a container u...

Page 43: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 43 4.4 engine oil - wacker see graphic: wc_gr003201 4.4.1 drain oil while engine is still warm. Note: in the interests of environmental protection, place a plastic sheet and a container under the machine to collect any liquid which drains off. Dispose of th...

Page 44: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 44 4.5 air cleaner - honda see graphic: wc_gr000025 the engine is equipped with a dual element air cleaner. Service air cleaner frequently to prevent carburetor malfunction. Notice: never run engine without air cleaner. Severe engine damage will occur. Neve...

Page 45: Ct 36 / Ct 48

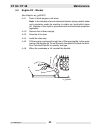

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 45 4.6 air cleaner - wacker see graphic: wc_gr000656 never use gasoline or other types of low flash point solvents for cleaning the air cleaner. A fire or explosion could result. Notice: never run engine without air cleaner. Severe engine damage will occur....

Page 46: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 46 4.7 spark plug see graphic: wc_gr000028 clean or replace the spark plug as needed to ensure proper operation. Refer to the engine owner’s manual. The muffler becomes very hot during operation and remains hot for a while after stopping the engine. Do not ...

Page 47: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 47 4.8 cleaning sediment cup - honda see graphic: wc_gr000029 4.8.1 turn the fuel valve off. 4.8.2 remove the sediment cup (a) and the o-ring (b). 4.8.3 wash both thoroughly in a nonflammable solvent. Dry and reinstall them. 4.8.4 turn the fuel valve on and...

Page 48: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 48 4.10 adjusting idle speed - honda see graphic: wc_gr001122 remove the drive belt before making any adjustment to the carburetor. See belt replacement. The blades will engage unless the belt is removed from the machine. Adjust engine to the no load or idl...

Page 49: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 49 4.11 carburetor adjustment - honda see graphic: wc_gr0001061 remove the drive belt before making any adjustment to the carburetor. See belt replacement. The blades will engage unless the belt is removed from the machine. The pilot screw (a) is fitted wit...

Page 50: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 50 4.12 belt replacement see graphic: wc_gr002380, wc_gr003221 the trowel is equipped with a self-adjusting clutch. This clutch automatically tightens the belt and compensates for belt wear. Replace the belt if the clutch can no longer tighten belt enough t...

Page 51: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 51 4.13 trowel lubrication see graphic: wc_gr001755 grease trowel arms (b) with shell alvania rl2 grease or equivalent. Oil the pitch control cable and other parts of trowel on an as needed basis. Oil in the gearbox should not require replacement unless it ...

Page 52: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 52 4.15 lifting see graphic: wc_gr001762 never lift the machine solely by the handle. The component may fail, causing the machine to fall, possibly injuring bystanders. See technical data for the weight of the machine. To lift the machine manually: 4.15.1 s...

Page 53: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 53.

Page 54: Maintenance

Maintenance ct 36 / ct 48 wc_tx000374gb.Fm 54 4.16 storage if trowel is being stored for more than 30 days: • change engine oil. • drain fuel from engine. • remove spark plug and pour 15 ml (½ ounce) of sae 30 engine oil into the cylinder. Replace spark plug and crank engine to distribute oil. Refer...

Page 55: Ct 36 / Ct 48

Ct 36 / ct 48 maintenance wc_tx000374gb.Fm 55 4.17 troubleshooting problem / symptom reason / remedy trowel does not develop full speed. • remove deposits built up in engine cylinder and engine head. • engine speed too low. Adjust speed. • clean or replace air filter. • clean debris from moving part...

Page 56: Guide Handle

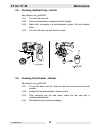

Guide handle ct repair wc_tx000551gb.Fm 56 5. Guide handle 5.1 replacing the throttle cable see graphic: wc_gr003362 disassembly: 5.1.1 remove the engine air cleaner (d) if necessary to gain access to the throttle cable at the engine. Unclamp the throttle cable from the throttle casing clamp (g). 5....

Page 57: Ct Repair

Ct repair guide handle wc_tx000551gb.Fm 57 wc_gr003362 honda honda wacker d a c b f e g f e g f e g.

Page 58: Guide Handle

Guide handle ct repair wc_tx000551gb.Fm 58 5.2 adjusting the throttle lever see graphic: wc_gr003361 the throttle lever is used to vary the speed of the engine and to control the rpm of the trowel blades to meet specific applications and job conditions. 5.2.1 be sure the engine’s throttle control ca...

Page 59: Ct Repair

Ct repair guide handle wc_tx000551gb.Fm 59 wc_gr003361 1 2 a e d c b.

Page 60: Guide Handle

Guide handle ct repair wc_tx000551gb.Fm 60 5.3 upper handle/twist pitch control—exploded view ! ! ' # $ " " # ! ' & % ! & % $ $.

Page 61: Ct Repair

Ct repair guide handle wc_tx000551gb.Fm 61 5.4 upper handle/twist pitch control—components ref. Description ref. Description 1 handle 13 pin 3 push button switch 14 retaining ring 4 nut 15 spring 5 bearing holder 16 ball 6 wiring harness 17 tie cable 7 cable 18 hex head screw 8 throttle cable 19 hex...

Page 62: Guide Handle

Guide handle ct repair wc_tx000551gb.Fm 62 5.5 replacing the upper handle see graphic: wc_gr003360 disassembly: 5.5.1 remove the throttle lever (a) and the throttle cable from the upper handle. See section replacing the throttle cable. 5.5.2 disconnect and remove the stop switch (b). See section rep...

Page 63: Ct Repair

Ct repair guide handle wc_tx000551gb.Fm 63 wc_gr003360 a d f b h g c d e.

Page 64: Guide Handle

Guide handle ct repair wc_tx000551gb.Fm 64 5.6 replacing the twist pitch control cable see graphic: wc_gr003363 disassembly: 5.6.1 remove the upper handle. See section replacing the upper handle. 5.6.2 remove the hex head screw (a) from the handle and the socket head screw (b) from the underside of ...

Page 65: Ct Repair

Ct repair guide handle wc_tx000551gb.Fm 65 wc_gr003363 g a d e b f c.

Page 66: Guide Handle

Guide handle ct repair wc_tx000551gb.Fm 66 5.7 replacing the lower handle see graphic: wc_gr003156 disassembly: 5.7.1 remove the upper handle. See section replacing the upper handle. 5.7.2 remove the two locknuts (80) and washers (73) from the screws (60). 5.7.3 pull the lower handle (17) from the g...

Page 67: Ct Repair

Ct repair guide handle wc_tx000551gb.Fm 67 5.8 replacing the stop switch see graphic: wc_gr003371 to replace the stop screw (a), carry out the following procedures: removal: 5.8.1 remove the protective boot (b). 5.8.2 disconnect the wire (c). 5.8.3 unthread the stop switch from the handle. Installat...

Page 68: Guide Handle

Guide handle ct repair wc_tx000551gb.Fm 68 notes.

Page 69: Ct Repair

Ct repair clutch wc_tx000552gb.Fm 69 6. Clutch 6.1 replacing the drive belt see graphic: wc_gr003153 and wc_gr003382 the trowel is equipped with the standard self-adjusting clutch or a variable speed clutch. Replace the belt if the clutch can no longer tighten the belt enough to engage the gearbox w...

Page 70: Clutch

Clutch ct repair wc_tx000552gb.Fm 70 6.2 drive belt—standard clutch ref. Description ref. Description 3 beltguard 53 hex head screw 4 beltguard plate 54 hex head screw 23 clutch assembly 69 fender washer 24 pulley 70 flat steel washer 26 v-belt 72 washer 36 spacer 82 key 50 screw 84 key (square) 51 ...

Page 71: Ct Repair

Ct repair clutch wc_tx000552gb.Fm 71 6.3 drive belt—variable speed clutch ref. Description ref. Description 3 upper belt guard 58 hex head screw 4 beltguard plate 69 fender washer 23 clutch 70 washer 24 clutch pulley 71 washer 26 belt 84 key 36 spacer 127 lower beltguard 51 screw 132 key 53 hex head...

Page 72: Clutch

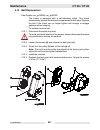

Clutch ct repair wc_tx000552gb.Fm 72 6.4 replacing the standard clutch see graphic: wc_gr003153, wc_gr002068 removal: 6.4.1 remove the drive belt as described in section replacing the drive belt. 6.4.2 remove the screw (51) and the washer (72) that secure the clutch assembly (23) to the crankshaft. ...

Page 73: Ct Repair

Ct repair clutch wc_tx000552gb.Fm 73 6.5 standard clutch—exploded view ref. Description ref. Description 1 clutch assembly (incl. 2–8) 5 clutch shoe 2 setscrew 6 ball bearing 3 clutch plate 7 clutch drum 4 spring 8 clutch pulley wc_gr002068 2 3 4 5 7 6 8 1.

Page 74: Clutch

Clutch ct repair wc_tx000552gb.Fm 74 6.6 standard clutch overhaul see graphic: wc_gr002068 and wc_gr003364 this procedure requires a propane torch or similar heating device. Disassembly: 6.6.1 remove the setscrew (2). Slide the clutch plate (3) off of the clutch pulley shaft (8). 6.6.2 remove and in...

Page 75: Ct Repair

Ct repair clutch wc_tx000552gb.Fm 75 wc_gr003364 a b wc_gr002068 2 3 4 5 7 6 8 1.

Page 76: Clutch

Clutch ct repair wc_tx000552gb.Fm 76 6.7 replacing the variable speed clutch see graphic: wc_gr003383, wc_gr002068 removal: 6.7.1 remove the drive belt. See section replacing the drive belt. 6.7.2 remove the bolt (51) that secures the clutch (23) to the engine drive shaft and slide the clutch from t...

Page 77: Ct Repair

Ct repair clutch wc_tx000552gb.Fm 77 81 4 50 23 84 74 51 3 36 71 24 132 26 70 58 69 53 127 wc_gr003383.

Page 78: Spider

Spider ct repair wc_tx000553gb.Fm 78 7. Spider 7.1 spider assembly—exploded view.

Page 79: Ct Repair

Ct repair spider wc_tx000553gb.Fm 79 7.2 spider assembly—components ref. Description ref. Description 8 spider 47 cotter pin 9 blade lift ring 55 hex head screw 10 bearing holder 57 hex head screw 11 tube 59 lifting bolt 12 yoke 61 setscrew 13 link 62 screw 14 eccentric adjuster 64 screw 27 bearing ...

Page 80: Spider

Spider ct repair wc_tx000553gb.Fm 80 7.3 replacing the blades see graphic: wc_gr003365 if any blade requires replacement, replace all the blades. The blades can become extremely sharp. Use great care when replacing the blades. Disconnect or remove the spark plug to avoid accidentally starting the en...

Page 81: Ct Repair

Ct repair spider wc_tx000553gb.Fm 81 wc_gr003365 a b.

Page 82: Spider

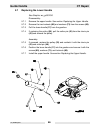

Spider ct repair wc_tx000553gb.Fm 82 7.4 replacing the arms see graphic: wc_gr003356 the blades can become extremely sharp. Use great care when replacing the blades. Disconnect or remove the spark plug to avoid accidentally starting the engine when turning the trowel blades. Removal: 7.4.1 remove th...

Page 83: Ct Repair

Ct repair spider wc_tx000553gb.Fm 83 wc_gr003356 a b c e d x x x x x x 180˚ g f i h.

Page 84: Spider

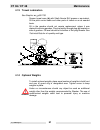

Spider ct repair wc_tx000553gb.Fm 84 7.5 balancing the blade pitch see graphic: wc_gr003357 to prevent wobble and for optimum performance balance the blade pitch. Carry out the following procedures whenever the blades or any of the arms have been replaced, or if the trowel is not performing as it sh...

Page 85: Ct Repair

Ct repair spider wc_tx000553gb.Fm 85 wc_gr003357 x a c d b 1 2 3 4.

Page 86: Spider

Spider ct repair wc_tx000553gb.Fm 86 7.6 removing the spider see graphic: wc_gr003154 disconnect or remove the spark plug to avoid accidentally starting the engine when turning the trowel blades. See section engine wiring. This procedure requires an appropriate hoist or crane to lift the trowel. 7.6...

Page 87: Ct Repair

Ct repair spider wc_tx000553gb.Fm 87.

Page 88: Spider

Spider ct repair wc_tx000553gb.Fm 88 7.7 installing the spider see graphic: wc_gr003154 7.7.1 install the setscrews (61) into the spider so that all but one thread is threaded into the spider. 7.7.2 apply alvania #2 or equivalent to the grease fittings (41) and install them into the spider. 7.7.3 co...

Page 89: Ct Repair

Ct repair spider wc_tx000553gb.Fm 89.

Page 90: Spider

Spider ct repair wc_tx000553gb.Fm 90 7.8 rebuilding the lift ring assembly see graphic: wc_gr003358 inspect the lift ring assembly for wear or damage. Replace any damaged or worm component. This procedure requires an arbor or similar press. Disassembly: 7.8.1 remove the retaining ring (88). 7.8.2 pr...

Page 91: Ct Repair

Ct repair spider wc_tx000553gb.Fm 91 wc_gr003358 88 28 28 10 10 11 59 9 9 27 27.

Page 92: Drivetrain

Drivetrain ct repair wc_tx000554gb.Fm 92 8. Drivetrain 8.1 drivetrain—exploded view a.

Page 93: Ct Repair

Ct repair drivetrain wc_tx000554gb.Fm 93 8.2 drivetrain—components ref. Description ref. Description 1 guard ring 68 lockwasher 4 beltguard plate 73 flat washer 36 spacer 76 flat washer 37 engine control module (gyro switch) 78 locknut 49 stud 79 locknut 50 screw 98 oil drain fitting 52 pan head scr...

Page 94: Drivetrain

Drivetrain ct repair wc_tx000554gb.Fm 94 8.3 engine removal see graphic: wc_gr003155 8.3.1 to gain access to the throttle cable at the engine, remove the air cleaner. Then, disconnect the throttle cable from the engine throttle bracket. See section replacing the throttle cable. 8.3.2 cut the tie-wra...

Page 95: Ct Repair

Ct repair drivetrain wc_tx000554gb.Fm 95 a.

Page 96: Drivetrain

Drivetrain ct repair wc_tx000554gb.Fm 96 8.4 engine installation see graphic: wc_gr003155 8.4.1 align the engine with the engine studs on the guard ring. Place the washer (73) and the ring terminal of the engine control module (gyro switch) (37) over the engine stud. Place the washers (68) over all ...

Page 97: Ct Repair

Ct repair drivetrain wc_tx000554gb.Fm 97 a.

Page 98: Drivetrain

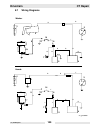

Drivetrain ct repair wc_tx000554gb.Fm 98 8.5 engine wiring 3 4 5 11 10 10 10 10 12 12 13 7 6 b b b g g g g b y y y 3 4 5 7 6 b b b b b y y or or 3 4 5 7 6 b b b b y y y 3 4 5 7 6 b b b b b y y or or wc_gr003370 2 2 2 2 6 8 9 14 9 g y y y g.

Page 99: Ct Repair

Ct repair drivetrain wc_tx000554gb.Fm 99 8.6 engine wiring components see graphic: wc_gr003369 and wc_gr003370 * used on newer machines. On older machines, the handle serves as the connection to ground. Ref. Description ref. Description 1 spark plug 8 handle 2 ignition module 9 handle ground wire* 3...

Page 100: Drivetrain

Drivetrain ct repair wc_tx000554gb.Fm 100 8.7 wiring diagrams b/w or or y b b b b b b y y y g g b b b y b b b wacker 1 1 2 2 3 3 4 4 5 5 14 6 7 14 8 honda 7 9 10 8 wc_gr003369 g g 9 10 6.

Page 101: Ct Repair

Ct repair drivetrain wc_tx000554gb.Fm 101 8.8 engine wiring components see graphic: wc_gr003369 and wc_gr003370 * used on newer machines. On older machines, the handle serves as the connection to ground. Ref. Description ref. Description 1 spark plug 8 handle 2 ignition module 9 handle ground wire* ...

Page 102: Drivetrain

Drivetrain ct repair wc_tx000554gb.Fm 102 8.9 replacing the gearbox see graphic: wc_gr003359 removal: 8.9.1 remove the handle. See section replacing the lower handle. 8.9.2 remove the spider. See section removing the spider. 8.9.3 remove the clutch as described in section replacing the standard clut...

Page 103: Ct Repair

Ct repair drivetrain wc_tx000554gb.Fm 103 wc_gr003359.

Page 104: Drivetrain

Drivetrain ct repair wc_tx000554gb.Fm 104 8.10 gearbox—exploded view wc_gr003367 93 94 1.

Page 105: Ct Repair

Ct repair drivetrain wc_tx000554gb.Fm 105 8.11 gearbox—components ref. Description ref. Description 1 gearbox complete 35 spacer 5 gearbox 38 relief valve 6 gearbox cover 39 plug (threaded) 7 gearbox cover 54 hex head screw 18 worm gear 82 key 19 input shaft 83 key 20 output shaft 86 key (square) 21...

Page 106: Drivetrain

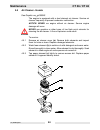

Drivetrain ct repair wc_tx000554gb.Fm 106 8.12 gearbox disassembly see graphic: wc_gr003157 and wc_gr003366 there are two very similar gearboxes used on ct trowels. Early versions used a cup-and-cone–style brake (a), later versions a disc- type brake (b). Any differences in the procedures to rebuild...

Page 107: Ct Repair

Ct repair drivetrain wc_tx000554gb.Fm 107 20 e f 29a 29b 18 6 89 d c 29a 33 87 wc_gr003157.

Page 108: Drivetrain

Drivetrain ct repair wc_tx000554gb.Fm 108 8.12.10 remove the screws (54) from the side cover (7) and remove the side cover. Inspect the o-ring (90) and replace it if it is worn. 8.12.11 for gearboxes with cup-and-cone–style brakes (a), press the brake cup (22) from the side cover using a hydraulic p...

Page 109: Ct Repair

Ct repair drivetrain wc_tx000554gb.Fm 109 b a 19 29 35 32 wc_gr003366 93 94 22 94 29 30 30 g h.

Page 110: Drivetrain

Drivetrain ct repair wc_tx000554gb.Fm 110 8.13 gearbox assembly see graphic: wc_gr003367 and wc_gr003368 8.13.1 install a new needle bearing (30) into the gearbox. 8.13.2 press the roller bearing (29) onto the input shaft (19). 8.13.3 press the roller bearing race into the gear box. 8.13.4 install a...

Page 111: Ct Repair

Ct repair drivetrain wc_tx000554gb.Fm 111 wc_gr003367 93 94 1 wc_gr003368 a.

Page 112: Drivetrain

Drivetrain ct repair wc_tx000554gb.Fm 112 notes.

Page 113: Threadlockers and Sealants

Threadlockers and sealants threadlockers and sealants threadlocking adhesives and sealants are specified throughout this manual by a notation of “s” plus a number (s#) and should be used where indicated. Threadlocking compounds normally break down at temperatures above 175°c (350°f). If a screw or b...

Page 114: Threadlockers and Sealants

Threadlockers and sealants threadlockers and sealants (continued) threadlocking adhesives and sealants are specified throughout this manual by a notation of “s” plus a number (s#) and should be used where indicated. Threadlocking compounds normally break down at temperatures above 175°c (350°f). If ...

Page 115: Torque Values

Torque values torque values metric fasteners (din) torque values (based on bolt size and hardness) wrench size size nm ft.Lb. Nm ft.Lb. Nm ft.Lb. Metric inch metric inch m3 1.2 *11 1.6 *14 2.1 *19 5.5 7/32 2.5 – m4 2.9 *26 4.1 *36 4.9 *43 7 9/32 3 – m5 6.0 *53 8.5 6 10 7 8 5/16 4 – m6 10 7 14 10 17 ...

Page 116: Torque Values

Torque values torque values (continued) inch fasteners (sae) size nm ft.Lb. Nm ft.Lb. Nm ft.Lb. Metric inch metric inch no.4 0.7 *6 1.0 *14 1.4 *12 5.5 1/4 – 3/32 no.6 1.4 *12 1.9 *17 2.4 *21 8 5/16 – 7/64 no.8 2.5 *22 3.5 *31 4.7 *42 9 11/32 – 9/64 no.10 3.6 *32 5.1 *45 6.8 *60 – 3/8 – 5/32 1/4 8.1...

Page 118

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific operations...