- DL manuals

- Wacker Neuson

- Heater

- Cub 200

- Repair Manual

Wacker Neuson Cub 200 Repair Manual

Summary of Cub 200

Page 1

Repair manual indirect-fired air heater cub 200 cub 300 0179422en 001 1009 0 1 7 9 4 2 2 e n.

Page 2

Copyright notice © copyright 2009 by wacker neuson corporation. All rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permission from wack...

Page 3: Cub 200/300

Cub 200/300 foreword ghi_tx001204gb.Fm 3 foreword machines covered by this manual machine documentation keep a copy of the operator’s manual with the machine at all times. Use the separate parts book supplied with the machine to order replacement parts. If you are missing any of these documents, ple...

Page 4: Foreword

Foreword cub 200/300 ghi_tx001204gb.Fm 4.

Page 5: Cub 200/300

Cub 200/300 table of contents 5 1 safety information 7 1.1 signal words found in this manual ...................................................... 7 1.2 safety guidelines for operating the machine ....................................... 8 1.3 safety guidelines for lifting the machine .................

Page 6: Table of Contents

Table of contents cub 200/300 ghi_br0179422en_001toc.Fm 6 6 troubleshooting the burner 37 6.1 checking the ignition transformer ......................................................39 6.2 checking the cad cell .........................................................................42 6.3 checking ...

Page 7: Cub 200/300

Cub 200/300 safety information ghi_si000343gb.Fm 7 1 safety information 1.1 signal words found in this manual notice: used without the safety alert symbol, notice indicates a situation which, if not avoided, could result in property damage. Note: a note contains additional information important to a...

Page 8: Safety Information

Safety information cub 200/300 8 ghi_si000343gb.Fm 1.2 safety guidelines for operating the machine operator training before operating the machine: read and understand the operating instructions contained in all manuals delivered with the machine. Familiarize yourself with the location and proper use...

Page 9: Cub 200/300

Cub 200/300 safety information ghi_si000343gb.Fm 9 when operating the machine: do not connect ductwork between the exhaust outlet port and the supply air inlet port. Never operate the machine in areas that contain flammable objects, fuels, or products that produce flammable vapors. Do not position t...

Page 10: Safety Information

Safety information cub 200/300 10 ghi_si000343gb.Fm 1.4 safety guidelines while using combustion burners when using the machine: clean up any spilled fuel immediately. Replace the fuel tank cap after refueling the machine. Refill the fuel tank in a well-ventilated area. Shut down the generator, if e...

Page 11: Cub 200/300

Cub 200/300 safety information ghi_si000343gb.Fm 11 1.5 safety guidelines for maintaining the machine training only trained personnel should troubleshoot or repair electrical problems occur- ring with the machine. Cleaning when cleaning and servicing the machine: keep the area around the burner free...

Page 12: Operation

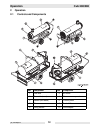

Operation cub 200/300 ghi_tx001205gb.Fm 12 2 operation 2.1 controls and components ref component ref component 1 fuel tank 2 air outlet 3 flue collar (vent) 4 burner access panel 5 handle (and base) 6 control panel 7 blower 8 fuel oil filter 9 lifting device 10 duct adapter.

Page 13: Cub 200/300

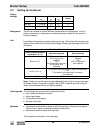

Cub 200/300 operation ghi_tx001205gb.Fm 13 2.2 control panel ref component function a remote thermostat receptacle the remote thermostat receptacle (shown with protective cap installed) is used for connecting an optional remote thermostat. B burner fault lamp and reset button (dual function) the dua...

Page 14: Operation

Operation cub 200/300 ghi_tx001205gb.Fm 14 2.3 starting/stopping the machine if not using the remote thermostat turning on 1. Move the power switch (c) to the on “i” position. The blower will turn on immediately. The burner will go through a prepurge cycle and then ignite. The burner will continue t...

Page 15: Cub 200/300

Cub 200/300 operation ghi_tx001205gb.Fm 15 notes.

Page 16: Burner Setup

Burner setup cub 200/300 16 ghi_tx001317gb.Fm 3 burner setup 3.1 control board sequence of operation periods the burner controller has several periods it sequences through during normal operation. These periods are described below. . Period action or function prepurge (t1) as soon as the control swi...

Page 17: Cub 200/300

Cub 200/300 burner setup ghi_tx001317gb.Fm 17 operation (t3) after the ignition period, the operation period begins. It will last as long as there is flame or until the heater is turned off. During this period: the fan runs. The ignition transformer (tr) is off. There is no spark across the electrod...

Page 18: Burner Setup

Burner setup cub 200/300 18 ghi_tx001317gb.Fm 3.2 setting up the burner factory settings background the burner consists of several different components and subsystems. Each of these components or subsystems must be operating correctly for the burner to function properly. Fuel low ambient temperature...

Page 19: Cub 200/300

Cub 200/300 burner setup ghi_tx001317gb.Fm 19 continued from the previous page. When adjust the burner: before operating the machine at elevations 305 m (1,000 ft) above or below the location of where the last adjustments were made before starting at a new job site after any burner maintenance or re...

Page 20: Burner Setup

Burner setup cub 200/300 20 ghi_tx001317gb.Fm continued from the previous page. 8. Analyze the combustion. Follow the combustion analyzer manufacturer’s instructions and the general guidelines below. Use the access hole in the exhaust stack. Take several samples as the heater warms. Take the final s...

Page 21: Cub 200/300

Cub 200/300 burner setup ghi_tx001317gb.Fm 21 3.3 removing and installing the burner assembly background before performing any maintenance on the burner assembly, it must be removed from the machine. Removal to remove or install the burner assembly perform the following procedure: 1. Shut down the m...

Page 22: Burner Setup

Burner setup cub 200/300 22 ghi_tx001317gb.Fm 3.4 checking and adjusting the burner electrodes requirements burner assembly removed background inspect the electrodes for the following: wear be sure to inspect the ends of the electrodes for pitting. Replace any worn elec- trodes. Straightness replace...

Page 23: Cub 200/300

Cub 200/300 burner setup ghi_tx001317gb.Fm 23 3.5 checking and replacing the burner nozzle requirements burner assembly removed removal perform the procedure to remove the nozzle. 1. Remove the burner assembly. See topic removing and installing the burner assembly. 2. Place an adjustable wrench on t...

Page 24: Burner Setup

Burner setup cub 200/300 24 ghi_tx001317gb.Fm 3.6 setting the air band requirements machine shut down power disconnected procedure perform the procedure below to set the air band. 1. Shut down the machine and allow it to cool. 2. Disconnect the power cord from the power source. 3. Remove the two bol...

Page 25: Cub 200/300

Cub 200/300 burner setup ghi_tx001317gb.Fm 25 3.7 checking and adjusting the fuel pressure requirements pressure gauge british parallel thread (bpt) adapter procedure to check and/or adjust the fuel pressure, carry out the following procedure: 1. Shut down the machine and allow it to cool. 2. Discon...

Page 26: Burner Setup

Burner setup cub 200/300 26 ghi_tx001317gb.Fm continued from the previous page. 9. Adjust the fuel pressure, if necessary, using the adjusting screw (e). Notice: do not adjust the fuel pressure outside of the parameters listed in the technical data charts. 10.Restart the machine and check the gauge....

Page 27: Cub 200/300

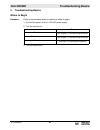

Cub 200/300 troubleshooting basics ghi_tx001207gb.Fm 27 4 troubleshooting basics where to begin procedure perform the procedure below to determine where to begin. 1. Connect the power cord to a 120 vac power supply. 2. Turn the machine on. 3. Turn the machine off. If then the blower runs, the proble...

Page 28: Troubleshooting The Blower

Troubleshooting the blower cub 200/300 28 ghi_tx001207gb.Fm 5 troubleshooting the blower best practice the best practice when troubleshooting this system is to: 1. Isolate and check each component of this system individually. 2. When a malfunctioning component is found, repair or replace it. 3. Afte...

Page 29: Cub 200/300

Cub 200/300 troubleshooting the blower ghi_tx001207gb.Fm 29 5.1 checking the fuse requirements 120v power source procedure perform the procedure below to check the fuse. 1. Connect the power cord to a 120 vac power supply. 2. Observe the green light (x). Does the green light illuminate? 3. Disconnec...

Page 30: Troubleshooting The Blower

Troubleshooting the blower cub 200/300 30 ghi_tx001207gb.Fm continued from the previous page. 5. Remove the cover (b) from the control panel. 6. Locate the fuse (c) and check its condition. 7. Replace the fuse if it is blown with a fuse of the same size and rating. Result the fuse has now been check...

Page 31: Cub 200/300

Cub 200/300 troubleshooting the blower ghi_tx001207gb.Fm 31 5.2 checking power to/from the control board requirements 120 vac power source multimeter machine’s fuse is ok procedure perform the procedure below to check power to/from the control board. 1. Remove the screws (a) that hold the control pa...

Page 32: Troubleshooting The Blower

Troubleshooting the blower cub 200/300 32 ghi_tx001207gb.Fm continued from the previous page. 5. Measure the voltage between terminal m8 and terminal m11 on the control board. Is 108–132 vac measured? 6. Measure the voltage between terminal m15 and terminal m14. Is 108–132 vac measured? Result the p...

Page 33: Cub 200/300

Cub 200/300 troubleshooting the blower ghi_tx001207gb.Fm 33 5.3 checking the on-off switch requirements electric power disconnected from the machine multimeter procedure perform the procedure below to check the on-off switch. 1. Disconnect the power cord from the power supply. 2. Remove the screws (...

Page 34: Troubleshooting The Blower

Troubleshooting the blower cub 200/300 34 ghi_tx001207gb.Fm continued from the previous page. 6. Check that there is continuity between the two terminals where the black and brown wires are connected. There should be continuity when in the on position and no continuity in the off position. Does the ...

Page 35: Cub 200/300

Cub 200/300 troubleshooting the blower ghi_tx001207gb.Fm 35 5.4 checking the capacitor requirements power disconnected multimeter procedure perform the procedure below to check the capacitor. 1. Disconnect the power cord from the electric power supply. 2. Remove the access cover (a). 3. Disconnect t...

Page 36: Troubleshooting The Blower

Troubleshooting the blower cub 200/300 36 ghi_tx001207gb.Fm continued from the previous page. Does the capacitor measure 45–55 µf? 6. If the capacitor checks ok but the motor still hums, the problem is with the wiring from the motor to the capacitor. Check this wiring. 7. If the capacitor and the wi...

Page 37: Cub 200/300

Cub 200/300 troubleshooting the burner ghi_tx001207gb.Fm 37 6 troubleshooting the burner background the two sources of flame problems are: fuel ignition note: make sure the blower runs before troubleshooting burner problems. If the blower does not run, the burner will not fire. See topic troubleshoo...

Page 38: Troubleshooting The Burner

Troubleshooting the burner cub 200/300 38 ghi_tx001207gb.Fm continued from the previous page. Fuel problems for fuel system problems, check the following items in the sequence listed. Depending on the results of the fuel pressure, continue with the appropriate sequence below. Order component see top...

Page 39: Cub 200/300

Cub 200/300 troubleshooting the burner ghi_tx001207gb.Fm 39 6.1 checking the ignition transformer requirements fuel solenoid disconnected procedure perform the procedure below to check the ignition transformer. 1. Begin this procedure with the power supply disconnected. 2. Open the access panel (a)....

Page 40: Troubleshooting The Burner

Troubleshooting the burner cub 200/300 40 ghi_tx001207gb.Fm continued from the previous page. 7. Turn the machine off. 8. Remove the screws (c) that hold the control panel and pull the control panel from the machine. 9. Remove the cover (d) from the control. 10.Turn the machine on. 11.Measure the vo...

Page 41: Cub 200/300

Cub 200/300 troubleshooting the burner ghi_tx001207gb.Fm 41 continued from the previous page. 12.Turn the machine off. 13.Check the condition of the ignition wires (g) between the transformer (h) and the flame head (i). If the ignition wires are damaged, replace them. 14.Check the resistance of the ...

Page 42: Troubleshooting The Burner

Troubleshooting the burner cub 200/300 42 ghi_tx001207gb.Fm 6.2 checking the cad cell requirements power disconnected from the machine multimeter procedure perform the procedure below to check the cad cell. 1. Disconnect the power cord from the power supply. 2. Open the access panel (a). 3. Twist an...

Page 43: Cub 200/300

Cub 200/300 troubleshooting the burner ghi_tx001207gb.Fm 43 continued from the previous page. 6. Disconnect the light green wires (e) from terminals m5 and m6 of the burner controller. 7. Measure the resistance of the cad cell by measuring across the light green wires. Be sure the cad cell is expose...

Page 44: Troubleshooting The Burner

Troubleshooting the burner cub 200/300 44 ghi_tx001207gb.Fm 6.3 checking the fuel filter heater requirements multimeter electric power disconnected from the machine procedure perform the procedure below to check the fuel filter heater. 1. Turn on the machine. 2. Wait 10–15 minutes, then feel the out...

Page 45: Cub 200/300

Cub 200/300 troubleshooting the burner ghi_tx001207gb.Fm 45 continued from the previous page. 6. Check that the fuel heater is connected to terminals m7 and m12 of the control board. 7. Connect the power cord to the power supply. 8. Turn on the machine. 9. Measure the voltage between terminals m7 an...

Page 46: Troubleshooting The Burner

Troubleshooting the burner cub 200/300 46 ghi_tx001207gb.Fm 6.4 checking output voltage from the control board requirements multimeter procedure perform the procedure below to check output voltage from the control board for the fuel system. 1. Start this procedure with the machine disconnected from ...

Page 47: Cub 200/300

Cub 200/300 troubleshooting the burner ghi_tx001207gb.Fm 47 continued from the previous page. 6. Measure the voltage between terminal m13 and terminal m18. To do so, you must wait through the 10-second prepurge cycle. Note: the voltage will only be present for approximately 1 second if the flame is ...

Page 48: Troubleshooting The Burner

Troubleshooting the burner cub 200/300 48 ghi_tx001207gb.Fm 6.5 checking the air pressure switch requirements multimeter procedure perform the procedure below to check the air pressure switch. 1. Start this procedure with the machine disconnected from the power supply. 2. Remove the side access pane...

Page 49: Cub 200/300

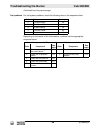

Cub 200/300 troubleshooting the burner ghi_tx001207gb.Fm 49 continued from the previous page. Is 108–132 vac measured? 6. Turn the machine off. 7. Disconnect the wiring from the air pressure switch. 8. With the machine off, check the continuity between the terminals of the air pressure switch as sho...

Page 50: Troubleshooting The Burner

Troubleshooting the burner cub 200/300 50 ghi_tx001207gb.Fm continued from the previous page. 10.With the machine on, check the continuity between the same terminals of the air pressure switch. Is there continuity? 11.Turn the machine off. 12.Reinstall the wires. Result the air pressure switch has n...

Page 51: Cub 200/300

Cub 200/300 troubleshooting the burner ghi_tx001207gb.Fm 51 6.6 checking the fuel solenoid requirements multimeter air pressure switch checks ok procedure perform the procedure below to check the fuel solenoid. 1. Turn the machine off. 2. Open the access panel (a). 3. Locate the fuel solenoid (b) an...

Page 52: Troubleshooting The Burner

Troubleshooting the burner cub 200/300 52 ghi_tx001207gb.Fm continued from the previous page. 4. Turn the machine on. If the machine is in a fault condition, press the reset (c) button on the control panel. 5. Measure the voltage at the connector (d). To do so, you must wait through the 10-second pr...

Page 53: Cub 200/300

Cub 200/300 troubleshooting the burner ghi_tx001207gb.Fm 53 continued from the previous page. 7. Measure the resistance across the coil of the solenoid as shown. Is 600–700 ohms measured? Result the fuel solenoid has now been checked. If the problem has not been resolved, leave the machine disassemb...

Page 54: Troubleshooting The Burner

Troubleshooting the burner cub 200/300 54 ghi_tx001207gb.Fm 6.7 checking the flame head requirements power disconnected hand tools procedure perform the procedure below to check the flame head. 1. Disconnect the power cord from the power supply. 2. Remove the burner assembly. See topic removing/inst...

Page 55: Cub 200/300

Cub 200/300 troubleshooting the burner ghi_tx001207gb.Fm 55 6.8 checking the fuel flow from the nozzle requirements container to catch fuel (5 gallon bucket) procedure perform the procedure below to check the fuel flow from the nozzle. 1. Disconnect the power cord from the power supply. 2. Disarm th...

Page 56: Troubleshooting The Burner

Troubleshooting the burner cub 200/300 56 ghi_tx001207gb.Fm continued from the previous page. 6. Connect the machine to the power supply. 7. Hold the nozzle assembly facing into a container to catch the fuel spray. 8. Turn the machine on. If the machine is in a fault condition, press the reset (d) b...

Page 57: Cub 200/300

Cub 200/300 troubleshooting the burner ghi_tx001207gb.Fm 57 6.9 checking the fuel lines requirements machine turned off power supply disconnected procedure perform the following procedure to check the fuel lines. 1. Turn the machine off. 2. Inspect the fuel lines (a) for leakage and loose fittings. ...

Page 58: Troubleshooting The Burner

Troubleshooting the burner cub 200/300 58 ghi_tx001207gb.Fm 6.10 checking the fuel pump adapter requirements machine turned off power supply disconnected procedure perform the following procedure to check the fuel pump adapter. 1. Turn the machine off. 2. Open the access panel (a). 3. Locate the fue...

Page 59: Cub 200/300

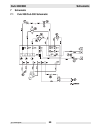

Cub 200/300 schematic ghi_tx001210gb.Fm 59 7 schematic 7.1 cub 200/cub 300 schematic.

Page 60: Threadlockers and Sealants

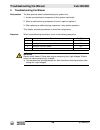

Threadlockers and sealants threadlockers and sealants threadlocking adhesives and sealants are specified throughout this manual by a notation of “s” plus a number (s#) and should be used where indicated. Threadlocking compounds normally break down at temperatures above 175°c (350°f). If a screw or b...

Page 61: Threadlockers and Sealants

Threadlockers and sealants threadlockers and sealants (continued) threadlocking adhesives and sealants are specified throughout this manual by a notation of “s” plus a number (s#) and should be used where indicated. Threadlocking compounds normally break down at temperatures above 175°c (350°f). If ...

Page 62: Torque Values

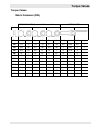

Torque values torque values metric fasteners (din) torque values (based on bolt size and hardness) wrench size size nm ft.Lb. Nm ft.Lb. Nm ft.Lb. Metric inch metric inch m3 1.2 *11 1.6 *14 2.1 *19 5.5 7/32 2.5 – m4 2.9 *26 4.1 *36 4.9 *43 7 9/32 3 – m5 6.0 *53 8.5 6 10 7 8 5/16 4 – m6 10 7 14 10 17 ...

Page 63: Torque Values

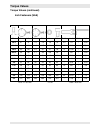

Torque values torque values (continued) inch fasteners (sae) size nm ft.Lb. Nm ft.Lb. Nm ft.Lb. Metric inch metric inch no.4 0.7 *6 1.0 *14 1.4 *12 5.5 1/4 – 3/32 no.6 1.4 *12 1.9 *17 2.4 *21 8 5/16 – 7/64 no.8 2.5 *22 3.5 *31 4.7 *42 9 11/32 – 9/64 no.10 3.6 *32 5.1 *45 6.8 *60 – 3/8 – 5/32 1/4 8.1...

Page 64

Ground heaters, inc. · 1271 judson road · spring lake, mi 49456 · tel: (231) 799-9600 · fax: (231) 799-9500 · tel: (877) 799-9600