- DL manuals

- Wacker Neuson

- Portable Generator

- G 25

- Operator's Manual

Wacker Neuson G 25 Operator's Manual

Summary of G 25

Page 1

Mobile generator g 25 operator’s manual 0158596en 013 0709 0 1 5 8 5 9 6 e n.

Page 3

Wc_tx000001gb diesel.Fm 3 california proposition 65 warning: engine exhaust, some of its constituents, and certain vehicle components, contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. Foreword this manual provides information an...

Page 4

Wc_tx000001gb diesel.Fm 4.

Page 5: G 25

G 25 table of contents wc_bo0158596en_013toc.Fm 5 foreword 3 1 safety information 7 1.1 operating safety .................................................................................. 8 1.2 service safety .................................................................................... 10 1.3...

Page 6: Table of Contents

Table of contents g 25 wc_bo0158596en_013toc.Fm 6 3 maintenance 48 3.1 periodic maintenance schedule ..........................................................48 3.2 new machines .....................................................................................49 3.3 resetting the periodic mainte...

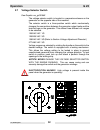

Page 7: G 25

G 25 safety information wc_si000137gb.Fm 7 1 safety information this manual contains danger, warning, caution, notice, and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is used to a...

Page 8: Safety Information

Safety information g 25 wc_si000137gb.Fm 8 1.1 operating safety familiarity and proper training are required for the safe operation of the machine. Machines operated improperly or by untrained personnel can be hazardous. Read the operating instructions contained in this manual and the engine manual,...

Page 9: G 25

G 25 safety information wc_si000137gb.Fm 9 1.1.17 always keep the area immediately surrounding and underneath the machine clean, neat, and free of debris and combustible materials. Make sure that the area overhead is clear of debris that could fall onto or into the machine or exhaust compartment. 1....

Page 10: Safety Information

Safety information g 25 wc_si000137gb.Fm 10 1.2 service safety a poorly maintained machine can become a safety hazard! In order for the machine to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 1.2.1 never perform even routine servi...

Page 11: G 25

G 25 safety information wc_si000137gb.Fm 11 1.2.11 always remain aware of moving parts and keep hands, feet, and loose clothing away from the moving parts of the machine. 1.2.12 always replace all guards, fasten doors, and make sure all safety devices operate properly after making repairs or servici...

Page 12: Safety Information

Safety information g 25 wc_si000137gb.Fm 12 1.3 operator safety while using internal combustion engines internal combustion engines present special hazards during operation and fueling. Read and follow the warning instructions in the engine owner’s manual and the safety guidelines below. Failure to ...

Page 13: G 25

G 25 safety information wc_si000137gb.Fm 13 1.4 towing safety towing a large trailer requires special care. Both the trailer and vehicle must be in good condition and securely fastened to each other to reduce the possibility of an accident. 1.4.1 always check that the hitch and coupling on the vehic...

Page 14: Safety Information

Safety information g 25 wc_si000137gb.Fm 14 1.6 label location.

Page 15: G 25

G 25 safety information wc_si000137gb.Fm 15.

Page 16: Safety Information

Safety information g 25 wc_si000137gb.Fm 16 1.7 safety and operating labels ref. Label meaning a b warning! Pressurized contents. Do not open when hot! C warning! Lock doors. Access can cause electric shock or injury. D caution lifting point. E notice never change switch position with engine running...

Page 17: G 25

G 25 safety information wc_si000137gb.Fm 17 f danger! Asphyxiation hazard. Read the opera- tor’s manual for instructions. No sparks, flames, or burning objects near machine. Stop the engine before adding fuel. Use only diesel fuel. G tie-down point. H warning! To prevent hearing loss, wear hearing p...

Page 18: Safety Information

Safety information g 25 wc_si000137gb.Fm 18 l m operator’s manual must be stored on machine. Replacement operator’s man- ual can be ordered through your local wacker neuson distributor. N danger! Electric shock will cause serious injury or death. Danger of asphyxiation! Ref. Label meaning.

Page 19: G 25

G 25 safety information wc_si000137gb.Fm 19 o warning! Generator can automatically start which can cause serious injury. Disconnect bat- tery before servicing. P warning! Read and understand the supplied oper- ator’s manual before operating the machine. Failure to do so increases the risk of injury ...

Page 20: Safety Information

Safety information g 25 wc_si000137gb.Fm 20 t warning! Disconnect battery before servicing. Read the operator’s manual. U v operator’s manual must be stored on machine. Replacement operator’s man- ual can be ordered through your local wacker neuson distributor. W drain containment system. X warning!...

Page 21: G 25

G 25 safety information wc_si000137gb.Fm 21 z neutral bonded to frame aa fuses read the operator’s manual for machine information. 1 - fuel solenoid 2 - fuel pump 3 - controller 4 - not used bb warning! Electric shock at cooling fins. Cc g 25 generator and receptacle wiring dd g 25 engine wiring ref...

Page 22: Safety Information

Safety information g 25 wc_si000137gb.Fm 22 ee warning! Hot surface! Ff (if equipped) caution: do not use battery disconnect switch while engine is running. Damage to electrical components may occur. Gg low sulfur fuel or ultra low sulfur fuel only. Hh warning lock doors. Access can cause electric s...

Page 23: G 25

G 25 safety information wc_si000137gb.Fm 23 \ a nameplate listing the model number, item number, revision number, and serial number is attached to each unit. Please record the information found on this plate so it will be available should the name- plate become lost or damaged. When ordering parts o...

Page 24: Operation

Operation g 25 wc_tx000137gb.Fm 24 2. Operation 2.1 control panels e m ergenc y s to p.

Page 25: G 25

G 25 operation wc_tx000137gb.Fm 25 ref. Description ref. Description a main circuit breaker l twist-lock receptacle (120/240 vac, 50amp) b voltage adjustment rheostat m twist-lock receptacle (120/240 vac, 30 amp) c shutdown led n gfi receptacle (120 vac, 20 amp) - two d pre-alarm led o remote run te...

Page 26: Operation

Operation g 25 wc_tx000137gb.Fm 26 2.2 generator monitoring generator information is displayed on the top line of the lcd panel and is scrolled continuously while the generator is operating, to show the voltage, amperage and frequency of each phase. Note: to prevent the display from scrolling, press...

Page 27: G 25

G 25 operation wc_tx000137gb.Fm 27 notes:.

Page 28: Operation

Operation g 25 wc_tx000137gb.Fm 28 2.3 engine monitoring with the engine start switch set to “run/start” or “remote start”, engine information will be continuously displayed on the bottom line of the lcd panel. Oil - displays engine oil pressure. The gauge registers oil pressure between 0–100 psi. N...

Page 29: G 25

G 25 operation wc_tx000137gb.Fm 29 sample display of engine hours. Sample display of periodic maintenance timer. Sample display showing engine fault set points. Running hours 135.2 time to service 180.2 hrs. Lop225 os>67.

Page 30: Operation

Operation g 25 wc_tx000137gb.Fm 30 2.4 engine shutdown faults the engine control module (ecm) continuously monitors vital engine functions for six fault conditions. When a fault condition occurs, the engine will shut down and the lcd panel will display the fault causing the shutdown. To reset the ec...

Page 31: G 25

G 25 operation wc_tx000137gb.Fm 31 2.5 current overload fault along with engine functions the ecm continuously monitors the current load in each phase. The values for current overload are programmed into the ecm at the factory and are different for each generator size. When an overload condition is ...

Page 32: Operation

Operation g 25 wc_tx000137gb.Fm 32 2.7 voltage selector switch see graphic: wc_gr001682 the voltage selector switch is located in a separate enclosure on the generator on the opposite side of the machine. The selector switch is a three-position switch which mechanically changes the connections betwe...

Page 33: G 25

G 25 operation wc_tx000137gb.Fm 33 2.8 emergency stop switch see graphic: wc_gr001677 the emergency stop switch (p) is the red button located below the receptacle panel and can be accessed with the panel doors closed. Activate the emergency stop switch by pushing the red button in. Pushing the emerg...

Page 34: Operation

Operation g 25 wc_tx000137gb.Fm 34 2.9 main line circuit breaker see graphic: wc_gr001683 the main line circuit breaker (c) is located on the control panel. In the off “o” position, the main line circuit breaker interrupts power from the selector switch to the terminal lugs at the bottom of the gene...

Page 35: G 25

G 25 operation wc_tx000137gb.Fm 35 2.10 engine start switch see graphic: wc_gr001683 the engine start switch (f) is a three-position switch: “remote start”, off “o”, and “start/run”. The “remote start” position is the normal setting used when using the generator as a back-up power supply connected t...

Page 36: Operation

Operation g 25 wc_tx000137gb.Fm 36 2.13 connection lugs see graphic: wc_gr001684 the customer connection lugs (r) are located on left at the bottom of the panel behind a hinged door. The lugs provide connection points for attachment of outside loads. A large label like the one shown in section termi...

Page 37: G 25

G 25 operation wc_tx000137gb.Fm 37 2.14 ground connection see graphic: wc_gr001684 a ground connection (s) is located next to the terminal lugs. The unit must have this ground lug connected to a good earthen ground for proper operating safety in compliance with nec and local standards. 2.15 convenie...

Page 38: Operation

Operation g 25 wc_tx000137gb.Fm 38 2.18 terminal connections all connections to the terminals must be made by a trained electrician. Backfeed from the generator into the utility’s distribution system can cause a serious injury or death to utility workers! Improper connection of generator to a buildi...

Page 39: G 25

G 25 operation wc_tx000137gb.Fm 39 2.19 before starting before putting the generator into service, review each item on the following checklist. Because generators are often run for long periods of time unattended, it is important to make sure that the machine is set up properly to reduce possible pr...

Page 40: Operation

Operation g 25 wc_tx000137gb.Fm 40 2.20 manual start-up see graphic: wc_gr001682, wc_gr001677, wc_gr001683 before starting the generator set, thoroughly review the pre-start-up checklist in the previous section. Proceed with generator start-up only after checking each item in that section. Thoroughl...

Page 41: G 25

G 25 operation wc_tx000137gb.Fm 41 2.20.7 after engine starts, allow it to warm up for a few minutes and check readouts on lcd panel. The “time to service” interval will be displayed. Make sure battery charging system, oil pressure and engine temperature readings are within normal ranges. 2.20.8 che...

Page 42: Operation

Operation g 25 wc_tx000137gb.Fm 42 2.21 running the generator see graphic: wc_gr001683 leave the engine start switch (f) in the “start/run” position while the generator is operating. If the generator was started using a remote switch, leave engine start switch in the “remote start” position. Let the...

Page 43: G 25

G 25 operation wc_tx000137gb.Fm 43 2.23 shutting down generator check with other personnel on the jobsite and let them know that power is being turned off. Make sure that the power shutdown will not create any hazards by turning off devices such as pumps, heaters, or lights that may need to be kept ...

Page 44: Operation

Operation g 25 wc_tx000137gb.Fm 44 2.28 automatic/remote start-up in the “remote start” position the generator can be started remotely, either through a transfer switch or some other type of remote start switch. “remote start” is the normal setting when using the generator as a standby power supply....

Page 45: G 25

G 25 operation wc_tx000137gb.Fm 45 2.29 remote/transfer switch when the generator is used as a stand-by power supply, it must be equipped with a device which isolates it from the utility’s distribution system. Failure to isolate the generator from the utility’s electrical distribution system could c...

Page 46: Operation

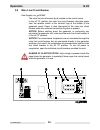

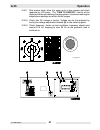

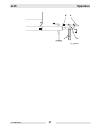

Operation g 25 wc_tx000137gb.Fm 46 2.30 towing see graphic: wc_gr000510 the generator trailer is equipped with brakes, lights, and coupler connection. Before towing the generator, perform the following: 2.30.1 check that the towing vehicle and hitch have a rating equal to or greater than the gvwr. R...

Page 47: G 25

G 25 operation wc_tx000137gb.Fm 47 w c _ g r 0 0 0 5 1 0 a d c b.

Page 48: Maintenance

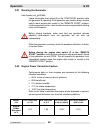

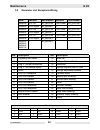

Maintenance g 25 wc_tx000197gb.Fm 48 3. Maintenance 3.1 periodic maintenance schedule the chart below lists basic machine and engine maintenance. Refer to your engine operator’s manual for additional information on engine maintenance. Daily 50 hr or 2 weeks 250 hr 600 hr or 12 mo 1200 hr or 24 mo 20...

Page 49: G 25

G 25 maintenance wc_tx000197gb.Fm 49 3.2 new machines 3.2.1 run generator at least 60–100% of continuous load for the first 100 hours. 3.2.2 change engine oil and replace oil filter after the first 50 hours. 3.3 resetting the periodic maintenance timer after maintenance has been performed on the gen...

Page 50: Maintenance

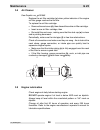

Maintenance g 25 wc_tx000197gb.Fm 50 3.4 air cleaner see graphic: wc_gr001685 replace the air filter cartridge (c) when yellow indicator of the engine air filter gauge reaches the red line. To replace the air filter cartridge: • remove the end cover (d) , then discard the entire air filter cartridge...

Page 51: G 25

G 25 maintenance wc_tx000197gb.Fm 51 check the coolant level of the radiator with the engine cold. After initial filling of radiator to 3/4 inch below bottom of filler neck, maintain proper level in overflow bottle daily. Never remove radiator cap or drain plug while engine is hot! Pressurized coola...

Page 52: Maintenance

Maintenance g 25 wc_tx000197gb.Fm 52 3.8 troubleshooting automatic shutdown there are six automatic shutdown conditions: low oil pressure, high coolant temperature, engine overspeed, engine underspeed, engine overcrank and low fuel. When these occur, the operator can perform certain diagnostic tests...

Page 53: G 25

G 25 maintenance wc_tx000197gb.Fm 53 overspeed or underspeed shutdown restart engine and read the ac frequency meter. Meter should read aproximately 61.5 hz under no-load condition. If frequency is high, adjust engine rpm for correct frequency (approximately 1850 rpm). Overcrank shutdown 3.8.1 check...

Page 54: Maintenance

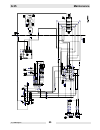

Maintenance g 25 wc_tx000197gb.Fm 54 3.9 generator and receptacle wiring bom revision see graphic: revision see graphic: 0009368 104–123 wc_gr003169 103 & lower wc_gr001686 0009368 124 & higher wc_gr004611 — — 0009466 105–128 wc_gr003169 104 & lower wc_gr001686 0009466 129 & higher wc_gr004611 — — 0...

Page 55: G 25

G 25 maintenance wc_tx000197gb.Fm 55.

Page 56: Maintenance

Maintenance g 25 wc_tx000197gb.Fm 56 bom revision see graphic: revision see graphic: 0009368 104–123 wc_gr003169 103 & lower wc_gr001686 0009368 124 & higher wc_gr004611 — — 0009466 105–128 wc_gr003169 104 & lower wc_gr001686 0009466 129 & higher wc_gr004611 — — 0620004 104–127 wc_gr003169 103 & low...

Page 57: G 25

G 25 maintenance wc_tx000197gb.Fm 57.

Page 58: Maintenance

Maintenance g 25 wc_tx000197gb.Fm 58 bom revision see graphic: revision see graphic: 0009368 104–123 wc_gr003169 103 & lower wc_gr001686 0009368 124 & higher wc_gr004611 — — 0009466 105–128 wc_gr003169 104 & lower wc_gr001686 0009466 129 & higher wc_gr004611 — — 0620004 104–127 wc_gr003169 103 & low...

Page 59: G 25

G 25 maintenance wc_tx000197gb.Fm 59.

Page 60: Maintenance

Maintenance g 25 wc_tx000197gb.Fm 60 3.10 trailer wiring ref. Description 1 front right side amber light 2 front left side amber light 3 trailer plug 4 battery 5 brake solenoid 6 right tail light 7 license plate holder lights 8 left tail light 9 rear right side red light 10 rear left side red light ...

Page 61: G 25

G 25 maintenance wc_tx000197gb.Fm 61 standard and hydraulic brakes electric brakes w c _ g r 0 0 0 5 2 2 b r b r w w b r w g b r w y b r w b r w y g b r w 1 9 8 6 2 1 0 3 b r b r 7 7 3 g y br w r r r br w r r + – w w w w br br br br br br w wc_gr000523 y w g r w r r 1 4 5 5 2 9 6 8 7 7 10 br w.

Page 62: Maintenance

Maintenance g 25 wc_tx000197gb.Fm 62 3.11 engine wiring bom revision see graphic: revision see graphic: revision see graphic: 0009368 107–123 wc_gr003217 106 wc_gr003170 105 & lower wc_gr001687 0009368 124 & higher wc_gr004609 – – – – 0009466 111–128 wc_gr003217 110 wc_gr003170 109 & lower wc_gr0016...

Page 63: G 25

G 25 maintenance wc_tx000197gb.Fm 63.

Page 64: Maintenance

Maintenance g 25 wc_tx000197gb.Fm 64 bom revision see graphic: revision see graphic: revision see graphic: 0009368 107–123 wc_gr003217 106 wc_gr003170 105 & lower wc_gr001687 0009368 124 & higher wc_gr004609 – – – – 0009466 111–128 wc_gr003217 110 wc_gr003170 109 & lower wc_gr001687 0009466 129 & hi...

Page 65: G 25

G 25 maintenance wc_tx000197gb.Fm 65.

Page 66: Maintenance

Maintenance g 25 wc_tx000197gb.Fm 66 bom revision see graphic: revision see graphic: revision see graphic: 0009368 107–123 wc_gr003217 106 wc_gr003170 105 & lower wc_gr001687 0009368 124 & higher wc_gr004609 – – – – 0009466 111–128 wc_gr003217 110 wc_gr003170 109 & lower wc_gr001687 0009466 129 & hi...

Page 67: G 25

G 25 maintenance wc_tx000197gb.Fm 67 br.

Page 68: Maintenance

Maintenance g 25 wc_tx000197gb.Fm 68 bom revision see graphic: revision see graphic: revision see graphic: 0009368 107–123 wc_gr003217 106 wc_gr003170 105 & lower wc_gr001687 0009368 124 & higher wc_gr004609 – – – – 0009466 111–128 wc_gr003217 110 wc_gr003170 109 & lower wc_gr001687 0009466 129 & hi...

Page 69: G 25

G 25 maintenance wc_tx000197gb.Fm 69.

Page 70: Factory-Installed Options

Factory-installed options g 25 wc_tx000853gb.Fm 70 4 factory-installed options this machine may be equipped with one or more of the following factory-installed options. To verify if any of these options are installed on your machine, contact wacker neuson corporation at 1-800-770-0957. A nameplate l...

Page 71: G 25

G 25 factory-installed options wc_tx000853gb.Fm 71 4.2 fuel/water separator see graphic: wc_gr001705 the fuel/water separator separates water from the fuel on models with isuzu engines. Empty the separator water bowl (a) as needed by opening the water bowl drain (b) . The separator element should be...

Page 72: Factory-Installed Options

Factory-installed options g 25 wc_tx000853gb.Fm 72 4.3 automatic lcd heat see graphic: wc_gr001723, wc_gr001724 to improve the performance of the lcd panel in cold weather, the lcd panel control module is equipped with an lcd heater. The heater draws power from the panel control module and is active...

Page 73: G 25

G 25 factory-installed options wc_tx000853gb.Fm 73 4.4 low coolant shutdown see graphic: wc_gr001708 the low-coolant shutdown system consists of an electronic sensor that monitors coolant level. The sensor (a) is mounted to the radiator and wired into the ecm. The sensor probe (b) is submerged in ra...

Page 74: Factory-Installed Options

Factory-installed options g 25 wc_tx000853gb.Fm 74 4.5 temperature-activated shutters see graphic: wc_gr005770, wc_gr001707 the shutters (a) are mounted to the top of the generator enclosure. The shutters are designed to keep the engine compartment warm, thus increasing engine temperature during col...

Page 75: G 25

G 25 factory-installed options wc_tx000853gb.Fm 75 4.7 extended run tank an extended run, 135-gallon fuel tank provides a 70-hour run time under a continuous full load. The long run time eliminates the need for daily refueling, saving money on fuel deliveries. The tank is fully fluid- contained and ...

Page 76: Factory-Installed Options

Factory-installed options g 25 wc_tx000853gb.Fm 76 4.9 cam-lock see graphic: wc_gr002584 a second optional outlet panel features camlock connectors (u) for easy tool changes. The door is equipped with an interlock switch (q) . When the door is opened this switch automatically trips the main circuit ...

Page 77: G 25

G 25 factory-installed options wc_tx000853gb.Fm 77 4.10 containment system see graphic: wc_gr002647 overspills and leaks are captured in the containment system. The containment system holds over 110% of the fluid contained in the machine. The containment system should be checked every 50 hours or 2 ...

Page 78: Factory-Installed Options

Factory-installed options g 25 wc_tx000853gb.Fm 78 4.11 wiring diagram—factory-installed options wire colors b black r red y yellow or orange g green t tan br brown pr purple l blue v violet cl clear sh shield p pink w white gr gray ll light blue.

Page 79: G 25

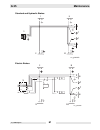

G 25 factory-installed options wc_tx000853gb.Fm 79 4.12 wiring diagram components—factory-installed options see graphic: wc_gr001868 ref description ref description 1 thermostat module 7 positive air shutoff solenoid actuator 2 terminal block 8 auxiliary relay terminals 3 1 amp fuse 9 plug 1, engine...

Page 80: Technical Data

Technical data g 25 wc_td000139gb.Fm 80 5. Technical data 5.1 engine power rating engine power rating gross standby power rating per iso 8528-1 and sae j1995. Actual power output may vary due to conditions of specific use. 5.2 engine data table 1 g 25 0009368, 0009466, 0620004 rev. 114 & lower g 25 ...

Page 81: G 25

G 25 technical data wc_td000139gb.Fm 81 5.3 engine data table 2 g 25 0620344 0620346 g 25 0620345 g 25 0620706 engine engine make / type isuzu model 4le2-nygv, tier 4 number of cylinders 4 displacement cm 3 (in 3 ) 2179 (133) engine speed rpm 1800 rated standby power @ 1800 rpm kw(hp) 26.4 (35.4) 25...

Page 82: Technical Data

Technical data g 25 wc_td000139gb.Fm 82 5.4 generator data g 25 0009368 rev.126 & lower 0009466 rev.131 & lower 0620004 rev.130 & lower 0009368 rev.127 & higher 0009466 rev.131 & higher 0620004 rev.130 & higher 0620344 0620345 0620346 0620706 generator make/type mecc alte / brushless model eco 28-1l...

Page 83: G 25

G 25 technical data wc_td000139gb.Fm 83 5.5 trailer and skid data g 25 0009368 rev.126 & lower 0009466 rev.131 & lower 0620004 rev.130 & lower 0009368 rev.127 & higher 0009466 rev.131 & higher 0620004 rev.130 & higher 0620344 0620345 0620346 0620706 trailer and skid dry weight of skid kg (lbs.) 862 ...

Page 84: Technical Data

Technical data g 25 wc_td000139gb.Fm 84 5.6 dimensions mm (in.) g 25 0620344 0620346 0620345 g 25 0620706 dimensions—mm (in.) a 890 (35) b 1620 (69) c 1700 (67) d 1945 (76.6) e 1130 (44.5) 1514 (59.6) f 1260 (49.6) 1644 (64.9) g 3920 (154.5) a d e f b c g.

Page 86

Wacker neuson se · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02-0 · fax: +49 - (0)89-3 54 02-390 wacker neuson corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker neuson limited - room 1701–03 & 171...